©

2020

Q-T

ran

Inc.

All

rights

reserved

|

155

Hill

St.

Milford,

CT

06460

|

203-367-8777

|

[email protected] |

www

.q-tran.com

Specification

subject

to

change.

Rev-03-08-21INSTALLATION FLEX Light - FLEX Square

NOTES:

• Field modifications must comply with Q-Tran’s installation methods otherwise warranty is null and void

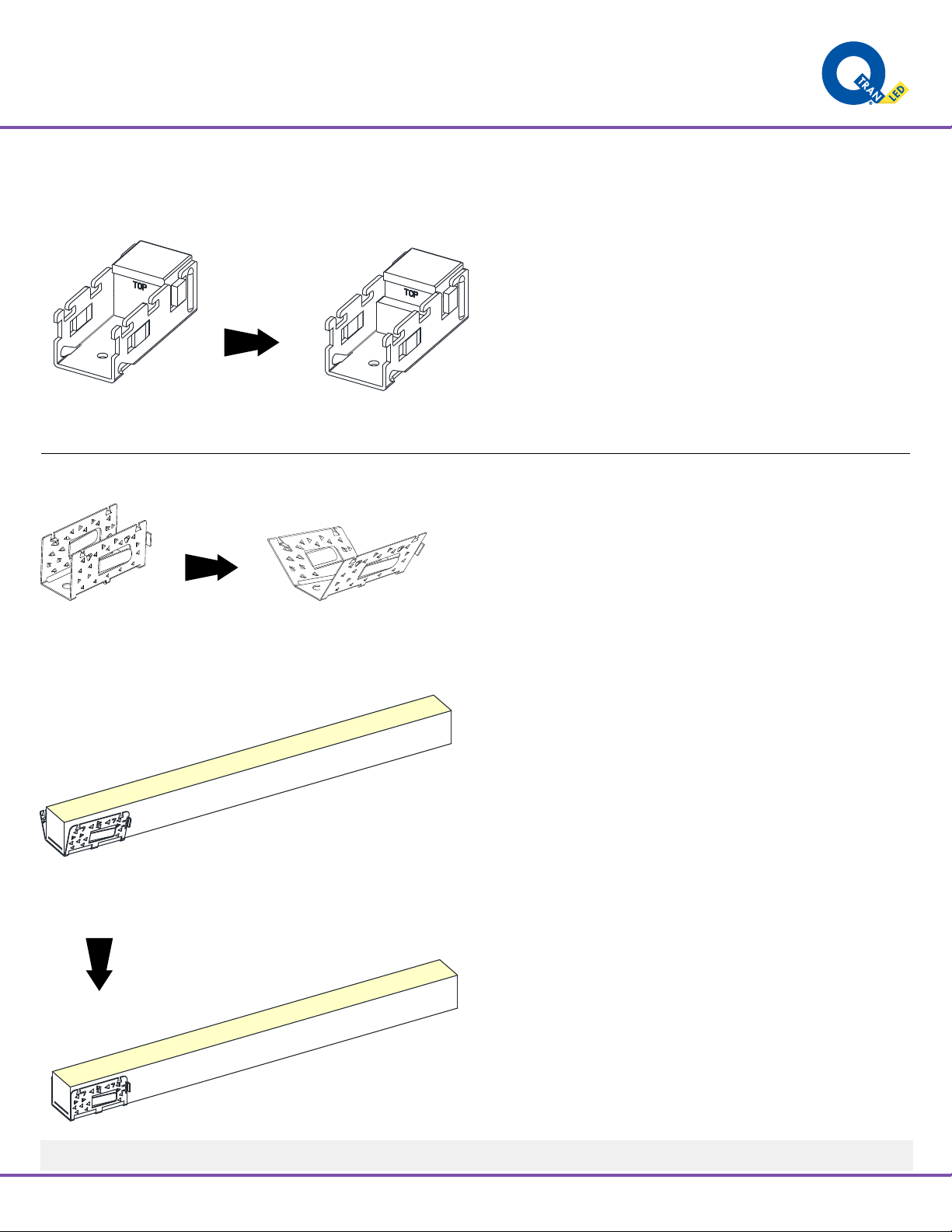

Clasp Front Connector

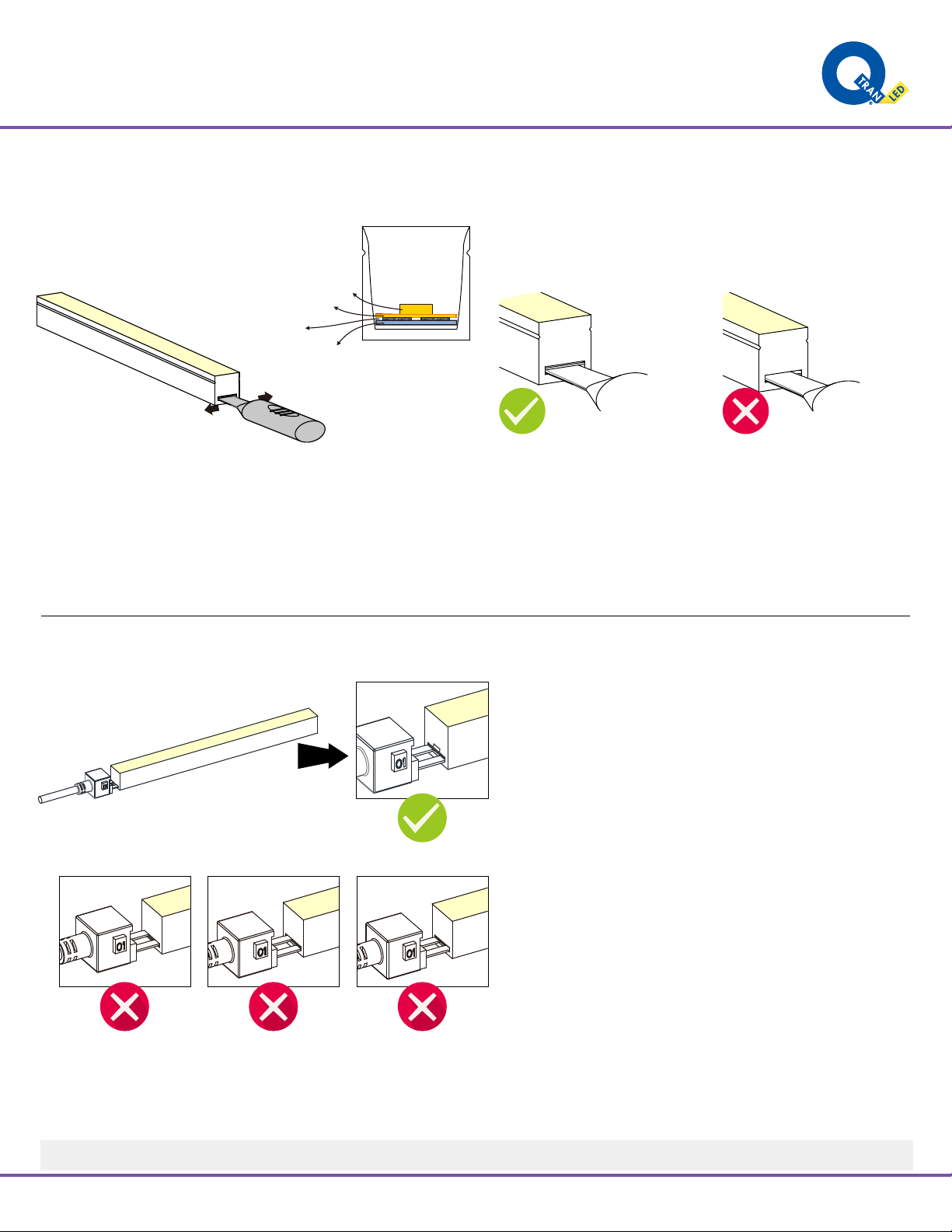

1. Inducing a Cavity for Feed Connector

2. Insert the Feed Connector

t the inducer to the backside of PCB around 0.39”-0.47”,

ove the inducer up and down 3-5 times gently to create a

l cavity.

Insert the inducer into the backside of PCBIt will damage the light if inserted into front

side of PCB

PCB

Insertion Placement

PVC Tape

Insert the feed connector pins into the

cavity that you created with the

inducer (backside of PCB)

The following operations are prohibited:

Insert into the front side of the PCB

Insert crosswise into the PCB Insert crosswise into the PCB

NEVER insert into the front side

(LED side) of the PCB

The silicone gasket is attached on the feed connector.

Insert the inducer to the backside of PCB around 0.39”-0.47”,

move the inducer right and left 3-5 times gently to create a

small cavity.

Insert the inducer into the backside of PCBIt will damage the light if inserted into front

side of PCB

Insert the feed connector pins into the

cavity that you created with the

inducer (backside of PCB)

The following operations are prohibited:

Insert into the front side of the PCB

Insert crosswise into the PCB Insert crosswise into the PCB

NEVER insert into the front side

(LED side) of the PCB

The silicone gasket is attached on the feed connector.

PCB

Insertion Placement

LED

PVC Tape

Insert the inducer to the backside of PCB around 0.39”-0.47”,

