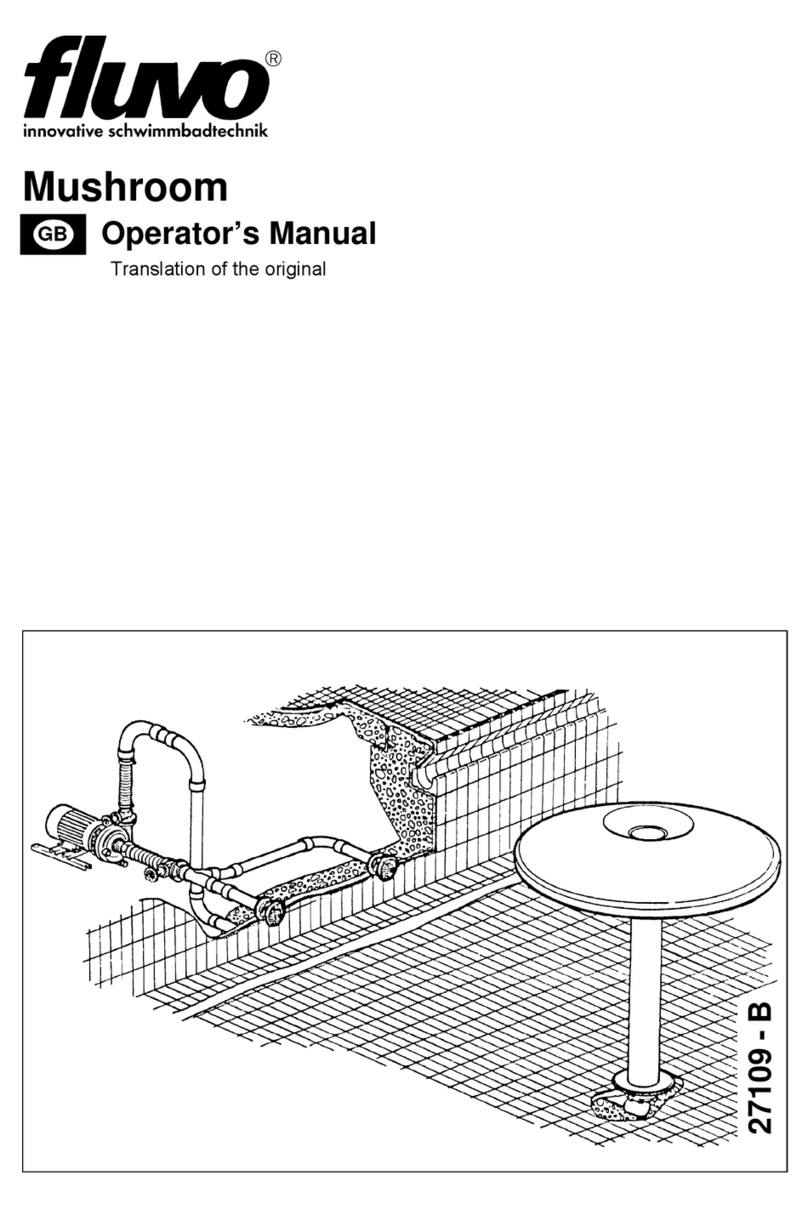

FLUVO XANAS 1.5 User manual

27263 - A.1

Operator’s Manual / assembly instructions

Translation of the original

GB

XANAS®Electrical Installation

2XANAS Electrical Installation

Version: 27263 - A.1

Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

Table of contents

1 General information ............................................................................... 3

1.1 Warranty notice .....................................................................................................3

1.2 General information ...............................................................................................3

1.3 Proper use .............................................................................................................3

2 Safety Instructions ................................................................................. 4

2.1 General information ...............................................................................................4

2.2 Marking ..................................................................................................................4

2.3 Safety instructions for the operator ........................................................................5

3 Description of the device / general technical data .............................. 6

3.1 Technical data for pump kit (sample selection) .....................................................6

3.2 Technical design of pump kit .................................................................................7

3.2.1 Manually controlled design ....................................................................................................7

3.2.2 Sensor-controlled design .......................................................................................................7

3.3 "Manually controlled design" modules ...................................................................8

3.3.1 Control unit ............................................................................................................................8

3.3.2 Control box NT .......................................................................................................................9

3.3.3 Pump type WK .....................................................................................................................10

3.3.4 Connection diagrams - Manually controlled design ...........................................................11

3.3.5 Operation - Manually controlled design ...............................................................................12

3.4 "Sensor-controlled design" modules ....................................................................13

3.4.1 Control unit ..........................................................................................................................13

3.4.2 Converter box ......................................................................................................................14

3.4.3 Pump type WK-FU ...............................................................................................................15

3.4.4 FU programming - XANAS® specific delivery state .............................................................15

3.4.4.1 Operating modes: ................................................................................................................16

3.4.4.2 "Internal potentiometer" operating mode .............................................................................17

3.4.4.3 "Analog control" operating mode .........................................................................................17

3.4.4.4 Additional feedback contacts ...............................................................................................18

3.4.4.5 Error message on FU ..........................................................................................................18

3.4.5 Connection diagrams - Sensor-controlled design ..............................................................19

3.4.5.1 Testing the wiring .................................................................................................................20

3.4.6 Connection for external operation ........................................................................................20

3.4.7 Operation - Sensor-controlled design ..................................................................................21

3.5 Installation instructions for sensor button and control unit ...................................22

3

XANAS Electrical Installation

Version: 27263 - A.1 Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

1 General information

1.1 Warranty notice

1.2 General information

All parts in contact with media are designed for water quality according to DIN 19643.

This counter-current system (XANAS®) represents the state of the art. It has been manu-

factured with the greatest care and is subject to continuous quality control.

This Operator’s Manual contains important information to ensure that the counter-current

system is operated safely, properly and economically.

Your strict observance is necessary to prevent dangers and ensure a long service life for

the counter-current system.

This operator's manual does not take into consideration local requirements. The operator

is responsible for ensuring these requirements are met, including personnel retained to

assemble the system.

The rating plate indicates the series and frame size, the most important operating data and

the factory number. If additional information is required, please always specify it when reor-

dering or ordering spare parts.

1.3 Proper use

The counter-current system was designed for use in private swimming pools.

Therefore it should not be installed in public swimming pools. The counter-current system

must not be operated beyond the values specified in technical data (3.1). If you have any

questions, please contact your Customer Service representative or the manufacturer.

The entire system or parts of it are not suitable for use in other systems. The

function of the entire system in combination with other systems or components

can not be guaranteed. Accordingly we explicitly instruct you only to use such

parts or the entire system for their intended purpose.

Failure to comply with the information provided in this operator's manual voids

all claims under warrantee.

4XANAS Electrical Installation

Version: 27263 - A.1

Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

2 Safety Instructions

2.1 General information

• Make certain before commissioning that the operating personnel have read and under-

stood the operator's manual. It is the owner rather than the operator who is responsible

for safety.

• Make certain the safety requirements and laws for the use of counter-current systems

which apply to the operating company and/or country in which the system is operated

are observed.

• Use the counter-current system only when it is in flawless condition technically and ac-

cording to its intended purpose. Be conscious of safety and dangers and observe all

the instructions of this Operator’s Manual!

• Eliminate all malfunctions that could have a detrimental effect on safety immediately.

• Before making repairs to the counter-current system, disconnect it from its electrical

power source and prevent it from being turned on again.

• Repairs of any nature must only be made by qualified specialists. The counter-current

system must also be emptied.

• The operator must ensure that:

- the operator's manual is always available for operating personnel,

- the instructions in the operator's manual are observed,

- the counter-current system is stopped immediately if any abnormal electrical volt-

ages, vibrations, temperatures, noises, vibrations, leaks, or other faults occur.

