Disposal Of Your Old Product

Your product is designed and manufactured with high quality material and components, which

can be recycled and reused. When this crossed-out wheeled bin symbol is attached to a

product, it means the product is covered by the European Directive 2002/96/EC. Please contact

your local authority about correct disposal for electrical and electronic equipment. Our WEE

Registration Number is WEE/FE1471RR.

Please act according to your local rules and do not dispose of your old products with your normal household

waste. The correct disposal of your old product will help prevent potential negative consequences for the

environment and human health.

WARNING: PLEASE READ THE FOLLOWING

SAFETY INFORMATION FIRST.

IMPORTANT SAFETY INFORMATION

- This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a person responsible for their safety.

- Children should be supervised to ensure that they don’t play with the appliance.

- Young children should always be supervised near water.

- If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

- WARNING: Do not operate the UV-C emitter when it is removed from the appliance enclosure.

- Unintended use of the appliance or damage to the housing may result in the escape of dangerous

UV-C radiation. UV-C radiation may, even in little doses, cause harm to the eyes and skin.

- Appliances that are obviously damaged must not be operated.

- Read the maintenance instructions before opening the appliance.

- Never look directly at an illuminated UV bulb.

- Do not run this unit dry. Do not cover this unit.

- Please ensure that the unit is full of water before switching it on.

- Always isolate the unit from mains electricity and turn off any water supply before carrying out

any maintenance.

- Always disconnect all pool appliances from the mains supply before putting your hands into the

water.

- Use in the area only if the installation complies with the relevant wiring regulations.

- Power must be supplied through a Residual Current Device (RCD) with a residual operating

current not exceeding 30mA.

- This unit must be earthed when earth wire is fitted.

- Never use a fuse larger than 3 amps on the power lead.

- The unit must not be submerged in water.

- If the quartz sleeve is cracked, replace it immediately.

- The unit must be either fully frost protected or taken inside during winter months.

The energy consumption of the unit is lower than the wattage of the bulb due to the high efficiency of the ballast.

