Pencil Line

DIAGRAM B

MALE JOINT—

WORKTOP FACE

DOWN

Left Hand 90° Joints

Page 6

1. FEMALE JOINT Refer to the diagrams on the different joints

available. For the female cut in your worktop, position the jig as

shown in diagram Aand the worktop face up and the post formed

(curved edge) towards you.

2. Insert three pins in the holes marked ‘♀’.

3. Insert the 4th pin in the hole dependant on your worktop width. e.g. If

your worktop is 650mm wide (as shown in diagram A) then insert the

4th pin in the hole marked 65.

4. Make sure the 3 pins in the holes marked with ’♀’are firmly pushed

against the front post formed edge and the pin in the hole marked

with the worktop width is pushed firmly against the edge of the

worktop (see diagram A)

5. Clamp the jig to the worktop checking that all 4 pins are still against

the worktop. Make sure the clamps will not obstruct the router path.

6. CUTTING Position the router in the far left side of the central

slot. Set the router to cut a depth of 10mm.

7. IMPORTANT - Position the router in the slot and cut from left to

right, pulling the router against the edge of the slot closest to

you.

8. Remove the router, and start again from the far left of the central

slot, but increase the depth a further 10mm.

9. Follow steps 6– 8, until cut is complete.

10. For the final finishing cut, position the router again in the far left side

of the central slot, and set the router to cut at the full depth of the

worktop. Again, cut from left to right but apply the pressure to the

edge furthest away from you.

11. MALE JOINT For the male cut in your worktop, prepare the

worktop face down and turn the jig over from the face used

previously.

12. Insert 2 pins in holes marked ‘♂’.

13. Refer to the page on ‘cutting to length’ on page 8 to find out where to

mark the pencil line to determine the position of the jig along the

length of the worktop.

14. Make sure the 2 pins in the holes marked ‘♂’ are firmly pushed

against the post formed edge (see diagram B)

15. Clamp the jig to the worktop checking that both pins are still against

the worktop. Make sure the clamps will not obstruct the router path.

16. Follow steps 6 to 10 for cutting the worktop.

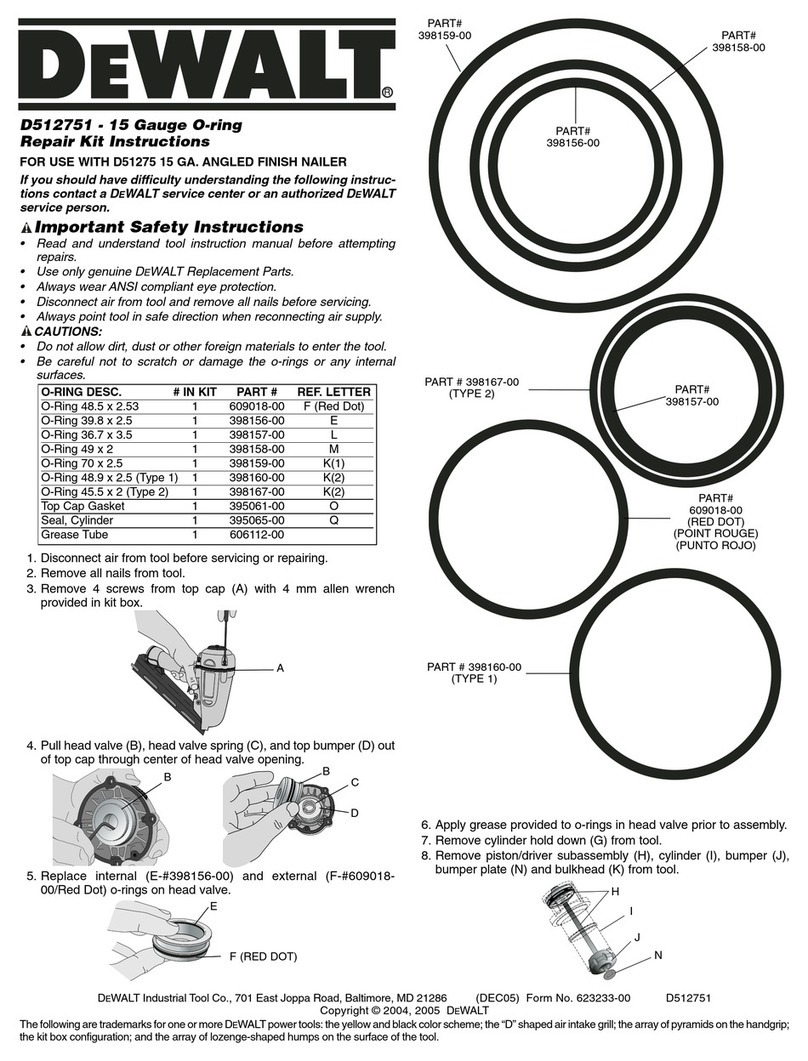

17. FEMALE BOLT RECESSES Take the worktop into which you have

cut the female cut and position the worktop face down.

18. Position the jig as shown in diagram C, and insert 4 pins in the

holes which have a symbol resembling a worktop connector bolt

recess as indicated on diagram C.