• All personsinvolvedinsetting up, commissioning, operating, maintaining, and repairing

this device must:

- consider the operator's manual to be part of the product,

- keep the operator's manual in a safe place throughout the service life of the prod-

uct,

- forward the operator's manual to each successive owner or user of the product,

- ensure that all additions that are received are inserted into the operator's manual,

- observe all legal requirements.

2.2 Marking

The following symbols are used in this operator's manual to make special reference to dan-

gers.

Notices placed directly on the pump, such as the arrow for direction of rotation, must

always be observed and must be maintained in legible condition.

Caution! Risk of injury! / Attention! Risk of damage!

This symbol warns of hazards due to mechanical effects and of actions

that will damage the product.

Caution! Danger of death!

This symbol warns you of dangers due to electrical current.

5

XANAS Electrical Installation

Version: 27263 - A.1 Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

2.3 Safety instructions for the operator

Electrical equipment must only be installed and serviced by qualified personnel.

Applicable safety regulations and equipment requirements at the installation site must be

observed.

The term qualified specialist (Fachkraft) is defined in VDE 0105 and IEC 364. This opera-

tor's manual does not contain any information for non-qualified persons. We explicitly draw

to your attention that the stipulations of the EC prohibit the use of non-qualified persons on

electrical systems.

• If serious operating problems occur, disconnect the system from the electrical power

source.

• Check the device and the electrical power line at regular intervals for damage.

• The L/N/PE connection of the power supply voltage must be made in accordance with

VDE 0100 and VDE 0160.

• A protective and isolating device must be provided for turning off the power supply volt-

age.

In case of damage caused by failure to observe the information provided in these

operator's manual, all claims under warranty shall be void. The manufacturer cannot

accept any liability for resulting consequential damages.

Attention:

• Failure to observe the safety instructions, for example touching live parts while the de-

vice is open or handling the device in an improper manner is hazardous with potentially

fatal consequences.

• If the guarantee seal is destroyed, the guarantee and manufacturer's warranty shall be

rendered null and void.

• If the values listed in the technical data are exceeded there is danger of the device

overheating, which can destroy the power supply and adversely affect electrical safety.

Danger of lethal electrical current!

Electrical connections must only be made by a professional electrician in

accordance with VDE Regulation 0100. Observe the local requirements of the

responsible electrical power provider as well as standards and safety require-

ments for electrical systems in swimming pools.

Comply with DIN EN 13451!

Note!

Comply with DIN EN 13451 in the design of the suction unit.

Important!

When installing a frequency inverter, follow the instructions in the Operator's

Manual "INVEOR Drive Controller" of the manufacturer (KOSTAL).

6XANAS Electrical Installation

Version: 27263 - A.1

Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

3 Description of the device / general technical data

• The counter-current system meets the requirements of the VDE regulations.

• The electric motor and pump through which water flows are electrically separated.

• The electric motor corresponds to protection type IP 55.

• The counter-current system as a whole meets the requirements of protection class I.

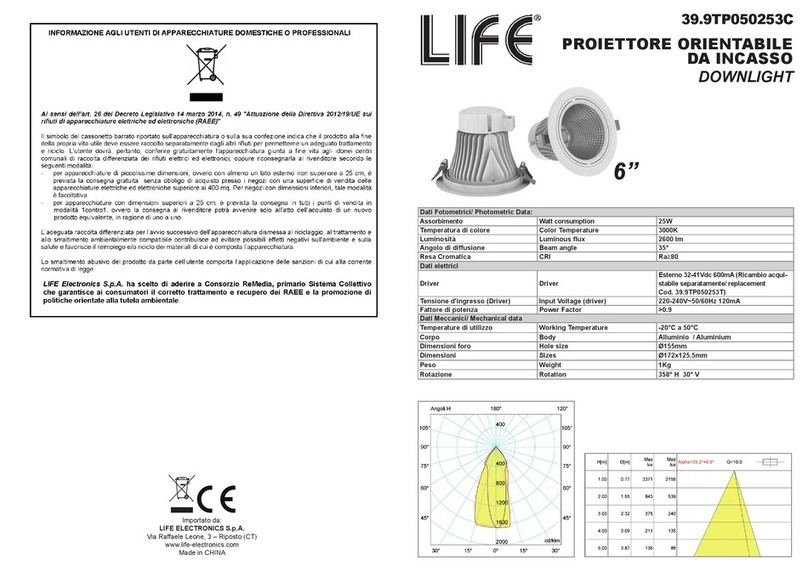

3.1 Technical data for pump kit (sample selection)

Definition of abbreviations used

WS - Single-phase alternating current motor (German Wechselstrommotor)

FU - Frequency inverter (German Frequenzumrichter), drive controller, speed-controlled

pump

System type: XANAS®

1.5 XANAS®

1.5 WS XANAS®

1.9 (FU) XANAS®

1.9 WS XANAS®

3.0 (FU) XANAS®

4.0 (FU)

Output 1.5 kW 1.5 kW 1.9 kW 1.9 kW 3.0 kW 4.0 kW

Mains voltage 3~ 400 V 1~ 230 V 3~ 400 V 1~ 230 V 3~ 400 V 3~ 400 V

Mains frequency 50 Hz 50 Hz 50 Hz 50 Hz 50 Hz 50 Hz

Motor voltage Y 400 V 230 V Y 400 V 230 V Y 400 V 400 V

Rated current Imax 2.9 A 9.5 A 4.1 A (4.6 A) 11.5 A 6.6 A (6.2 A) 8.5 A (7.9 A)

Speed 2900 rpm 2900 rpm (1200-) 2900

rpm 2900 rpm (1200 -) 2900

rpm (1200 -)

2900 rpm

max. pump capacity 700 l/min (42

m³/h) 700 l/min (42

m³/h) 800 l/min (48

m ³/h) 800 l/min (48

m ³/h) 1000 l/min

(60 m³/h) 1200 l/min

(72 m³/h)

max. delivery pres-

sure 1.2 bar 1.2 bar 1.4 bar 1.4 bar 1.9 bar 2.0 bar

max. water tempera-

ture 50° C

Usage limit (pump

only) 3000 mg/l Cl

expected acoustic

pressure level 65 + 2dB (A) 65 + 2dB (A) 67 + 2dB (A) 67 + 2dB (A) 70 + 2dB (A) 71 + 2dB (A)

Connections Pressure side DN 50

Suction side DN 65 Pressure side DN

65

Suction side DN

80

Weight 27.5 kg 27.5 kg 29.5 kg

(38 kg) 29.5 kg 36.5 kg

(45 kg) 43 kg

(51 kg)

Item no. PBS 98420 98421 98422

(98390) 98423 98425

(98391) 98426

(98392)

