Foley Belsaw 200 User manual

FOLEY-BELSAW

MODEL

200

KEY

MACHINE

ADJUSTMENT

&

OPERATION

INSTRUCTIONS

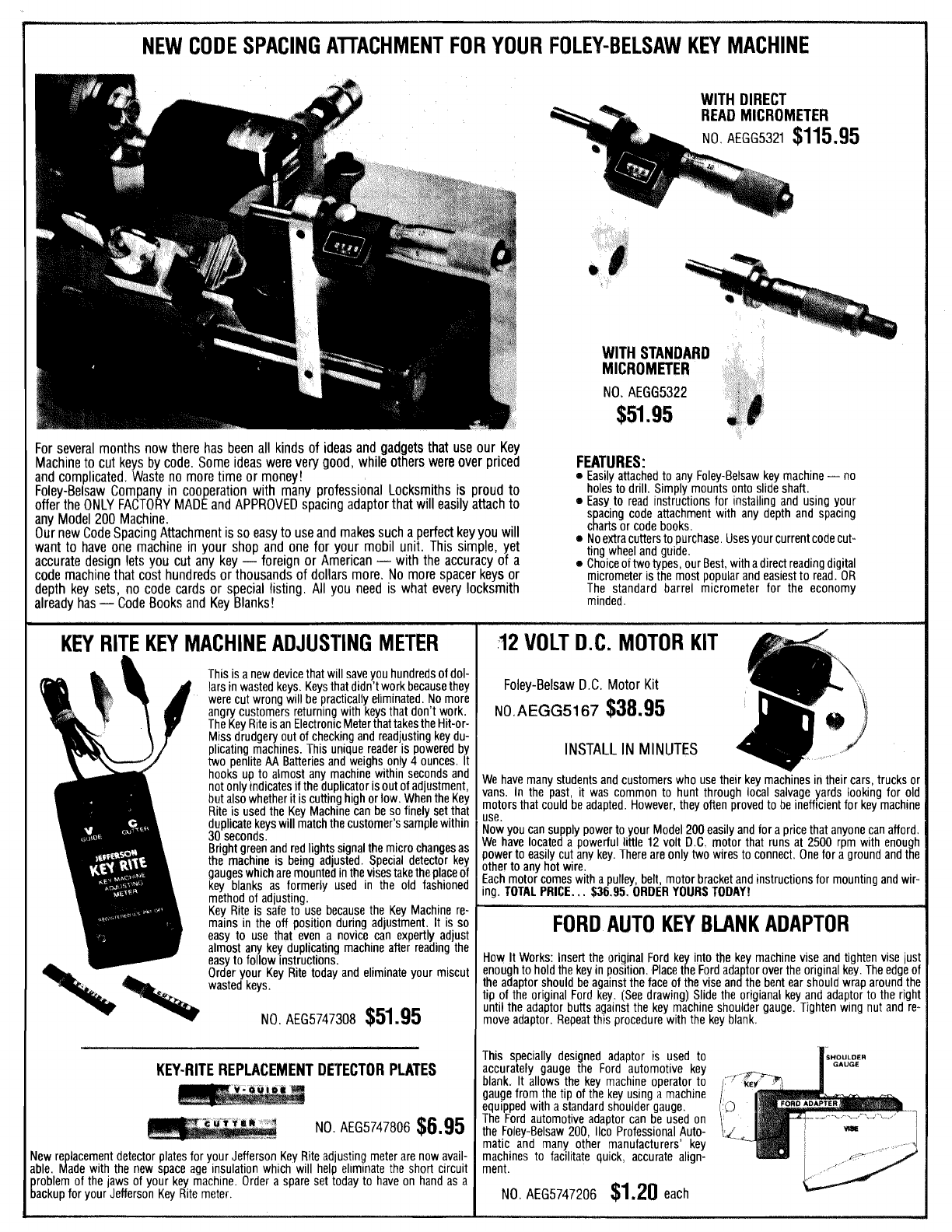

and complicated. Waste no more time or money!

Foley-Belsaw Compan in cooperation with many professional Locksmiths

is

proud to

offer the ONLY FACTO~YMADE and APPROVED spacing adaptorthat will easily attach to

0

Noextracuttersto purchase. Usesyour currentcodecut-

INSTALL IN MINUTES

NO. AEG5747308

$51.95

until the adaptor butts against the key machine shoulder gauge. Tighten wing nut and re-

move adaptor. Repeat this procedure with the key blank.

MODEL

200

KEY

MACHINE

PARTS

LIST

ORDER

NO.

AEG5726003

AEG5726005

AEG57260W

AEG5726007

AEG5726008

AEG5726009

AEG5726013

AEG5726014

AEG5726015

AEG5726016

AEG5726017

AEG5726018

AEG5726019

AEG572600

1

Base

Slide Casting

Clamp

Spring

Tracer Guide (Steel)

Tracer Guide (Duplicating)

Tracer Guide (Code)

Guide Arm Casting

Retainer

Stud

Shaft

Slide Shaft

Pulley (Motor)

Motor

ORDER

NO.

AEG5726029

AEG5726021

AEG5726022

AEG5726023

AEG5726020

AEG572602A

AEG5726002

AEG5726025

AEG5726010

AEG5726012

AEG5726011

AEG5726026

AEG5726027

AEG5726028

Bearing

Wing Nut

Micrometer

Pulley (Cutter Shaft)

Bearing

Alemite Fitting

Belt

Spring

Slotting Cutter

Duplicating Cutter

Code Cutter

Gauge

Motor Mount

Chip Guard

KEY

MACHINE

MODEL

200

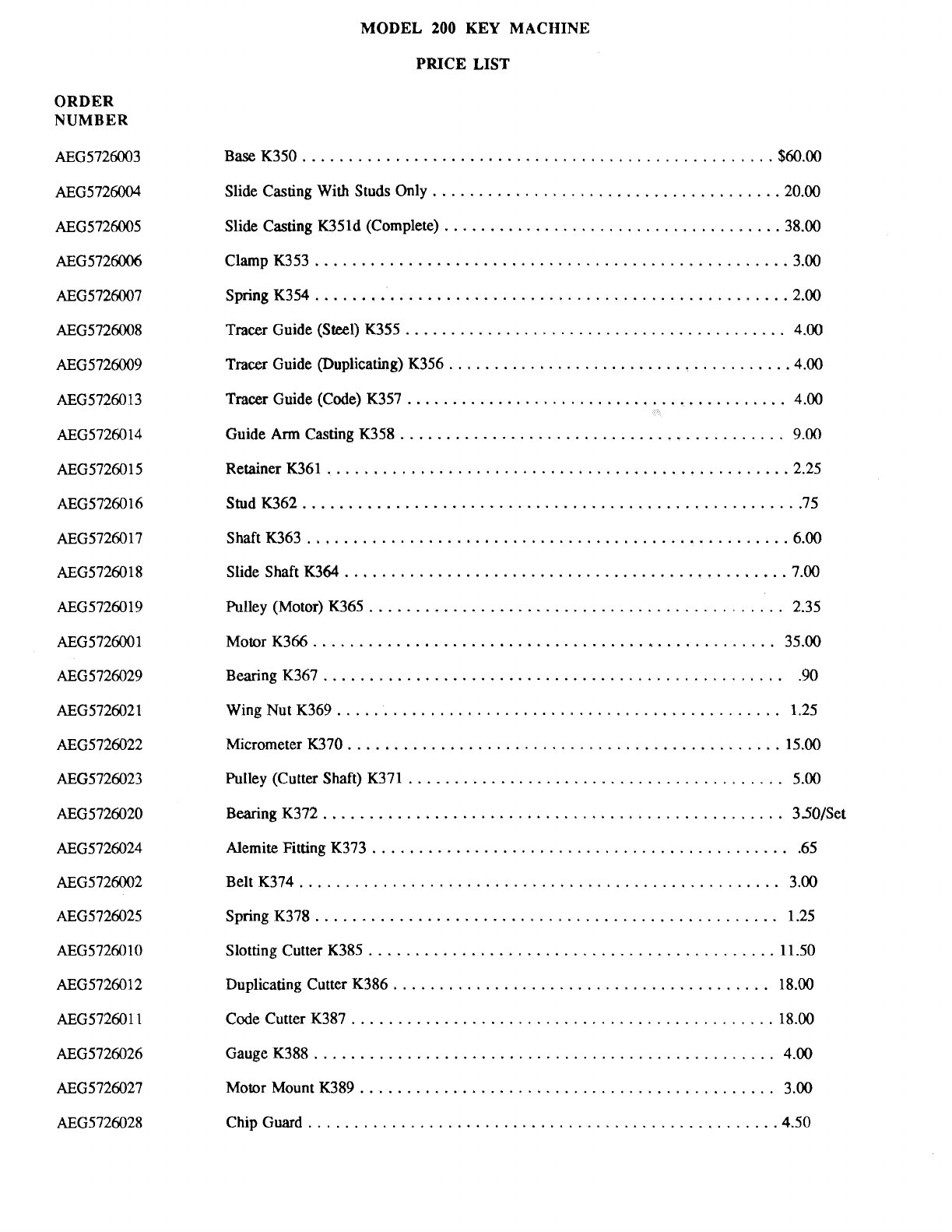

KEY MACHINE

PRICE LIST

ORDER

NUMBER

BaseK350

...................................................

