Instrument Compatibility

The i2000flex can be used with any Fluke ScopeMeter test tool,

Power Quality Analyzer, Oscilloscope, or Multimeter that has the

following features:

• BNC input connector. The Dual Banana to BNC Adapter

included in the package, can be used to connect to standard

inputs on multimeters. For the 120 series ScopeMeters and

the Fluke 43 Power Quality Analyzer, use the BB120 Shielded

Banana to BNC Adapter (optional accessory).

• Input accuracy of 1% or better to take full advantage of the

accuracy of the Current Probe.

• Input impedance of greater than or equal to 1 kΩ, and for full

bandwidth and accuracy, a maximum input capacity of 100 pF.

• A passband of more than four times the frequency of the

waveform to be measured.

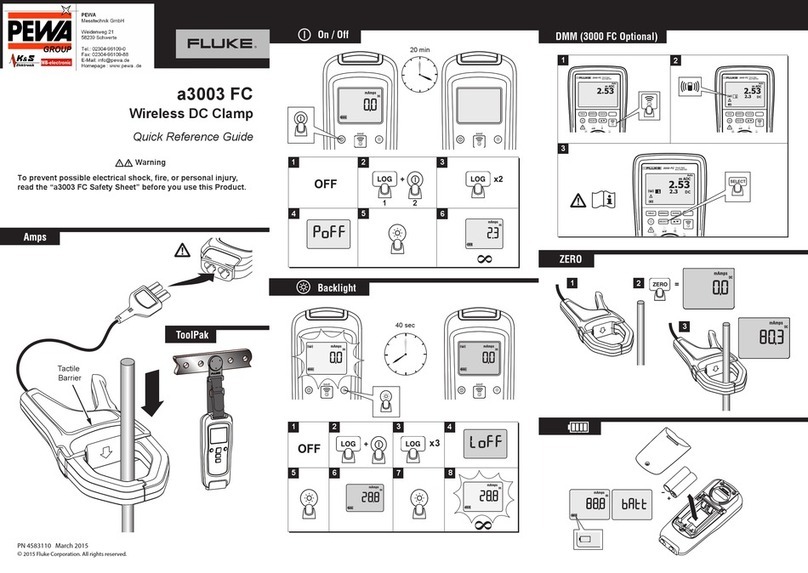

Using the i2000flex

To use the i2000flex, follow these instructions:

1. Connect the BNC connector of the i2000flex to the desired

input on the measuring instrument. When you are using a

multimeter, use the Dual Banana to BNC Adapter

(PM9081/001) to connect the i2000flex to the input. (See

Figure 5.)

2. On the i2000flex unit, select the least sensitive range (set the

slide switch to position ‘1 mV/A’).

3. Select the corresponding sensitivity (.. mV/A) on your

ScopeMeter test tool or oscilloscope. If you are using a

multimeter, select an appropriate AC voltage range.

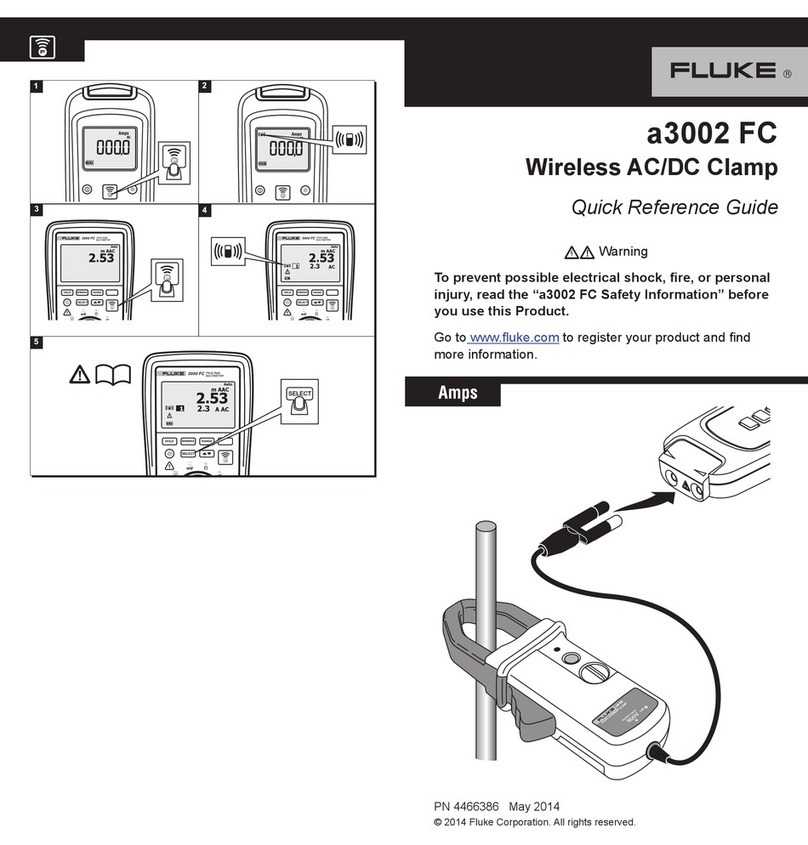

Figure 4. Connecting the flexible probe around the conductor.

