Teral Patron SP-20 User manual

SP-20 / SP-25

Submersible Dewatering Pump

Operation Manual

Teral Inc.

OPERATION MANUAL

SUBMERSIBLE DEWATERING PUMP

Thank you for selecting SP-20/25 Submersible Pump for your pumping requirement.

Please take a moment to review this manual before, installing, operating or servicing these

pumps.

The pump should not be used other than the applications listed in this manual. Failure to

do so may lead to a malfunction or an accident to which the manufacturer will not assume

any liability.

After reading this Operation Manual, keep it in a location where it can be referred to during

the operational life of the pump.

In the event the product is damaged, please contact your authorized local dealer or sales

representative.

SAFETY FIRST

DANGER

CAUTION

NOTICE

I.

II.

III.

IV.

V.

VI.

VII.

VIII.

IX.

X.

2

2

3

4

5

6

7

8

9

9

Safety Instructions.........................

Before you Start.............................

Pump Identification........................

Installation....................................

Pump Operation.............................

Maintenance..................................

Repair Parts...................................

Preventative Maintenance...............

Trouble Shooting............................

Product Disposal............................

WARNING

Indicates a hazardous situation which, if not avoided WILL result in DEATH, SERIOUS INJURY,

PROPERTY DAMAGE.

Indicates a hazardous situation which, if not avoided MAY result in DEATH, SERIOUS INJURY,

PROPERTY DAMAGE.

Indicates a hazardous situation which, if not avoided MAY result in MINOR or MODERATE INJURY,

PROPERTY DAMAGE.

Indicates special instructions which are very important and must be followed.

Content

OPERATION MANUAL

SUBMERSIBLE DEWATERING PUMP

Thank you for selecting SP-20/25 Submersible Pump for your pumping requirement.

Please take a moment to review this manual before, installing, operating or servicing these

pumps.

The pump should not be used other than the applications listed in this manual. Failure to

do so may lead to a malfunction or an accident to which the manufacturer will not assume

any liability.

After reading this Operation Manual, keep it in a location where it can be referred to during

the operational life of the pump.

In the event the product is damaged, please contact your authorized local dealer or sales

representative.

SAFETY FIRST

DANGER

CAUTION

NOTICE

I.

II.

III.

IV.

V.

VI.

VII.

VIII.

IX.

X.

2

2

3

4

5

6

7

8

9

9

Safety Instructions.........................

Before you Start.............................

Pump Identification........................

Installation....................................

Pump Operation.............................

Maintenance..................................

Repair Parts...................................

Preventative Maintenance...............

Trouble Shooting............................

Product Disposal............................

WARNING

Indicates a hazardous situation which, if not avoided WILL result in DEATH, SERIOUS INJURY,

PROPERTY DAMAGE.

Indicates a hazardous situation which, if not avoided MAY result in DEATH, SERIOUS INJURY,

PROPERTY DAMAGE.

Indicates a hazardous situation which, if not avoided MAY result in MINOR or MODERATE INJURY,

PROPERTY DAMAGE.

Indicates special instructions which are very important and must be followed.

Content

SAFETY INSTRUCTION

BEFORE YOU START

PUMP IDENTIFICATION

All electrical work must be performed by an authorized electrician, in compliance with

local electrical codes. NEVER, allow an unauthorized person to perform electrical work

as it could lead to electrical shock, fire, or damaging the pump.

Risk of Electrical Shock. The pump comes supplied with a grounding conductor and a

grounding type attachment plug. NEVER, operate a pump with a plug in type power

cord without a ground fault circuit interrupter. Keep power end connection dry.

Upon receiving the pump, inspect for damages or shortages.

NEVER, use the power cord to lift or lower the pump. ALWAYS, tie a chain or rope to

the handle of the pump to lift and lower the pump.

NEVER, splice or use damaged or worn cables and cords.

ALWAYS, disconnect the electrical power before servicing the pump.

DO NOT, pump liquids which are flammable.

DO NOT, operate pump in a hazardous environment.

