8024B

Pulse Response

{200 k£2 range)

Input Impedance

Overload Protection

ENVIRONMENTAL

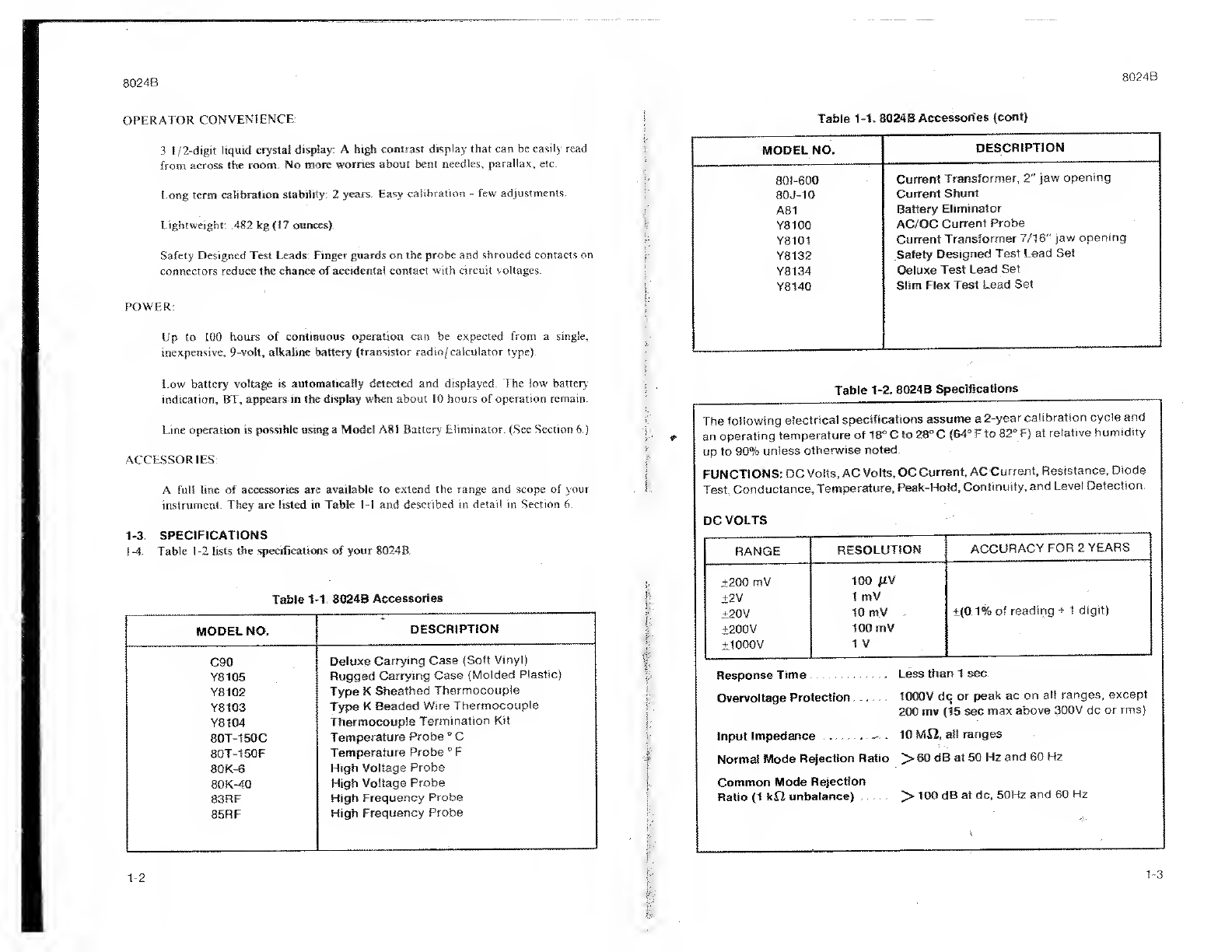

Table 1-2, 8024B Specifications (cont)

50 ftS {Minimum width of 0to +3V

pulse required to toggle display. Pulse

stretcher holds display for approx. 100

ms when short pulses are detected.)

>100 k£2 in parallel with <100 pF

500V dc or rms ac (15 sec max above 300V

dc or rms ac) ___

Temperature

OPERATING 0° Cto 50° C(32° Fto 122° F)

STORAGE -35 to +60° C

Relative Humidity 0to 90% from 0° Cto 35° Cexcept 0to 80%

from 0° Cto 35° Con 2MS2; 20M11, and

200 nS ranges; 0to 70% from 35° Cto

50° C

Temperature

Coefficient ’<0.1 times the applicable accuracy speci-

fication per °Cfor 0° Cto 18° Cand 28°Cto

50° C(32° Fto 64.4° Fand 82.4° Fto 122° F),

except temperature {<0.02 Xaccuracy,

per °C)

GENERAL:

Protection Class 2 (Relates solely to insulation or grounding

properties defined in IEC 348)

Maximum Common Mode

Voltage 500V dc or rms

Power Requirements Single 9V battery, NEDA 1604

BATTERY LIFE Alkaline: 100 hours typical

Zinc carbon: 50 hours typical

BATTERY INDICATOR ... “BT” in display illuminates when approxi-

mately 20% of life remains

Display 372 digit LCD (1 ,999 count), autozero, auto-

polarity

LxWxH: 18.0 cm x8.6 cm x4,5 cm

(7.1 in x3.4 in x1.8 in) !

