14-5

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

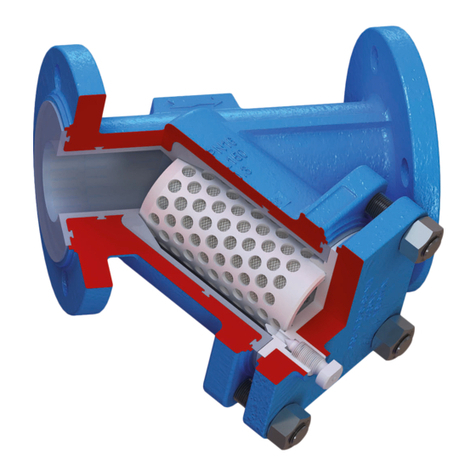

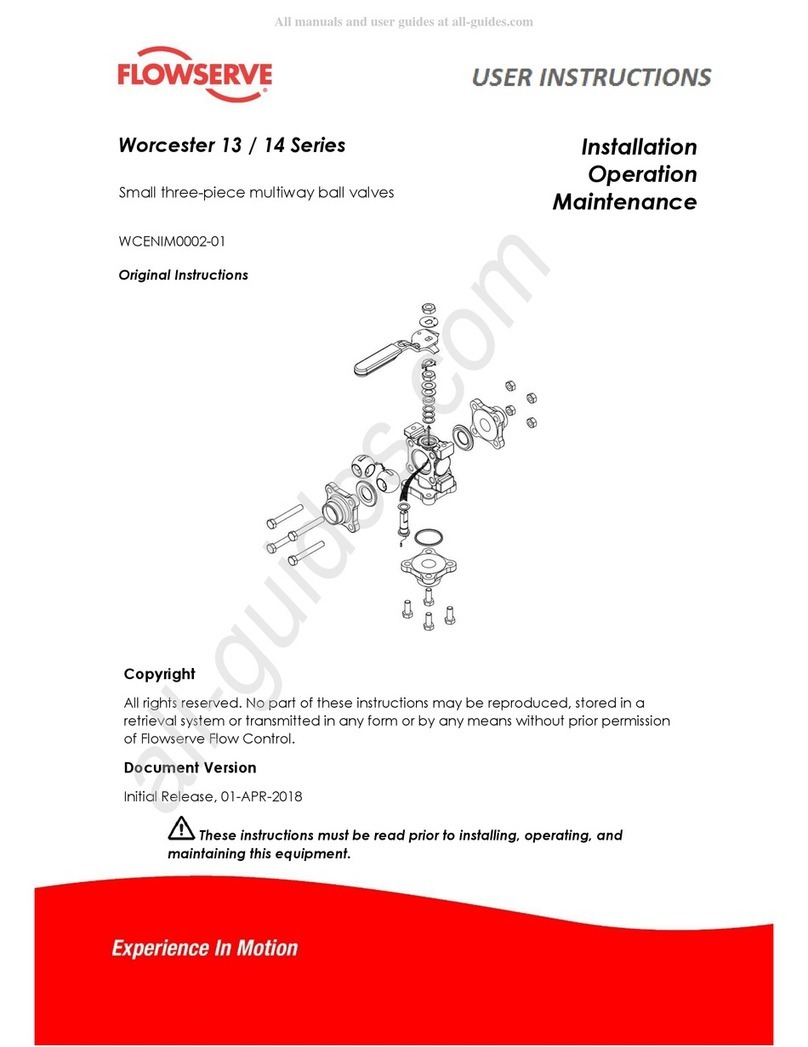

Figure 4: Bolted Extension Figure 5: Bolted Flange Extension

Bonnet

(Item No. 40)

Extension

Bonnet

(Item No. 41)

Bolting

(Item no. 110)

Bonnet

Extension

Gasket

(Item No. 60)

Bolting

(Item no. 110)

Bonnet

Extension

Gasket

(Item No. 60)

Extension Bonnet

(Item No. 41)

Half Ring

(Item No. 13)

Bonnet

(Item No. 40)

Flange

(Item No. 73)

Note: Item numbers correspond directly to the valve's bill of material. Refer to the bill of material for specific part numbers.