Risk of Electric Shock, this pump has not been investigated for use in a swimming pool

application.

When installing the pump, be mindful of the pump's center of gravity and weight.

Failure to do so, may result in the pump to fall and break which may lead to injury.

This pump is NOT designed for applications involving Acid, or Alkaline.

NEVER, operate the pump dry. Doing do so will damage the seals and overheat the

motor.

Periodically, check the oil level and water in the seal chamber. Check the seal condition

quarterly for heavy duty applications or annually otherwise.

This manual does not fully cover all safety issues. For this reason, the person using or

maintaining the pump must pay special attention to their own safety as well as those

around.

NEVER, pump water with a temperature greater than 30°C.

Check the name plate of the pump to ensure product is of the correct specification you

ordered. Ensure that the voltage and frequency are correct.

Please check the nameplate on the received pump against your ordered pump.

Paying special attention to the Model, Output(Hp), Voltage and Frequency.

SAFETY INSTRUCTION

BEFORE YOU START

PUMP IDENTIFICATION

All electrical work must be performed by an authorized electrician, in compliance with

local electrical codes. NEVER, allow an unauthorized person to perform electrical work

as it could lead to electrical shock, fire, or damaging the pump.

Risk of Electrical Shock. The pump comes supplied with a grounding conductor and a

grounding type attachment plug. NEVER, operate a pump with a plug in type power

cord without a ground fault circuit interrupter. Keep power end connection dry.

Upon receiving the pump, inspect for damages or shortages.

NEVER, use the power cord to lift or lower the pump. ALWAYS, tie a chain or rope to

the handle of the pump to lift and lower the pump.

NEVER, splice or use damaged or worn cables and cords.

ALWAYS, disconnect the electrical power before servicing the pump.

DO NOT, pump liquids which are flammable.

DO NOT, operate pump in a hazardous environment.

Risk of Electric Shock, this pump has not been investigated for use in a swimming pool

application.

When installing the pump, be mindful of the pump's center of gravity and weight.

Failure to do so, may result in the pump to fall and break which may lead to injury.

This pump is NOT designed for applications involving Acid, or Alkaline.

NEVER, operate the pump dry. Doing do so will damage the seals and overheat the

motor.

Periodically, check the oil level and water in the seal chamber. Check the seal condition

quarterly for heavy duty applications or annually otherwise.

This manual does not fully cover all safety issues. For this reason, the person using or

maintaining the pump must pay special attention to their own safety as well as those

around.

NEVER, pump water with a temperature greater than 30°C.

Check the name plate of the pump to ensure product is of the correct specification you

ordered. Ensure that the voltage and frequency are correct.

Please check the nameplate on the received pump against your ordered pump.

Paying special attention to the Model, Output(Hp), Voltage and Frequency.

Electrical

The electrical voltage required to operate this pump can burn, shock, or even cause

death. Before, installing, operating or servicing this pump, please thoroughly read

this manual.

DO NOT operate this pump anywhere near explosive or flammable material.

Serious personal injury, death, or major property damage will result.

Accidental starting of the pump can cause severe injury or death.

DO NOT, splice the power cord.

It is absolutely essential that the rotation of the pump be checked. All the pumps

covered in this manual turn clockwise as viewed from the motor end.

If the motor protector trips frequently, check for the cause. It could be due to impeller

blockage, wrong/low voltage, etc…

For Automatic operation, the pump must stop before the water level reaches Pump

Minimum Water Level.(W.M.L.)

This pump comes with a built in motor protector. In the event of a current overload

or overheating, the pump will stop automatically to protect the motor. After the motor

cools down, the motor protector will automatically reset and the pump can be used

again.

DO NOT, handle or service the pump while it is connected to the power supply.

ALWAYS, ensure that the voltage and frequency supplied to the pump are correct.

Refer to the nameplate to determine the correct voltage and frequency.

ALWAYS, make sure the pump is grounded properly in accordance to local law.

DO NOT, connect the ground wire to gas pipe, water pipe, etc… as improper

grounding will result in electrical shock.

