FoamPRO F1000 User manual

FOAMPRO® F1000 1

©2001 R11.01

CONTENTS

Section

INSTALLATION 1.0 ................................................................................................. 2

Connecting the hose/dispenser assembly to the chemical cylinders 1.1.............2

Connecting the red "A" hose to the "A" chemical cylinder 1.2 ..............................2

Connecting the red "B" hose to the "B" chemical cylinder 1.2...............................4

Connecting the nitrogen hoses 1.3.................................................................................4

STARTUP | CALIBRATION 2.0................................................................................ 6

Startup 2.1 .............................................................................................................................6

Calibration of A:B ratio 2.2............................................................................................ 12

MAINTENANCE | SERVICE 3.0............................................................................ 22

Air Injection System 3.1.................................................................................................. 22

Trigger (D300) 3.1.1.......................................................................................................... 24

Handle (D201) 3.1.2.......................................................................................................... 24

Air Cylinder/ Piston Assembly (D300) 3.1.3............................................................... 26

Carrier Assembly (D500) 3.2.1....................................................................................... 40

Chemical Valve Service (D503R & D503B) 3.2.2...................................................... 40

Filter Screen Service (D504) 3.2.3 ................................................................................ 42

Check Valve Service 3.2.4 ...............................................................................................44

Mix Cartridge Service (D603 or Optional Cartridge) 3.2.5....................................46

Mix Cartridge Removal and Cleaning (D603 or Optional Cartridge) 3.2.6....... 48

SHUTDOWN 4.0 ................................................................................................... 52

Shutdown Procedure 4.1................................................................................................. 52

TROUBLESHOOTING 5.0 ...................................................................................... 54

PARTS LIST 6.0 .....................................................................................................55

FOAMPRO® F1000

2©2001 R11.01

INSTALLATION

Usually the Foampro dispenser is shipped to customers with the hose assembly

already connected to the dispenser. If your Foampro dispenser is not connected to

the hose assembly:

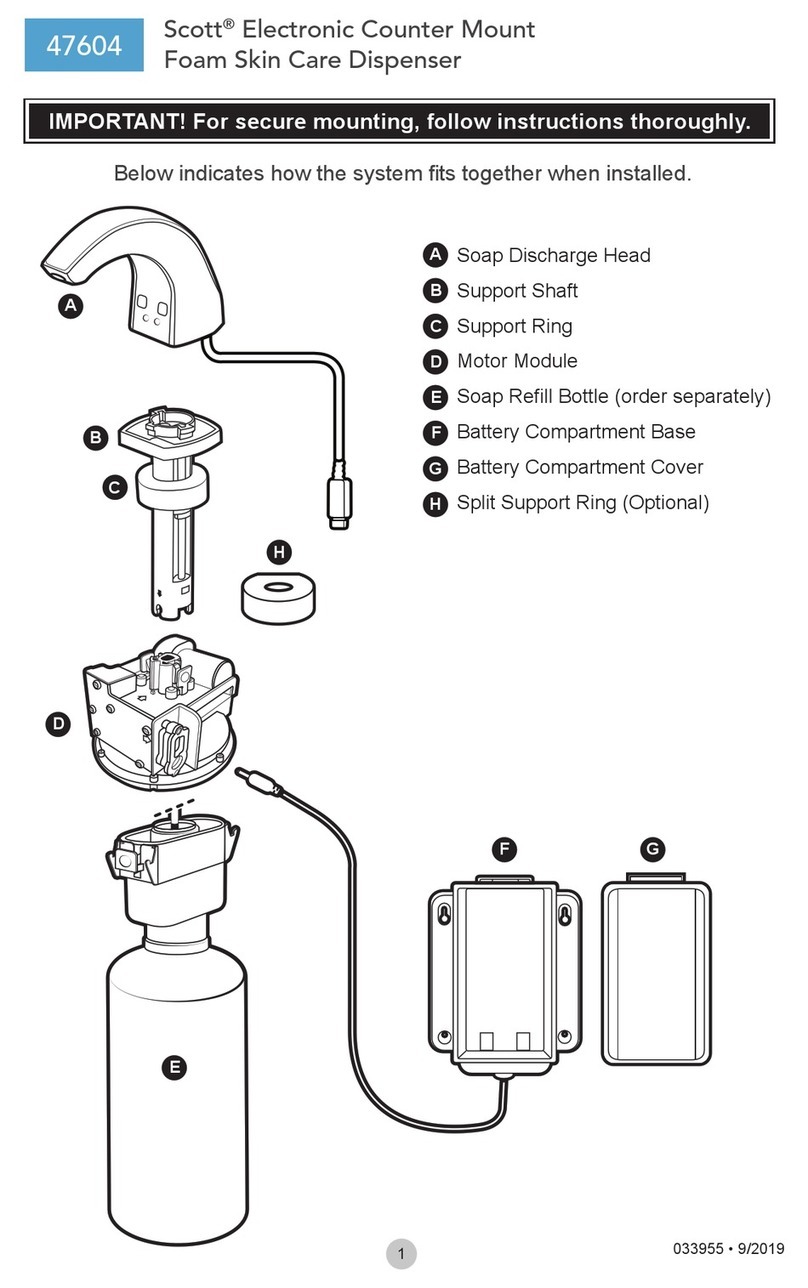

Attach the red “A” hose to the Hose Connection Fitting (D507) on the left side

of the dispenser, just behind the red valve. (See diagram 3A)(See diagram 3A)

(See diagram 3A)(See diagram 3A)

(See diagram 3A)

Attach the blue “B” hose to the Hose Connection Fitting (D507) on the right

side of the dispenser, just behind the blue valve. (See diagram 3A)(See diagram 3A)

(See diagram 3A)(See diagram 3A)

(See diagram 3A)

Attach the gray air pressure line to the quick connect fitting at the rear of the

dispenser. (See diagram 3A)(See diagram 3A)

(See diagram 3A)(See diagram 3A)

(See diagram 3A)

Lay out the dispenser/hose assembly.

Place the cylinders of “A” chemical and “B” chemical in a position where the

hoses can be connected without strain.

Be sure all valves on both of the cylinders, and the hoses are closed

before connecting or disconnecting hoses, or removing caps or

plugs from cylinder.

After checking to be sure all valves on the cylinder are closed, remove the

cap from the outlet of the chemical valve. (See diagram 3B)(See diagram 3B)

(See diagram 3B)(See diagram 3B)

(See diagram 3B) Keep the cap

handy so that it can refitted to the cylinder after the cylinder is empty.

Remove the plug from the filter end of the red "A" hose (See diagram 3B)(See diagram 3B)

(See diagram 3B)(See diagram 3B)

(See diagram 3B).

Keep the plug handy- it will be needed to reseal the hose after the hose

is disconnected from the cylinder.

Connect the red "A" hose to the outlet of the chemical valve on the

"A" component cylinder.

CAUTION:CAUTION:

CAUTION:CAUTION:

CAUTION:

Connecting the redConnecting the red

Connecting the redConnecting the red

Connecting the red

"A" hose to the "A""A" hose to the "A"

"A" hose to the "A""A" hose to the "A"

"A" hose to the "A"

chemical cylinder:chemical cylinder:

chemical cylinder:chemical cylinder:

chemical cylinder:

Connecting theConnecting the

Connecting theConnecting the

Connecting the

hose/dispenserhose/dispenser

hose/dispenserhose/dispenser

hose/dispenser

assembly to theassembly to the

assembly to theassembly to the

assembly to the

chemical cylinders:chemical cylinders:

chemical cylinders:chemical cylinders:

chemical cylinders:

1.0

1.1

1.2

FOAMPRO® F1000 3

©2001 R11.01

INSTALLATION

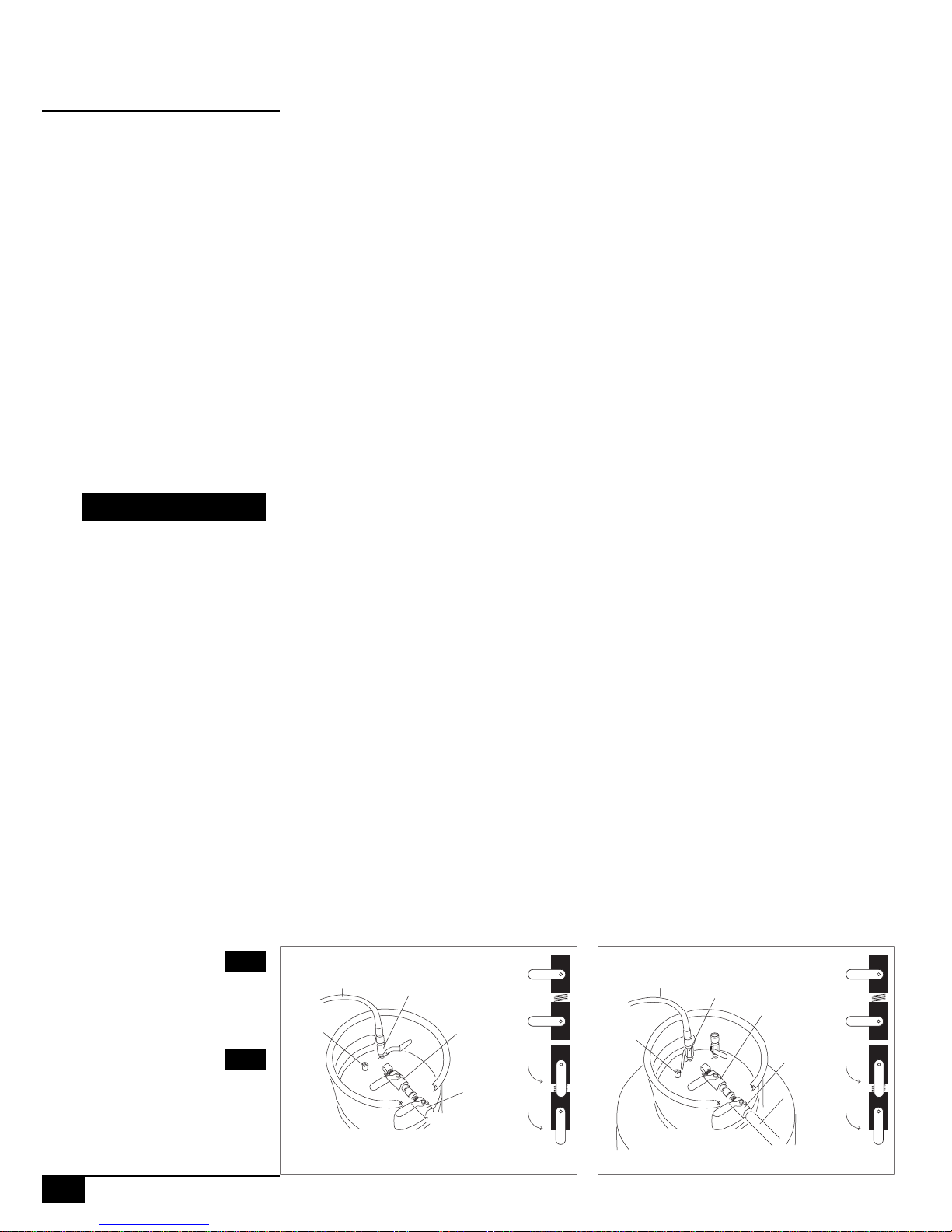

1.2

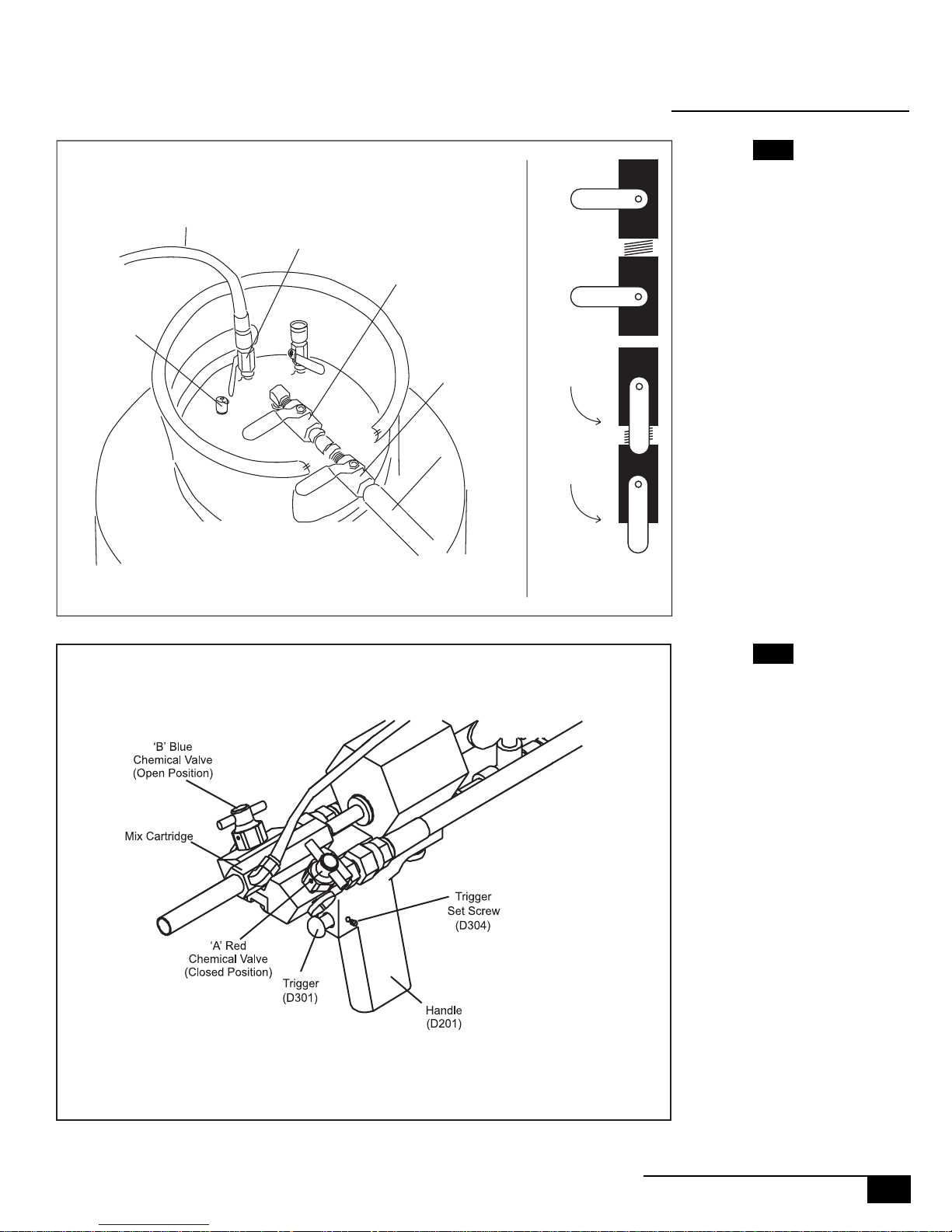

Nitrogen

Supply

Hose Nitrogen

Valve

Pressure

Relief

Valve

Cylinder

Chemical

Valve

Hose Filter

Chemical

Valve

Cylinder Valves - 17 Gal.

Closed

Open

Chemical

Valve

Positions:

Diagram 3A

Diagram 3B

FOAMPRO® F1000

4©2001 R11.01

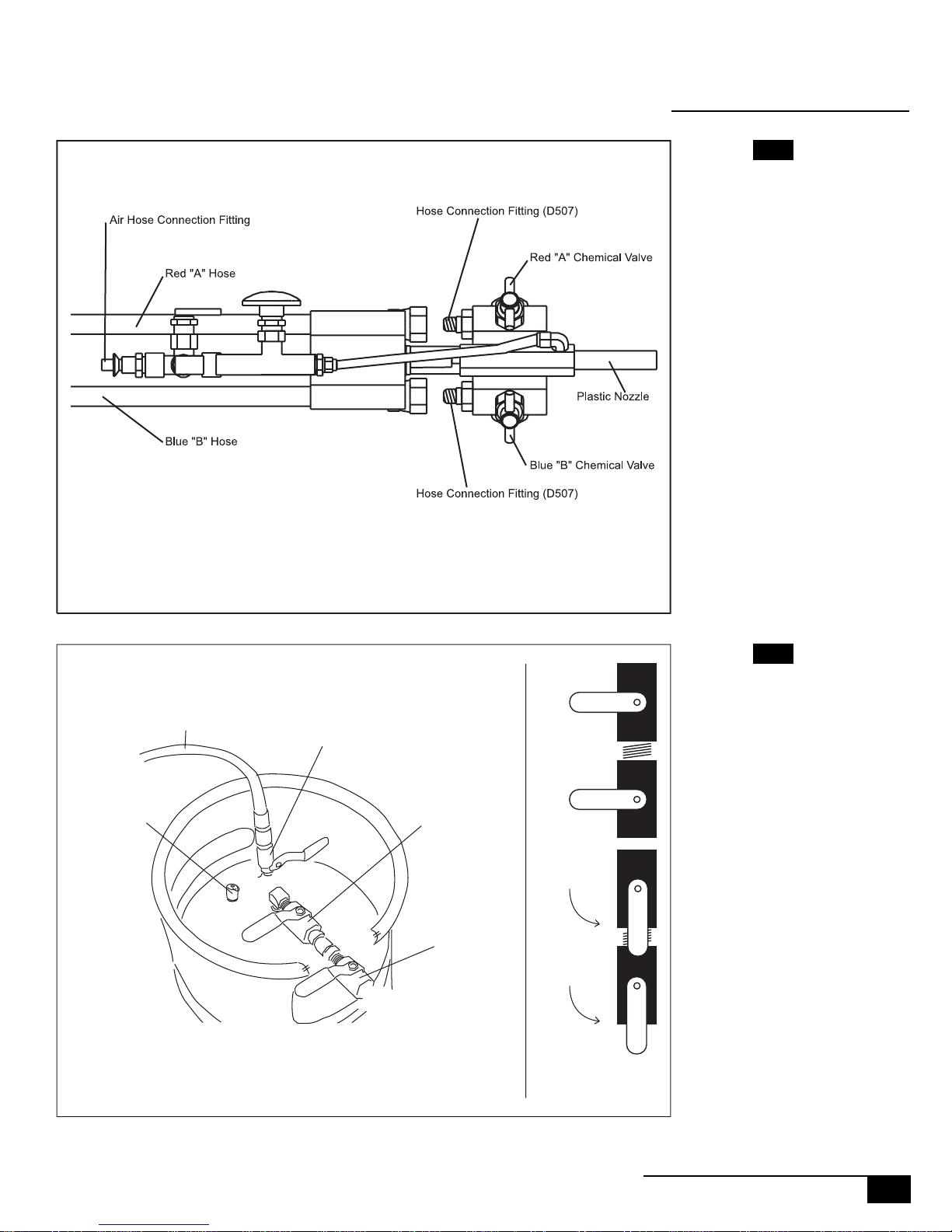

To connect the blue "B" hose to the "B" chemical cylinder: After checking to

be sure that all valves on the cylinder are closed, remove the plug from the

outlet of the chemical valve (See diagram 5A).(See diagram 5A).

(See diagram 5A).(See diagram 5A).

(See diagram 5A). Keep the plug handy so that

it can be refitted to the cylinder after the cylinder is empty.

Remove the cap from the filter end of the blue "B" hose. Keep the plug handy it

will be needed to reseal the hose after the hose is disconnected from the

cylinder.

Connect the blue "B" hose to the outlet of the chemical valve on the "B" chemi-

cal cylinder.

Connect the dispenser air line to an air regulator 100 to 125 psi with moisture

separator and filter.

Compressed air that contains high levels of water or oil can adversely

affect the performance and service life of some of the parts of the

Foampro dispenser. This is particularly important when using portable

compressors. Be sure to drain the compressor of any water prior to use.

Also, it is recommended that an in line air filter and moisture separator are

used to remove oil from the compressed air source.

Place the nitrogen cylinder near the chemical cylinders, being sure to secure the

nitrogen cylinder so that it cannot be accidentally knocked over.

Connect the nitrogen regulator to the nitrogen cylinder using the threaded

pressure fitting on the rear of the nitrogen regulator assembly.

(See diagram 5B)(See diagram 5B)

(See diagram 5B)(See diagram 5B)

(See diagram 5B)

Connect the red hose leading from the nitrogen regulator assembly to the

nitrogen fitting on the "A" chemical cylinder . It will be fitted with a quick

connect fitting that will simply snap into place. (See diagram 3B, previous(See diagram 3B, previous

(See diagram 3B, previous(See diagram 3B, previous

(See diagram 3B, previous

page)page)

page)page)

page)

Connect the blue hose leading from the nitrogen regulator assembly to the

nitrogen fitting on the "B" chemical cylinder. It will be fitted with a quick

connect fitting that will simply snap into place. (See diagram 5A)(See diagram 5A)

(See diagram 5A)(See diagram 5A)

(See diagram 5A)

NONO

NONO

NOTE:TE:

TE:TE:

TE:

Connecting theConnecting the

Connecting theConnecting the

Connecting the

nitrogen hoses:nitrogen hoses:

nitrogen hoses:nitrogen hoses:

nitrogen hoses:

1.3

INSTALLATION

1.2Connecting the blueConnecting the blue

Connecting the blueConnecting the blue

Connecting the blue

"B" hose to the "B""B" hose to the "B"

"B" hose to the "B""B" hose to the "B"

"B" hose to the "B"

chemical cylinder:chemical cylinder:

chemical cylinder:chemical cylinder:

chemical cylinder:

FOAMPRO® F1000 5

©2001 R11.01

INSTALLATION

1.3

Nitrogen

Supply

Hose

Nitrogen

Valve

Pressure

Relief

Valve

Cylinder

Chemical

Valve

Hose Filter

Chemical

Valve

Cylinder Valves - 60 Gal.

Closed

Open

Chemical

Valve

Positions:

Chemical

Filter

Diagram 5A

Diagram 5B

FOAMPRO® F1000

6©2001 R11.01

STARTUP | CALIBRATION

2.0 Make sure all installation steps have been completed prior to startup and calibra-

tion. Make sure that the chemicals are at the correct operating temperature, usually

70° to 90° F.

1| Be sure that all valves are closed. (See diagrams for valve locations)(See diagrams for valve locations)

(See diagrams for valve locations)(See diagrams for valve locations)

(See diagrams for valve locations) This

would include: The valve on top of the nitrogen cylinder. The nitrogen valve on

top of both chemical cylinders ("A" Chemical and "B" Chemical). (See dia-(See dia-

(See dia-(See dia-

(See dia-

grams 6A & 7A)grams 6A & 7A)

grams 6A & 7A)grams 6A & 7A)

grams 6A & 7A) The chemical outlet valve on top of both chemical cylinders

("A" chemical and "B" chemical) (See diagrams 6A & 7A)(See diagrams 6A & 7A)

(See diagrams 6A & 7A)(See diagrams 6A & 7A)

(See diagrams 6A & 7A) The chemical valve

on the filter end of both the red "A" component hose and the blue "B" compo-

nent hose. (See diagram 6A & 7A)(See diagram 6A & 7A)

(See diagram 6A & 7A)(See diagram 6A & 7A)

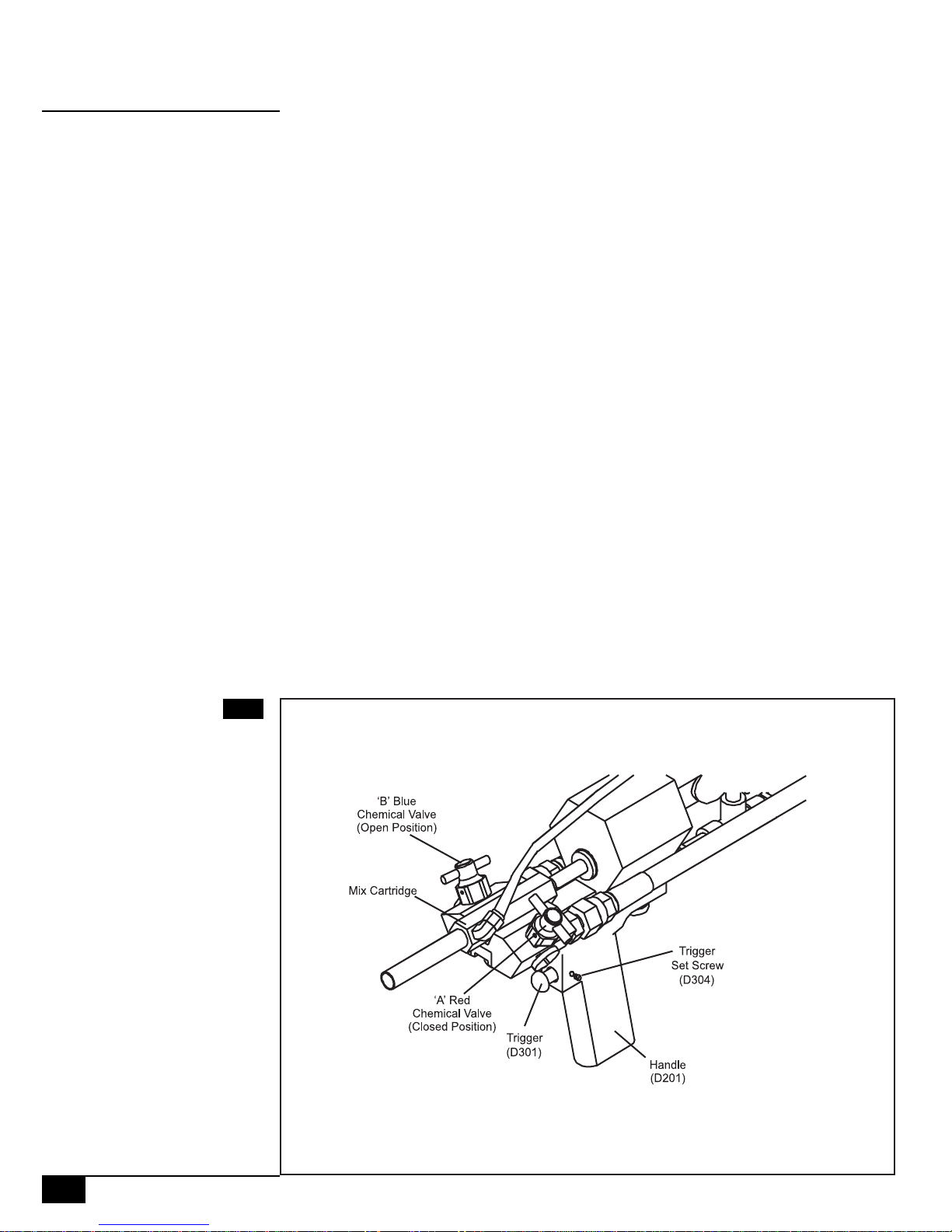

(See diagram 6A & 7A) Both the red chemical valve and the blue

chemical valve on the F1000 dispenser (See diagram 7B).(See diagram 7B).