7

XANAS Electrical Installation

Version: 27263 - A.1 Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

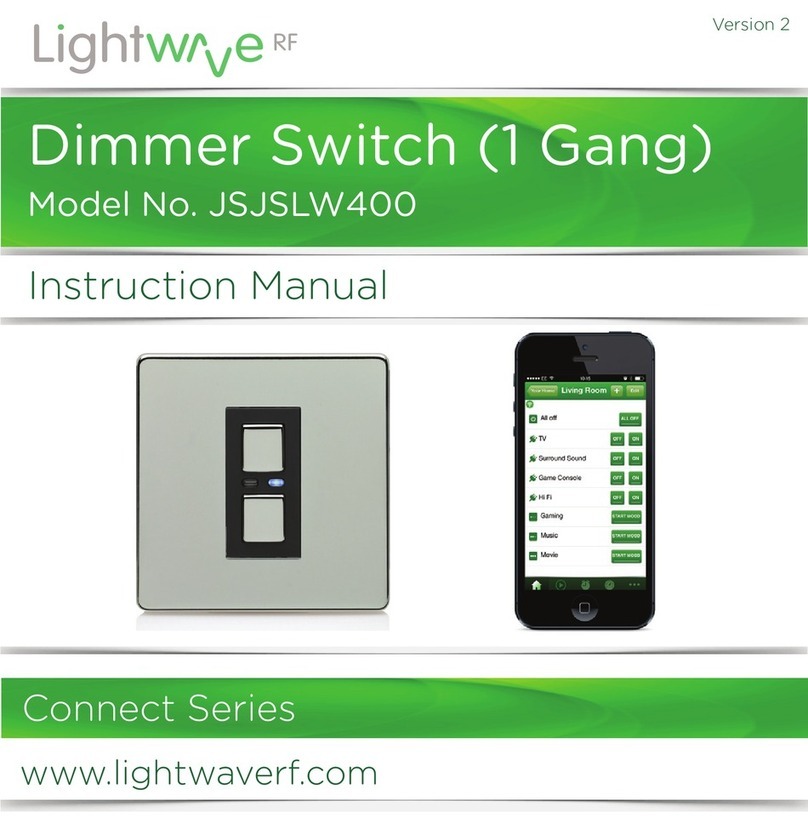

3.2 Technical design of pump kit

XANAS® is available in two different control variants

a) Manually controlled design

b) Sensor-controlled design

3.2.1 Manually controlled design

3.2.2 Sensor-controlled design

The two design variants are presented separately from each other below.

Control unit

with 1 sensor button

and 2 twist grips

Control box NT Centrifugal pump WK

Control unit

with 3 sensor buttons Converter box

for the safety isolation Centrifugal pump WK

with FU

8XANAS Electrical Installation

Version: 27263 - A.1

Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

3.3 "Manually controlled design" modules

3.3.1 Control unit

Sensor button - connection assignment

Sensor button - technical information

See also section 3.5 "Installation instructions for sensor button and control unit"

Activation via

1 x sensor button lit

2 x twist grips

Sensor button connection cable

• 5-wire special cable

• Standard cable length 2m

• Colour coded DIN 47100

• External diameter 5.5mm

• Wire cross-section 0.5 mm²

Wire colour Functions

White Switching contact S1

Brown Switching contact 24V

Grey LED1

Yellow LED2

Green LED3

Effect of switching: Pulse activated one time

Electrical function: normally open / N/O contact

Electrical data: Imax = 200mA / UB= 24V DC

Note:

When laying cables, safe isolation between different types of currents within an

installation system must be ensured without exception. Comply with the

requirements of DIN EN 50174 and DIN VDE 0100-520 for communication wir-

ing when laying the cables.

Safety isolation

For reasons of electrical safety, the sensor button must without exception be

operated via "safety isolation" such as a control box item no. 61405 or directly

on the NT switch box. The defined maximum line lengths must also be

observed.

9

XANAS Electrical Installation

Version: 27263 - A.1 Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

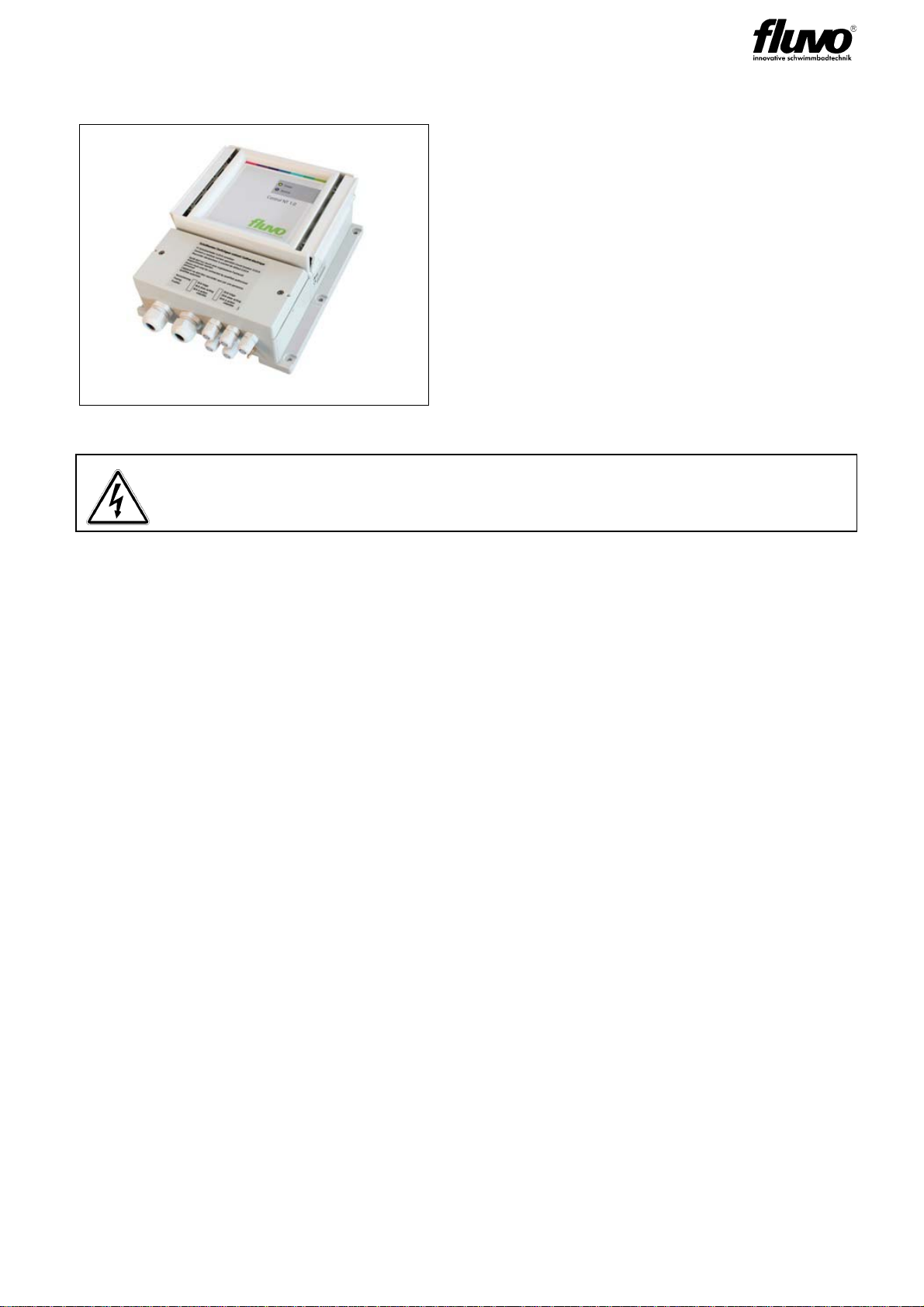

3.3.2 Control box NT

Operator's Manual 27248 "Control Box Control NT" applies

• Technical data

• Wall installation with dimensions

• Connections and settings

- Mains pump / connection terminal

- Connection terminals for control and feedback contacts

- Bus connection

- Terminal compartment disconnection

• Fault message

• Current monitoring

• 1-Phase and 3-Phase Operation

• Run time limit, time relay function

Control box NT

The control box can be used to switch a

1-phase or 3-phase pump on and off.

The sensor button is designed as an actua-

tor.

The device status is displayed by two operat-

ing LEDs with output via two floating feed-

back contacts.

The control box must always be positioned above the water level of the

pool!

