Fona XDG User manual

FONA XDG

Service and Installation Manual

English

FONA XDG –Service & Installation Manual

2/32 69 550 70210 150715

Table of Contents

FONA XDG Service and Installation Manual

English Edition

Version 150715 July 2015

Code 69 550 70210

Manufactured by FONA S.r.l.

Via Galilei 11 - 20090 Assago (MI) Italy

Distributed by FONA Dental s.r.o.

Stefanikova 7 SK-811 06 Bratislava, Slovakia www.fonadental.com

1. INTRODUCTION................................................ 4

1.1 PURPOSE........................................................ 4

1.2 EQUIPMENT CLASSIFICATION.............................. 4

1.3 APPLICABLE STANDARDS ................................... 4

1.4 ENVIRONMENTAL DATA .................................... 4

1.5 OBLIGATIONS OF THE INSTALLER ......................... 4

1.6 WARNING ...................................................... 4

1.7 DEMONSTRATION ............................................ 4

2. TECHNICAL DATA ............................................. 5

2.1 SYSTEM SUPPLY............................................... 5

2.2 X-RAY HEAD ASSEMBLIES .................................. 5

2.3 BEAM LIMITING DEVICE .................................... 5

2.4 TIPSET TIMER ................................................. 5

2.5 MECHANICAL SUSPENSION SYSTEM ..................... 5

2.6 WEIGHTS ....................................................... 5

3. ASSEMBLY AND INSTALLATION ........................ 6

3.1 WALL MOUNTED SYSTEMS ................................ 6

3.2 DIP SWITCH SETTING ...................................... 16

3.3 LAYOUT POWER BOARD TIMER......................... 17

3.4 MOBILE SYSTEMS .......................................... 18

3.5 MOUNTING THE TIMER ................................... 19

4. MAINTENANCE............................................... 20

4.1 MAINTENANCE OF WALL ADAPTOR................... 20

4.2 MAINTENANCE OF SUPPORT ARM..................... 20

4.3 MAINTENANCE OF SCISSOR ARM ...................... 21

4.4 MAINTENANCE OF X-RAY HEAD........................ 22

4.5 MAINTENANCE OF BEAM LIMITING DEVICE......... 22

4.6 MAINTENANCE OF TIMER................................ 22

4.7 CHECKING FILAMENT PRE-HEATING TIME .......... 22