CAUTION: Do not overtighten packing. This can

cause excessive packing wear and stem friction

which may impede stem movement.

7. After installing a new seat gasket, the seat ring, seat

retainer and a new bonnet gasket, lower the actua-

tor/bonnet assembly squarely into body. Be careful

to not scratch or gall plug as it enters the body.

8. Install bonnet flange bolting to finger-tightness.

Apply air pressure above the piston to seat the plug

in the seat ring. Tighten each bonnet bolt about 1/6

(one flat) of a turn at a time in a clockwise direction

around the bonnet flange. Firmly tighten all bolts

evenly and completely to compress the bonnet

gasket until the bonnet is seated metal-to-metal in

the body. Proper tightness is achieved when metal-

to-metal resistance can be felt with the wrench.

CAUTION: If the bolting is insufficiently tight-

ened, the seat ring gasket will not have enough

compression, resulting in leakage. Overtighten-

ing beyond the point of metal-to-metal resis-

tance may damage interior valve parts.

9. The amount the plug stem is screwed into the

actuator stem is not particularly important on air-to-

close valves as long as the plug fully contacts the

seat when the valve is closed. It is necessary only to

leave two to three threads exposed. For correct plug

engagement on air-to-open valves, screw the plug

stem into the actuator stem as far as possible. Apply

air pressure above the piston to drive it to the bottom

of the actuator cylinder. Back the plug stem out of

the actuator stem until the plug just touches the seat

ring. Apply air under the piston to lift the plug off the

seat and back the plug stem out of the actuator stem

exactly one complete turn.

10. Apply air over the piston to seat the plug. With the

stem clamp adjusted to the “closed”position of the

stroke indicator plate, tighten stem clamp bolting.

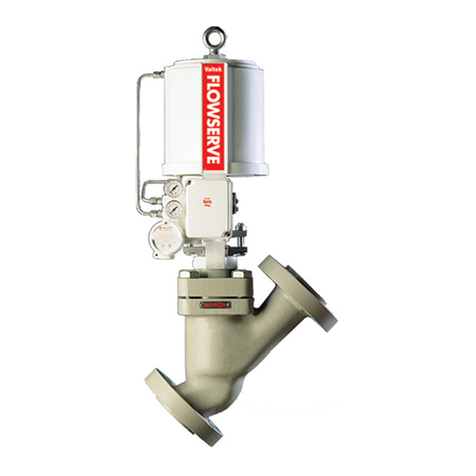

Disassembling Bonnet Extensions

To disassemble valves equipped with bonnet extensions,

refer to Figures 4, 5, 6 and 7 then proceed as follows:

WARNING: Depressurize line to atmospheric pres-

sure, drain all fluids and decontaminate the valve (if

caustic or hazardous materials are present). Failure

to do so can cause serious injury.

1. Remove bonnet flange bolts or nuts.

2. Remove the entire actuator/bonnet extension as-

sembly –including the bonnet and plug –by lifting it

straight out of the body.

CAUTION: Heavy assemblies may require a

hoist. Attach lifting straps to actuator yoke legs.

3. Loosen the actuator stem clamp.

4. Remove packing box bolting.

5. Remove the yoke bolting, clamps and half rings (if

present).

6. Remove the actuator by unscrewing the plug and

bonnet in unison from the actuator stem. Unscrew-

ing the plug and bonnet together prevents damage

to the plug stem and packing box wall.

WARNING:Donotallowtheplugorbonnettofall

during removal from the actuator. Serious per-

sonal injury or valve damage may result.

7. Pull the plug carefully through the packing box and

bonnet.

WARNING: Process fluid may be trapped in the

bonnet extension; therefore, be extremely cau-

tious when removing the plug from the bonnet

and bonnet extension.

IM014 Extended Bonnets.p65 8/21/01, 2:14 PM5