$60.00

Slide CastingWith Studs Only

.....................................

'20.00

Slide Casting K35ld (Complete)

....................................

.38.00

...................................................

ClampK353 3.00

SpringK354

...................................................

2.00

..........................................

Tracer Guide (Steel) K355 4.00

......................................

Tracer Guide (Duplicating) K356 4.00

Tracer Guide (Code) K357

..........................................

4.00

..........................................

Guide

Arm

Casting K358 9.00

RetainerK361

..................................................

2.25

......................................................

StudK362 75

ShaftK363

....................................................

6.00

SlideShaftK364

................................................

7.00

Rmlley (Motor) K365

.............................................

2.35

MotorK366 .................................................. 35.00

BearingK367 ...................................................90

Wing Nut K369

................................................

1.25

Micrometer K370

...............................................

15.00

.........................................

Pulley (Cutter Shaft) K371 5.00

Bearing K372

..................................................

3501Set

Alemite Fitting K373

..............................................

65

BeltK374

....................................................

3.00

SpringK378

..................................................

1.25

SlottingCutter K385

............................................

11.50

Duplicating Cutter K386

.........................................

18.00

Code Cutter K387

..............................................

18.00

..................................................

GaugeK388 4.00

Motor Mount K389 .............................................3.00

ChipGuard

...................................................

4.50

LOCKSMITHSUPPLIERS

LOCKSMlTH

SUPPLIES

(CANADA)

Agencies W. Pelletier1980, Inc.

651 Motre Dame QuestSte. 375

Montreal, PQ H3C

1H9

Southernlockand Supply Go.

+&It0

EndeavorWay

Pinellas Park, FL33565

Acme Lock and Key

Co.

8020 Olive St.

New Orleans,

LA

70125

Armstrong's Lock

8

Supply, Inc.

1440DutchValley Place. N.E.

Atlanta,

GA

30324

Capitol Lockand Hdwe. Co., Inc.

3730 Georgia Ave., N.W.

Washington, D.C. 20010

Clark Security Products, Inc.

7140 Engineer Rd.

San Diego,

CA

92117

Dire Locksmith Supply Co.

2201 Broadway

Denver, CO 80205

DiversifiedMfg.

8

Marketing

Co., Inc.

P.O. Box 2260

Burlington, NC 27215

Dixie Lock and Key Supplies

2025 N.W.167th St.

Miami, FL 33056

DoorClosers and L.S. Supplies

Pimlico Key Senrice, Inc.

5254 ReisterstownRoad

Baltimore. MD 21215

Doyle Lock

Co.

2211W. River Rd., N.

Minneapolis, MN 5541

1

Dugmoreand Duncan, Inc.

30 Pond Park Rd.

Hingham,

MA

02043

Ewert Wholesale Hardware

4709 W. 120thSt.

Alsip, IL60656

Fairmy Supply, Inc.

2631 Lombardy Lane

Dallas, TX 75220

Foley-BelsawCo.

6301 EquitableRd.

Kansas City, MO 64120

H. Hoffman Co.

7330 W. Montrose Ave.

Chicago, IL60634

IntermountainLock

8

SupplyCo.

3106 S. Main St.

Salt Lake City, UT 84115

Island PacificDistributors, Inc.

1668 King St.

Honolulu, HI 96822

Hans Johnson

Co.

8901 Chancellar Row

Dallas, TX 75247

A.T. Jones and Son

449 W. Congress St.

Detroit, MI48226

(Serving MI Only)

Key HardwareCo.

2400 San Fernando Rd,

Los Angeles, CA 90065

Key Supply

149 Gough St.

San Francisco, CA 94102

M,

Ta lor and Co., Inc.

5645

f

u~ip

st.

Philadelphia, PA 19124 Benton Ltd.J.W.

1271Hornby St,

Vancouver, BC V6A 1

W4

Blander. P.

Locksmith SupplyCo.

28 Mt. RoyalW.

Montreal, PQ

Craig Co. Ltd., C.C.

1500

King Edward St.

Winnipm, MB R3HOR5

HardwareAgencies Ltd.

1220Dundas St,

E.

Toronto. ON

M4M

IS3

.

'The InternationalKey Co.

28 Mount Royal West

Montreal, PQ

Serrubec Inc.

2069 Ave. Chartier

Dorval, PQ H9P 1H3

The

LockwareCo.

1613W. PrattSt.

Baltimore,

MD

21223

Lawrence Locksmith Supply

300Long Beach Rd.

Oceanside, NY 11572

Locks Company

2050 N.E. 151St

Miami, FL 13204

Tweeds Locksmiths, Inc.

601 ElmAve.

Portsmouth,UA 23704

McDonaldLocksmithSupplyCo. Veehoff Supply Co.

P.O. Box 16907 Box 361,908 LakeAve.

Memphis, TN 38116 Storm Lake, IA50588

H.E. Mitchell Co. Wacker Hardware Co.

118 S.E. 8th St. 560

W.

Randolph

Portland. OR 97214 Chicago, IL60606

Mountain West AlanSu

P.O. Box 10780

Pheonix. AZ 85064

Independent Hardware,

I

14 S. Front St.

Ph~ladelphia,PA 19106

Safemasters Co.. Inc.

Shield Su ly

8

Services Ltd.

Unit 17-1!11 St.James St.

Winnipeg, MB R3HOZ1

Judy's Locksmith, Inc.

534 Burlew Dr.

Charleston,W.V. 25302

Stearman Ltd.. Jack

Vancouver, BC V5Y 7L2

Assoc. LS of America, Inc.

3003 Live Oak St.

Dallas, TX 57204

2700 GarfieldAve.

Silver Spring, MO 20910 Locksmith Ledger

850 Busse

Hwy.

M. Shepse Co. Park Ridge, IL60068

1506FifthAvenue 31

2-693-5940

Pittsburgh, PA 15219 NationalLocksmith

K.D.L. Hardware Supply

1621-8th Avenue

Seattle, WA 98101

Kenton LocksmithSupplies, Inc.

10 Lincoln St.

Kansas City, KS 66103

D. Silver Hardware Co., Inc.

I

I

1533 Burgundy Parkway

145 LafayetteAve. Streamwood, IL60107

NorthWhite Plains, NY 10603 31

2-837-2044

MANUFACTURERS

Ideal Security Hardware Gorp.

The

Masler

Sate

Company

45 E. MarylandAve. 1561Grand Bkd.

St. Paul, MN55107 Hamilton, OH 46013

612-488-0202 513-867-4000

Diebld, Inc.

1035 Industrial Parkway

Medina, OH 44256

216-725-0811

All-Lock

P.O. Box 3042

North Brunswick,NJ 08092

201-545-7000

Star Key

8

LockMfg.

1274 FlushingAve.

Brooklyn, NY 11237

21-821-8300

Best Lock Corp.

P.O. Box 50444

Indianapolis. IN46250

317-849-2250

Ilco/Unican Coro. NationalCabinet Lock

Dominion LockCompany, Ltd.

7301 Decarie Blvd.

Montreal, Quebec

CANADAH4P267

514-735-5411

Taylor Lock Company

(See IlcoNnican)

400 Jefferies ~d,

-

P.O.

Box

200

Rockv Mount. NC 27801 Mauldin, SC

29662

919-446-3321 803-297-6655

JunkuncBros./Amer~canLockCo. Norton

Door

Controls

Exchange Rd.

8

Kedtie P.O. Box 25288

Crete, IL 60417 Charlotte, NC 28212

312-534-2000 704-283-2103

VSI HardwareInd.

P.O. Box 4445

Sylmar, CA 91342

213-367-2131

Briggs

8

Stratton

P.O. Box 702

Milwaukee. WI 53201

414-259-5218 ESP Corp.

Enaineered Securih, Products

373 HarvardSt.

.

Leominster, MA 01453

617-534-6121

Weiser Lock

5555 McFaddenAve.

Chicago Lock Company

4311W. Belmont Ave.

Chicago. lL60641

312-282-7177

Kwikset Sargent

&

Company

516 E. Santa Ana St. 100 Sargent Drive

Anaheim, CA 92805 New Haven. CT 06509

714-535-8111 203-562-2151

Huntington Beach, CA 92649

714-898-081

1

Fort Lock Corp.

3000 N. River Rd. Weslock Company

13344 S. Main Street

Los Angeles, CA 90061

213-327-2770

Lab Secur~tySystemsCorp. SargentY Greenleaf, Inc.

P.O. Box

54

1 Sercurity Drive

Terlyville. CT 06786 Nicholasville,

KY

40356

203-5896037 606-885-941

1

Corbin Cabinet Lock

225 EpiscopalRd.

Berlin, CT 06037

203-255-241

1

River Grove, IL 60171

312-456-1100

Gil-Ray Tool

1306 McGrawStreet

Box 801

Bay City, MI48706

517-892-6870

Wright Prod., Inc.