4.8 SERVICE FUNCTIONS....................................... 23

5. MEASUREMENTS ............................................ 24

5.1 LINE VOLTAGE .............................................. 24

5.2 ANODE VOLTAGE –KVP................................. 24

5.3 ANODE CURRENT –MA .................................. 24

5.4 EXPOSURE TIME ............................................ 24

5.5 LEAKAGE RADIATION ...................................... 25

5.6 EARTH RESISTANCE-....................................... 25

5.7 EARTH LEAKAGE ............................................ 25

APPENDIX A SYSTEMS AND COMPONENTS ............ 26

APPENDIX B ICONS................................................. 27

APPENDIX C EXPOSURE TABLE ............................... 28

APPENDIX D ALARM CONDITIONS ......................... 29

APPENDIX E IDENTIFICATION LABELS ..................... 30

APPENDIX F COOLING CURVES ............................... 31

FONA XDG –Service & Installation Manual

150715 69 550 70210 3/32

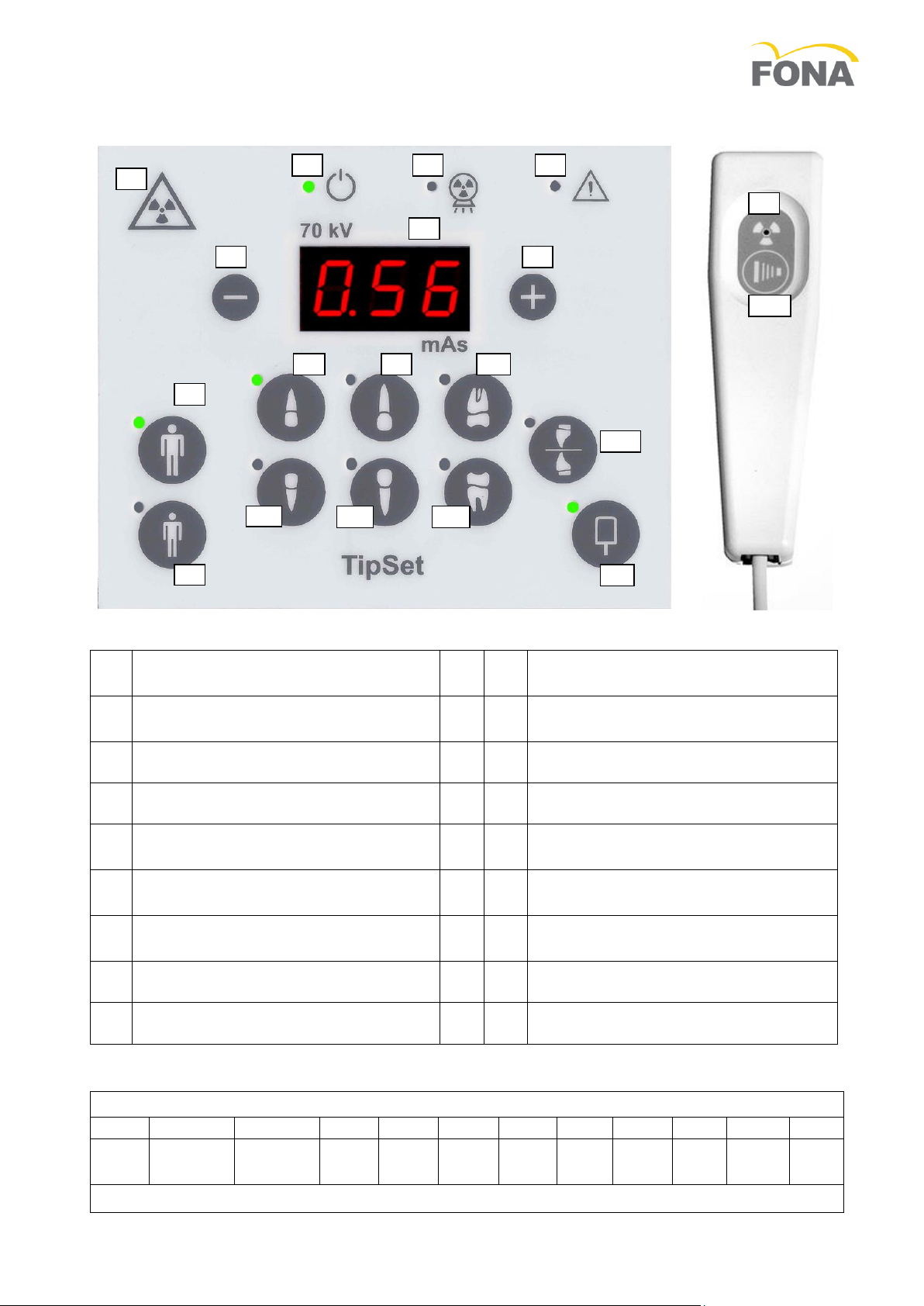

The Control Panel

1

Device for emission of ionizing

radiation on request

10

Maxillary incisor

2

Indication of system turned on and

ready

11

Maxillary canine or premolar

3

Irradiation

12

Maxillary molar

4

Alarm

13

Mandibular incisor

5

mAs display, the controlled

technique factor

14

Mandibular canine or premolar

6

Manual decrease of controlled

technique factor

15

Mandibular molar

7

Manual increase of controlled

technique factor

16

Bite-wing premolar

8

Patient size adult/large

17

Digital detector in use

9

Patient size child/small

18

Radiation exposure pushbutton

EXPOSURE INDEX

0.32

0.4

0.5

0.63

0.8

1.0

1.25

1.6

2.0

2.5

3.2

4.0

CDR

SENSOR

XIOS

SENSOR

F

FILM

E

FILM

D

FILM

CDR Sensor by Shick Technologies Inc., XIOS Sensor by Sirona Dental Systems GmbH

18

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

FONA XDG –Service & Installation Manual

4/32 69 550 70210 150715

1. INTRODUCTION

1.1 Purpose

The FONA XDG X-ray Equipment is designed to fulfil the needs for high resolution intra-oral radiography in

the general dental practice. The systems can be configured for wall, mobile solutions.