(See diagram 7B).(See diagram 7B).

(See diagram 7B).

Startup:Startup:

Startup:Startup:

Startup:

2.1

Nitrogen

Supply

Hose Nitrogen

Valve

Pressure

Relief

Valve

Cylinder

Chemical

Valve

Hose Filter

Chemical

Valve

Cylinder Valves - 17 Gal.

Closed

Open

Chemical

Valve

Positions:

Diagram 6A

FOAMPRO® F1000 7

©2001 R11.01

STARTUP | CALIBRATION

2.1

Nitrogen

Supply

Hose

Nitrogen

Valve

Pressure

Relief

Valve

Cylinder

Chemical

Valve

Hose Filter

Chemical

Valve

Cylinder Valves - 60 Gal.

Closed

Open

Chemical

Valve

Positions:

Chemical

Filter

Diagram 7A

Diagram 7B

FOAMPRO® F1000

8©2001 R11.01

2| Turn on the air supply to the dispenser, and check for leaks.

3 | Remove Mix Cartridge Plug (D620) if one is in place..

..

.Do not install nozzle

until calibration steps are completed.

4 | Open both of the air injection valves (D704, D705) (See diagram 9A)(See diagram 9A)

(See diagram 9A)(See diagram 9A)

(See diagram 9A) to see

if the air passes freely through the dispenser. Re-close both of the air injection

valves, as they must be closed to complete the calibration of the dispenser.

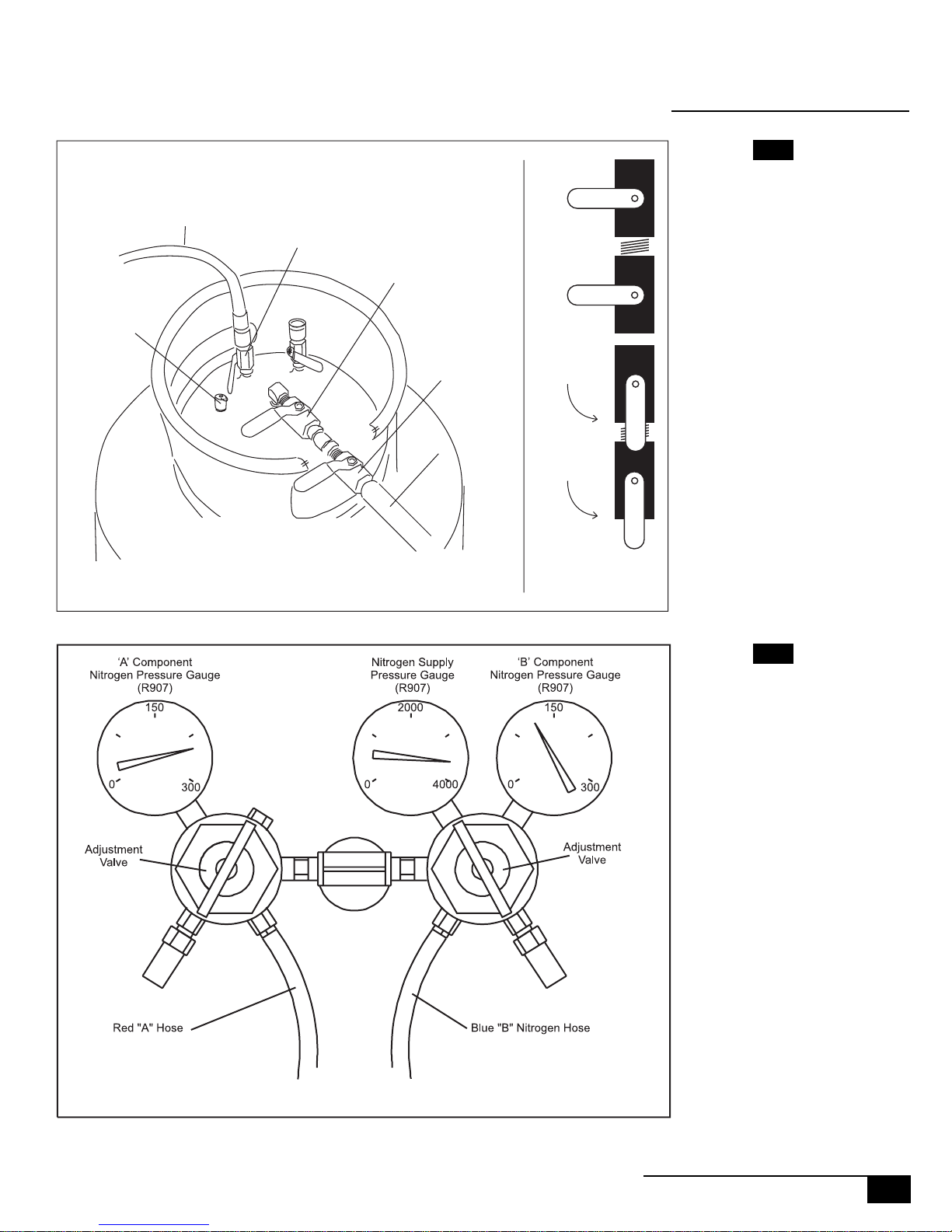

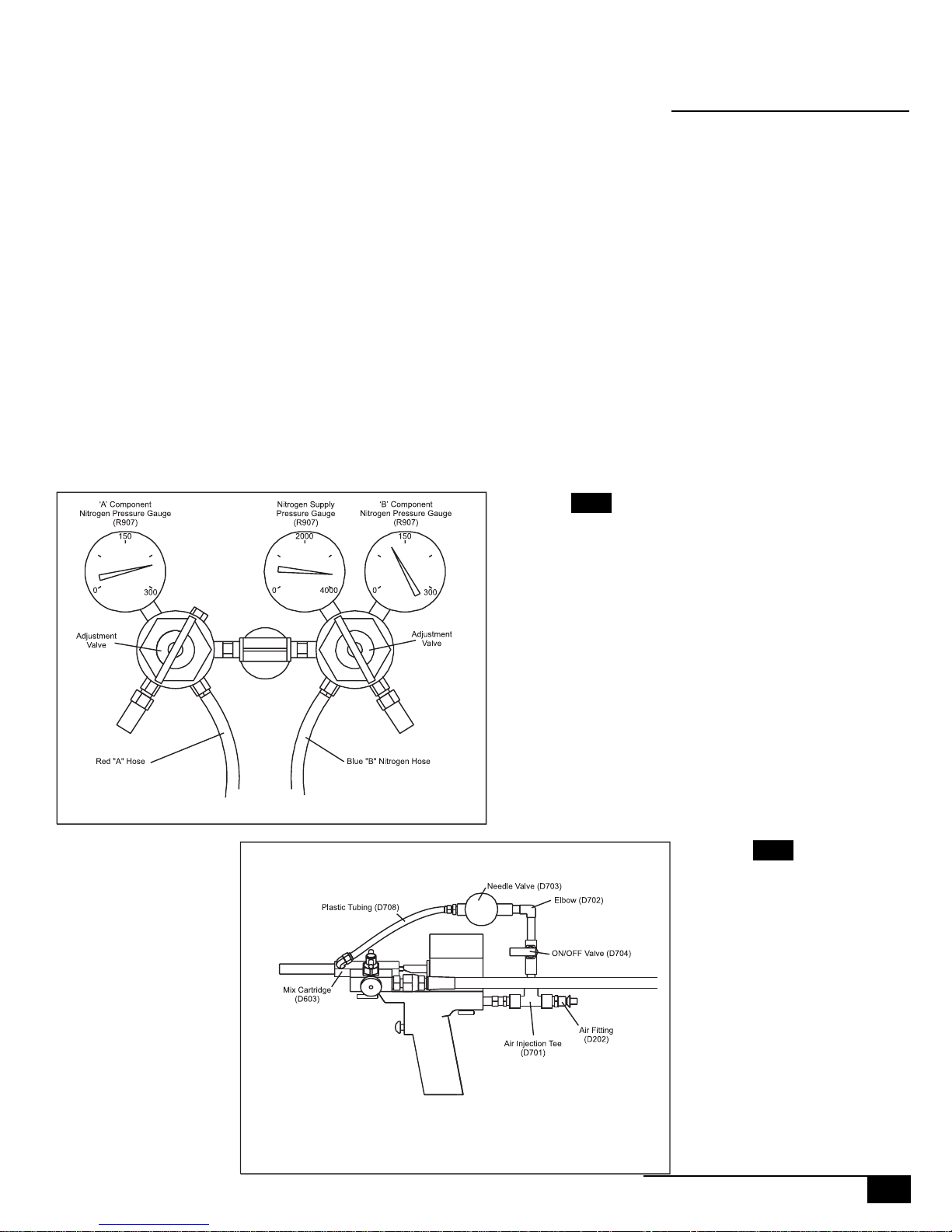

5 | Turn the adjustment valves on both nitrogen regulators leading to the "A"

chemical and the "B" chemical counterclockwise two full turns. (See diagram(See diagram

(See diagram(See diagram

(See diagram

9B)9B)

9B)9B)

9B)

6 | Open the valve on top of the nitrogen cylinder, and check for leaks.