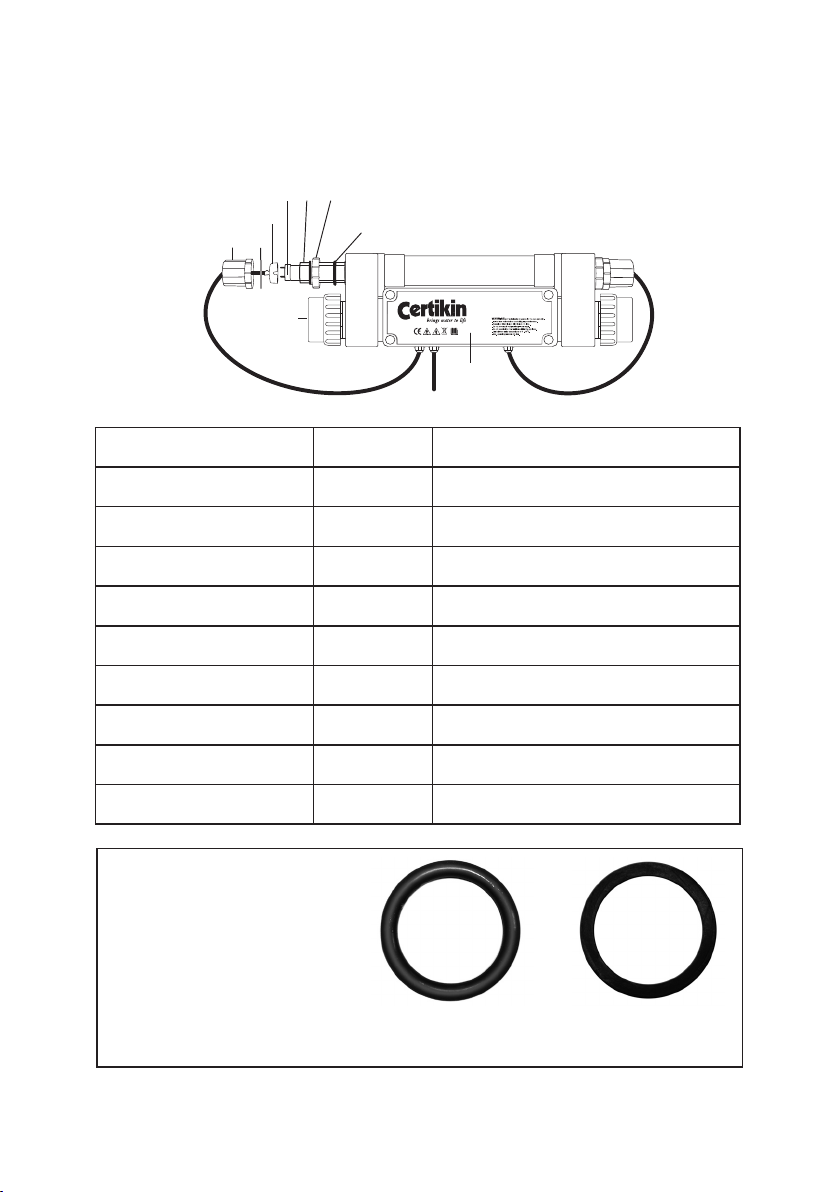

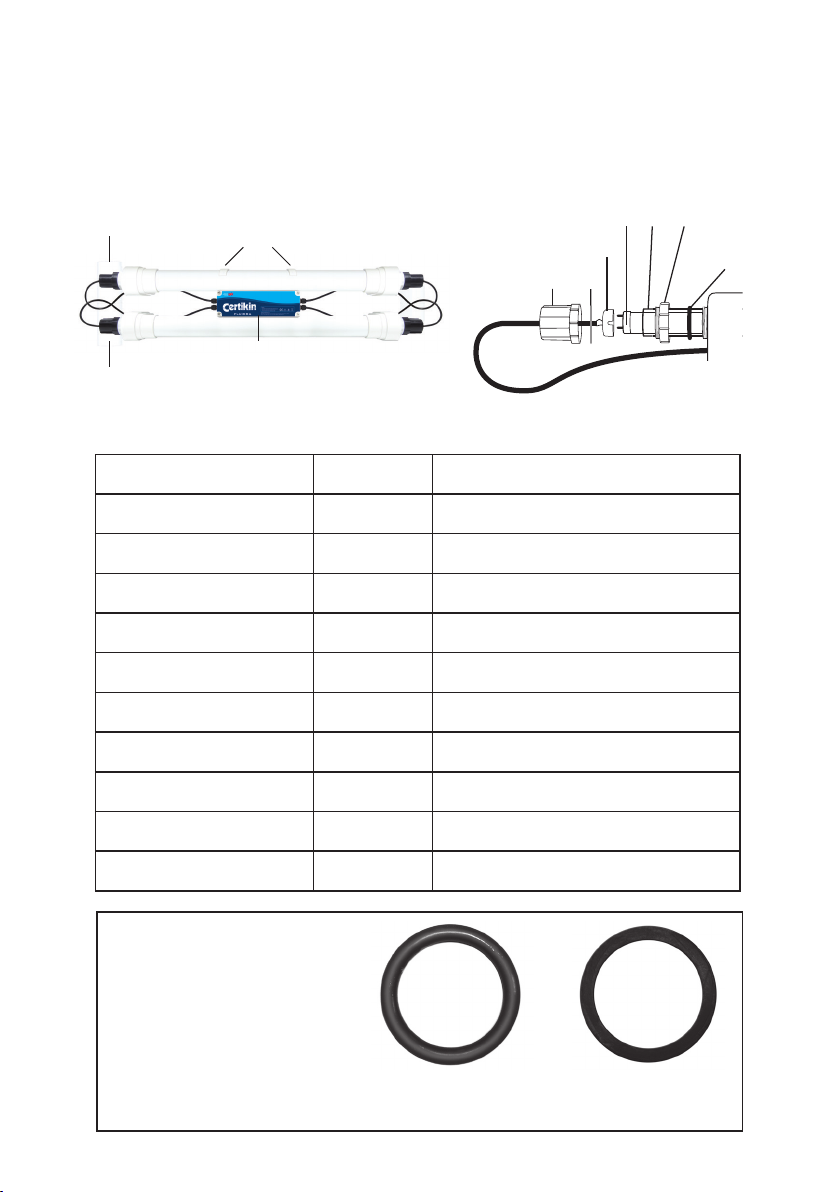

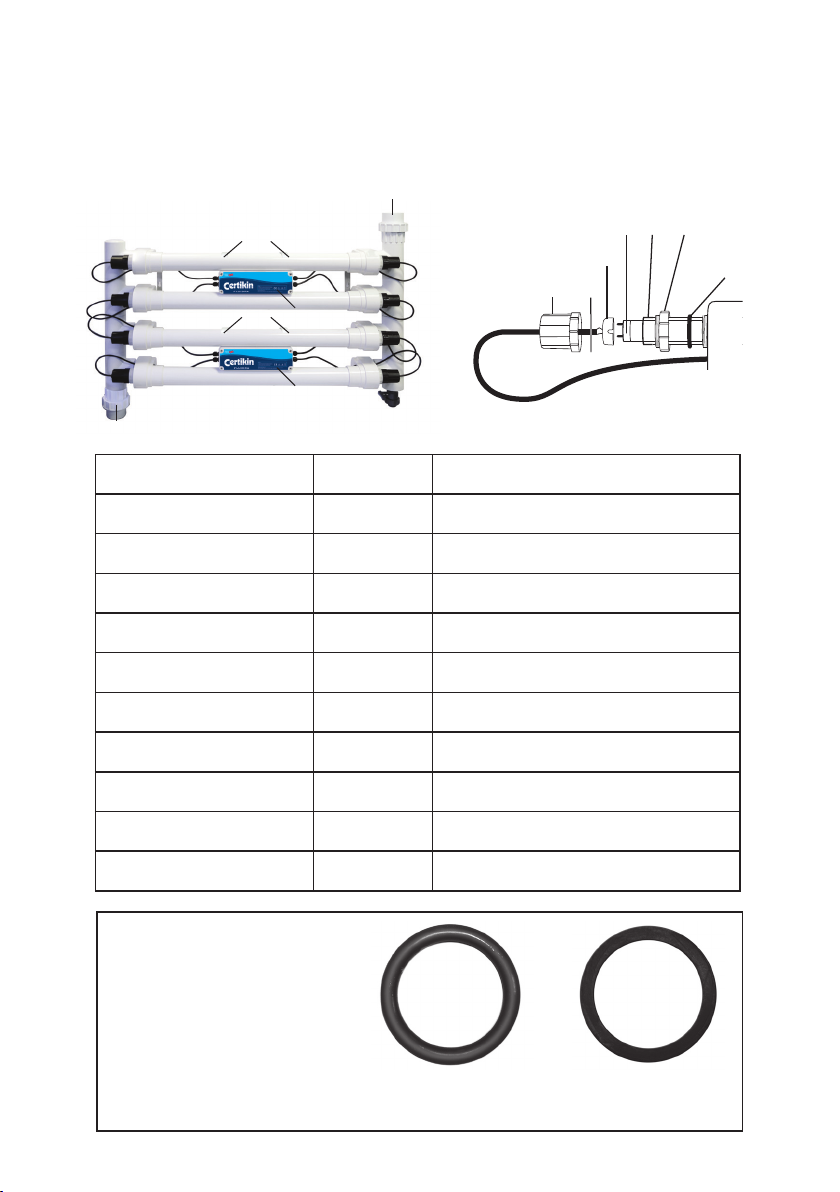

PRODUCT INFORMATION

- CUV15V3, CUV25V3, CUV30V3, CUV55V3, CUV75V3, CUV110N, CUV220N RATING:

UK / EU: 220-240V 50 / 60Hz. USA: 120V 50 / 60HZ.

- All units are Class 1, IPX5. All components are CE compliant.