The Operator’s Manual and the Service and Installation Manuals supplied with the system are integral part

of the product. The original language of the Operator’s Manual is English.

1.2 Equipment Classification

IEC: FONA XDG is a Class I, type B equipment

FDA: FONA XDG is a Class II medical device equipment (21 CFR 872-1800).

1.3 Applicable Standards

The FONA XDG system configurations comply with the following standards.

IEC 601-1

General requirements for safety

IEC 601-1-2

Electromagnetic compatibility

IEC 601-1-3

General requirements for radiation protection in diagnostic X-ray equipment

IEC 601-2-7

Particular requirements for the safety of high voltage generators of diagnostic

X-ray generators

IEC 601-2-28

Particular requirements for the safety of X-ray source assemblies and X-ray

tube assemblies for medical diagnosis

21 CFR 1020.30

Diagnostic x-ray systems and their major components

21 CFR 1020.31

Radiographic equipment

93/42/EEC

European Directive concerning medical devices (1993)

1.4 Environmental Data

Applicable ranges of temperature, humidity, and atmospheric pressure are reported here below both for

operation and transport conditions.

Ambient

Transport & Storage

Temperature

from 10 to 40 °C

from –20 to +50 °C

Relative Humidity

from 30 to 75%

10 to 90%

Pressure

from 700 to 1060 hPa

from 500 to 1060 hPa

1.5 Obligations of the Installer

Obligations of the Installer are:

To make sure that the line voltage specified by the Manufacturer of the equipment is available

and within the specified range.

For safety reasons verify that a proper switch is available to disconnect from line voltage supply when

needed during installation.

Install and test the equipment with due diligence according to the installation instructions from the

Manufacturer.

To provide the Operating Instructions to the User.

1.6 Warning

Use the system only after proper assembly and installation as per manufacturer’s instructions.

X-ray equipment produce ionizing radiation that may be harmful if not properly controlled. It is therefore

recommended that the equipment be operated by trained personnel only in accordance with existing law.

Even if compliant to specifications of electromagnetic compatibility, it is recommended not to use the

equipment in presence of external electromagnetic fields, such as those generated by cellular phones,

which might interfere with the electronic circuits of the system.

1.7 Demonstration

In order to use of the system for demonstration purposes radiation emission has to be inhibited by

disconnecting the supply cables to the X-ray head into the wall adaptor or into the timer.

Cables to be disconnected are those leaving the connection block towards the X-ray head (“out”).

Make sure that the disconnected cables are properly insulated to prevent undesired contacts with live

points. This task has to be done by trained personnel only to avoid the risk of electrical shock.

FONA XDG –Service & Installation Manual

150715 69 550 70210 5/32

2. TECHNICAL DATA

2.1 System Supply

Line Voltage

110-120 V (from 99 V to 132 V in sub-ranges depending on THA mounted)

220-240 V (from 198 V to 264 V in sub-ranges depending on THA mounted)

Line Power

400 W

Line Voltage Range

108 - 132 V for type 93 256 01300, 207 - 253 V for type 93 256 01700,

216 - 264 V for type 93 256 01800

Line Fuse

Slow Blow: 6.3 A at 110-120 V, 4 A at 220-240 V, second fuse for 2 phases or cord

Line Frequency

50/60 Hz 1 Hz

Line Resistance

0.4 Ohm at 110-120 V, 0.8 Ohm at 220-240 V

Voltage regulation for max. line current: 2.1% at 110-120 V, 1.4% V at 220-240 V

2.2 X-ray Head Assemblies

Nominal Line Voltage

120 V for type 93 256 01300, 230 V for type 93 256 01700,

240 V for type 93 256 01800

Nominal Line Current

6 A at 120 V for type 93 256 01300, 4 A at 230 V for type 93 256 01700,

4 A at 240 V for type 93 256 01800

Anode Voltage

(peak tube potential)