2515 Wabash

St. Paul,MN 55114

612-642-2800

Lori Corp. Schlage LockCompany

Old Turnp~ke P.O.

Box

3324

Southington, CT 06786 San Francisco, CA 94119

203-621-3601 415-467-1

100

Corkey ControlSystems, Inc.

207050 S. Western Ave. $108

Torrance, CA 90501

213-533-1425 Yale Security Prod.

P.O. Box 25288

Charlotte, NC 28212

740-283-2101

Lucky Line Prod Scotsman Securily Prod., Inc.

P0. Box 17397 P.O. Box 1250

San Diego, CA 92117 Pine Grove, CA $5665

619-270-0153 209-295-5498

Curtis Industries,Inc.

34999 Curtis Blvd.

Eastlake,

OH

44094

216-951-2400

H.PC., Inc.

3999 N. 25th Ave.

Schiller Park, IL60176

312-671-6280

Dexter Locks

Sub. of Master Lock

300 Webster Rd.

Auburn, AL 36830

205-826-330

Master Lock Company Simplex Access Controls, Corp

2600 North

32nd

St. 2941 lrldiana A*.

Milwaukee,WI 53210 Winston Salem, NC 27115

414-444-2800 919-725-1331

Harloc Product CorD.

135 Wood Street

West Haven, CT 06516

203-934-2683

POCKET PATCHES

3

x

3'/4"

BONDED

(Royal

BluetWhite)

realattention getterwhen displayedinyourwindow or

utsideyour shop. Itistough, white vinyl coated onthe

back with its own adhesive. Just peel off the backing

TOP

QUALITY

LOCKSMITH CAPS

YOUR ANSWER TOWARDS INCREASING KEY SALES!

ditional give-a-ways, but also givesyou a much faster way of ringing newlycut

SOFTIE BRUSH

3

Diameter

-

112"

Hole

Find keys

quickly

and

MODEL

200

KEY MACHINE INSTALLATION

ADJUSTMENT AND OPERATION

FOR

DUPLICATING CYLINDER KEYS

The key machine is the locksmith's primary tool and one of his best sources of income. The basic function

of a key machine is to duplicate keys accurately. It is a delicate piece of equipment and requires the

maintenance and care of a precision machine. It should be use

for general shop use. Once your key machine is set main that way if you

do not abuse it by misuse.

A

good key machine curately duplicate a

key to within one or two thousandths of an inch. This properly duplicate keys

that

will

work.

A

locksmith takes great pride in up for accurate duplication.

Many key machines in use today do not duplicate t adjusted or operated

properly. You have no doubt heard the complai

dime stores, or grocery stores, that the key did not wor

because of the quality of the key machine but d

in

settingthe machine in proper adjustment and keeping it that

way.

Your FOLEY-BELSAW Model

200

Key Machine has been designed with precision, accuracyand versatility

in mind. Specialfeatures have been incorporated into the design to make it a combination key duplicating

machine and a code cutting machine. These instructions

will

dealwith the installation and operation of the

machine for duplicating cylinder keys. Cuttingkeys by codeand cuttingflat steelkeyswill also be covered.

The location of your key machine is

very

important. Itshould be set up in a place in your shop that offers

natural light if at all possible.

A

bench tool light should also be used. You should have enough work area to

allow for a key display board to be hung on the wall beside or behind the machine for easy accessibility.

KEY

MACHINE

Page

1

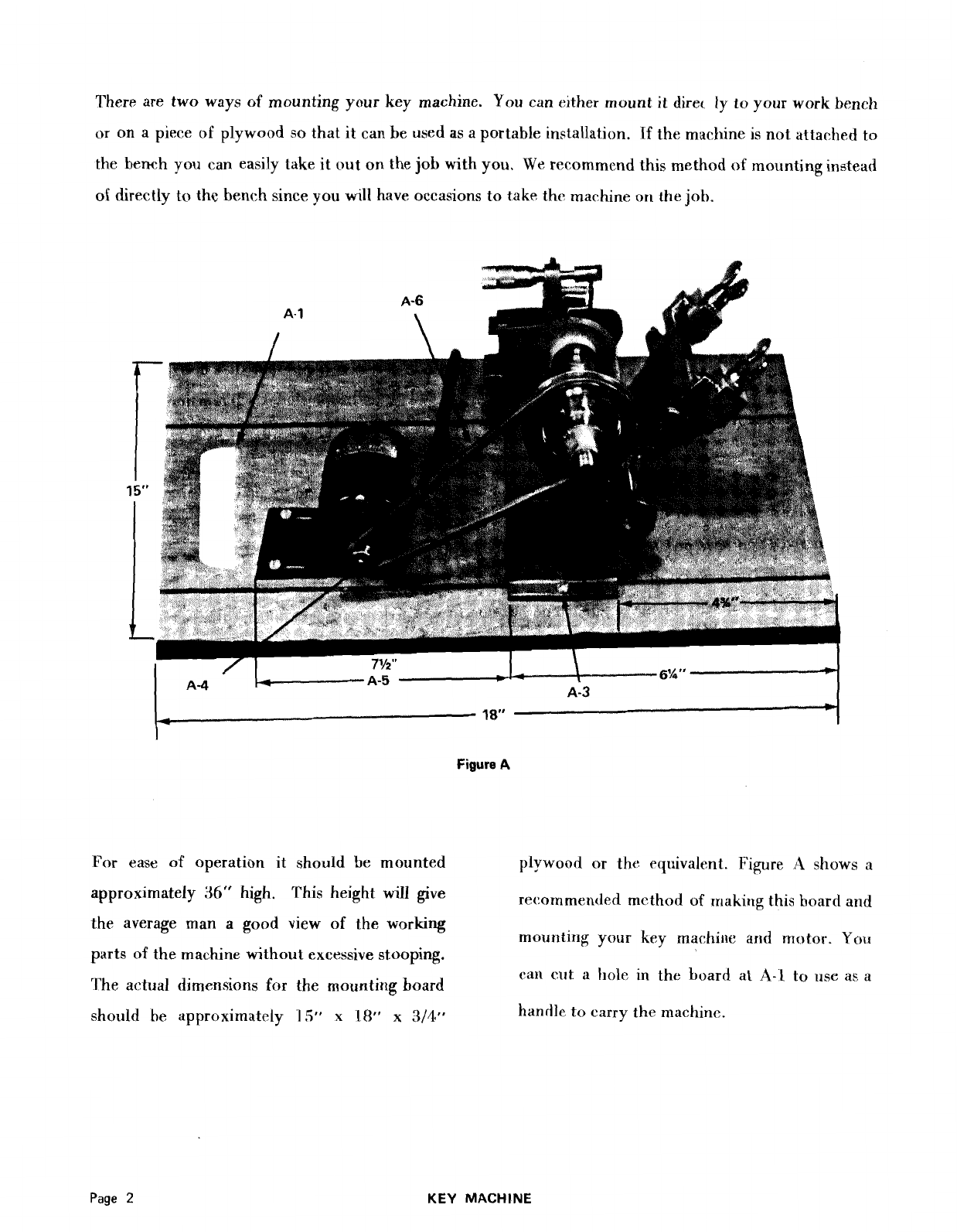

There

are

two ways of mounting your key machine. You can elther mount it direc ly

to

your work bench

or

on a piece of plywood

so

that it can

be

used as a portable installation.

If

the machine is not attached to

the

bench you can easily take it out on the job with

yea.

We rerommcnd this method

of

mounting instead

of directly

to

the bench since you

will

have occasions totake the machine or1 the job.

Figure

A

For ease of operation

it

should be mounted plywood or the equivalent.

Figure

i.1

shows

a

approximately

36"

high. This height

will

give recornmenJed method of making this hoard

and

the average man a good view of the working mounting your key machirle

ar~d

motor.

Yo11

parts of the machine without excessive stooping. can cut

il

hole in the board at

A-1

to

rise

as a

'I'he actual dimensions for

the

mounting board

should

he

approximately

15"

x

18"

x

3/411

handle

to

carry the machine.

KEY

MACHINE

shown in Figure

A.

Line up the front edge so be seton the shaft with the set screw toward the

that it is square with the mounting board. The motor and flush with the end of the motor shaft

front edge should be approximately

4%"

back as shown at

A-4.

Then attach the motor mount

from the frontedge of the board as shown. to the motor, with screws provided in the motor.

Line up the motor so that the belt

A-6,

will

run

straight between the motor and machine pulley.

Line up the side edges of the machine so there In the diagram shown above, at position

A-5,

is an equal distance on each side of the board. the distance from the back of the Key Machine

Use the mounting holes on the base of the base, to the back of the motor mount,

is

ap

machine as shown at

A-3

to mark the board for poximately

7%

inches. Next mark the holes in

the mounting screws which you will find in your the motor mount and using the screws you re-

parts bag. Tighten these screws down tight so ceived in the parts bag, fasten the motor to the

the machine

is

solid. Next unpack the motor mounting board. Install the drive belt,

A-6.

