PN 2811836

April 2007

©2007 Fluke Corporation. All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies.

4. Connect the input of the pressure instrument under test

to the test pressure port (item B).

5. Unscrew the pressure release knob (item I) to vent

pressure from the pump.

6. Zero the pressure module. The zeroing procedure

depends on which pressure module and calibrator you

are using.

7. Turn the fine adjustment knob (item D) to mid-range.

8. Tighten the pressure release knob finger tight.

9. Set the handle stroke length to maximum.

10. Prime pump as described under “Priming the Pump”.

11. Shorten handle-stroke length to reduce pumping force.

WCaution

Pressure may rise rapidly if the

pressurized volume is small.

12. Compress the handles to apply incrementally higher

pressure.

13. For fine pressure adjustment, use the fine adjustment

knob.

Priming the Pump

To prime the pump:

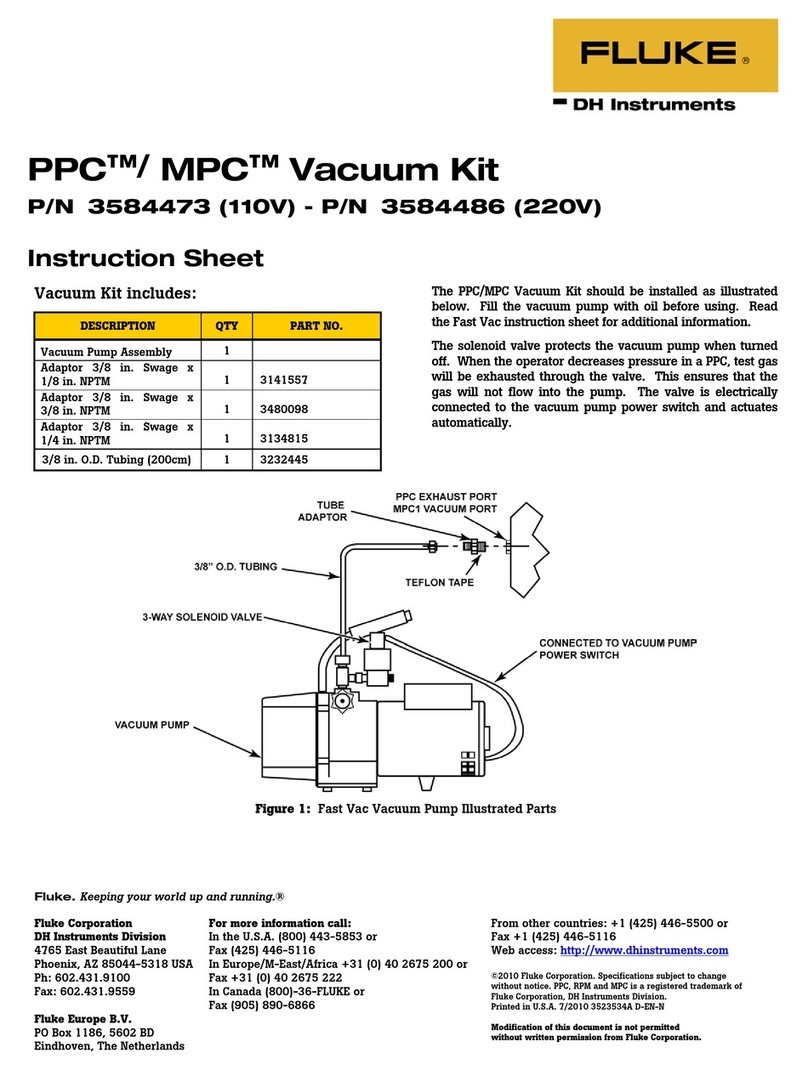

1. Connect the pressure module and calibration hose

(Fluke HTH or equivalent) as shown in the drawing. Be

sure to use several wraps of Teflon tape on all threaded

connections to insure a proper seal.

2. Fill the reservoir approximately 2/3 with either de-ionized

water or mineral oil.

3. Before connecting the other end of the calibration hose

to the device under test, raise the open end of the hose

to a level above the fluid in the reservoir.

4. Close the pressure release knob and begin pumping the

HTP until fluid begins to come out of the hose. Note that

depending on the volume of the hose this may take 50 or

more strokes.

5. Once the fluid starts to flow out of the hose, connect to

the unit under test.

6. When testing is complete, disconnect the hose from the

unit under test. If using the Fluke HTH hose, place the

plastic sealing cap back over the exposed end of the

hose to help retain the fluid until the pump is used again.

Retaining the fluid in the hose will greatly reduce the

number of strokes required to re-prime the pump.

Replacement Parts

Rebuild Kit, Fluke PN 2812606

Hydraulic Fluid Reservoir Rebuild Kit, Fluke PN 2844341

Handle Assembly Rebuild Kit, Fluke PN 2844352

LIMITED WARRANTY AND LIMITATION OF LIABILITY

This Fluke product will be free from defects in material and workmanship for

one year from the date of purchase. This warranty does not cover fuses,

disposable batteries, or damage from accident, neglect, misuse, alteration,

contamination, or abnormal conditions of operation or handling. Resellers are

not authorized to extend any other warranty on Fluke’s behalf. To obtain

service during the warranty period, contact your nearest Fluke authorized

service center to obtain return authorization information, then send the product

to that Service Center with a description of the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER WARRANTIES,

SUCH AS FITNESS FOR A PARTICULAR PURPOSE, ARE EXPRESSED OR

IMPLIED. FLUKE IS NOT LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, ARISING

FROM ANY CAUSE OR THEORY. Since some states or countries do not

allow the exclusion or limitation of an implied warranty or of incidental or

consequential damages, this limitation of liability may not apply to you.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

Introduction

The Fluke-700HTP-1 Hydraulic Test Pump (hereafter called

the pump) is a portable source of high pressure. The pump

has the following specifications:

•Maximum pressure: 690 bar (10,000 psi)

•Hydraulic media: distilled water or mineral based

hydraulic oil

•Wetted materials: 303 stainless steel, aluminum,

polyurethane, PTFE, nitrile, and nylon

•Weight: 1.29 lb (.58 kg)

•Dimensions: length 9.5 in (241 mm), width 6.1 in

(155 mm), depth 2.6 in (66 mm)

Box Contents

•Model 700HTP-1 Hydraulic Test Pump with 1/4 in NPT

tee installed

•(2) 1/4 in NPT male to 1/4 in BSP female adapter

•1/4 in NPT male to 1/4 in NPT male fitting

•Instruction Sheet

Contacting Fluke

To contact Fluke or for service, call one of the following

telephone numbers:

USA: 1-888-44-FLUKE (1-888-443-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-675-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

Or, visit Fluke's Web site at www.fluke.com.

Fluke-700HTP-1

Hydraulic Test Pump

Instruction Sheet

Downloaded from Elcodis.com electronic components distributor