move the inducer right and left 3-5 times gently to create a

small cavity.

Insert the inducer into the backside of PCBIt will damage the light if inserted into fron

side of PCB

Insert the feed connector pins into the

cavity that you created with the

inducer (backside of PCB)

The following operations are prohibited:

Insert into the front side of the PCB

Insert crosswise into the PCB Insert crosswise into the PCB

NEVER insert into the front side

(LED side) of the PCB

The silicone gasket is attached on the feed connector.

PCB

Insertion Placement

LED

PVC Tape

Insert the inducer to the backside of PCB around 0.39”-0.47”,

move the inducer right and left 3-5 times gently to create a

small cavity.

Insert the inducer into the backside of PCBIt will damage the light if inserted into front

side of PCB

Insert the feed connector pins into the

cavity that you created with the

inducer (backside of PCB)

The following operations are prohibited:

Insert into the front side of the PCB

Insert

crosswise

into the PCB Insert

crosswise

into the PCB

NEVER insert into the front side

(LED side) of the PCB

The silicone gasket is attached on the feed connector.

PCB

Insertion Placement

LED

PVC Tape

Insert the inducer to the backside of PCB around 0.39”-0.47”,

move the inducer right and left 3-5 times gently to create a

small cavity.

Insert the inducer into the backside of PCBIt will damage the light if inserted into front

side of PCB

Insert the feed connector pins into the

cavity that you created with the

inducer (backside of PCB)

The following operations are prohibited:

Insert into the front side of the PCB

Insert crosswise into the PCB Insert crosswise into the PCB

NEVER insert into the front side

(LED side) of the PCB

The silicone gasket is attached on the feed connector.

PCB

Insertion Placement

LED

PVC Tape