Cut

out hole

A-1

for handle.

KEY

MACHINE

Page

3

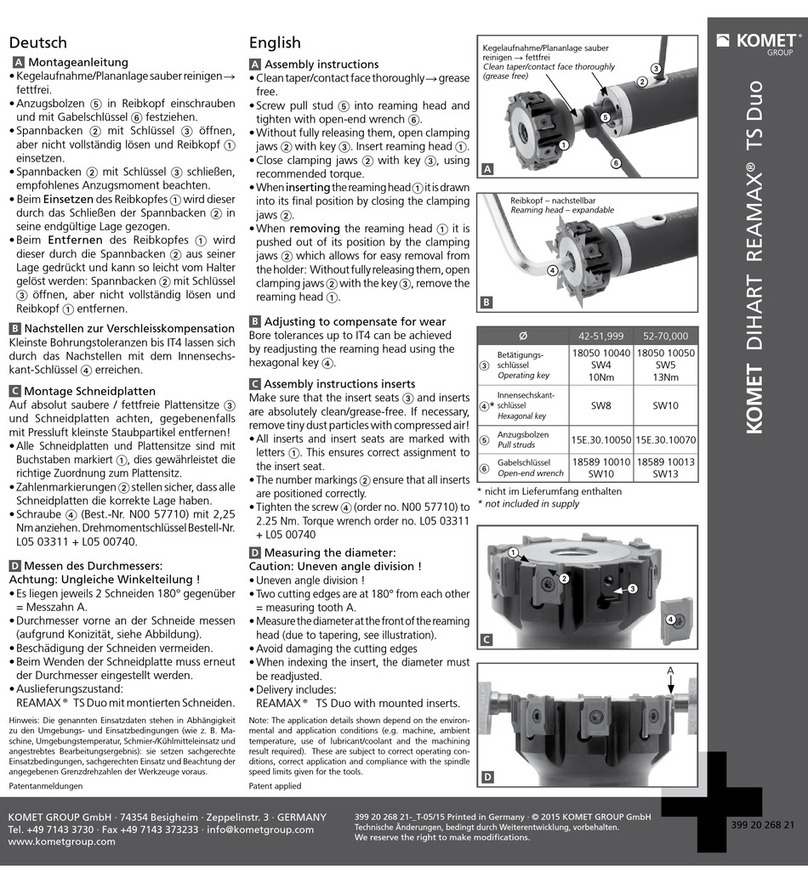

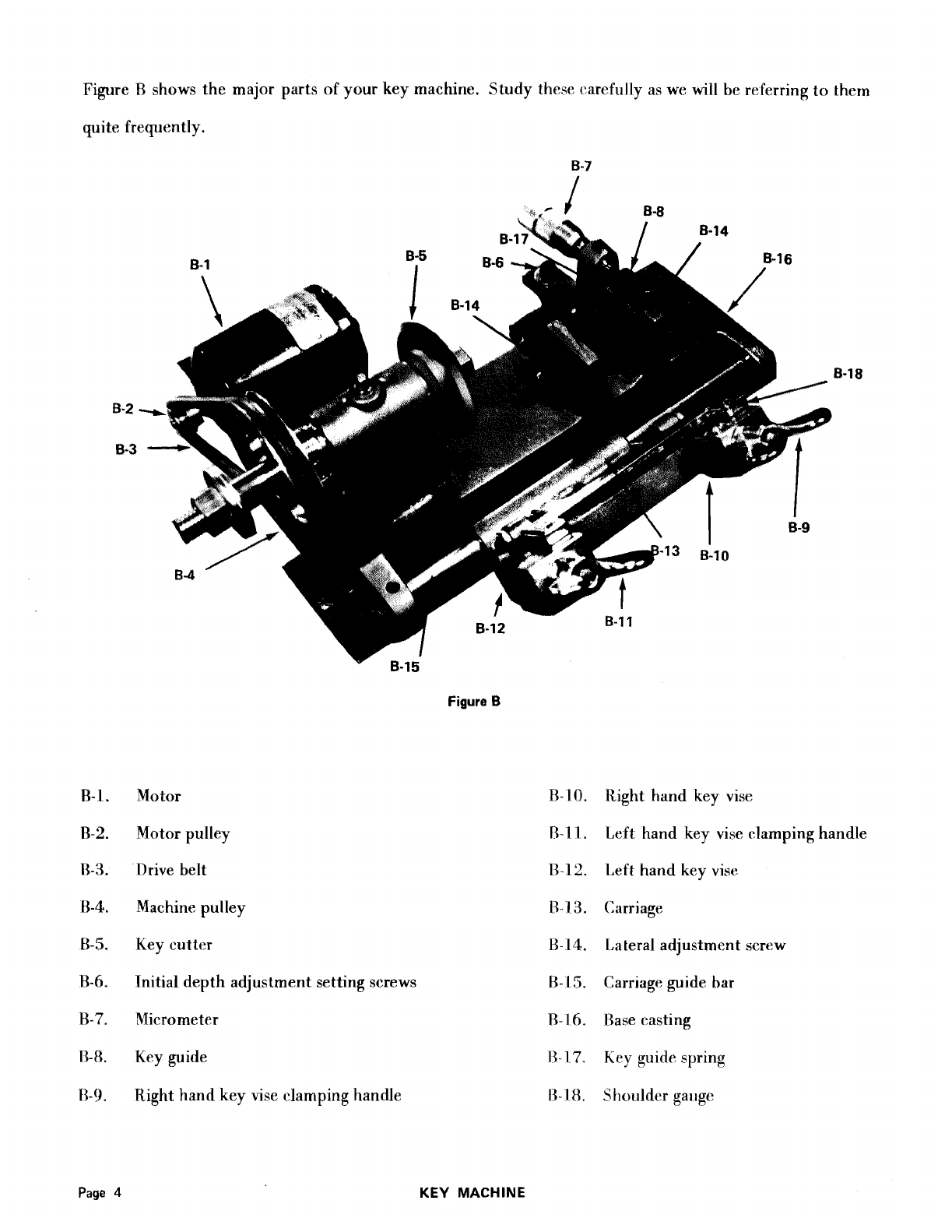

Figure

R

shows the major parts of your key machine. Study these carefully as we will be referring to thern

quite frequently.