7 | Adjust the "A" component nitrogen regulator (one with the red hose) to 190

psi (starting point) by turning clockwise (See diagram 9B)(See diagram 9B)

(See diagram 9B)(See diagram 9B)

(See diagram 9B)

8 | Adjust the "B" component nitrogen regulator (one with the blue hose) to

140 psi (starting point) by turning clockwise (See diagram 9B)(See diagram 9B)

(See diagram 9B)(See diagram 9B)

(See diagram 9B)

The chemical cylinders are equipped with a pressure overload relief valve

that will open if the pressure of the cylinder exceeds approximately 220

psi. Do not adjust nitrogen pressure on the chemical cylinders to approach

220 psi.

NONO

NONO

NOTE:TE:

TE:TE:

TE:

STARTUP | CALIBRATION

2.1

FOAMPRO® F1000 9

©2001 R11.01

STARTUP | CALIBRATION

2.1

Diagram 9A

Diagram 9B

FOAMPRO® F1000

10 ©2001 R11.01

STARTUP | CALIBRATION

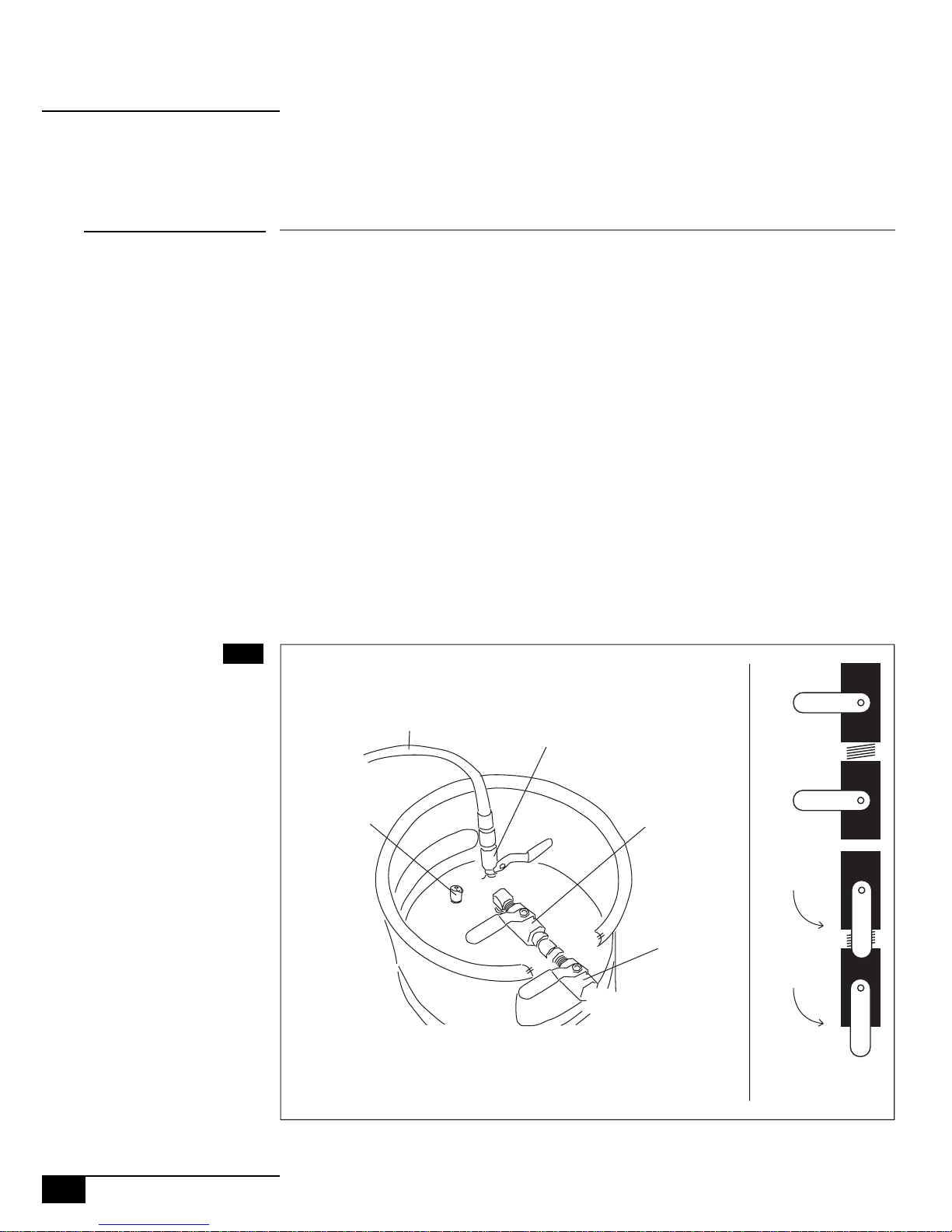

2.1 9| Open the nitrogen valves on both chemical cylinders ( "A" component and

"B" component). (See diagram 1(See diagram 1

(See diagram 1(See diagram 1

(See diagram 11A & 11A & 1

1A & 11A & 1

1A & 11B)1B)

1B)1B)

1B)

10 | Open the chemical valves on both chemical cylinders ( "A" component and

"B" component). (See diagram 1(See diagram 1

(See diagram 1(See diagram 1

(See diagram 11A & 11A & 1

1A & 11A & 1

1A & 11B)1B)

1B)1B)

1B) Check for leaks. Tighten any leaking

fittings.

11 | Open the chemical valves on the filter end of the hose assembly for both

the "A" component and "B" component. (See diagram 1(See diagram 1

(See diagram 1(See diagram 1

(See diagram 11A & 11A & 1

1A & 11A & 1

1A & 11B)1B)

1B)1B)

1B) Check for

leaks. Tighten any leaking fittings.

12 | Position a garbage can with a plastic liner at the work area.

13 | Make sure mixing cartridge plug is removed.

14 | Open the red valve and the blue valve on the F1000 dispenser.

(See diagram 1(See diagram 1

(See diagram 1(See diagram 1

(See diagram 10A)0A)

0A)0A)

0A)

15 | While aiming the F1000 into the trash can, pull the trigger on the F1000

dispenser for 10 seconds, dispensing the foam into the trash can liner. If your

F1000 is brand new, you may have to pull the trigger for a longer period to

purge the air out of the hoses. If your F1000 dispenser was put into storage

with the hoses full of chemicals, you may have to dispense foam for longer than

10 seconds to be sure that the chemicals that were stored in the hoses is fully

flushed out by fresh chemicals from the chemical cylinders.

Diagram 10A

FOAMPRO® F1000 11

©2001 R11.01

STARTUP | CALIBRATION

2.2

Nitrogen

Supply

Hose

Nitrogen

Valve

Pressure

Relief

Valve

Cylinder

Chemical

Valve

Hose Filter

Chemical

Valve

Cylinder Valves - 60 Gal.

Closed

Open

Chemical

Valve

Positions:

Chemical

Filter

Nitrogen

Supply

Hose Nitrogen

Valve

Pressure

Relief

Valve

Cylinder

Chemical

Valve

Hose Filter

Chemical

Valve

Cylinder Valves - 17 Gal.

Closed

Open

Chemical

Valve

Positions:

Diagram 11A

Diagram 11B

FOAMPRO® F1000

12 ©2001 R11.01

Proper mixing of the “A” and “B” component chemicals in the correct propor-

tions is important in producing foam. Foams produced with an improper propor-

tion of “A” to “B” chemical can in some cases affect foam properties.

When and how often should the A:B ratio be checked?

•At the beginning of the workday.

•When a new cylinder of “A” or “B” component is installed.

•When a new cylinder of nitrogen is installed.

•About halfway through the normal workday.

•When the temperature in the work area increases or decreases by more

than 10 degrees. If the temperature of the chemicals changes, the viscosity

of the chemicals changes. This viscosity change can have an effect on the

A:B ratio.

•If a noticable change takes place in the foam being produced.

•After any restriction in the chemical flow is removed, for example cleaning

the filters or the ports in the mixing cartridge in the F1000 will likely

increase the flow of chemical which in turn may change the A:B ratio.

•When a new mixing cartridge is installed.

