Flowserve.com 3

VAIOM000103-02 (EN/AQ) March 2020

Valtek®Control Products Mark 100™ and Mark 100SC Control Valves

The following instructions are designed to assist in unpacking,

installing and performing maintenance as required on Valtek

Mark 100 and Mark 100SC control valves. Product users and

maintenance personnel should thoroughly review this bulletin

prior to installing, operating or performing any maintenance on

the valves. Separate Installation, Operation and Maintenance

instructions cover additional features (such as actuators,

handwheels, packing and positioners).

To avoid possible injury to personnel or damage to valve parts,

WARNING and CAUTION notes must be strictly followed.

Modifying this product, substituting non-factory parts, or using

maintenance procedures other than outlined could drastically

affect performance, be hazardous to personnel and equipment,

and may void existing warranties.

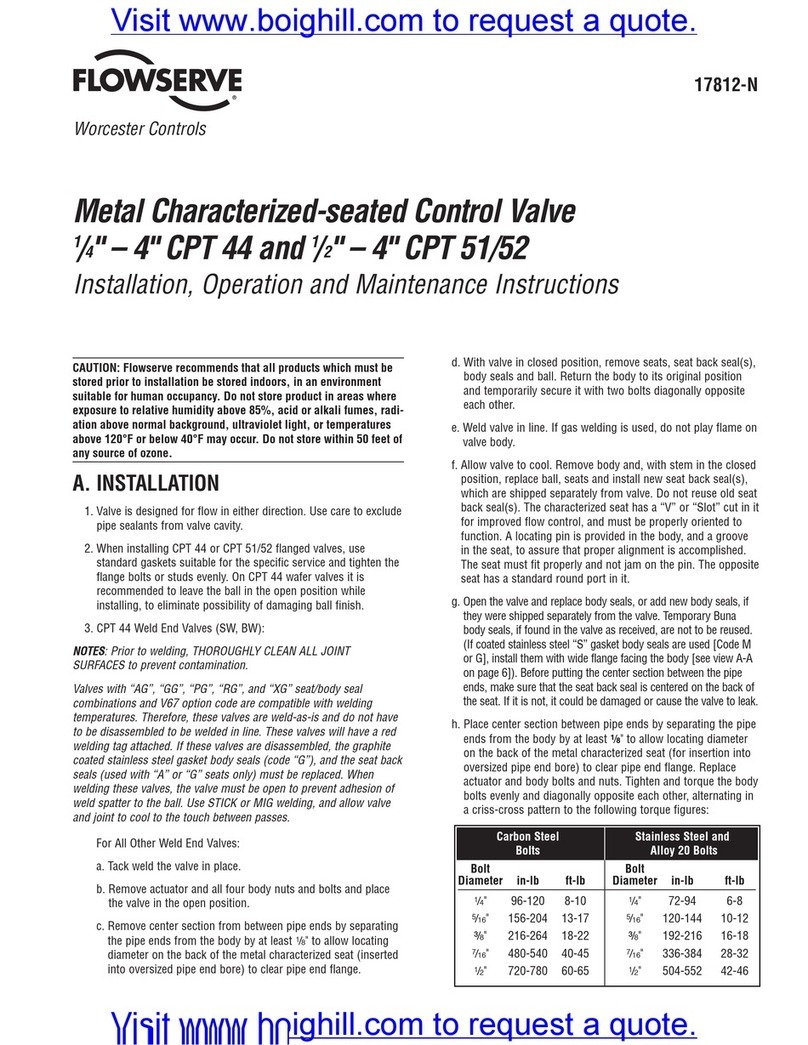

cWARNING: Standard industry safety practices must be

adhered to when working on this or any other process

control product. Specifically, personal protective and

lifting devices must be used as warranted.