19. Make sure the 4 pins are firmly pushed against the front cut out and

the edge of the worktop.

20. Clamp the jig to the worktop checking that all 4 pins are still firmly

against the worktop. Make sure the clamps will not obstruct the

router path.

21. You will need a depth of 20mm for the worktop connectors. Do not

exceed 10mm per cut.

22. Cut the bolt recesses out, each time clearing the waste material after

each cut.

23. MALE BOLT RECESSES Take the worktop into which you have

cut the male cut and position the worktop face down.

24. Position the jig as shown in diagram D and insert 4 pins in the holes

which have a symbol resembling a worktop connector bolt recess -

this was shown in diagram C.

25. Make sure the 4 pins are firmly pushed against the front cut out and

the edge of the worktop.

26. Clamp the jig to the worktop checking that all 4pins are still firmly

against the worktop. Make sure the clamps will not obstruct the

router path.

27. You will need a depth of 20mm for the worktop connectors. Do not

exceed 10mm per cut.

28. Cut the bolt recesses out, each time clearing the waste material after

each cut.

DIAGRAM D

MALE BOLT RECESS -

WORKTOP FACE DOWN.

DIAGRAM C

FEMALE BOLT RECESS -

WORKTOP FACE DOWN.

DIAGRAM A

FEMALE JOINT -

WORKTOP FACE UP

Pencil Line

Right Hand 90° Joints

Page 7

1. FEMALE JOINT For the female cut in your worktop, position the

jig as shown in diagram A and the worktop face down and the post

formed (curved edge) towards you.

2. Insert three pins in the holes marked ‘♀’.

3. Insert the 4th pin in the hole dependant on your worktop width, e.g.

If your worktop is 650mm wide then insert the 4th pin in the hole

marked 65 (see diagram A).

4. Make sure the 3 pins in the holes marked ’♀’ are firmly pushed

against the front post formed edge and the pin in the hole marked

with the worktop width is pushed firmly against the edge of the

worktop (see diagram A)

5. Clamp the jig to the worktop double-checking that all 4 pins are still

against the worktop. Make sure the clamps will not obstruct the

router path.

6. CUTTING Position the router in the far left side of the central slot.

Set the router to cut a depth of 10mm.

7. IMPORTANT - Position the router in the slot and cut from left

to right, pulling the router against the edge of the slot closest

to you.

8. Remove the router, and start again from the far left of the central

slot, but increase the depth a further 10mm.

9. Follow steps 6 – 8, until cut is complete.

10. For the final finishing cut, position the router again in the far left

side of the central slot, and set the router to cut at the full depth of

the worktop. Again, cut from left to right but apply the pressure to

the edge furthest away from you.

11. MALE JOINT For the male cut in your worktop, prepare the

worktop face up and turn the jig over from the face used previously.

12. Insert 2 pins in holes marked ‘♂’.

13. Refer to the page on ‘cutting to length' on page 8 to find out where

to mark the pencil line to determine the position of the jig along the

length of the worktop.

14. Make sure the 2 pins in the holes marked ’♂’are firmly pushed

against the post formed edge (see diagram B)

15. Clamp the jig to the worktop checking that both pins are still

against the worktop. Make sure the clamps will not obstruct the

router path.

16. Follow steps 6 to 10 for cutting the worktop.

17. FEMALE BOLT RECESSES Take the worktop into which you

have cut the female cut and position the worktop face down.

18. Position the jig as shown in diagram C, and insert 4 pins in the

holes which have a symbol resembling a worktop connector bolt

recess as indicated in diagram C.

19. Make sure the 44 pins are firmly pushed against the front cut out

and the edge of the worktop (see diagram C).

20. Clamp the jig to the worktop checking that all 4 pins are still firmly

against the worktop. Make sure the clamps will not obstruct the

router path.

21. You will need a depth of 20mm for the worktop connectors. Do not

exceed 10mm per cut.

23. Cut the bolt recesses out, each time clearing the waste material

after each cut.

23. MALE BOLT RECESSES Take the worktop into which you have

cut the male cut and position the worktop face down.

24. Position the jig as shown in diagram D and insert 4 pins in the

holes which have a symbol resembling a worktop connector bolt

recess as indicated in diagram C.

24. Make sure the 4 pins are firmly pushed against the front cut out

and the edge of the worktop (see diagram D).

25. Clamp the jig to the worktop checking that all 4 pins are still firmly

against the worktop. Make sure the clamps will not obstruct the

router path.

26. You will need a depth of 20mm for the worktop connectors. Do not

exceed 10mm per cut.

27. Cut the bolt recesses out, each time clearing the waste material

after each cut.

DIAGRAM A

FEMALE JOINT -

WORKTOP FACE DOWN

DIAGRAM B

MALE JOINT—

WORKTOP FACE UP

DIAGRAM C

FEMALE BOLT RECESS -

WORKTOP FACE DOWN.

DIAGRAM D

MALE BOLT RECESS —

WORKTOP FACE DOWN.