1| Make sure that the F1000 dispenser is correctly installed to the chemical

cylinders, nitrogen cylinders, and compressed air supply as described in the

Startup procedures above. Check all hose connections to be sure that there are

no leaks. Make sure the air injection on/off valve is closed. For calibration,

remove the plastic nozzle. (See diagram 13A)(See diagram 13A)

(See diagram 13A)(See diagram 13A)

(See diagram 13A)

2| Place a 32oz paper cup on a scale, and tare the scale to read zero.

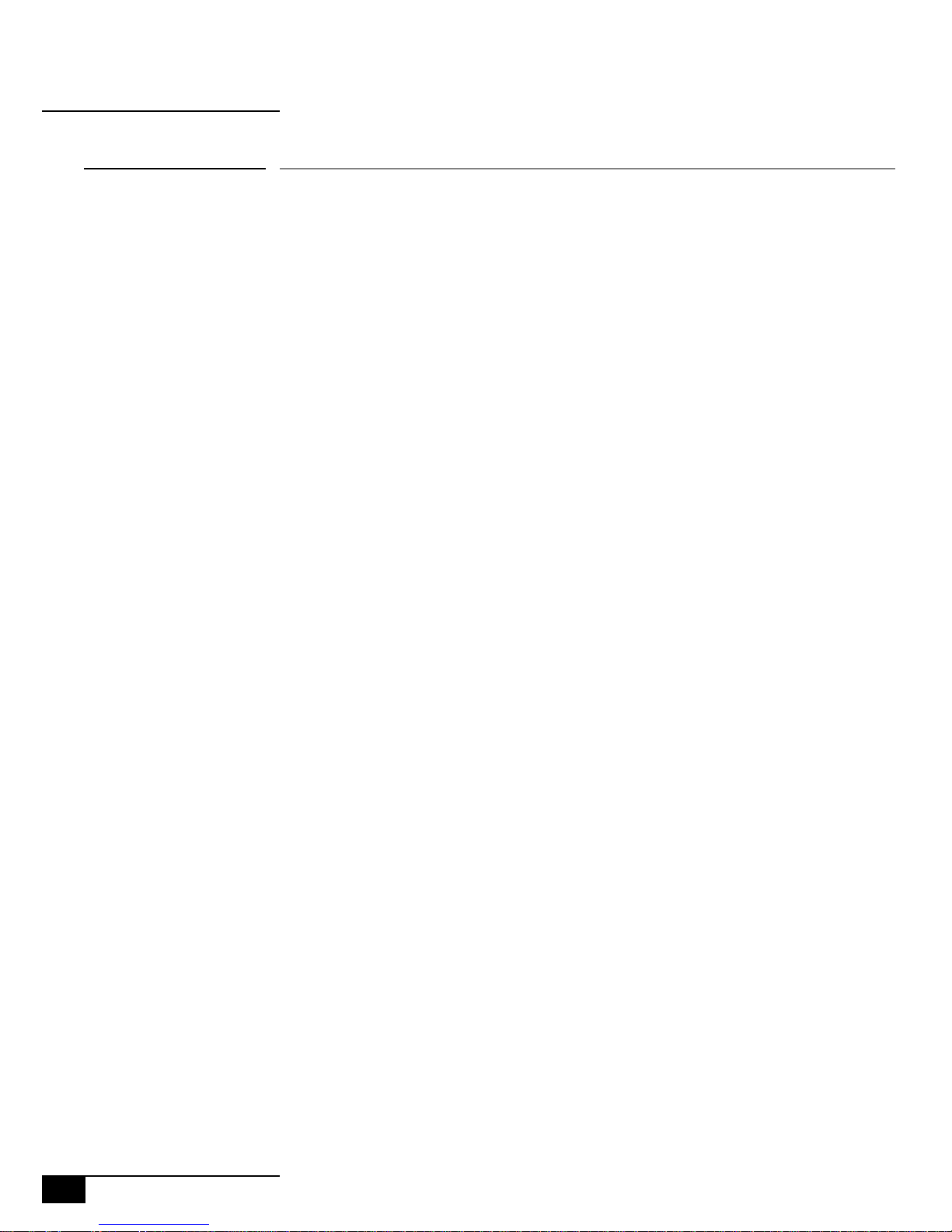

3| Open the "A" (red) chemical valve and close the "B" chemical (blue) valve on

the F1000 dispenser. (See diagram 13B)(See diagram 13B)

(See diagram 13B)(See diagram 13B)

(See diagram 13B)

4| Using a stop watch, or optional timer, trigger the F1000 dispenser for exactly

3 seconds, directing the flow of the "A" chemical into the paper cup on the

scale. Record the weight of "A" chemical dispensed.

5| Critical Step- Purging the mix cartridge: After measuring the weight of

the dispensed "A" chemical in step 4, open the both "B" chemical (blue) valve

and the "A" chemical (red) valve on the F1000 dispenser. (See diagram 13B)(See diagram 13B)

(See diagram 13B)(See diagram 13B)

(See diagram 13B)

Then, while directing the flow of the dispenser into a trash can, trigger the

F1000 dispenser for a few seconds to dispense a mixture of "A" and "B" chemi-

cals into the trash can. This step is important because it will reduce plugging of

the mix cartridge.

Calibration ofCalibration of

Calibration ofCalibration of

Calibration of

A:B ratio:A:B ratio:

A:B ratio:A:B ratio:

A:B ratio:

STARTUP | CALIBRATION

2.2

FOAMPRO® F1000 13

©2001 R11.01

STARTUP | CALIBRATION

2.2

Diagram 13B

Diagram 13A

FOAMPRO® F1000

14 ©2001 R11.01

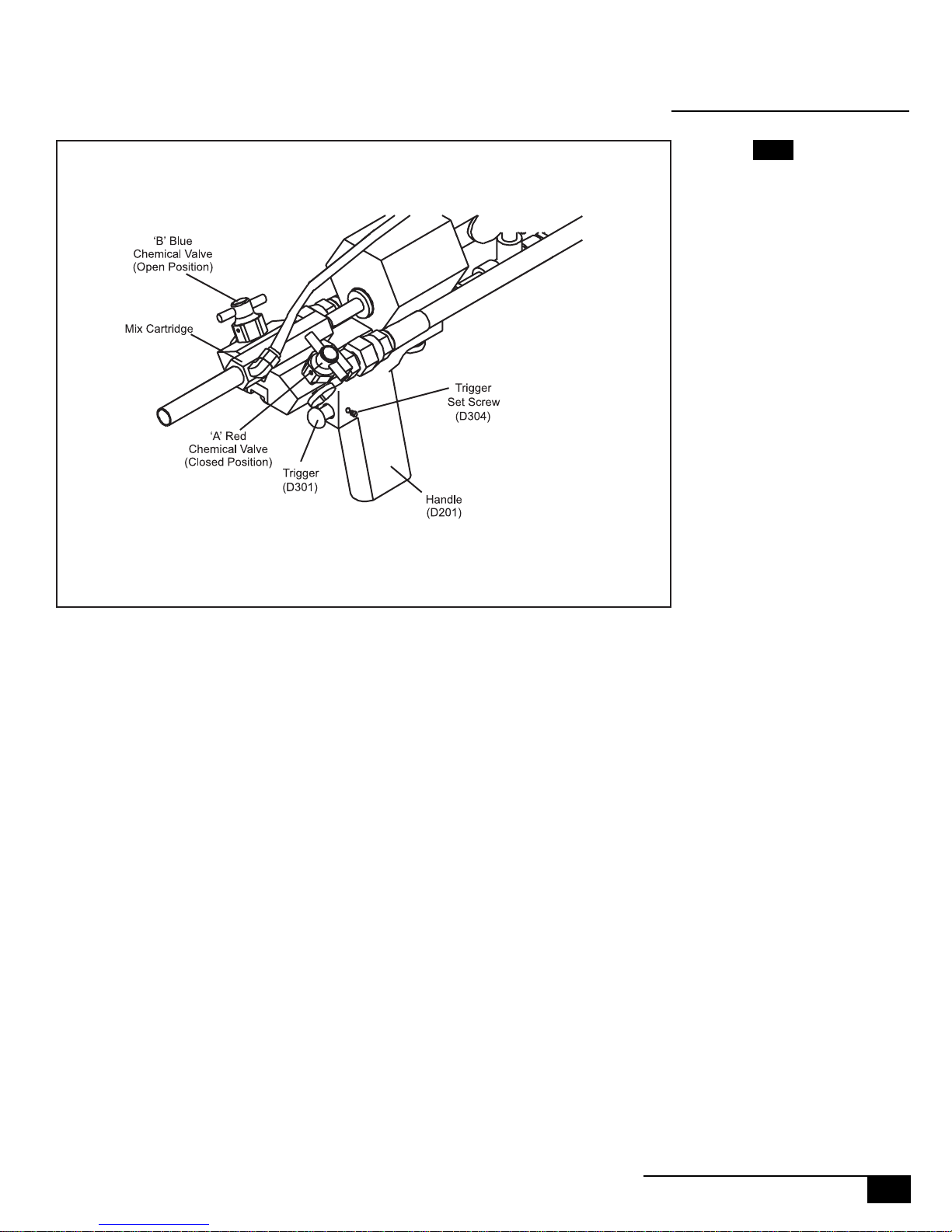

6| Close the "A" chemical (red) valve on the F1000 dispenser, leaving the "B"

chemical (blue) valve open. (See diagram 15A)(See diagram 15A)

(See diagram 15A)(See diagram 15A)

(See diagram 15A)

7| Place a 32 oz. paper cup on a scale, and tare the scale to read zero.