10 XANAS Electrical Installation

Version: 27263 - A.1

Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

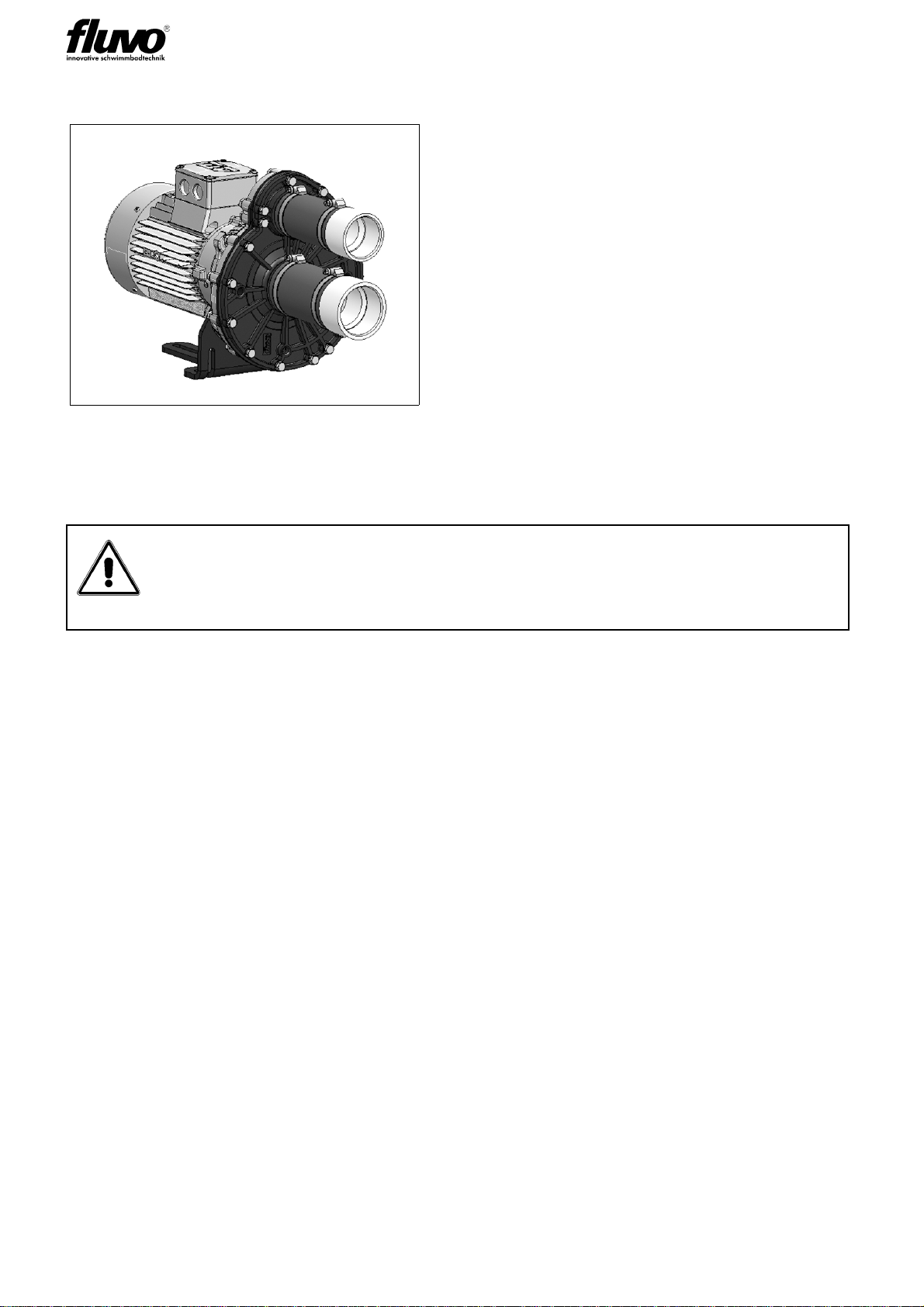

3.3.3 Pump type WK

The electrical output values between the switch box NT and centrifugal pump WK are coor-

dinated in the device kit.

Operator's Manual 27220 "Centrifugal

Pump WK" applies

• General information with data sheet for

pump WK

• Safety Instructions

• Transport and storage

• Electrical connection of the pump

• Operating the Centrifugal Pump

Check the circuit type Y / .

