2352 Walsh Ave. Santa Clara, CA 95051. U. S. A. Tel.: (408) 748-9100, Fax: (408) 748-9111 www.analogtechnologies.com

Copyrights 2000 – 2012, Analog Technologies, Inc. All Rights Reserved. Updated on 11/22/2012 1

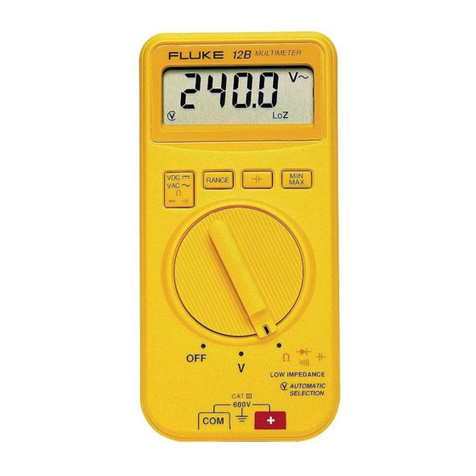

nalog Technologies 317 and 319

Clamp Meter

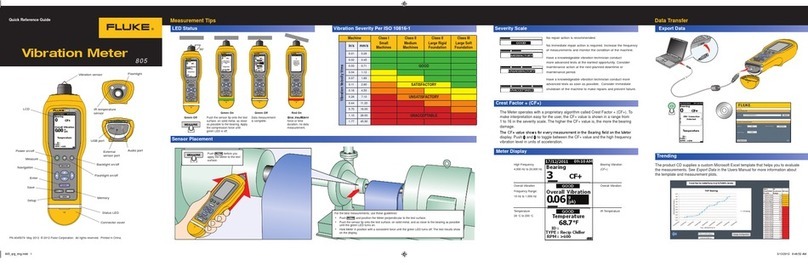

Figure 1. The Photo of Actual 317

Figure2.ThePhotoofActual319

Figure 3. The Photo of Actual 319

FEATURES

Digital Display: 6000 count resolution

Low Battery Indication: Display when the batteries are

below their required voltage

Power Source: Three AAA IEC LR03 batteries

Clamp Opening Size: 1.45"

Jaw Diameter: 1.45"

Dimension (L×W×H): 6.39"×2.29"×1.20"

Auto Range: Available in Ohms

Safety: CE

EN/IEC 61010-1 and IEC 61010-2-032

Measurement Category: 600 V CAT Ⅲ

Weight: About 384g

APPLICATIONS

It’s widely used to measure alternating voltage, direct

voltage, current, capacitance, diode, audion, resistance,

temperature, frequency, etc.

DESCRIPTION

The 317 and 319 are hand-held and battery-operated clamp

meters that can measure AC current, DC current, AC voltage,

DC voltage, resistance, continuity and frequency.

The clamp meter is battery powered with a digital display.

Except where noted, the descriptions and instructions in this

datasheet apply to both the 317 and 319 clamp meters.

Warning: To avoid possible electric shock or

personal injury, read “Safety Information” before using

the clamp meter.

SAFETY INFORMATION

Use the clamp meter only as specified in this datasheet,

otherwise the protection provided by the clamp meter may be

impaired.

Adhere to local and national safety codes. Individual

protective equipment must be used to prevent shock and arc

blast injury where hazardous live conductors are exposed.

Use extreme caution when working around bare conductors

or bus bars. Contact with the conductor could result in

electric shock.

Use caution when working with voltages above 30V AC rms,

42V AC peak, or 60V DC. These voltages pose a shock

hazard.

Never measure current while the test leads are inserted into

the input jacks.

Do not use the clamp meter in wet, dirty or hazardous