B-7

Figure

B

Motor

Motor pulley

Drive belt

Machine pulley

Key cutter

Initial depth adjustment setting screws

Micrometer

Key guide

Right hand key vise clamping handle

Right hand key vise

1,eft hand key vise clamping handle

l,eft hartd key vise

Carriage

Lateral adjustment screw

Carriage guide bar

Base casting

Key

guide spring

Slioi~ldcrgallge

KEY

MACHINE

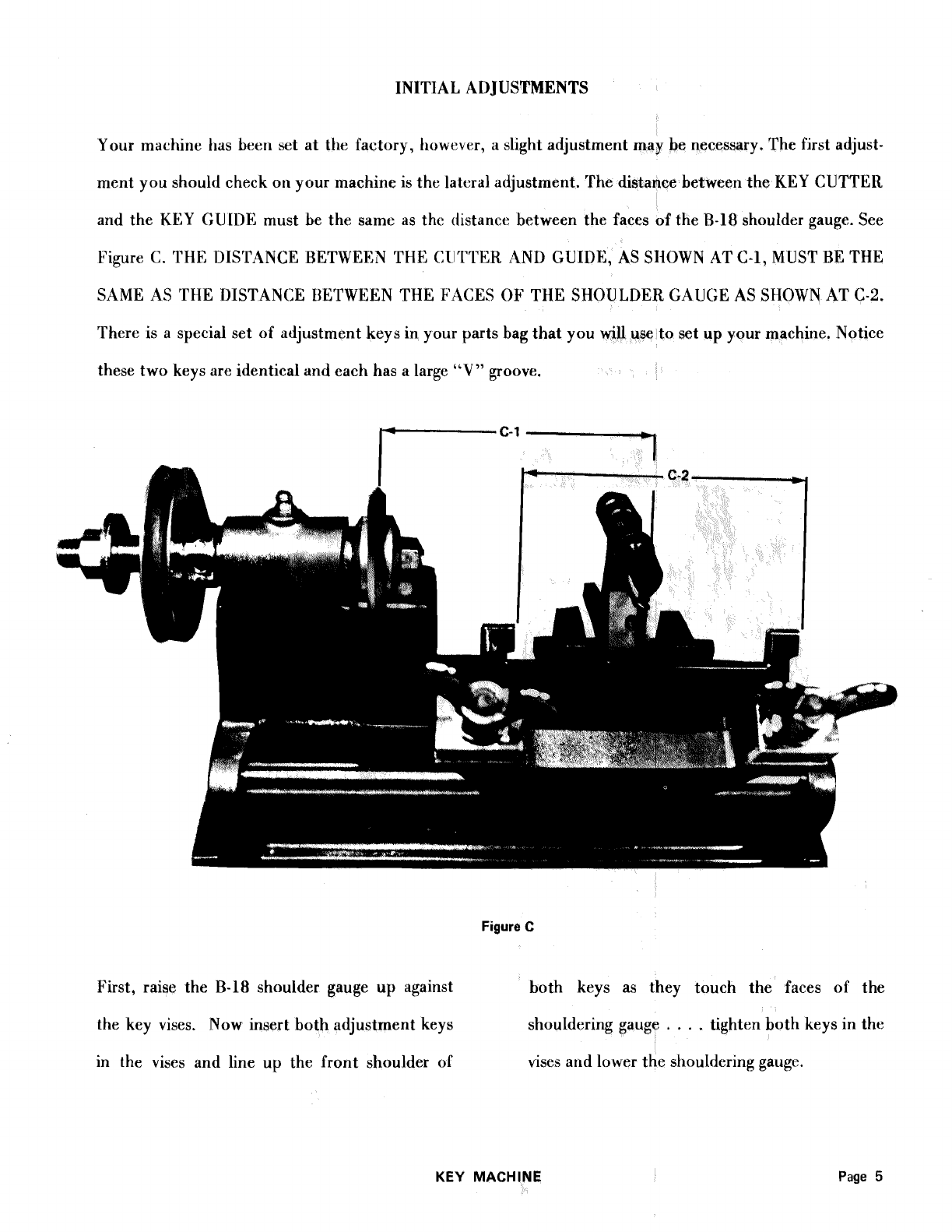

INITIAL AT) JUSTMENTS

Your machine has been set at the factory, however, a slight adjustment may be necessary. The first adjust-

ment you should check on your machine is the latc-raladjustment. The distance between the KEY CUTTER

and the KEY GUIDE must be the same as the distance between the faces of the

€3-18

shoulder gauge. See

Figure

C.

THE DISTANCE RETWEEN THE

CII'TTEK.

AND GUIDE, AS SHOWN AT C-1, MUST RE THE

SAME AS THE DISTANCE BETWEEN THE

FACES

OF THE SHOULDER GAUGE AS SHOWN AT C-2.

There is

a

special set of adjustment keysin your parts bag that you

HriU

use

to

set

up

your machine. Notice

these two keys are identical and each has a large

"V"

groove.

Figure

C

First, raise the

B-18

shoulder gauge

up

against both keys as they touch the faces of the

the key vises. Now insert both adjustment keys shouldering gauge

.

.

.

.

tighten both keys in the

in the vises and line up the front shoulder of vises and lower the shouldering gauge.

KEY

MACHINE

Page

5

Raise the carriage so the

"V"

in the adjustment

key in the

LEFT

hand vise contacts the key

cutter as shown at

11-2,

Figure

I).

Notice where

the guide contacts the adjustment key in the

RIGHT hand vise. It may be off to one side or

another as shown at

11-3.

As this figure shows, it

would be necessary to move the key vise to the

RIGHT to make it line up, or move tht: guide to

the

LEFT.

Since the key vise cannot be moved it

will be necessary to move the guide to the left

until

the

point is in the bottom of

the

"V"

of

the adjustment key.

To

do

this you loosen the

lateral adjustment screw showti at point

W-14.

On the right side is another adjustment screw,

Tighten the screw on the right and this will

move the guide to the

L,EFfI'.

Continue doing

this until you have the point of the guide in line

with the bottom of the

"V".

Don't worry if the

guide doesn't touch the bottom of the

"V"

as

this will be taken care of in the next adjustment.

Figure

D

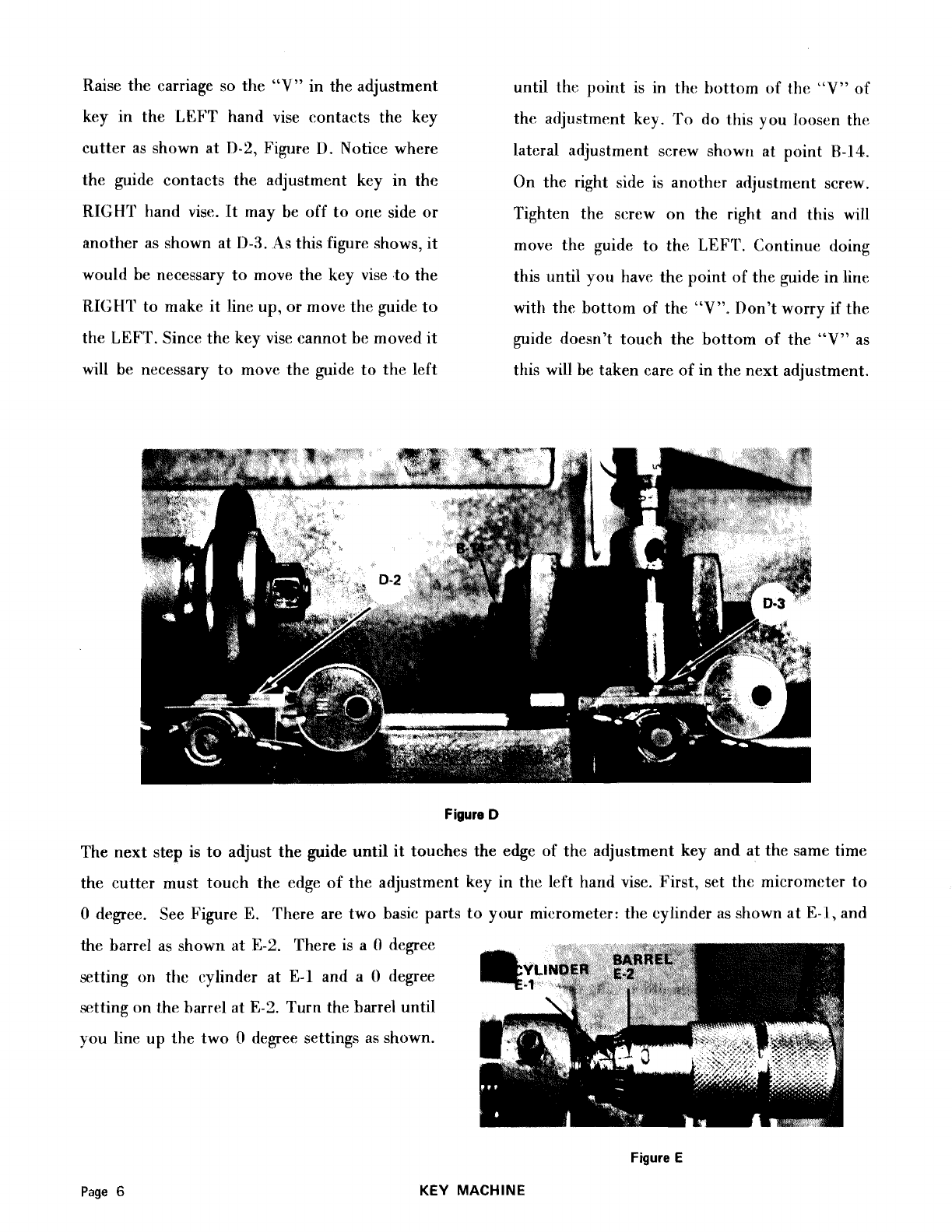

The next step is to adjust the guide until it touches the edge of the adjustment key and at the same time

the cutter must touch the edge of the adjustment key in the left hand vise. First, set the micrometer to

0

degree. See Figure

E.

There are two basic parts to your micrometer: the cylinder as shown at

E-1,

and

the barrel as shown at

E-2.

There is a

0

degree

setting

on

the cylinder at

E-l

and a

0

degree

setting on t.hebarrel at

E-2.

Turn the barrel until

you line up the two

0

degree settings as shown.