NOTE ON FASTENERS: Selecting the proper fastener material is

the responsibility of the customer. Typically, the supplier does

not know what the valve service conditions or environment may

be. Flowserve’s standard body bolting material is B7/2H. B8

(stainless steel) is optional for applications more than 425°C

(800°F) and with stainless steel or alloy-body valves. The

customer, therefore, must consider the material’s resistance

to stress corrosion cracking in addition to general corrosion.

As with any mechanical equipment, periodic inspection and

maintenance are required. For more information about fastener

materials, contact your Flowserve representative.

1

General

information

1.2 Applicability

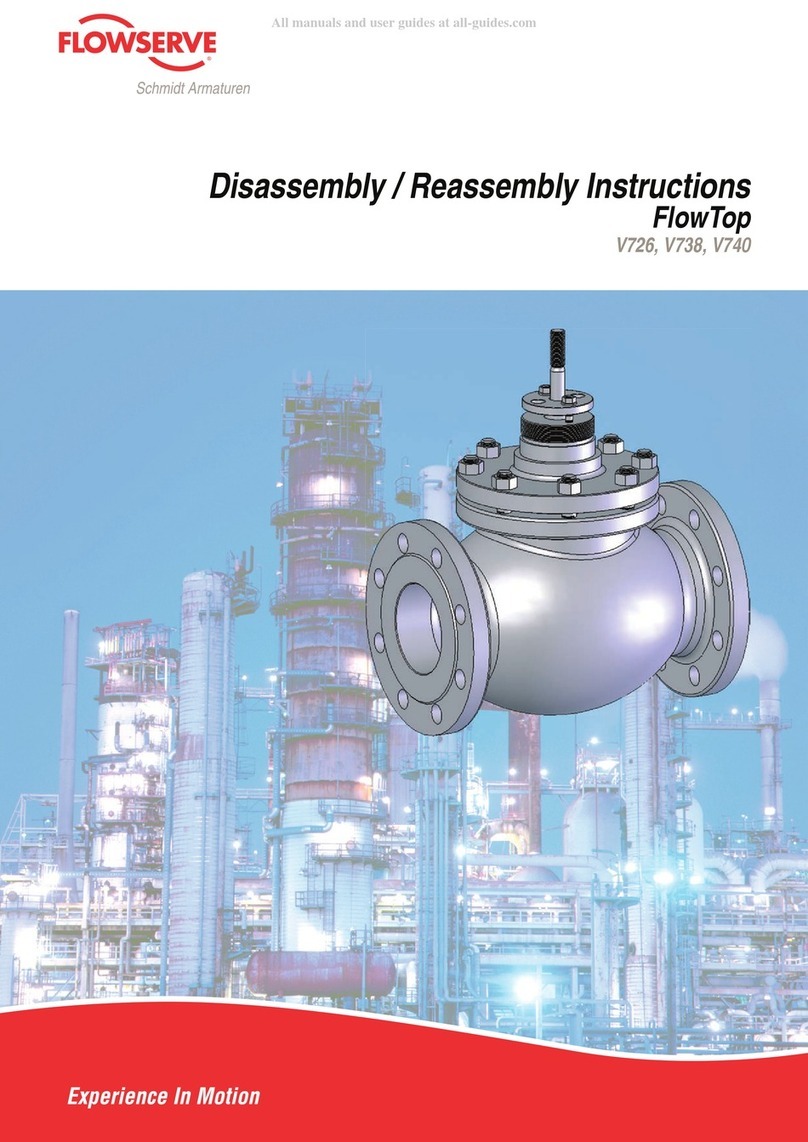

The following instructions are applicable to the maintenance

and installation of Valtek Mark 100 and Mark 100SC globe

and angle body design control valves. These instructions

cannot claim to cover all details of all possible product

variations, nor can they provide information for every possible

example of installation, operation or maintenance. This means

that the instructions normally include only the directions to

be followed by qualified personnel using the product for its

defined purpose. If there are any uncertainties in this respect,

particularly in the event of missing product-related information,

clarification must be obtained via the appropriate Flowserve

sales office. All Flowserve User Manuals are available at

www.flowserve.com.