8| Using a stop watch, or optional timer, trigger the F1000 dispenser for exactly

3 seconds, directing the flow of the "B" chemical into the paper cup on the

scale. Record the weight of "B" chemical dispensed.

9| Purge the mix cartridge once again as outlined in step 5 above.

10 | Calculate the A:B chemical ratio by dividing the weight of the "A" chemical

obtained from step 4 by the weight of the "B" chemical obtained in step 8.

Example:

"A" chemical (3 second shot) weighs 41 grams

"B" chemical (3 second shot) weighs 37 grams

41 grams ÷ 37 grams = 1.11 A:B ratio

Most Polypro formulations should be run with an A:B ratio in the range of 1.00

to 1.15. Consult the technical data sheet for the Polypro formulation you are

running- it will list the best A:B ratio for that particular product (See Ratio

Calibration Charts on pages 18 - 21).

11 | If the A:B chemical ratio obtained in step 10 is too high, ie above 1.15,

adjust the nitrogen pressure on the "B" chemical up by 10 psi and repeat the

calibration procedure starting at step 1. If the A:B ratio obtained in step 10 was

too low, ie below 1.00, the adjust the nitrogen pressure on the "A" chemical up

by 10 psi and repeat the calibration procedure. It may be necessary make more

than one adjustment to the nitrogen pressure of the "B" chemical before reach-

ing the correct A:B ratio. It is advisable to adjust the nitrogen pressure on the

B" component in order to adjust the A:B ratio, not the nitrogen pressure on the

"A" chemical.

12 | It may be necessary during the calibration process to reduce the nitrogen

pressure on one of the chemical cylinders. This situation occurs when the proper

A:B component ratio cannot be achieved without raising the pressure on one of

the cylinders to its maximum pressure of 220 psi. REMEMBER: Each of the

chemical cylinders is equipped with a pressure relief valve that will auto-

matically open if the nitrogen pressure on the cylinder exceeds 220 psi.

Use the following steps to reduce nitrogen pressure on the cylinder. SAFETY

GLASSES SHOULD BE WORN DURING THIS PROCEDURE.

STARTUP | CALIBRATION

2.2

FOAMPRO® F1000 15

©2001 R11.01

STARTUP | CALIBRATION

2.2

Diagram 15A

FOAMPRO® F1000

16 ©2001 R11.01

STARTUP | CALIBRATION

2.2

NONO

NONO

NOTE:TE:

TE:TE:

TE:

1 - Close nitrogen valve on the chemical cylinder. (See diagrams 16A & 16B)(See diagrams 16A & 16B)

(See diagrams 16A & 16B)(See diagrams 16A & 16B)

(See diagrams 16A & 16B)

2 - Using the nitrogen pressure adjustment valve for the chemical cylinder

being adjusted, turn the adjustment valve counterclockwise two full turns.

(See diagram 17A)(See diagram 17A)

(See diagram 17A)(See diagram 17A)

(See diagram 17A)

3 - Locate the pressure relief valve on the chemical cylinder being adjusted.

(See diagrams 16A & 16B)(See diagrams 16A & 16B)

(See diagrams 16A & 16B)(See diagrams 16A & 16B)

(See diagrams 16A & 16B)

4 - Pull upward on the ring of the pressure relief valve for 2 or 3 seconds, then

release the ring to allow the valve to close. A burst of pressure will escape from

the valve.

5 - Open the nitrogen valve on the chemical cylinder. (See diagrams 16A &(See diagrams 16A &

(See diagrams 16A &(See diagrams 16A &

(See diagrams 16A &

16B)16B)

16B)16B)

16B)

6 - Using the nitrogen pressure adjustment valve for the chemical cylinder

being adjusted, turn the valve clockwise to the desired pressure.

(See diagram 17A)(See diagram 17A)

(See diagram 17A)(See diagram 17A)

(See diagram 17A)

Following these steps should result in a decrease in the pressure on the chemi-

cal cylinder.

The chemical cylinders are equipped with a pressure overload relief valve

that will open if the pressure of the cylinder exceeds approximately 220

psi. Do not adjust nitrogen pressure on the cylinders to approach 220 psi.

Before using the F1000 dispenser, you will need to install the plastic nozzle onto

the Mix Cartridge. The valves on the Air Injection System will have to be opened so

that air is passing freely.

The Air Injection System is comprised of two valves, an On/Off Valve (D704) and a

Needle Valve (D703) that are connected to the F1000 by a series of simple 1/8”

fittings. (See Diagram 17B) The Air Injection System serves three purposes. The air

flowing into the Mix Cartridge (D603) helps:

• the mixing of the “A” and “B” chemicals

• propel the chemicals out of the nozzle,

• keep the Mix Cartridge (D603) clear of curing foam.

The Needle Valve (D703) can be adjusted by turning the knob to control the amount

Nitrogen

Supply

Hose Nitrogen

Valve

Pressure

Relief

Valve

Cylinder

Chemical

Valve

Hose Filter

Chemical

Valve

Cylinder Valves - 17 Gal.

Closed

Open

Chemical

Valve

Positions:

Nitrogen

Supply

Hose

Nitrogen

Valve

Pressure

Relief

Valve

Cylinder

Chemical

Valve

Hose Filter

Chemical

Valve

Cylinder Valves - 60 Gal.

Closed

Open

Chemical

Valve

Positions:

Chemical

Filter

Diagram 16A

Diagram 16B

(Left)

(Right)

FOAMPRO® F1000 17

©2001 R11.01

STARTUP | CALIBRATION

2.2

of air flowing through the system. Different uses of the F1000, for example spraying

foam, may require a higher flow of air than pouring foam. Experience in using the

F1000 will help the user determine what air flow level suits their needs.

Once the proper amount of airflow through the Air Injection System has been

achieved, the F1000 dispenser is ready for use. Foam product can be dispensed by

depressing the trigger.

After using the F1000 dispenser, if it is to momentarily sit idle for more than a few

minutes, either let air flow through the Air Injection System, or place a few drops of

solvent into the open end of the plastic nozzle. Keep the plastic nozzle pointed

upward so the solvent remains and prevents any foam product from curing in the

end of the nozzle or mix cartridge. If the F1000 dispenser is to be shut down or

stored for a long period of time, follow the procedure for Shutdown described in

Section 4.1.

