Fi 25.622(5)GB

08.09

Fi 25.622(5)GB

Maintenance and installation instructions

Material specifi cations, various connections,

measurements etc. are to be found in catalogue sheet

- Assess all the risks to eliminate the risk of personal

injury and material damage. Read these instructions

- Always use the necessary protective equipment

and comply with applicable safety directives when

working with hazardous or hot/cold medium.

- Never operate a valve without fi rst ensuring that there

is no risk of crush injuries. The risk is highest with

- Take necessary safety precautions to prevent

unintentional manoeuvre - i.e to atmosphere.

- Never dismantle a valve or part of a valve without

ensuring that the line is free of pressure and any

- Ball valves must always be dismantled in semi-open

position to avoid trapping pressure and medium.

- Always check that the valve type and material is

suitable for its intended use. This applies especially to

highly oxidising and corrosive medium. Observe also

the risk of erosion and explosion as well as decaying

medium. If in doubt, always request a written

recommendation from NAF AB.

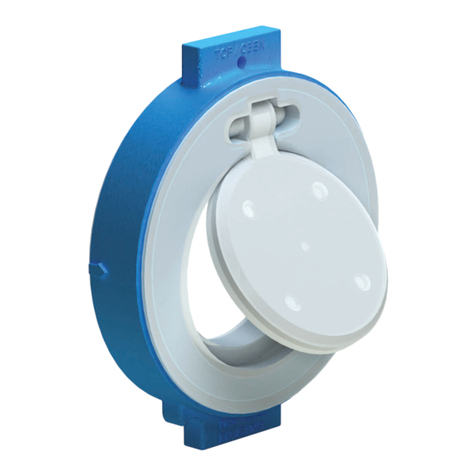

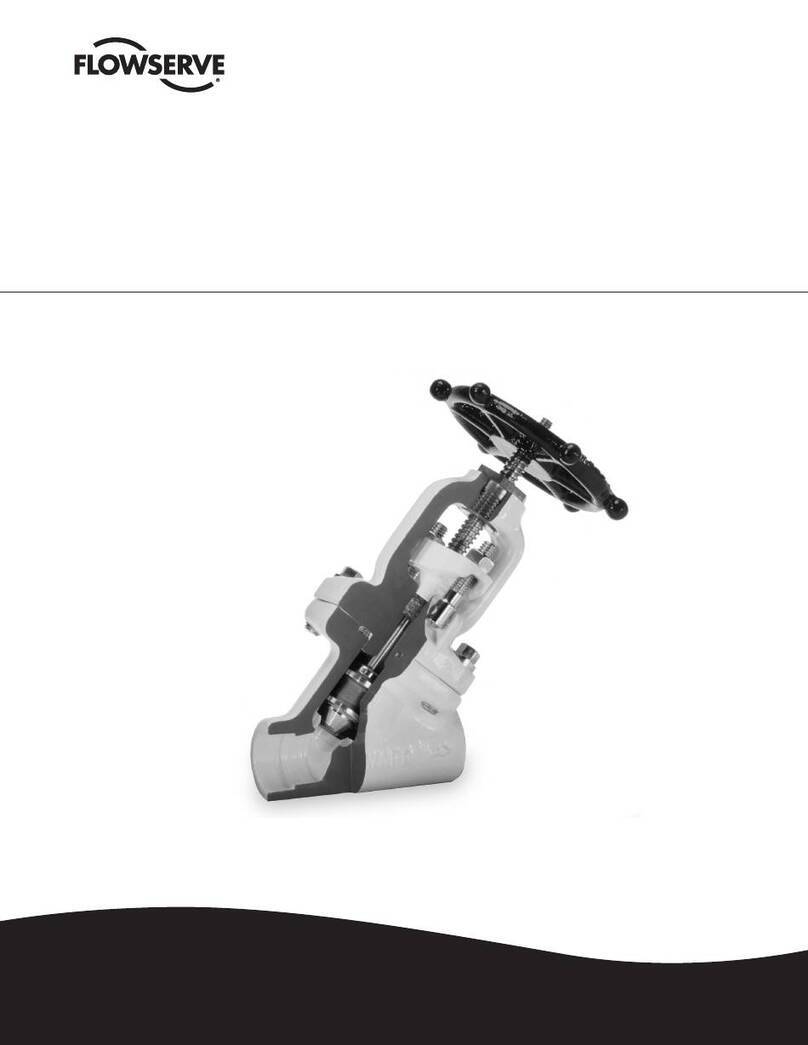

2 Assembly/disassembly of NAF-Triball

Please keep special attention to the following:

- To simplify assembly and avoid unnecessary strain

on the valve, i.e pipe forces, always check that the

pipes which the valve is to be welded between are

parallel and have the same centre line.

- Remember that damage to the seat ring can cause

leakage. Always use great care when disassembling

and reassembling the valves to avoid damage to the

rings from contamination.

2.1 Welding-in NAF-Triball

The version with long welding ends,

be disassembled before welding.

must be in the open position during welding.

length of the welding ends is such that the temperature

will not damage the interior of the valve.

- NAF-Triball with short welding ends,

XXXX-XX and NAF 8886X4-XXXX-XX

disassembled before welding. The valve body and its

seatrings must be removed as described below and

replaced with a suitable spacer, such as a body of the

same DN but without internal parts. Screw the end

pieces together and weld the unit into the pipe. After

welding, refi t the complete valve body and tighten the

screws to specifi ed torque, see below.

- The above applies on the condition that welding is

done professionally and in accordance with applicable

! After welding, both valves and connecting p

be cleaned from welding debris, scale etc.

Note: When re-assembling the valve, always use new

body seals in order to simplify

minimise risk for leakage.

1. Turn the ball to the open position. Remove one of the bolts

(or stud) and release the other three.

2. Remove the body section.

3. Refi t the body section after the planned action is carried out

and tighten the bolts (or studs), see required torque as per

table below. Use MoSo2 based grease to lubricate the threads

Assembly/disassembly of NAF-Triball

2.1 Welding-in NAF-Triball

2.2 NAF-Triball disassembly

2.3 NAF-Triball gland leakage

2.4 Screw torque specifi cation (Nm)

NAF-Triball: Spares for new CE-marked valves

888X5X-XXXX-XX resp. 888X6X-XXXX-XX or versions

3.1 Spare parts and spare part kits

4. Material specifi cation

5 NAF-Triball Sampling valve

Welding-in of the sampling valve

Connection plate for sampling 8886X4-XXXX-XX

V

R