4. Connect the flexible probe around the conductor (See

Figure 4.)

5. Make sure that the arrow marked on the probe coupling points

toward the correct orientation for correct phase display on the

oscilloscope. (See Figure 6.)

6. Keep the probe coupling more than 2.5 cm (1 inch) away from

the conductor.

7. Observe the current value and waveform on the instrument’s

display.

8. If desired, select the lower range on the i2000flex unit and set

the corresponding sensitivity on the measurement instrument.

If the i2000flex is used with a multimeter, the actual current value

can be calculated from the displayed AC voltage value.

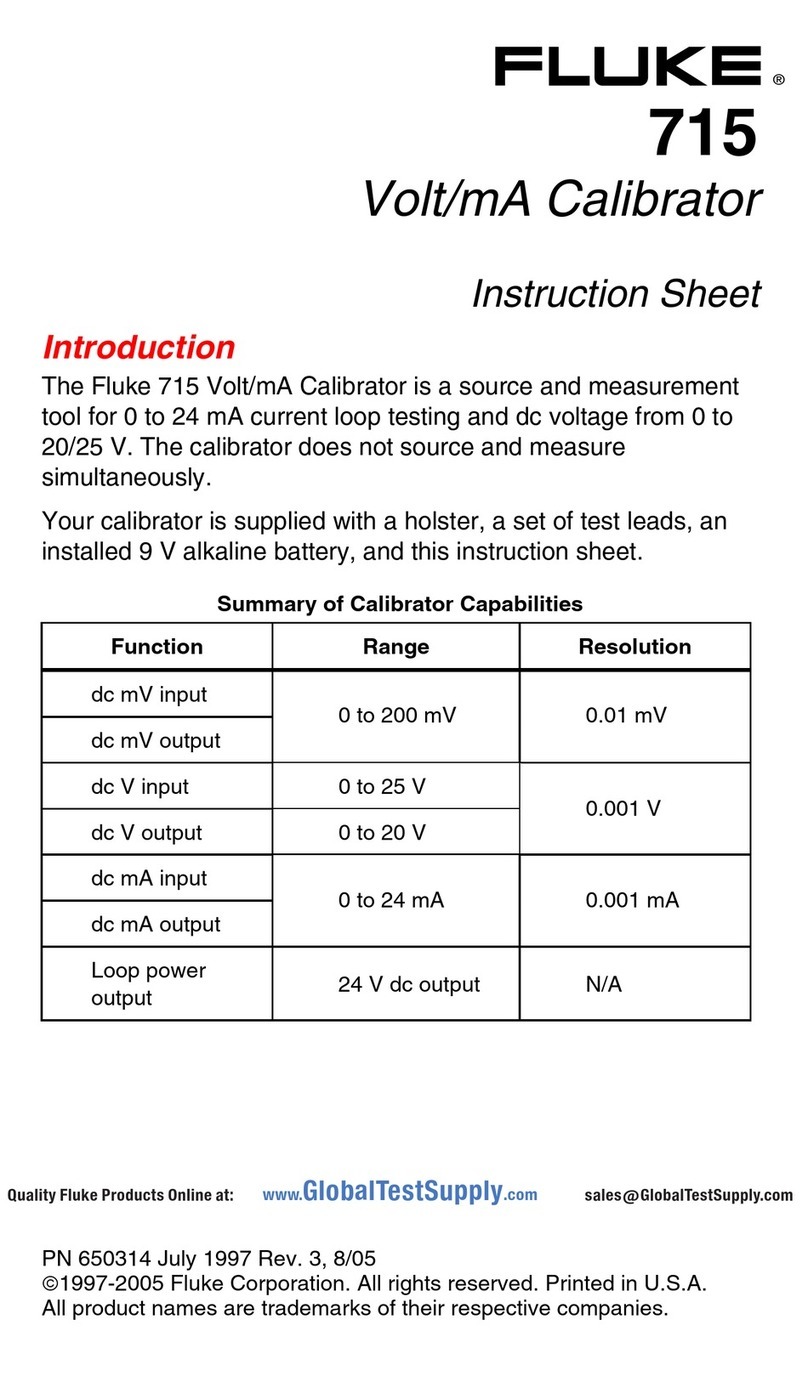

Example 1 : Current Probe set to 1 mV/A (2000A range).

Multimeter displays 1.85Vac rms.