During installation note

- the mains voltage information on the type plate of the control box and motor

- the direction of rotation arrow on the pump

11

XANAS Electrical Installation

Version: 27263 - A.1 Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

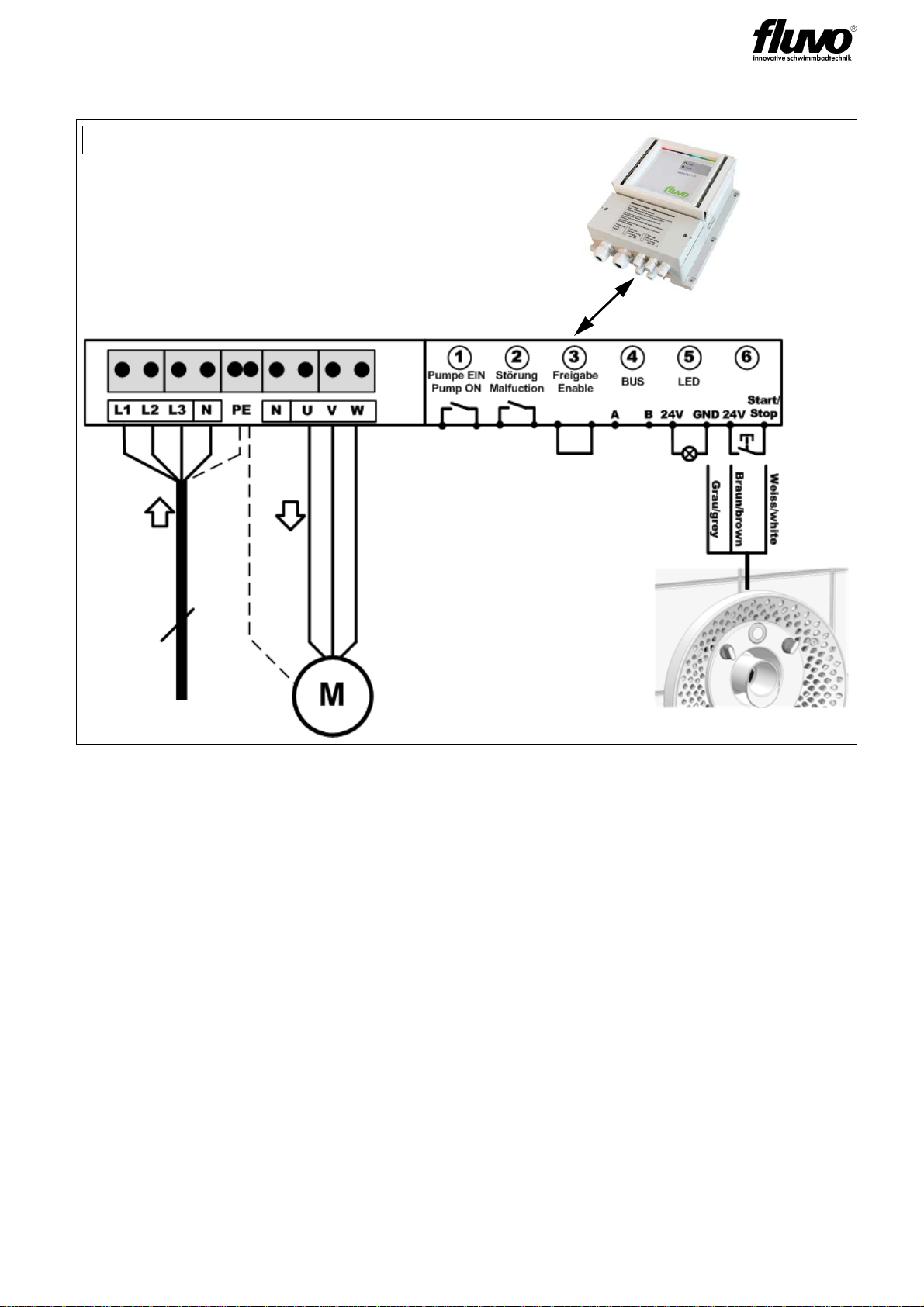

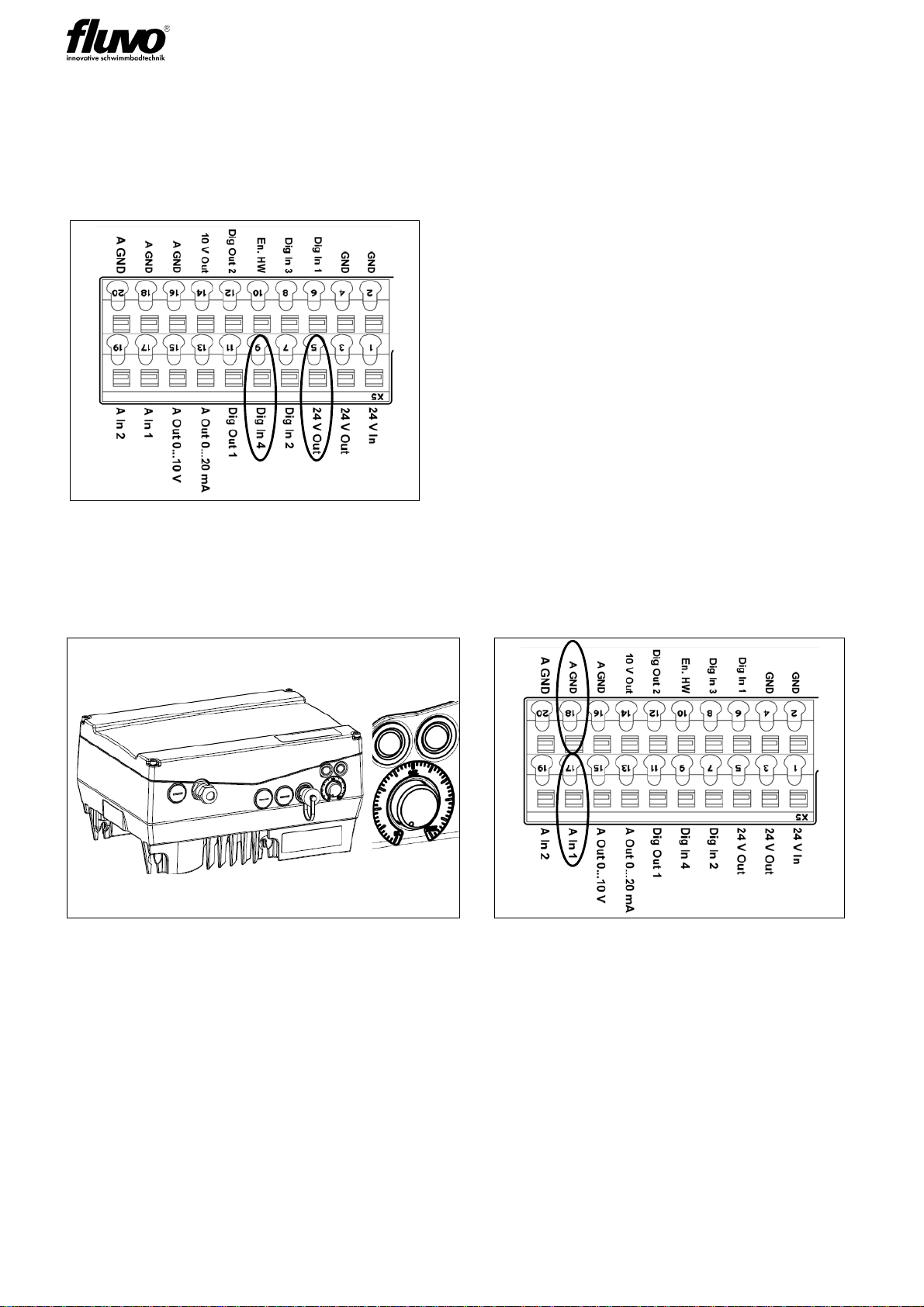

3.3.4 Connection diagrams - Manually controlled design

Range of the

connection terminals

5

Electrical power source

Example 3~ 400V

12 XANAS Electrical Installation

Version: 27263 - A.1

Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

3.3.5 Operation - Manually controlled design

Switching On/Off

Pressing the ON/OFF button turns the system on or off. The button is always lit and flashes

to provide visual feedback.

Regulating the intensity

ON/OFF

Water control

Air control

13

XANAS Electrical Installation

Version: 27263 - A.1 Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

3.4 "Sensor-controlled design" modules

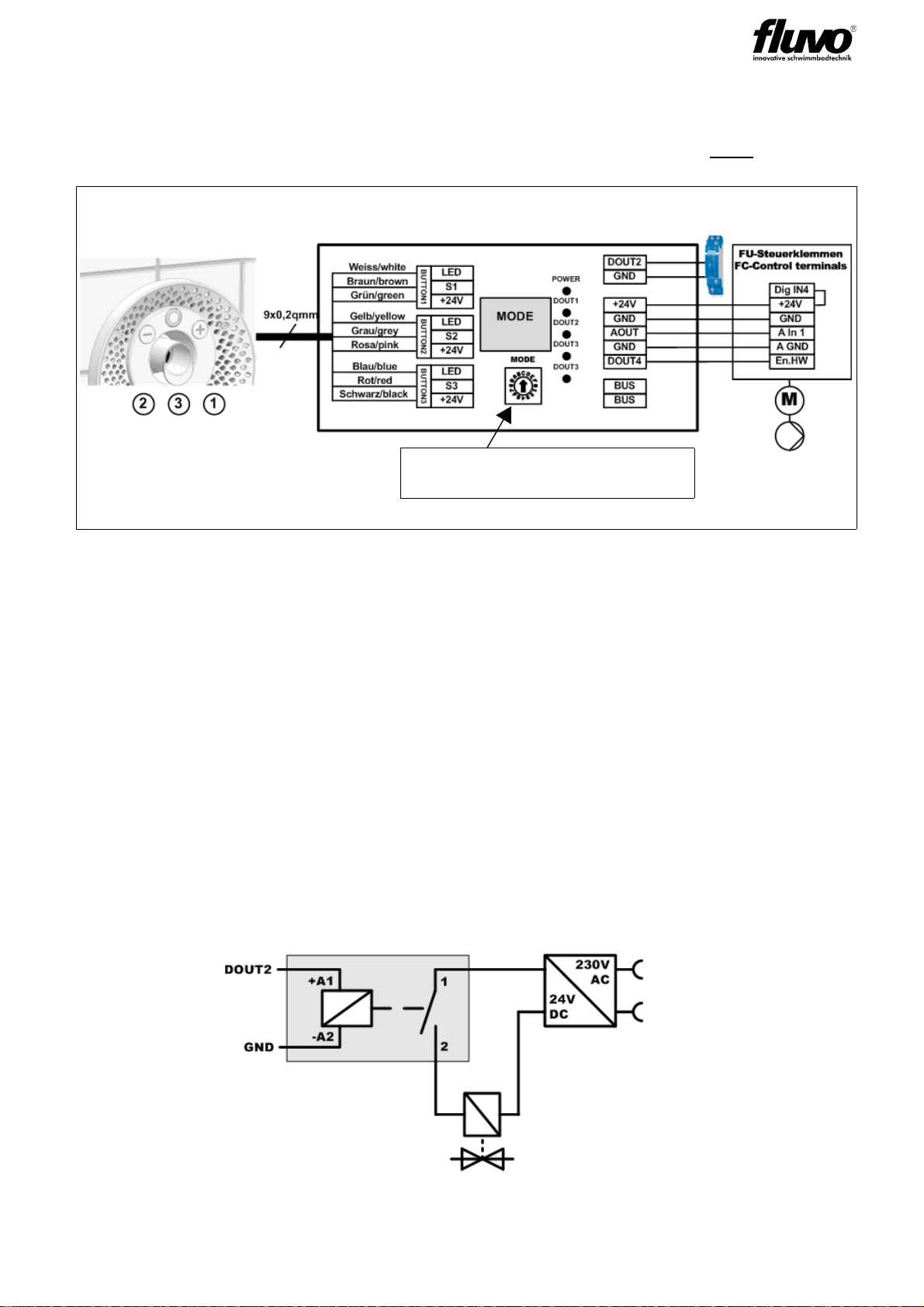

3.4.1 Control unit

Sensor button - connection assignment

Note: Arrangement corresponds to the order of terminals in the corresponds to box

