i

Table of Contents

Chapter Title Page

1 Introduction and Specifications........................................................ 1-1

1-1. Using the Meter Safely......................................................................... 1-3

1-2. Operating Instructions .......................................................................... 1-4

1-3. Specifications........................................................................................ 1-5

2 Theory of Operation........................................................................... 2-1

2-1. Introduction........................................................................................... 2-3

2-2. Functional Description ......................................................................... 2-3

2-3. Block Diagram Description.................................................................. 2-3

2-4. Input Overload Protection................................................................ 2-4

2-5. Function Switching Circuits............................................................. 2-4

2-6. Signal Conditioning Circuits............................................................ 2-4

2-7. Custom Analog IC (U1) ................................................................... 2-4

2-8. Peripherals to U1.............................................................................. 2-6

2-9. Microcomputer Control.................................................................... 2-6

2-10. Display.............................................................................................. 2-7

3 Maintenance........................................................................................ 3-1

3-1. Introduction........................................................................................... 3-3

3-2. Service Information .............................................................................. 3-4

3-3. Operator Maintenance .......................................................................... 3-4

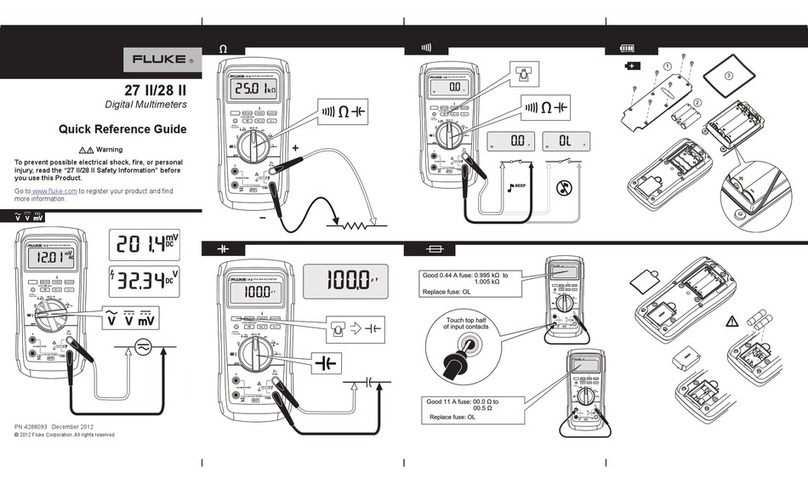

3-4. Battery Replacement ........................................................................ 3-5

3-5. Fuse Test........................................................................................... 3-6

3-6. Fuse Replacement............................................................................. 3-6

3-7. General Maintenance Information........................................................ 3-7

3-8. Handling Precautions for Static-Sensitive Devices.......................... 3-7

3-9. Disassembly...................................................................................... 3-7

3-10. Reassembly....................................................................................... 3-10

3-11. Cleaning............................................................................................ 3-12

3-12. Performance Tests ................................................................................ 3-12

3-13. Display Test...................................................................................... 3-12

3-14. Voltage Functions Performance Verification................................... 3-13

3-15. AC and DC Current Performance Verification................................ 3-13

3-16. Ohms Function Performance Verification ....................................... 3-14