Actualcurrent

displayvalue

sensitivityCurrent 1.85V

1 mV / A 1850 mV

1 mV / A 1850A ac rms

=

== =

Probe

Example 2: Current Probe set to 10 mV/A (200A range).

Multimeter displays 750 mVac rms.

Actualcurrent

displayvalue

sensitivityCurrent 750 mV

1 mV/A 75A ac rms

=

==

Probe 0

Figure 5. Measurement Setup

Warning

If the sensitivity setting (mV/A) of the ScopeMeter

test tool or oscilloscope does not correspond with

the setting of the Current Probe, the ScopeMeter test

tool or oscilloscope may display a much lower

current than the actual value. This may result in a

false and misleading reading.

Figure 6. Orientation of the flexible probe

Measurement Considerations

Though the i2000flex is intended for measurements on hard to

reach conductors, observe the following guidelines to approach the

maximum measurement accuracy of ±1% of full scale as far as

possible:

• Center the conductor perpendicularly inside the flexible probe

area. If this is not possible, an additional measurement error

of ±2% of full scale can occur.

• Avoid taking measurements close to other current-carrying

conductors if possible. An external field of maximum 40 A/m

can cause an additional measurement error of 1% of full

scale.

The probe coupling must be at least 2.5 cm (1 inch) away from the

conductor to which the probe is attached, to meet specified

measurement accuracies.

Also see under “Additional errors” in the section “Specifications”.

Maintenance

• Before each use, assure continued safety by inspecting the

flexible probe and its latching system for any damage. Pay

particular attention to the insulation surrounding the flexible

probe. An i2000flex under warranty will be promptly repaired or

replaced (at Fluke's discretion) and returned at no charge.

Cleaning and Storage

• The flexible probe and its latching system require no special

care. Ensure that no foreign body obstructs the latching

mechanism.

• Clean the i2000flex unit with a damp cloth and a mild

detergent. Do not use abrasives, solvents, or alcohol.

• Remove the battery when storing the i2000flex for a long

period of time.

Replacing the Battery

Replace the 9V battery when the ‘BATTERY LOW’ LED on the

i2000flex unit flashes when the power is switched on (a range is

selected.)

• Remove the flexible current probe, from any circuit to

be measured.

• Set the unit switch to OFF.

• Disconnect the unit from the measurement

instrument.

Note:

The i2000flex unit contains an alkaline battery. Do not

dispose of this battery with other solid waste. Used

batteries should be disposed of by a qualified recycler

or hazardous materials handler. Contact your

authorized FLUKE Service Center for recycling

information.

Follow the steps 1 to 5 depicted in the following figure to replace

the battery.

Figure 7. Replacing the battery

If your i2000flex does not work

If the i2000flex does not perform properly, use the following steps

to help isolate the problem:

• Inspect the coupling system for any damage. If any foreign

material is present, the coupling system will not close properly

and errors will result.

• Inspect the cables between the flexible probe and the unit and

between the unit and the measurement instrument for any

damage.

• Check if the slide switch on the unit is set to the appropriate

current range, matching with the range (or sensitivity) of the

measurement instrument.

• Check if the “POWER ON” LED on the unit is flashing, and the

“BATTERY LOW” LED is not flashing. Otherwise replace the

battery. Also replace the battery if both LEDs stay off.

• Verify that the function selection on the measurement

instrument is correct.

• If your measurement instrument has a sensitivity setting for a

current probe, select the correct setting (1 mV/A or 10 mV/A).

• If you use a multimeter, preferably select the 2V ac range for

full range measurements with best accuracy results.

LIMITED WARRANTY & LIMITATION OF LIABILITY

This Fluke product will be free from defects in material and

workmanship for one year from the date of purchase. This warranty

does not cover fuses, disposable batteries or damage from

accident, neglect, misuse or abnormal conditions of operation or

handling. Resellers are not authorized to extend any other warranty

on Fluke’s behalf. To obtain service during the warranty period,

send your defective product to the nearest Fluke Authorized

Service Center with a description of the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER

WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR

PURPOSE, ARE EXPRESSED OR IMPLIED. FLUKE IS NOT

LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, ARISING FROM

ANY CAUSE OR THEORY.

Since some states or countries do not allow the exclusion or

limitation of an implied warranty or of incidental or consequential

damages, this limitation of liability may not apply to you.

Fluke Corporation Fluke Industrial B.V.

P.O. Box 9090 P.O. Box 680

Everett WA 7600 AR Almelo

98206-9090, USA The Netherlands

SERVICE CENTERS

To locate an authorized service center,

visit us on the World Wide Web:

http://www.fluke.com

or call Fluke using any of the phone numbers listed below:

+1-888-993-5853 in U.S.A. and Canada

+31-402-678-200 in Europe

+1-425-356-5500 from other countries

Measurement

at a neutral

conductor

Measurement

at a phase

conductor