Sensor button - technical information

Activation via

1 x sensor button lit

2 x sensor buttons unlit

Sensor button connection cable

• 9-wire special cable

• Standard cable length 2m

• Colour coded DIN 47100

• External diameter 6.3mm

• Wire cross-section 0.25 mm²

Wire colour Functions

White LED1

Brown Switching contact S1

Green 24V

Yellow LED2

Grey Switching contact S2

Pink 24V

Blue LED3

Red Switching contact S3

Black 24V

Effect of switching: Pulse activated one time

Electrical function: normally open / N/O contact

Electrical data: Imax = 200mA / UB= 24V DC

14 XANAS Electrical Installation

Version: 27263 - A.1

Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

See also section 3.5 "Installation instructions for sensor button and control unit“

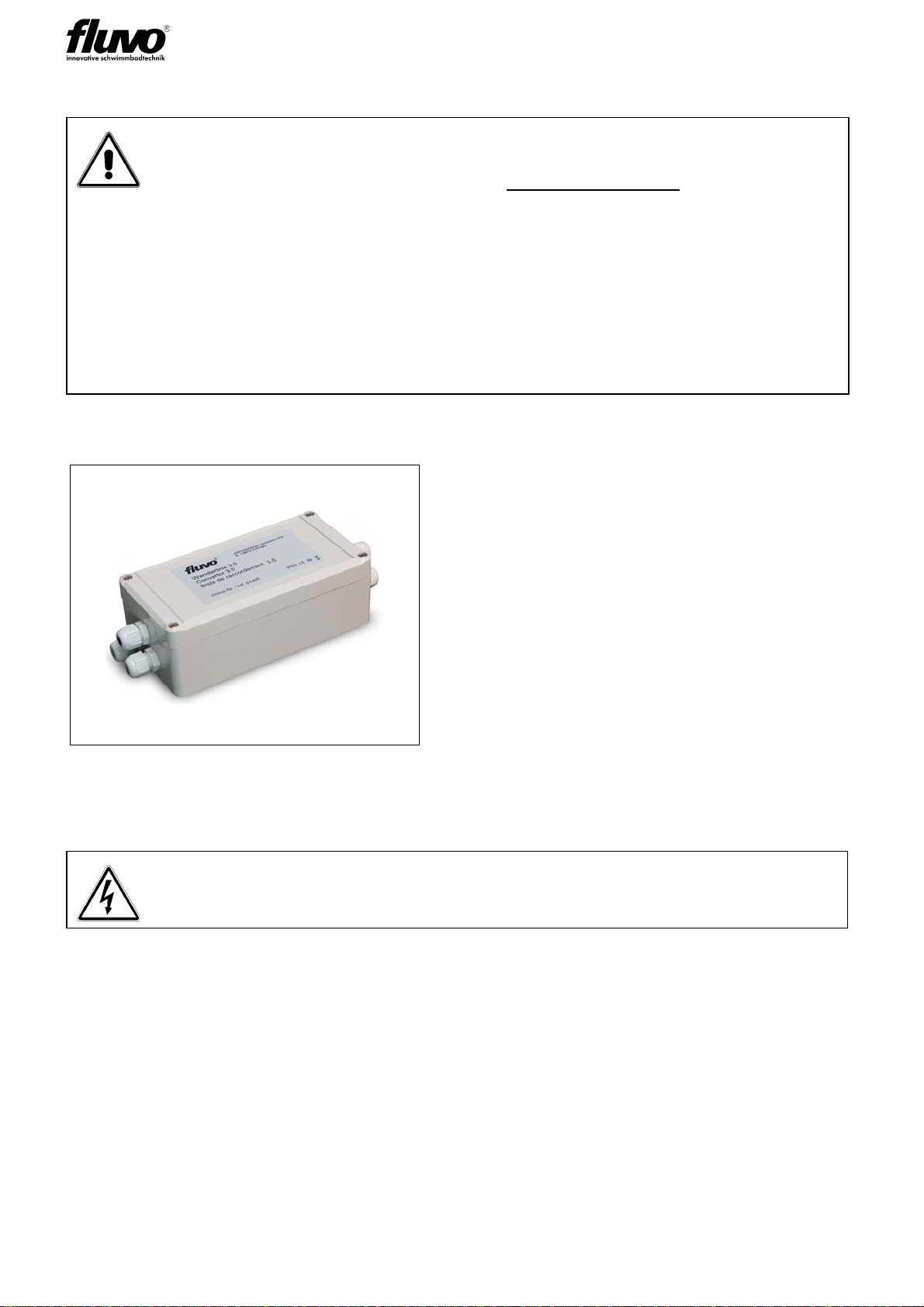

3.4.2 Converter box

Operator's Manual 27251 "Converter Box 3.0" applies

• Device overview

• Operating mode – mode 1 "THREE-button control with analog signal“

• Installation instructions and cable length

• Housing dimensions

Note:

When laying cables, safe isolation between different types of currents within an

installation system must be ensured without exception. Comply with the

requirements of DIN EN 50174 and DIN VDE 0100-520 for communication wir-

ing when laying the cables.

Safety isolation

For reasons of electrical safety, the sensor button must without exception be

operated via "safety isolation" such as a control box item no. 61405 or directly

on the NT switch box. The defined maximum line lengths must also be

observed.

The converter box 3.0 also serves as a

safety isolating element and for

evaluating button pulses of the sensor

button.

The signal output for the XANAS® is via an

analog output (AOUT).

The main task of the converter box is to

ensure a safe isolation between the sensor

buttons (buttons 1-3) on one side and the

analog and Vcc connections on the other

side of the frequency inverter. The purpose

of the converter box is to ensure safe and

reliable operation of the sensor buttons in the

swimming pool.

The converter box must always be positioned above the water level of the

pool!

15

XANAS Electrical Installation

Version: 27263 - A.1 Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

3.4.3 Pump type WK-FU

The abbreviation FU stands for the frequency inverter (German Frequenzumrichter) and

the drive controller

• General information

• Safety Instructions

• Installation

• Start-up

• Detecting and eliminating errors

• Technical data

3.4.4 FU programming - XANAS® specific delivery state

Information to supplement the INVEOR Operator's Manual

The centrifugal pump is generally delivered with the FU attached. The power data is coor-

dinated between the FU and the motor.

The FU has an active motor overcurrent protection function. The mains power connection

for the FU must be designed according to the information in the INVEOR Operator's Man-

ual (KOSTAL).

Operator's Manual 27220 "Centrifugal

Pump WK" applies

• General information with data sheet for

pump WK

• Safety Instructions

• Transport and storage

• Electrical connection of the pump

• Operating the Centrifugal Pump

Operator's Manual "INVEOR drive controller" applies

http://www.kostal-industrie-elektrik.com/de-DE/Download/Antriebs-

technik

If three-phase frequency inverters are used, conventional FI circuit breakers

type A, also called RCD (residual current-operated protective device) are not

approved for protection against direct or indirect contact!