Weight 48 Kg, (17 oz)

8024B

2-1. INTRODUCTION

2-2. Tofully utilize the measurement capabilities of your 8024B, abasic understanding of

its measurement techniques and limitations is required. This section of the manual

provides that information.

2-3. PREPARING FOR OPERATION

2-4. Unpacking

2-5,Your 8024B, this manual, one 9V battery, and two test leads (one red and one black)

were shipped to you in aspecially designed container. Check the shipment carefully and

contact the place of purchase immediately if anything is wrong. If the place of purchase

fails to satisfy you, contact the nearest John Fluke Service Center. Alist of these service

centers is located at the end of this manual.

2-6. If reshipment is necessary, please use the original shipping container. If the original

container is not available, anew one can be obtained from the John Fluke Mfg. Co., Inc.

Please state the instrument model number when requesting anew shipping container.

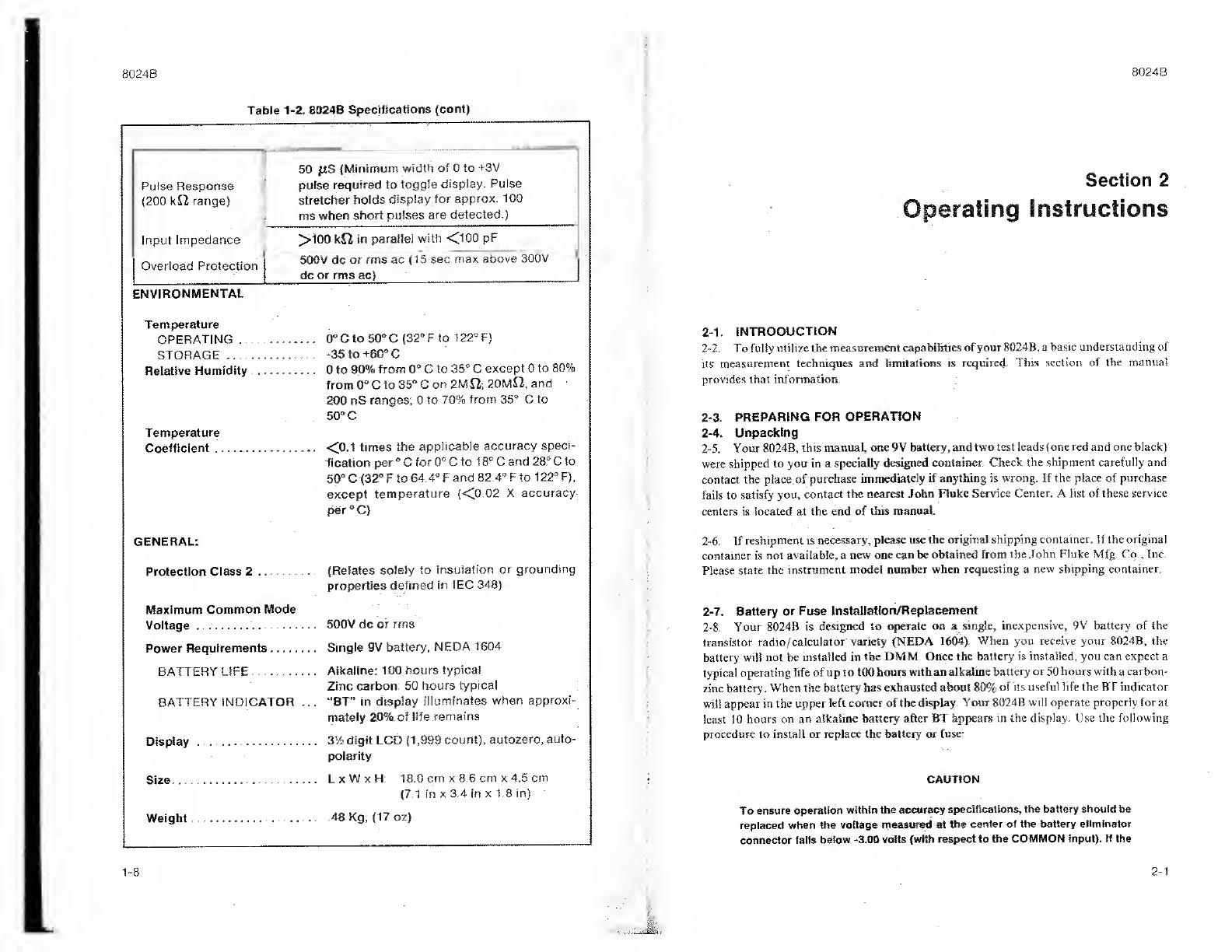