PUMP OPERATION

DANGER

INSTALLATION

ALWAYS, place the pump in an upright position. Ensure, that the pump will not burrow

itself on the soft sand or mud.

All piping must be independently supported, properly aligned and capable of handling

semi-solids.

DO NOT, restrict the discharge flow of the pump as it will cause the pump to overheat.

Be mindful of the discharge hose whipping under pressure.

To avoid backflow or outflow of the pump. Backflow, discharge hose is above the water

surface. Outflow, the discharge hose is above the source water surface.

NEVER, allow the pump to freeze in the liquid it is pumping.

Pump Mount

Piping

NOTICE

NOTICE

Electrical

The electrical voltage required to operate this pump can burn, shock, or even cause

death. Before, installing, operating or servicing this pump, please thoroughly read

this manual.

DO NOT operate this pump anywhere near explosive or flammable material.

Serious personal injury, death, or major property damage will result.

Accidental starting of the pump can cause severe injury or death.

DO NOT, splice the power cord.

It is absolutely essential that the rotation of the pump be checked. All the pumps

covered in this manual turn clockwise as viewed from the motor end.

If the motor protector trips frequently, check for the cause. It could be due to impeller

blockage, wrong/low voltage, etc…

For Automatic operation, the pump must stop before the water level reaches Pump

Minimum Water Level.(W.M.L.)

This pump comes with a built in motor protector. In the event of a current overload

or overheating, the pump will stop automatically to protect the motor. After the motor

cools down, the motor protector will automatically reset and the pump can be used

again.

DO NOT, handle or service the pump while it is connected to the power supply.

ALWAYS, ensure that the voltage and frequency supplied to the pump are correct.

Refer to the nameplate to determine the correct voltage and frequency.

ALWAYS, make sure the pump is grounded properly in accordance to local law.

DO NOT, connect the ground wire to gas pipe, water pipe, etc… as improper

grounding will result in electrical shock.

PUMP OPERATION

DANGER

INSTALLATION

ALWAYS, place the pump in an upright position. Ensure, that the pump will not burrow

itself on the soft sand or mud.

All piping must be independently supported, properly aligned and capable of handling

semi-solids.

DO NOT, restrict the discharge flow of the pump as it will cause the pump to overheat.

Be mindful of the discharge hose whipping under pressure.

To avoid backflow or outflow of the pump. Backflow, discharge hose is above the water

surface. Outflow, the discharge hose is above the source water surface.

NEVER, allow the pump to freeze in the liquid it is pumping.

Pump Mount

Piping

NOTICE

NOTICE

STORAGE:

Disassembling the pump or modifying the pump will void manufacturer warranty.

ALWAYS, check that the voltage and amperage readings are in line with the nameplate

of the pump. Check if the water level is normal.

If the pump will not be used for a long period of time, wash the pump under tap water

removing any debris. Allow the pump to dry and then store indoors. Before, reinstalling

perform a test run to ensure it is operating correctly and within the parameters stated on

the nameplate

NOTICE

REPAIR PARTS

If the pump must be disassembled for repair, please contact an Authorized Dealer in

your area.

Accidental starting of the pump can cause severe injury or death. ALWAYS,

disconnect the electrical power before examining/working on the pump.

For heavy parts, use a hoist lift to avoid injury.

MAINTENANCE

CABLE OUTER COVER

BEARING

LUBRICANT

M. SEAL

OIL SEAL

IMPELLER

WEAR PLATE

STRAINER

CASING COVER

CAP NUT

OILPLUG GASKET

HANDLE

BEARING

BRACKET

SHAFT

CAPACITOR

UPPER COVER

1 8

9

10

11

12

13

14

15

16

17

18

2

3

4

5

6

7

STORAGE:

Disassembling the pump or modifying the pump will void manufacturer warranty.

ALWAYS, check that the voltage and amperage readings are in line with the nameplate

of the pump. Check if the water level is normal.