70 kVp ± 8% at nominal line voltage

66 kVp ± 8% at nominal line voltage –10%

74 kVp ± 8% at nominal line voltage+ 10%

Anode Current

(tube current)

3.5 mA ± 10% at nominal line voltage

3.0 mA ± 10% at nominal line voltage –10%

4.0 mA ± 10% at nominal line voltage + 10%

Nominal Power

0.2 kW at 70 kVp, 3.5 mA, 0.1 s

X-ray Insert

CF4G070

Anode

Tungsten, angle 16° to the tube axis

Focal Spot

0.4 (EN 60336:1995-04)

Focal spot mark

Dot embossed on plastic covers of tube-head

Inherent Filtration

> 2.5 mm Al/70kVp (EN 60522: 1999)

Duty Cycle

1/15

Radiation Leakage

< 0.1 mGy/h a 1 m (< 11.5 mR/h a 1 m)

2.3 Beam Limiting Device

Beam Limiting

Device

Focus skin distance 21 cm (8.27”)

Circular radiation field 6 cm (2.35”) diameter /Rectangular 3.2x4.2 cm

(1.26”x1.65”)

Maximum 10% eccentricity

2.4 TipSet Timer

Supply Voltage

110-120 for type 93 354 60200, 220-240 for type 93 354 60100

Exposure factor

Time-current in mAs: from 0.21 to 11.2 mAs

0.21

0.28

0.35

0.42

0.56

0.70

0.88

1.12

1.40

1.75

2.20

2.80

3.50

4.40

5.60

7.00

8.75

11.2

Precision

± 0.04 mAs o 10% (whichever the greater) supplied at nominal line voltage

Exposure factors

Automatic setting through tooth type selection and patient build, for use with

traditional film or digital sensor, or manual setting with plus and minus keys.

Irradiation signal

Yellow light on hand-switch and on control panel plus acoustic buzzer

Hand-switch

Hand-switch with 3 m coiled cord, with remote mounting optional kit

Overall size

Width: 15 cm /6”, Height: 24 cm /9”½, Depth: 9 cm /3”½

2.5 Mechanical Suspension System

Wall Adaptor

12 cm /4.7” width, 24 cm /9.4” height, 9 cm /3.5” depth

Arm Length

Short (S): 30 cm /11.8”, Medium (M): 60 cm /23.6”,

Long (L): 80 cm /31.5”, Extra Long (XL) 100 cm /39,4”

Useful Reach

Arm S: 138 cm /54.3”, M: 168 cm /66.1”, L: 188 cm /74”, XL: 208 cm /81.9”

Mobile Stand

Size 78 x 92 cm (30” ¾ x 36” ¼), Height: 186 cm /73” ¼” with scissor arm

2.6 Weights

Timer

1.7 kg / 3.7 lb

Support Arm

Arm S: 2.8 kg /6.2 lb , M: 4.0 kg /8.8

lb, L: 4.8 kg /10.6 lb,

XL: 5.4 kg /11,9 lb

X-ray Head

6.6 kg / 14.5 lb

Circular BLD

0.1 kg / 0.22 lb

Rectangular BLD

0.2 kg / 0.44 lb

Wall Adaptor

1.3 kg / 2.9 lb

Scissor Arm

11.7 kg / 25.8 lb

Mobile Stand

29.4 kg / 64.8 lb

FONA XDG –Service & Installation Manual

6/32 69 550 70210 150715

T1

T2

T3

B1

B2

B3

3. ASSEMBLY AND INSTALLATION

3.1 Wall Mounted Systems

3.1.1 Installation Options

The timer box can be mounted together with the X-ray head on the right of the wall adaptor or can be

placed remote either inside or outside the examination room. The release hand-switch can be directly

connected to the timer box or placed remote making use of specific mounting kit including 10 m cable. A

door contact and/or a second exposure button can be added via the internal socket on the timer board.

3.1.2 Unpacking

Unpack the components of the system and check the following:

AEach item is in good conditions and was not damaged during

transportation.