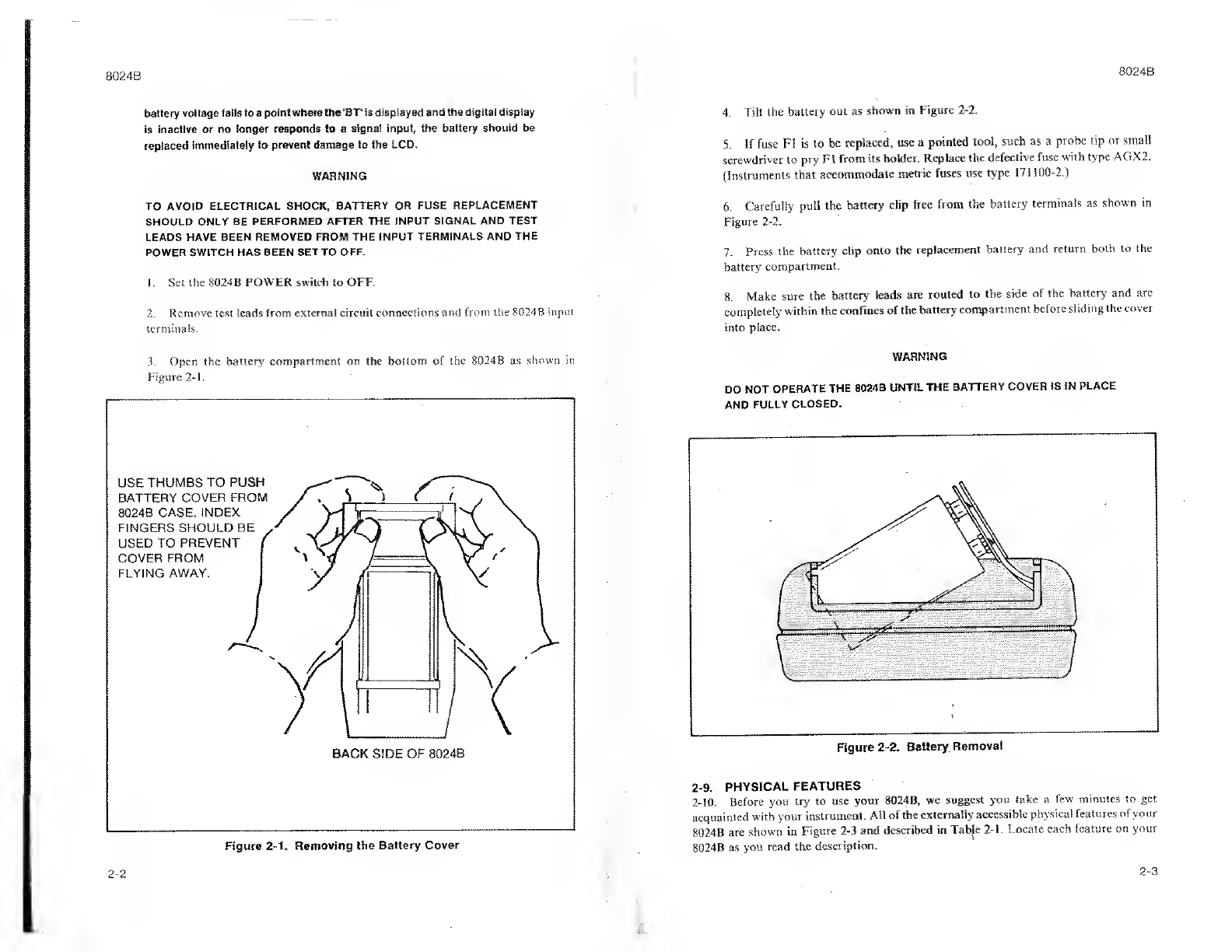

2-7. Battery or Fuse Installation/Replacement

2-8. Your 8024B is designed to operate on asingle, inexpensive, 9V battery of the

transistor radio/ calculator variety (NEDA 1604). When you receive your 8024B, the

battery will not be installed in the DMM. Once the battery is installed, you can expect a

typical operating life of up to 100 hours with an alkaline battery or 50 hours with acarbon-

zinc battery. Wrhen the battery has exhausted about 80% of its useful life the BT indicator

will appear in the upper left corner of the display. Your 8024B will operate properly for at

least 10 hours on an alkaline battery after BT appears in the display. Use the following

procedure to install or replace the battery or fuse:

CAUTION

To ensure operation within the accuracy specifications, the battery should be

replaced when the voltage measured at the center of the battery eliminator

connector falls below -3.00 volts (with respect to the COMMON input). If the

2-1