In accordance with DIN VDE 0160 and EN 50178, the FI circuit breaker must

be a FI circuit breaker RCD type B (sensitive to all currents)!

16 XANAS Electrical Installation

Version: 27263 - A.1

Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

3.4.4.1 Operating modes:

The FU is delivered with two operating modes.

At the time of delivery operating mode 2 is activated via a wire jumper.

You can change between the two operating modes with DigIn4.

Operating mode 1:

Internal potentiometer Operating mode 2:

Analog control

Commissioning function XANAS® function

• Manual speed setting via rotary potenti-

ometer directly on the FU

• Control range between saved MIN / MAX

speed

• Active when DigIn4 is unassigned

• Speed setting via analog signal 0-

10V on control terminal A In1

• Control range between saved MIN /

MAX speed

• Active with jumper between DigIn4

and 24VOut

17

XANAS Electrical Installation

Version: 27263 - A.1 Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

3.4.4.2 "Internal potentiometer" operating mode

The FU does not start up until the hardware enable (En.HW) is set.

At the time of delivery the hardware enable (En.HW) is not set.

The FU is ready for operation when the green signal LED is flashing. Mains voltage is

applied then with the hardware enable not set. If the hardware enable is set now, the green

signal LED is lit continuously, the motor can start up and manual speed control between

MIN and MAX speed is now possible using the potentiometer on the FU.

3.4.4.3 "Analog control" operating mode

As terminals for XANAS® function

The FU does not start up until the hardware enable (En.HW) is set.

At the time of delivery the hardware enable (En.HW) is not set.

The FU is ready for operation when the green signal LED is flashing. Mains voltage is

applied then with the hardware enable not set. If the hardware enable is set now, the green

signal LED is lit continuously.

The hardware enable is set via Dout4 when the converter box is connected according to

the connection diagrams, sensor-controlled design. This Dout4 is switched together with

Aout when the Start button is pressed.

This ensures that the FU is disabled in Stop status.

The analog signal 0-10V which is present is used to control the speed between the MIN

and MAX speed value.

18 XANAS Electrical Installation

Version: 27263 - A.1

Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

3.4.4.4 Additional feedback contacts

Switches with "Malfunction"

Relay 1 (potential-free change) + DigiOUT1

Switches with "Operation"