Figure

E

KEY

MACHINE

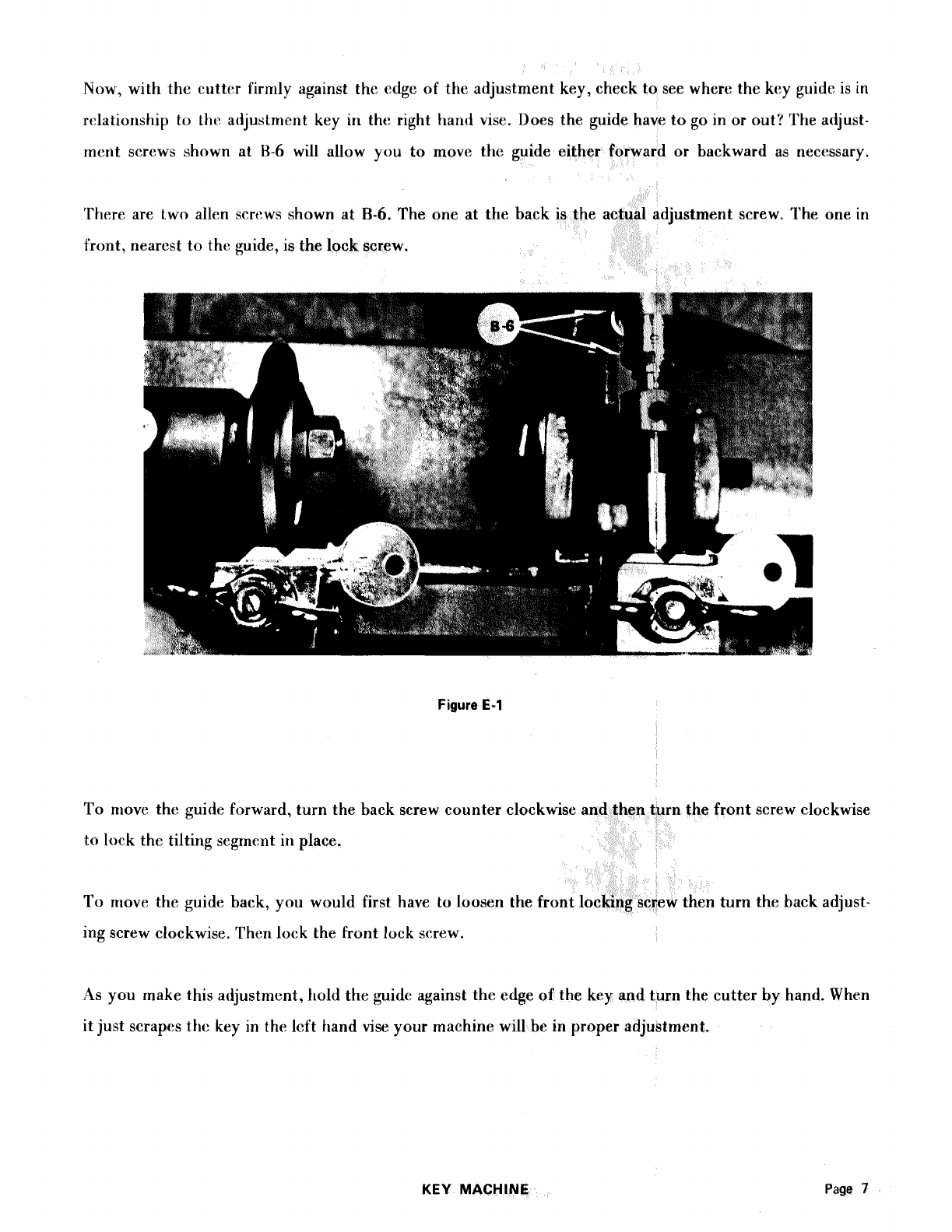

]Vow,

with the cutter firmly against the edge of the adjustment key, check to see where the key guide is in

relationship

tu

thc adjustment key in tht: right

hand

vise. Does the guide have togo in or out? The atijust-

rnerit screws shown at

H-6

will allow you to move the guide either forward or backward as necessary.

There are two allen screws shown at

B-6.

The one at the djustment screw. The one in

front, nearest tothe guide, is the lock screw.

Figure

E-1

To move the guide forward, turn the back screw counter clockwise n thefront screw clockwise

to lock the tilting segrnent in place.

To move the guide back, you would first have to loosen the fro turn the back adjust-

ing screw clockwise. Then lock the front lock screw.

As you rnake this acijustmcnt, hold the guide against the edge of the key and turn the cutter by hand. When

itjust scrapes the key in the lcft hand vise your machine will be in proper adjustment.

KEY

MACHINE

Page

7

1,UHRICATION AND CUTTER ROTATION

LIGHT

OIL

ON

MICROMETER

Figure

E-2

Use a light

#10

motor oil for-the

B-1

S

carriage machine clear of metal chips and shav

guide bar, use medium gun grease on the key times. The main shaft carrying the

machine cutter shaft. Oil the carriage guide bar factory lubricated and needs only

as needed to insure ease of operation. Be sure amount of gun grease once a year.

7

to keep this guide bar and the rest of the does not require

ANY

lubrication.

ings

cul

a

'he

I

at all

:ter is

small

motor

Figure

F

The cutter rotation is very important. The file type cutter was installed on your machine at the factory

and the teeth should he pointing DOWN. A11 cutters have teeth pointing in the same direction. AI,WAYS

install the cutters as shown in Figure

F

with the teeth pointing DOWN. lnstallatiori of a cutter with the

teeth pointing

11P

would make the cutter work in the wrong direction and damage it. The rotation of your

motor is so that the cutter revolves in the direction of Figure

I?.

This

throws the chips and shavings down

and away from your face.

Page

8

KEY

MACHINE

CODE

CUTTER

There are three types of cutters used onyour machine. Th

type file cutter was installed at the factory. 'This cutter i

cylinder keys only. This

"V"

type file cutter can be

both duplicating and cutting keys by code. The other file

in the parts hag is the one you will be using most of the time.

It is primarily for duplicating cylinder keys.

Steel

keys should

NOT be cut with these cutters. The third cutter in the parts bag

is used for cutting steel keys.

STEEL

CUTTER

Since most of your cutting on the key machine will be duplicating keys, we'll change over tothe duplicat-

ing cutter. You

will

be

using the

"V"

type cutter rnore

fo

ing cylinder keys.

In your parts bag you

will

find a file type dup

are made with the same angle

as

the cutter.

DUPLICATING STEEL

GUIDE GUIDE

CODE

GUIDE

KEY MACHINE

Page

9

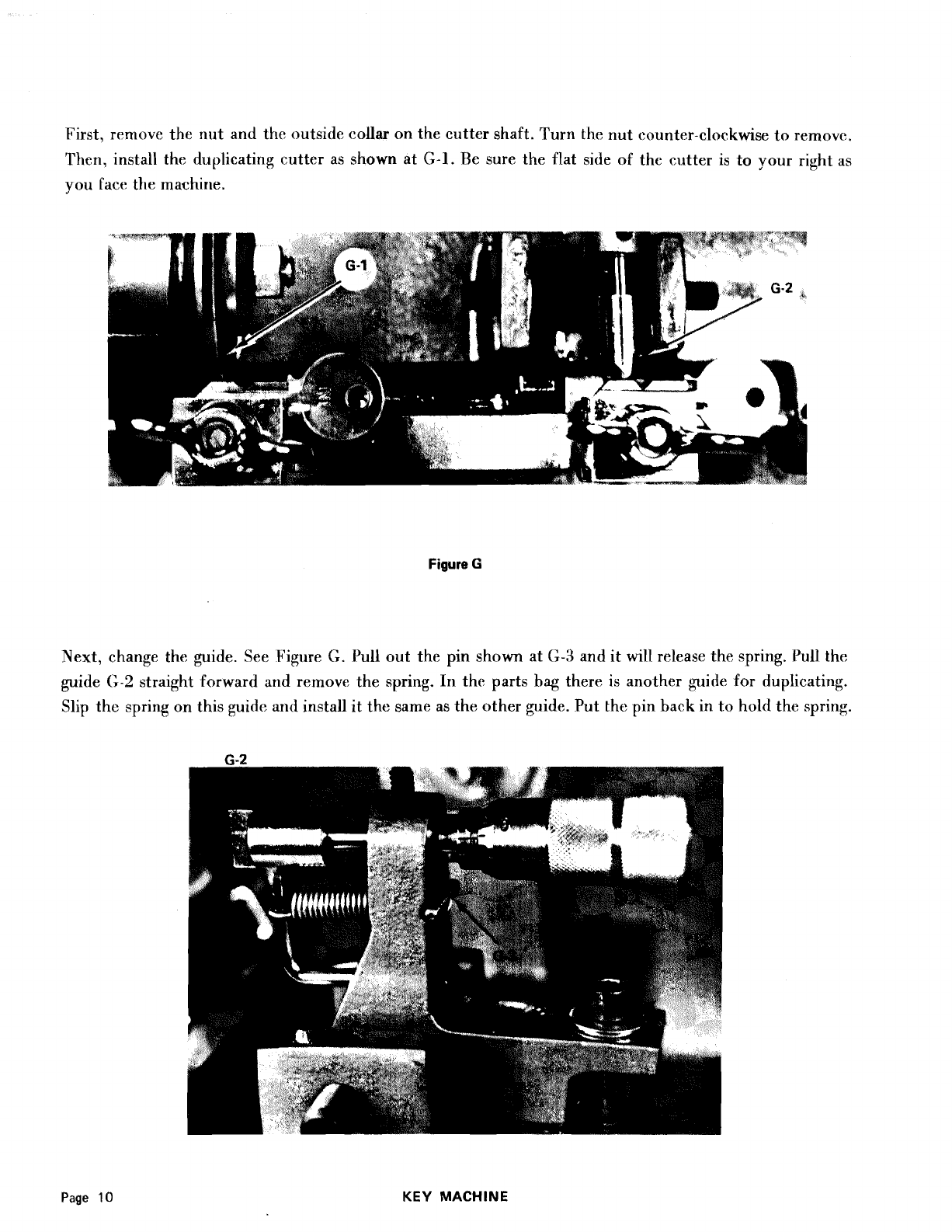

First, rrnlove the nut and tho outsido collar on the cutter shaft. l'urn the nut counter-clockwise to removo.

