1-6 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

should be installed with the upper set. Lower

packing installed in extended bonnets or metal

bellowssealvalveswilldiminishtheintegrityof

the packing assembly.

The graphite guide liners should be replaced each

time the valve packing is replaced. Do not rebuild

the valve without graphite liners in the guides.

2. Reinsert the plug stem into the packing box, being

careful not to score the stem or the guides.

3. Turn actuator back onto the plug, without turning

the plug inside the bonnet. Make sure the gland

flangeandbonnetflangeareinplacebeforeengag-

ing the plug stem and actuator stem threads.

NOTE:Donotallowtheglandflangetocontactand

gall the polished plug stem.

Leave approximately three to four plug stem

threads exposed. Attach yoke clamp and gland

flange bolting. For valves with a 2-inch spud, be

sure the half rings are in place between the yoke

and bonnet. Firmly tighten yoke clamp bolting. The

packing box nuts should be just over finger tight.

4. Install new bonnet and seat gaskets with the bev-

eled edge up for Teflon gaskets.

5. Insert the seat ring into the body with the step side

down.Place the seatretainerinto thebodywith the

thin end of the cathedral window down.

NOTE: For ANSI Class 900 and above valves with

valve sizes

1

/

2

- through 1

1

/

2

-inch, the seat retainer

window should be placed in the body with the

window facing toward the valve ports. With valves

2-inches and larger, the retainer's bar should face

toward the valve ports.

6. Place air under the actuator piston on air-to-open

valves to retract the plug.

7. Lower the plug and bonnet squarely into the body.

Becareful nottoscratch orgall theplugas itenters

the body.

8. To properly align the seat ring and plug, first bring

the bonnet bolting to finger-tightness.

a. With pneumatic actuators, apply air pressure

abovethe pistonto seatthe plugin theseat ring.

Proceed to step 9.

b. With electric or hydraulic actuators, move the

actuator stem down until it is completely ex-

tended. Next, retract the actuator stem 1/8inch /

3.175 mm. Install the stem clamp onto the plug

stem / actuator stem and tighten the associated

bolting. Move the actuator stem completely

down.Adjustactuatorlimitswitchesaccordingto

the actuator’s operating manual.

NOTE:Withair-to-close,fail-openvalves,itmaybe

necessary to apply a small amount of air to the top

of the actuator to move the plug away from the

bonnet. Otherwise, plug galling may occur.

Turn the actuator off the plug and bonnet without

allowingtheplugtorotatewithinthebonnet.Pullthe

plug carefully through the packing box.

CAUTION: To avoid scoring guides and plug

stem, follow the above procedure exactly.

6. If the seat surfaces need remachining, both sur-

faces on plug and seat ring must be reworked. The

seatangleontheplugis30degrees(36degreesfor

CavControl and Channel Stream valves); the seat

ring,33degrees.Lappingisnotnecessaryifproper

assembly procedures are followed.

CAUTION: If remachining, protect the stem

while turning. Ensure concentricity of the seat

surface with the plug stem (or outside diameter

of the seat ring, if machining the seat).

7. To replace packing or change the packing box

configuration,fromunderneaththebonnetpushout

packing, spacer and guides with a dowel of the

same approximate size as the plug stem.

WARNING: For valves equipped with separable

end flanges, do not machine body gasket sur-

faces. Machining could cause failure of the

separable flange lip causing end gasket leak-

age and valve failure.

8. Ifseparableendflangesneedtoberemoved,fileoff

tack welds or pull rivets behind the flanges.

CAUTION: When using separable end flanges

and spiral wound gaskets, use gaskets with

outerbackuprings.Failuretodosocouldresult

in excess stress in some applications.

NOTE:Toprevent flangesfromdroppingoff during

shipping, a tack weld or stainless steel rivet has

been installed behind the end flanges.

Reassembling the Body

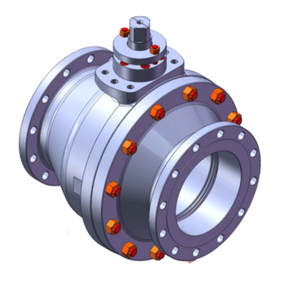

Toreassemblethe valvebody,referto Figures1,2and

4 then proceed as follows:

1. If the packing has been removed, refer to Figure 2

and reinstall new packing exactly as shown. Make

sure at least 1/8-inch is left at the top of packing box

for the top guide to enter. Different spacer lengths

permit a wide variety of packing configurations,

such as twin seal and vacuum-pressure packing.

WARNING: Valves with extended bonnets or

metal bellows seals must not have lower pack-

ing installed. Instead, lower packing rings