Fluke 845AR User manual

Other Fluke Measuring Instrument manuals

Fluke

Fluke 902 User manual

Fluke

Fluke 1520 Use and care manual

Fluke

Fluke 525B User manual

Fluke

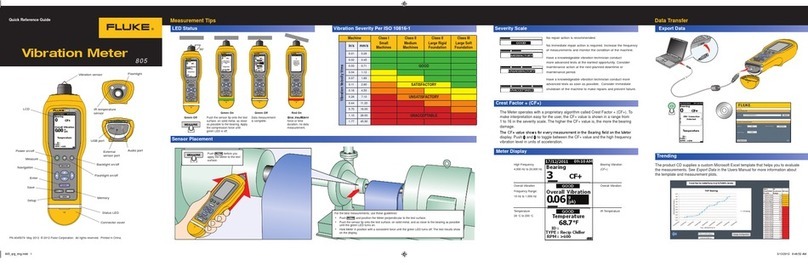

Fluke 805 User manual

Fluke

Fluke 917X Series Quick start guide

Fluke

Fluke 095969674225 User manual

Fluke

Fluke I430FLEX User manual

Fluke

Fluke IRR1-SOL User manual

Fluke

Fluke 78 User manual

Fluke

Fluke 925 User manual

Fluke

Fluke i5s User manual

Fluke

Fluke RUSKA 2482 User manual

Fluke

Fluke Micro-Bath 7102 User manual

Fluke

Fluke 830 User manual

Fluke

Fluke CableAnalyzer DSX-602 User manual

Fluke

Fluke i430-Flexi-TF User manual

Fluke

Fluke 374 FC Use and care manual

Fluke

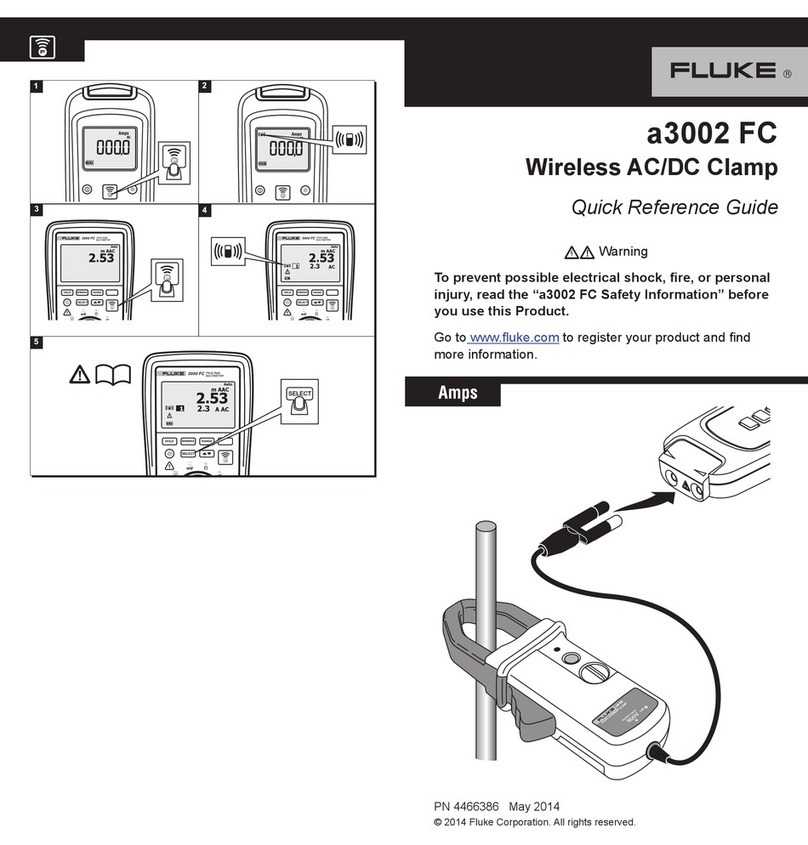

Fluke a3002 FC User manual

Fluke

Fluke 931 User manual

Fluke

Fluke 165X User manual