Then, install the duplicating cutter as shown at

G-1.

Be sure the flat side of the clatter is to your right as

you

Eacc

the machine.

Figure

G

Next, change the guide. See Figure

G.

Pull out the pin shown at

G-3

and it will release the spring. Pull the

guide

G-2

straight forward

and

rernove the spring. In the parts

bag

there is another guide for duplicating.

Slip thc spring on this guide

and

install it the sarne as the other guide. Put the pin back in to

hold

the spring.

Page

10

KEY

MACHINE

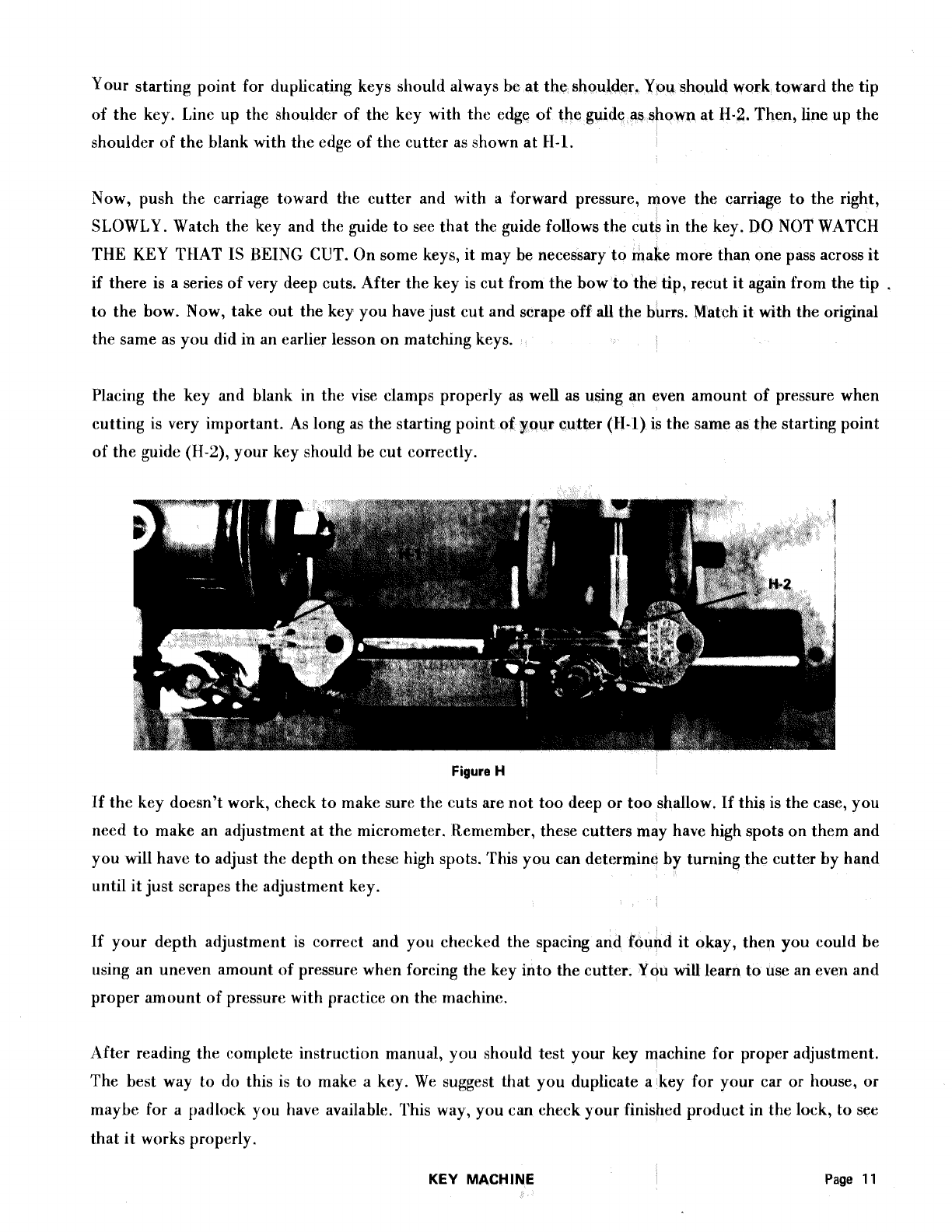

Your starting point for duplicating keys should always be at the shoulder, You should work toward the tip

of the key. Line up the shoulder of the key with the edge of the guide as shown at

H-2.

Then, line up the

shoulder of the blank with the edge of the cutter as shown at 11-1.

Now, push the carriage toward the cutter and with

a

forward pressure, move the carriage to the right,

SLOWLY. Watch the key and the guide to see that the guide follows the cuts in the key.

DO

NOT WATCH

THE KEY TI-IAT IS BEING CUT. On some keys, it may be necessary to make more than one pass across it

if there is a series of very deep cuts. After the key is cut from the bow tothe tip, recut it again from the tip

,

to the bow. Now, take out the key you have just cut and scrape off

all

the burrs. Match it with the original

the same as you did in an earlier lesson on matching keys.

Placing the key and blank in the vise clamps properly as well as using an even amount of pressure when

cutting is very irnportant. As long as the starting point of your cutter (11-1) is the same as the starting point

of the guide

(H-2),

your key should he cut correctly.

-

-

-

-

-

--

-

Figure

H

If the key doesn't work, check tomake sure the cuts arenot too deep or too shallow. If this is the case, you

need to make an adjustment at the micrometer. Remember, these cutters may have high spots on them and

you will have to adjust the depth on these high spots. 'I'his you can determine by turning the cutter by hand

until itjust scrapes the adjustment key.

If your depth adjustment is correct and you checked the spacing and found

it

okay, then you could be

using an uneven amount of pressure when forcing the key into the cutter. You will learn touse an even and

proper amount of pressure with practice on the machine.

After reading the complete instruction manual,

you

should test your key machine for proper adjustment.

The best way

to

do

this is to make

a

key. We suggest that you duplicate a key for your car or house, or

maybe for a patllock you have available. This way, you can check your finished product in the lock, to see

that it works propcrly.

KEY

MACHINE

Page

11

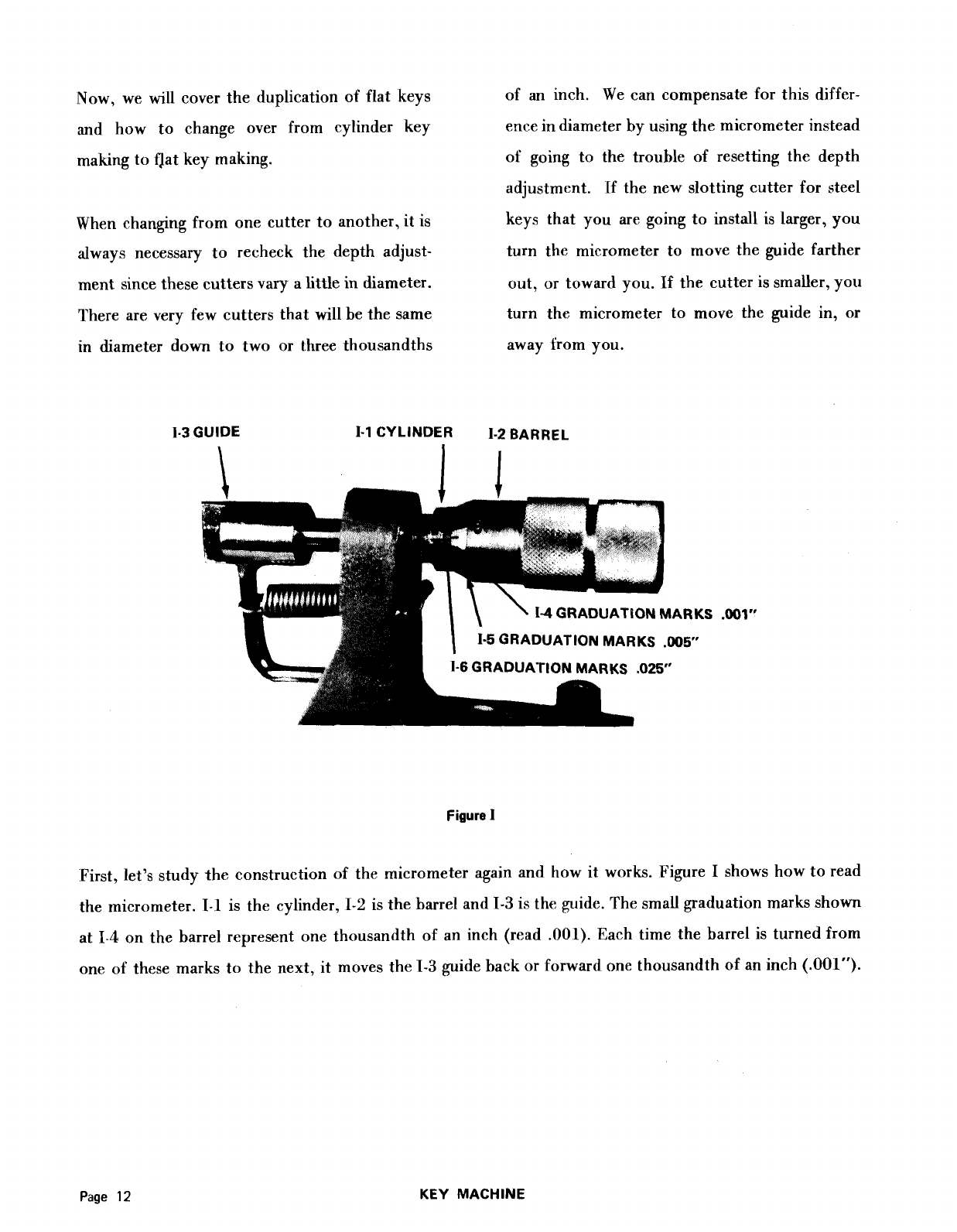

Now, we

will

cover the duplication of flat keys

and how to change over from cylinder key

making toQat key making.