Relay 2 (potential-free change) + DigiOUT2

For additional terminal assignments, please see the INVEOR Operator's Manual

Section 3.3.4 Control connections table, 4 Terminal assignment

3.4.4.5 Error message on FU

Red

LED Green

LED Status

Warning

Error

Key

LED off LED on

LED flashing LED flashing quickly

19

XANAS Electrical Installation

Version: 27263 - A.1 Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

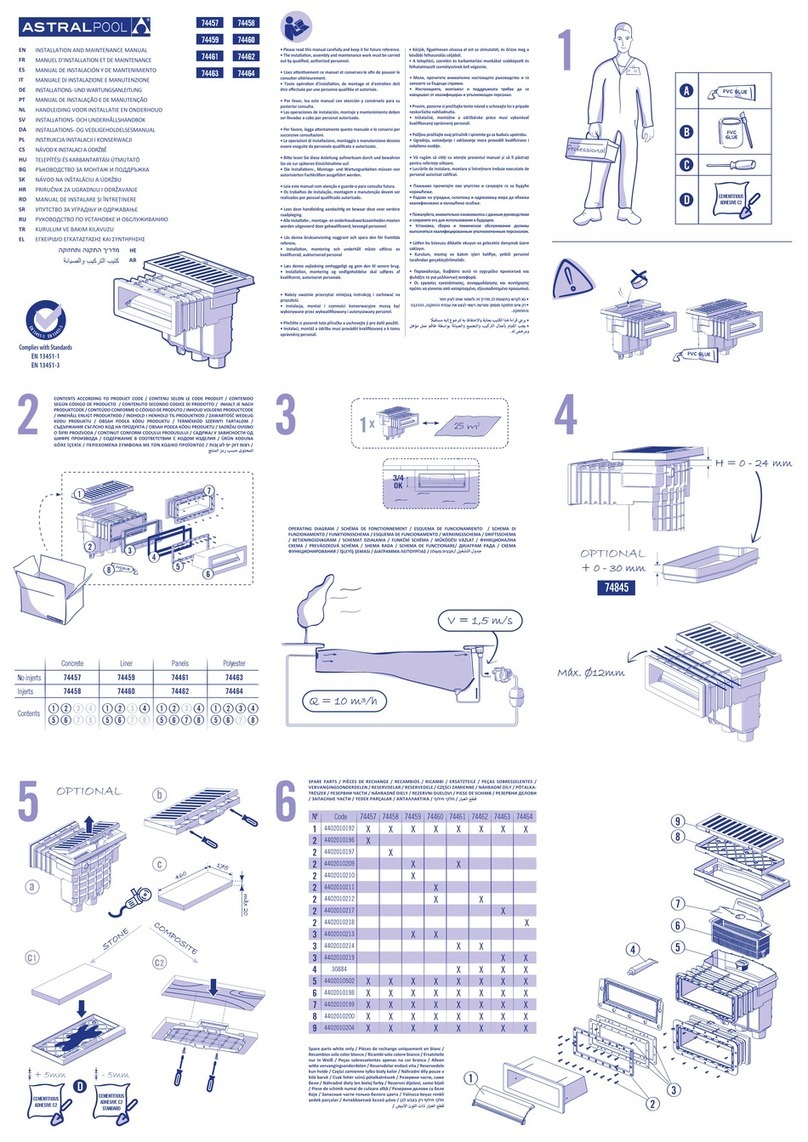

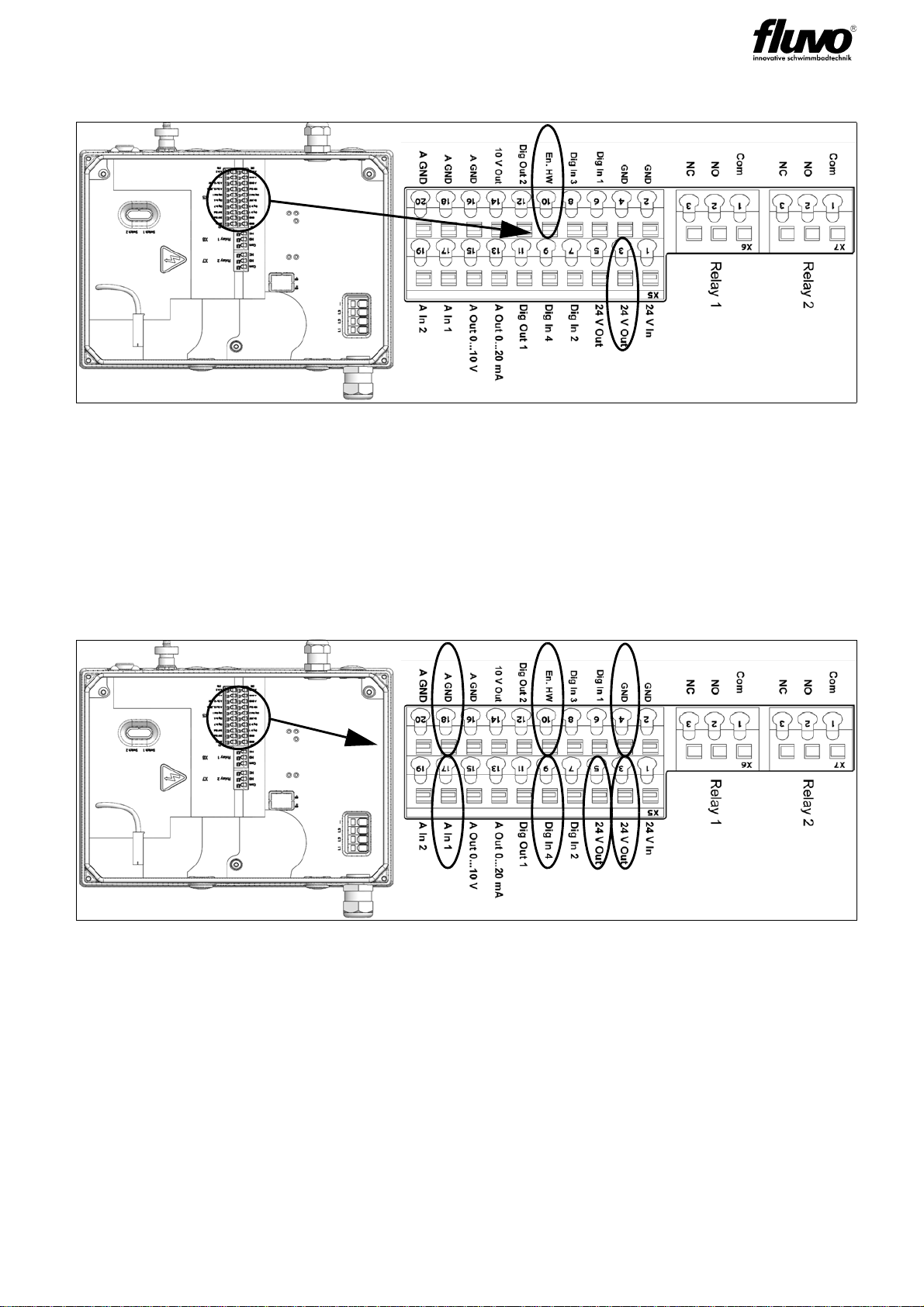

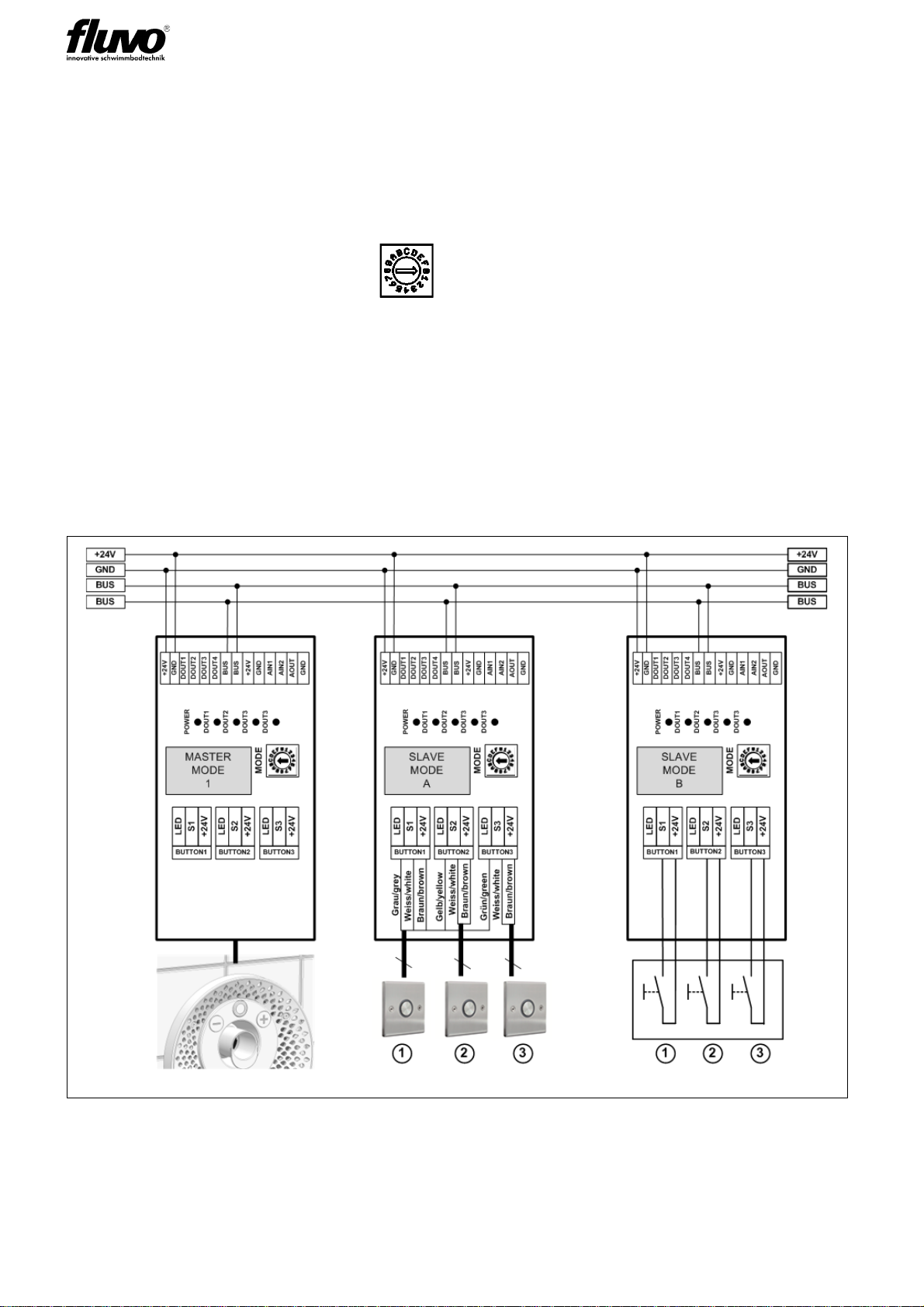

3.4.5 Connection diagrams - Sensor-controlled design

Function of XANAS® switching unit with 3 sensor buttons

Connection diagram of the switching unit with 3 sensor buttons and a 9-pin connection

cable

The button pulses (buttons 1-3) cause an incremental change to analog output

AOUT.

A lit button provides visual feedback.

When a lit button is connected, optical feedback (flashing) is generated when it is activated.

AOUT: Starting voltage 4V control range 4 / 5 / 6 / 7 / 8 / 9 / 10V

Dout4: ON when AOUT is active / ON when AOUT 0V and non-active (enable)

Air valve control:

If AOUT is active, a pulse combination to S2 (2 pulses within 0.5sec) causes digital output

DOUT2 to be activated.

DOUT2 can be set to inactive again with

a) S3 - System OFF

b) Pulse combination to S2 (2 pulses within 0.5sec)

Switching output of Dout2: 24V DC Imax = 20mA DC

To be able to switch an air valve with a higher electrical output, a multi-function relay item

no. 55323 can be connected to DOUT2.

FU

Converter box 3.0

Sensor button 3x

1x lit

2x unlit

Sensor button 1 incrementally falling

Sensor button 2 incrementally rising

Sensor button 3 ON / OFF

Rotary switch

MODE 1: Lit with one colour

20 XANAS Electrical Installation

Version: 27263 - A.1

Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

3.4.5.1 Testing the wiring

Sensor button with converter box.

1. The button pulse of the connected sensor buttons is received by the connected box

when the lit ON/OFF button indicates this visually by flashing.

2. MODE1 active via rotary switch .

Measurable signals

OFF Aout = 0V / Dout4 = 0V

ON Start status AOUT = 4 / 5 / 6 / 7 / 8 / 9 / 10V / Dout4 = 24V

Pressing the +/- key causes AOUT to change +/- 1V

Lower limit: AOUT = 4V

Upper limit: AOUT = 10V

Reaching the lower and upper limit is indicated by the button flashing several times.

3.4.6 Connection for external operation

Optional: Customer connection

This manual suits for next models

8

Table of contents

Other FLUVO Lighting Equipment manuals