If the pump will not be used for a long period of time, wash the pump under tap water

removing any debris. Allow the pump to dry and then store indoors. Before, reinstalling

perform a test run to ensure it is operating correctly and within the parameters stated on

the nameplate

NOTICE

REPAIR PARTS

If the pump must be disassembled for repair, please contact an Authorized Dealer in

your area.

Accidental starting of the pump can cause severe injury or death. ALWAYS,

disconnect the electrical power before examining/working on the pump.

For heavy parts, use a hoist lift to avoid injury.

MAINTENANCE

CABLE OUTER COVER

BEARING

LUBRICANT

M. SEAL

OIL SEAL

IMPELLER

WEAR PLATE

STRAINER

CASING COVER

CAP NUT

OILPLUG GASKET

HANDLE

BEARING

BRACKET

SHAFT

CAPACITOR

UPPER COVER

1 8

9

10

11

12

13

14

15

16

17

18

2

3

4

5

6

7

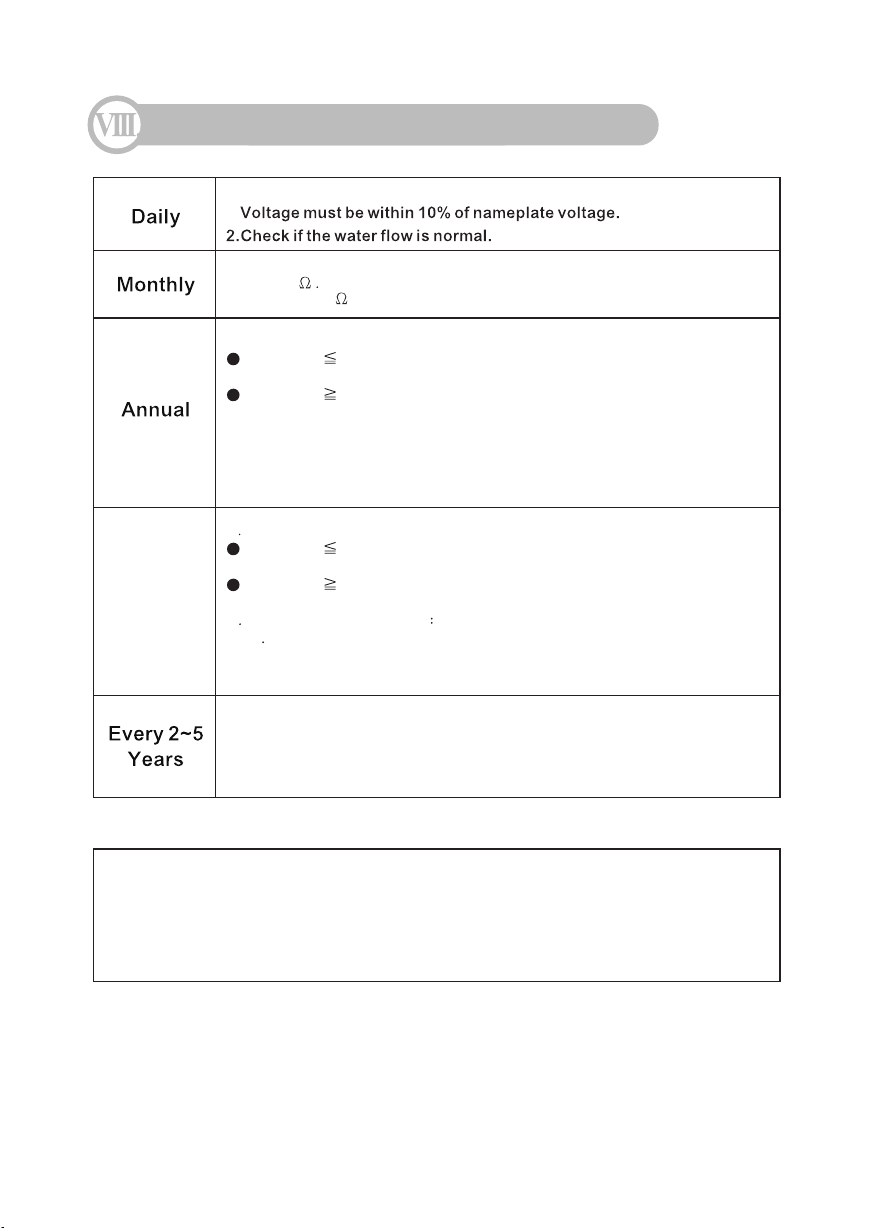

PREVENTATIVE MAINTENANCE

Pump Fails

to Start

Incorrect Voltage/AmpsCheck power and correct connections.

Replace Power Cable

Replace with new protector.

Replace Motor

Replace Float Switch

Repair or Replace Control Panel

Remove foreign debris from impeller

or casing.

Check power to ensure it corresponds to

the nameplate

Change the power connection

Change the Impeller.

Remove debris

Remove obstruction

Replace with new cable

Reconnect after drying out.

Replace mechanical seal and oil seal

Replace with new motor.

Change the power connection

Decrease the viscosity of the liquid

Remove debris from the pump.

Check the power to make sure it

corresponds to the nameplate.

Check if pump is completely submerged.

Ensure the liquid temperature being

pumped is below 30°C.

Remove foreign debris from impeller

or casing.

Defective Cable

Clogged Impeller

Burned Out Motor

Defective Float Switch

Bad Control Panel

Jammed Impeller

Irregular Voltage

Tripped Motor Protector

Incorrect Rotation

Strainer is clogged

Damaged Power Cable

Wet Cable Terminals

Burned out Motor

Irregular Voltage

Incorrect Rotation

Highly Viscous Liquid

Debris inside the pump

Damaged Bearings

Worn out mechanical seal

causes water to enter.

Worn Out or Damaged

Impeller