When changing from one cutter to another, it is

always necessary to recheck the depth adjust-

ment since these cuttersvary a little in diameter.

There are very few cutters that will be the same

in diameter down to two or three thousandths

of

an

inch. We can compensate for this differ-

ence

in

diameter hy using the micrometer instead

of going to the trouble of resetting the depth

adjustment. [f the new slotting cutter for steel

keys that you are going to instdl is larger, you

turn the micrometer to move the guide farther

out, or toward you.

If

the cutter is smaller, you

turn the micrometer to move the guide in, or

away from you.

1-3

GUIDE

1-1

CYLINDER

1-2

BARREL

\

1-5

GRADUATIONMARKS

.W5

1-6

GRADUATIONMARKS

,025"

Figure

I

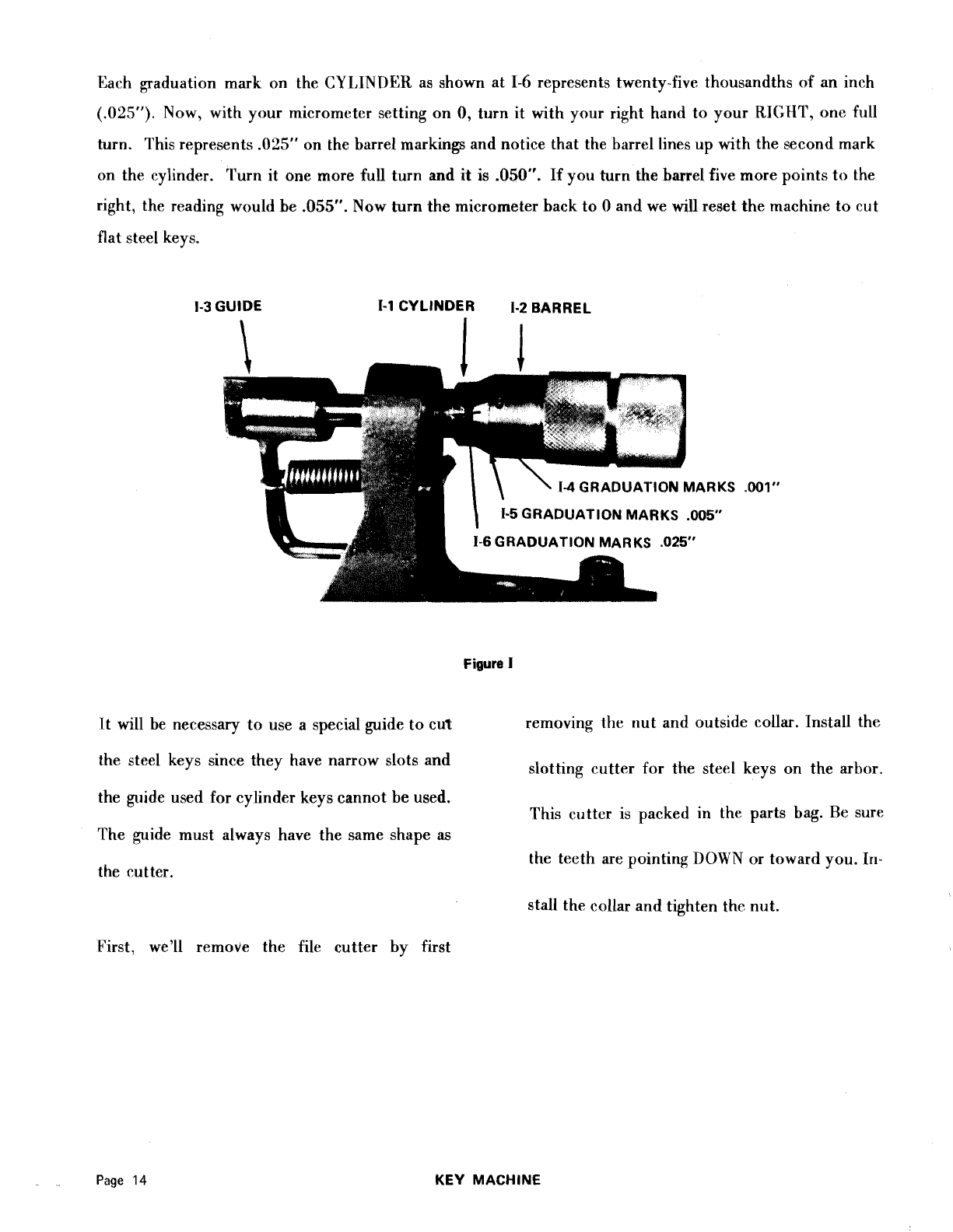

First, let's study the construction of the micrometer again and how it works. Figure

I

shows how toread

the micrometer.

1-1

is the cylinder,

1-2

is the barrel and

1-3

is the guide. The small graduation marks shown

at

1-4

on the barrel represent one thousandth of an inch (read .001). Each time the barrel is turned from

one of these marks to the next, it moves the

1-3

guide back or Forward one thousandth of an inch (.001").

Page

12

KEY MACHINE

1-3

GUIDE

1-1

CYLINDER

1-2

BARREL

-5

GRADUATION MARKS

.00W

There are

25

of these graduation marks around the barrel wh -five thousandthsof an

inch

(.025").

If

you turn the barrel one complete circle, ould move the

1-3

guide

.025**.

The second

graduation marks on the barrel are shawn

at

1-5.

The epresent five thousandths of

an

inch

(.005").

By turning the barrel from one mar

0

degree to

5

would move

the guide

.005".

All

you have toremember for the barrel graduation

marks

is

that the short ones represent

-001"

and the long onesrepresent

.005"

and one complete circle represents

.025".

To make these decimals

clear in your mind, the following shows the decimal equivalent of the inch and how toread it:

.001"

..........

One thousandths of an inch

.005"

..........

Five thousandths

.025"

..........

Twenty-five thousandths

.05Ou

..........

Fifty thousandths

.075"

..........

Seventy-five thousandths

.100"

..........

One hundred thousandths

..........

.125"

One hundred and twenty-five thousandths

.150"

..........

One hundred and fifty thousandths

.175"

..........

One hundred and seventy-fivethousandths

.200"

..........

Two hundred thousandths

KEY MACHINE

Page

13

Rach graduation mark on the

CY1,INI)E:R

as shown at

1-6

represents twenty-five thousandths of an inch

(-025").

Now, with your micrometer setting on

0,

turn it with your right hard to your

RIGHT,

one f~ll

turn. This represents

.025"

on the barrel markings and notice that the barrel lines up with the second mark

on the cylinder. Turn it one more full turn and

it

is

.050".

If you turn the barrel five more points to the

right, the reading would be

.055".

Now turn the micrometer back to

0

and we will reset the machine to cut

flat steel keys.

1-3

GUIDE

1-1

CYLINDER 1-2 BARREL

-5GRADUATIONMARKS .005"

-6

GRADUATION MARKS .025"

Figure

I

It will be necessary to use a special guide tocut removing the nut and outside collar. Install the

the steel keys since they have narrow slots and slotting cutter for the steel keys on the arbor.

the guide used for cylinder keys cannot be used. This cuttcr is packed

in

the parts bag. Re sure

The guide must always have the same shape

as

the teeth are pointing

DOWN

or toward you.

111-

the cutter.

stall the collar and tighten the nut.

First, we'll remove the file cutter by first

Page

14

KEY MACHINE

Other manuals for 200

1

Popular Tools manuals by other brands

U-Line

U-Line H-3402 quick start guide

Rose electronics

Rose electronics ALL2GETHER owner's manual

MSW Motor Technics

MSW Motor Technics MSW-PTM-01 user manual

Berner

Berner X-Lux Wireless instruction manual

Max

Max TA551A/16-11 CE Operating and maintenance manual

Roller

Roller ROLLER'S King 1 instruction manual