BAll the items for the desired system configuration are available.

CThe line voltage on the labels of timer and X-ray head are

corresponding to the local line voltage.

3.1.3 Structural Requirements

The wall adaptor has to be mounted in a convenient position on left or

right side of the chair or on back wall (head of the patient).

The maximum useful reach is of 208 cm (81.9”) from the wall when using

an 100 cm (39.4”) support arm.

The wall adaptor can be mounted with 2, 4, or 6 bolts, depending on wall

quality.

ATwo bolts only (top and bottom central holes –T2, B2) are used when

there is a solid slim column (e.g. iron mounting) with weak sides (e.g.

wooden wall). Considering the requested safety factor, the top bolt

has to withstand a load of 8878 N, comprehensive of a safety factor,

i.e. about 2013 lbs or 906 kg. Proper screw to be selected for a solid

connection to the wall. Classes ISO 8.8 (M 8, M 8x1, M 8x1.25) or SAE

Grade 5 (5/16” 18UNC, 5/16” 24 UNF) are recommended.

BFour bolts, two on top sides (T1, T3) and two on bottom sides (B1,

B3) is the regular mounting for solid (concrete) wall, but also on large metal plate. Considering the

requested safety factor, each bolt at top has to withstand a load of 4439 N, comprehensive of a safety

factor, i.e. about 1007 lbs or 453 kg.

Proper expansion screw to be selected for a solid connection to the concrete wall; the permissible load

of each screw has to be greater than 308 lbs (about 140 kg).

On solid concrete use heavy duty metal anchors.

On hollow bricks use injection chemical fixing.

CSix bolts, three on top (T1, T2, T3) and three at bottom (B1, B2, B3) are required when the wall is not

solid enough and the load has to be distributed on more points. Considering the requested safety

factor, each bolt at top has to withstand a load of 2959 N, comprehensive of a safety factor, i.e. about

671 lbs or 302 kg.

In case the wall is not in condition to withstand the indicated load, corrective actions can be evaluated by

adoption of reinforcing plates:

DLarge plate to fit vertical supports at 16” distance, with 4 mounting holes and one cable opening for

the wall mount in the middle.

EIn case of a thin (wooden) wall not solid enough, the use of a steel counter plate 2 mm thick can be

the solution. Make sure that the wall is solid enough to carry the load.

FThe use of two reinforcing steel plates of about 4 times the surface of the wall adaptor, one by each

side of the wall, can help when a single plate looks not adequate; additional bolts have to be used to

hold together the two plates.

Make sure that the wall is solid enough to carry the load.

Recommended Bolts

Diameter

Class

Core Section mm2

M 8X1.25

ISO 8.8

36.6

M 8X1

ISO 8.8

39.2

5/16” – 18 UNC

SAE- Grade 5

33.8

5/16 –24 UNF

SAE- Grade 5

37.41

INSUFFICIENT WALL OR HARDWARE STRENGHT MAY CAUSE THE WALL ADAPTOR TO

PULL OUT FROM THE WALL AND THE FULL SYSTEM TO FALL ON TO THE PATIENT OR

THE OPERATOR CAUSING INJURIES.