Diagram 17A

Diagram 17B

FOAMPRO® F1000

18 ©2001 R11.01

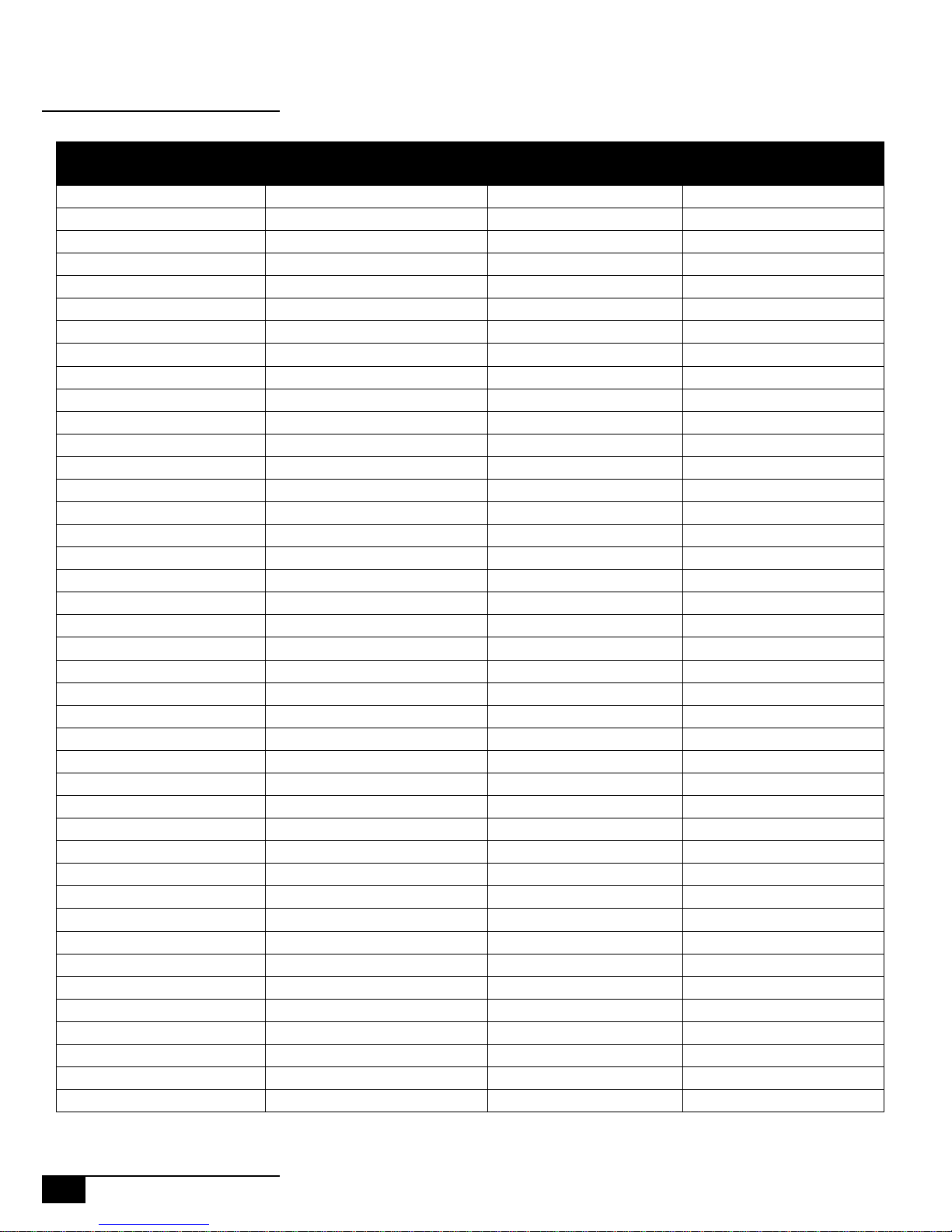

Three second shot of "A" Three second shot of "B" Approximate Total Output

Grams of "A" Component FROM - Grams of "B" component - TO in Pounds per minute

30 26.1 28.6 2.5

31 27.0 29.5 2.6

32 27.8 30.5 2.7

33 28.7 31.4 2.8

34 29.6 32.4 2.9

35 30.4 33.3 2.9

36 31.3 34.3 3.0

37 32.2 35.2 3.1

38 33.0 36.2 3.2

39 33.9 37.1 3.3

40 34.8 38.1 3.4

41 35.7 39.0 3.4

42 36.5 40.0 3.5

43 37.4 41.0 3.6

44 38.3 41.9 3.7

45 39.1 42.9 3.8

46 40.0 43.8 3.9

47 40.9 44.8 4.0

48 41.7 45.7 4.0

49 42.6 46.7 4.1

50 43.5 47.6 4.2

51 44.3 48.6 4.3

52 45.2 49.5 4.4

53 46.1 50.5 4.5

54 47.0 51.4 4.5

55 47.8 52.4 4.6

56 48.7 53.3 4.7

57 49.6 54.3 4.8

58 50.4 55.2 4.9

59 51.3 56.2 5.0

60 52.2 57.1 5.0

61 53.0 58.1 5.1

62 53.9 59.0 5.2

63 54.8 60.0 5.3

64 55.7 61.0 5.4

65 56.5 61.9 5.5

66 57.4 62.9 5.6

67 58.3 63.8 5.6

68 59.1 64.8 5.7

69 60.0 65.7 5.8

70 60.9 66.7 5.9

STARTUP | CALIBRATION

2.2

FOAMPRO® F1000 19

©2001 R11.01

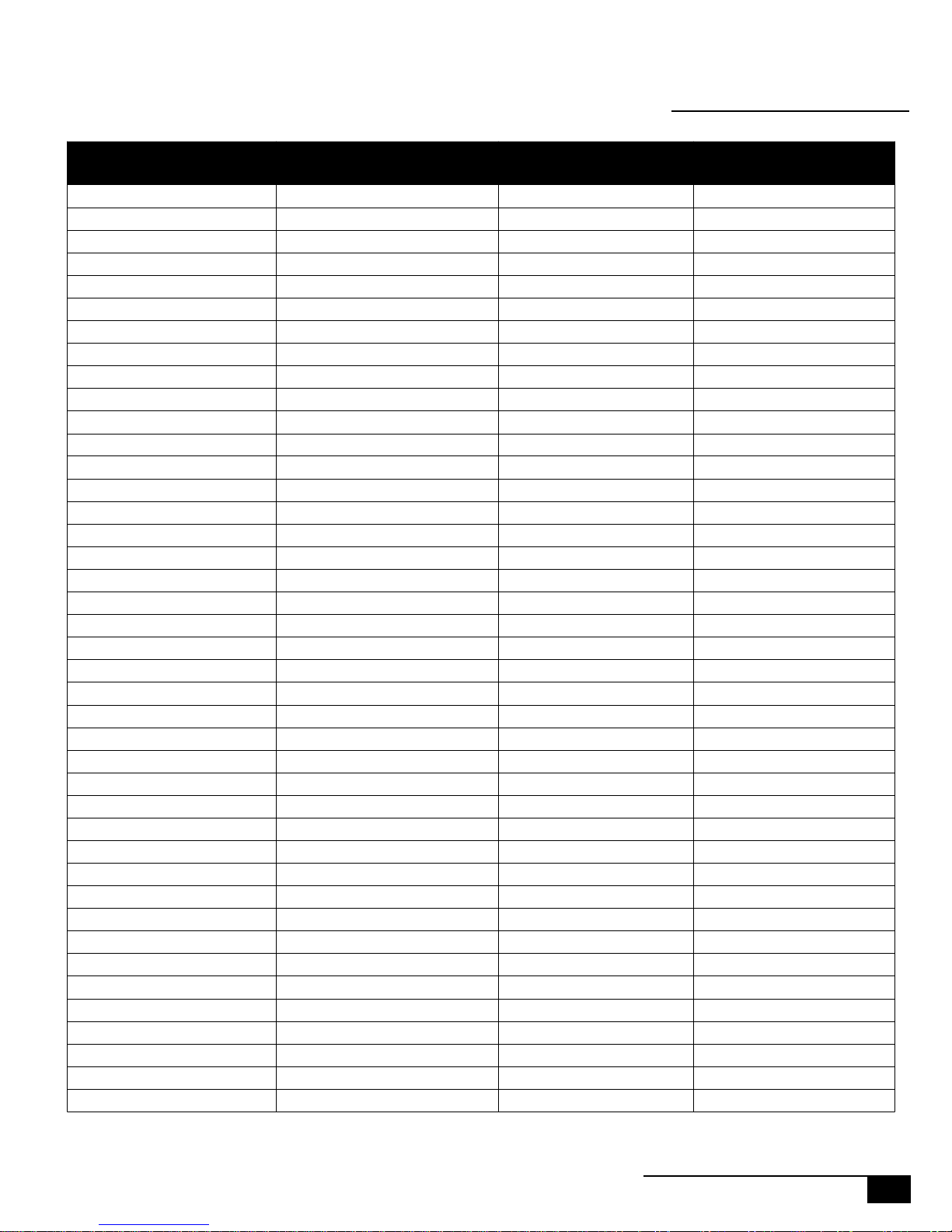

Three second shot of "A" Three second shot of "B" Approximate Total Output

Grams of "A" Component FROM - Grams of "B" component - TO in Pounds per minute

71 61.7 67.6 6.0

72 62.6 68.6 6.1

73 63.5 69.5 6.1

74 64.3 70.5 6.2

75 65.2 71.4 6.3

76 66.1 72.4 6.4

77 67.0 73.3 6.5

78 67.8 74.3 6.6

79 68.7 75.2 6.6

80 69.6 76.2 6.7

81 70.4 77.1 6.8

82 71.3 78.1 6.9

83 72.2 79.0 7.0

84 73.0 80.0 7.1

85 73.9 81.0 7.1

86 74.8 81.9 7.2

87 75.7 82.9 7.3

88 76.5 83.8 7.4

89 77.4 84.8 7.5

90 78.3 85.7 7.6

91 79.1 86.7 7.7

92 80.0 87.6 7.7

93 80.9 88.6 7.8

94 81.7 89.5 7.9

95 82.6 90.5 8.0

96 83.5 91.4 8.1

97 84.3 92.4 8.2

98 85.2 93.3 8.2

99 86.1 94.3 8.3

100 87.0 95.2 8.4

101 87.8 96.2 8.5

102 88.7 97.1 8.6

103 89.6 98.1 8.7

104 90.4 99.0 8.7

105 91.3 100.0 8.8

106 92.2 101.0 8.9

107 93.0 101.9 9.0

108 93.9 102.9 9.1

109 94.8 103.8 9.2

110 95.7 104.8 9.3

111 96.5 105.7 9.3

STARTUP | CALIBRATION

2.2

Table of contents

Popular Dispenser manuals by other brands

Georgia Pacific

Georgia Pacific GP PRO Pacific Blue Ultra 56602A reference guide

Technical Concepts

Technical Concepts OneShot Plus installation instructions

Georgia Pacific

Georgia Pacific enMotion 10 reference guide

Steris

Steris Basil 3600 installation instructions

Bunn

Bunn JDF-2S Service & repair manual

Cornelius

Cornelius In-N-Out Burger NGF 255 installation manual