FOM/FOS

Service Information

2

Table 1. FOM Specifications

Output 1 mV per 1 dB

Input Connector Type Fixed ST

Photodetector Type Germanium

Application range 800 to 1600 nm

Calibrated

Wavelengths 850, 1300, and 1550 nm

Acceptable Fiber

Types 9/125 to 100/140 µm

Operating Range +3 to -50 dBm

Maximum Power Level +5 dBm

Absolute Accuracy ±0.25 dB (specified at 25°C

-10 dBm per NIST standard)

Relative Accuracy ±0.15 dB, (specified over any

10 dB within measurement

range)

Repeatability ±0.04 dB

Battery Life 9V alkaline, NEDA 1604A or

IEC 6LR61

Battery Type 16 hours minimum, 100

hours typical, 9V alkaline

Low Battery Indication Blinking LED indicator

Operating Temperature 0°to +40°C

Storage Temperature -20°to +70°C

Humidity 0 to 40°C up to 75% RH

Table 2. FOS Specifications

Type Infrared LED

Wavelength 850 ±30 nm

1300 -40/+50 nm

850/1300 ±30 nm,

-40/+50 nm

Output power -20 dBm, nominal into

62.5/125 micron multimode

fiber

Output connector type Fixed ST

Beam divergence 0.3 radians

Pulse duration Continuous wave

Maximum output 200 µW (radiated into free

space)

Stability ±0.2 dB per 8 hours at 20°C

after 20 minute warmup

Temperature

coefficient -0.08 dB per °C, < 18°C or >

20°C

Battery Life 9V alkaline, NEDA 1604A or

IEC 6LR61

Battery Type 16 hours minimum, 24 hours

typical, 9V alkaline

Low Battery Indication Blinking LED indicator

Operating Temperature 0°to +40°C

Storage Temperature -20°to +70°C

Humidity 0 to 40°C up to 75% RH

Safety Information

CLASS I

LED PRODUCT

The FOS is rated as a class 1 LED source per

IEC 825.

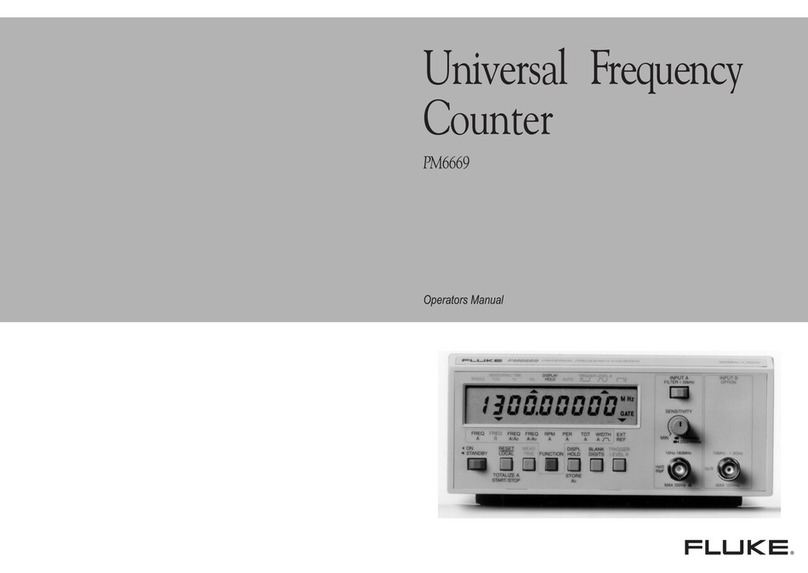

General Description

The FOM measures optical power on fiber optic

cables. It indicates power loss on tested cables

using any digital multimeter (DMM) or graphical

multimeter (GMM) that has a 10 Meinput

impedance, standard diameter banana jacks, and

mVdc capability. The FOS is used as a light source

with the FOM or other fiber optic meters.

Low Battery Detection

For both the FOM and FOS, a steady, green LED

indicates a good battery. A blinking LED indicates

a low battery that needs to be replaced.

Cleaning the Optical Connector

Most problems with optical power meters and light

sources result from contaminated connectors.

Therefore, always clean the connector before

troubleshooting or calibration.

To clean the FOM or FOS ST connector, wipe the

internal portion gently with an optical-grade swab

dampened with optical-grade alcohol. To remove

loose dirt and dust from the connector, use filtered,

compressed air.

Always cover the connector with a dust cap when

the unit is not in use.

Equipment Required

The following equipment is required for servicing

the FOM:

•0-10V power supply

•Digital multimeter

•Optical power meter calibrated at 850, 1300,

and 1550 nm traceable to NIST Standards

•850 nm laser source; Po= -10 dBm

•1300 nm laser source; Po= -10 dBm

•1550 nm laser source: Po= -10 dBm

•Variable optical attenuator