Non Functioning Motor

Protector

SYMPTOM SOLUTION

Fails to

Deliver Full

Output

ELCB Trips

High

Amperage

Pump Starts

but

Immediately

Stops

PRODUCT DISPOSAL

Properly dispose the product in accordance with your local waste disposal program.

IX

X

89

1.Ensure the Voltage and Amperage conform to the nameplate.

Maintenance is recommended when the insulation reading is lower

than 10MReplace new motor immediately when insulation is

lower than 1M .

Inspecting of Lubricant:

For pumps1hp, the item should be checked every 3000 hours

or 12 months (whichever comes first).

For pumps2hp, the item should be checked every 6000 hours

or 12 months (whichever comes first).

PS:Loosen the oil plug screw and check the color of the lubricant. If

the lubricant is non-translucent, please change the mechanical seal

and the lubricant immediately. Apply adhesive before resecuring

the oil plug screw to strengthen the screw against leakage.

1Replacing Lubricant:

For pumps1hp, the item should be replaced every 4500 hours

or 24 months (whichever comes first).

For pumps2hp, the item should be replaced every 9000 hours

or 24 months (whichever comes first).

2change mechanicalsealInspectingand replacingthe mechanical

sealOnlyqualifiedmechanicswith propertoolsandknowledge

should be attempting to servicethis pumporcontactourauthorized

local

1.During the typical operating cycle, it is recommended to have the

pump overhauled and inspected periodically. This preventative

maintenance activity can extend the pump operating life cycle.

2.Please contact your authorized local dealers.

Please record the following information for future reference:

Model Number:

Serial Number:

Purchase Date:

Biennial

PROBABLE CAUSE

Obstruction in Valves and

Pipes.

Replace with new Bearings.

dealer in your area.

PREVENTATIVE MAINTENANCE

Pump Fails

to Start

Incorrect Voltage/AmpsCheck power and correct connections.

Replace Power Cable

Replace with new protector.

Replace Motor

Replace Float Switch

Repair or Replace Control Panel

Remove foreign debris from impeller

or casing.

Check power to ensure it corresponds to

the nameplate

Change the power connection

Change the Impeller.

Remove debris

Remove obstruction

Replace with new cable

Reconnect after drying out.

Replace mechanical seal and oil seal

Replace with new motor.

Change the power connection

Decrease the viscosity of the liquid

Remove debris from the pump.

Check the power to make sure it

corresponds to the nameplate.

Check if pump is completely submerged.

Ensure the liquid temperature being

pumped is below 30°C.

Remove foreign debris from impeller

or casing.

Defective Cable

Clogged Impeller

Burned Out Motor

Defective Float Switch

Bad Control Panel

Jammed Impeller

Irregular Voltage

Tripped Motor Protector

Incorrect Rotation

Strainer is clogged

Damaged Power Cable

Wet Cable Terminals

Burned out Motor

Irregular Voltage

Incorrect Rotation

Highly Viscous Liquid

Debris inside the pump

Damaged Bearings

Worn out mechanical seal

causes water to enter.

Worn Out or Damaged

Impeller

Non Functioning Motor

Protector

SYMPTOM SOLUTION

Fails to

Deliver Full

Output

ELCB Trips

High

Amperage

Pump Starts

but

Immediately

Stops

PRODUCT DISPOSAL

Properly dispose the product in accordance with your local waste disposal program.

IX

X

89

1.Ensure the Voltage and Amperage conform to the nameplate.

Maintenance is recommended when the insulation reading is lower

than 10MReplace new motor immediately when insulation is

lower than 1M .

Inspecting of Lubricant:

For pumps1hp, the item should be checked every 3000 hours

or 12 months (whichever comes first).

For pumps2hp, the item should be checked every 6000 hours

or 12 months (whichever comes first).

PS:Loosen the oil plug screw and check the color of the lubricant. If

the lubricant is non-translucent, please change the mechanical seal

and the lubricant immediately. Apply adhesive before resecuring

the oil plug screw to strengthen the screw against leakage.

1Replacing Lubricant:

For pumps1hp, the item should be replaced every 4500 hours

or 24 months (whichever comes first).

For pumps2hp, the item should be replaced every 9000 hours

or 24 months (whichever comes first).

2change mechanicalsealInspectingand replacingthe mechanical

sealOnlyqualifiedmechanicswith propertoolsandknowledge

should be attempting to servicethis pumporcontactourauthorized

local

1.During the typical operating cycle, it is recommended to have the

pump overhauled and inspected periodically. This preventative

maintenance activity can extend the pump operating life cycle.

2.Please contact your authorized local dealers.

Please record the following information for future reference:

Model Number:

Serial Number:

Purchase Date:

Biennial

PROBABLE CAUSE

Obstruction in Valves and

Pipes.

Replace with new Bearings.

dealer in your area.

SP-20 / SP-25

Submersible Dewatering Pump

Operation Manual

Teral Inc.

This manual suits for next models

1

Table of contents

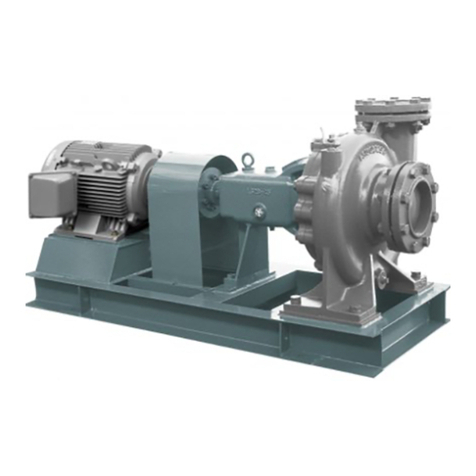

Other Teral Water Pump manuals

Teral

Teral LPE-e User manual

Teral

Teral SP3-e User manual

Teral

Teral LS2 User manual

Teral

Teral Patron SP-10 User manual

Teral

Teral S User manual

Teral

Teral LPWE-GS User manual

Teral

Teral VKD-e Series User manual

Teral

Teral VKN-e Series User manual

Teral

Teral VFZ Series User manual

Teral

Teral LHW-e User manual