FONA XDG –Service & Installation Manual

150715 69 550 70210 7/32

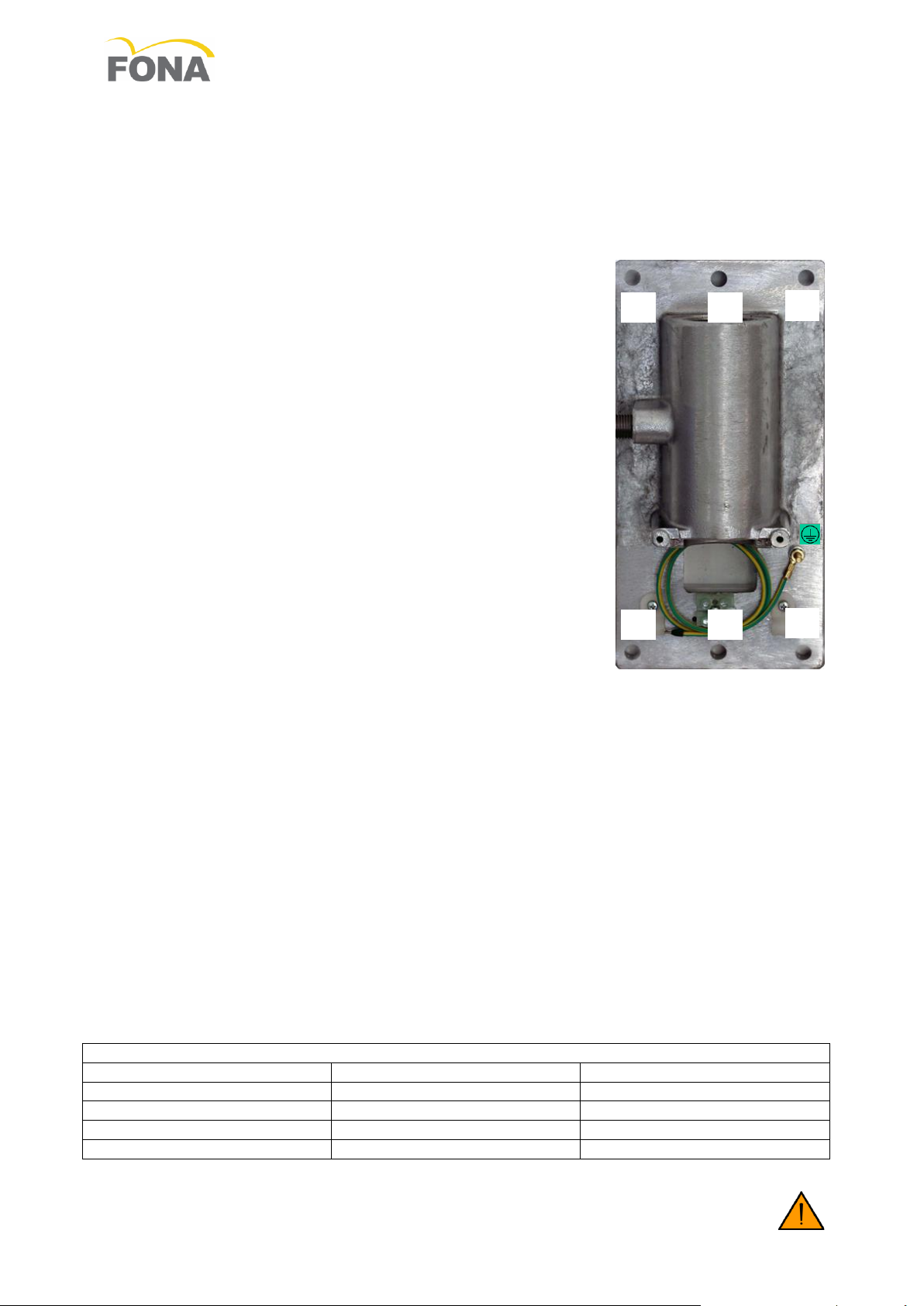

INPUT

POWER

LINE

SWITCH

ELECTRONIC

TIMER

WALL

ADAPTOR

IN

OUT

X-RAY

HEAD

3.1.4 Electrical Requirements

The power line cable must be connected to the input terminals (IN) of the timer to supply the timer itself

and to make available power for the X-ray head at the output terminals (OUT), upon request by the

operator (via the hand switch). Power to the X-ray head is thus controlled by the timer (acting as a

SWITCH).

The cables (2 poles plus ground) to connect the power line to the timer and the timer to the wall adaptor

are not provided. Cables with large section conductors have minimum electrical resistance and voltage

drop.

Wire Type

Cross Section Area

Resistance/m

m/0.05 Ohm

AWG 14

2.08 mm2

0.00829 Ohm/m

6.0 m

AWG 12

3.31 mm2

0.00521 Ohm/m

9.6 m

The resistance between the ground provision in the connecting block of the timer and the metal body of

the tube housing assembly has not to exceed 0.1 Ohm. Proper section of the yellow green wire to be used

in case remote mounting of the timer.

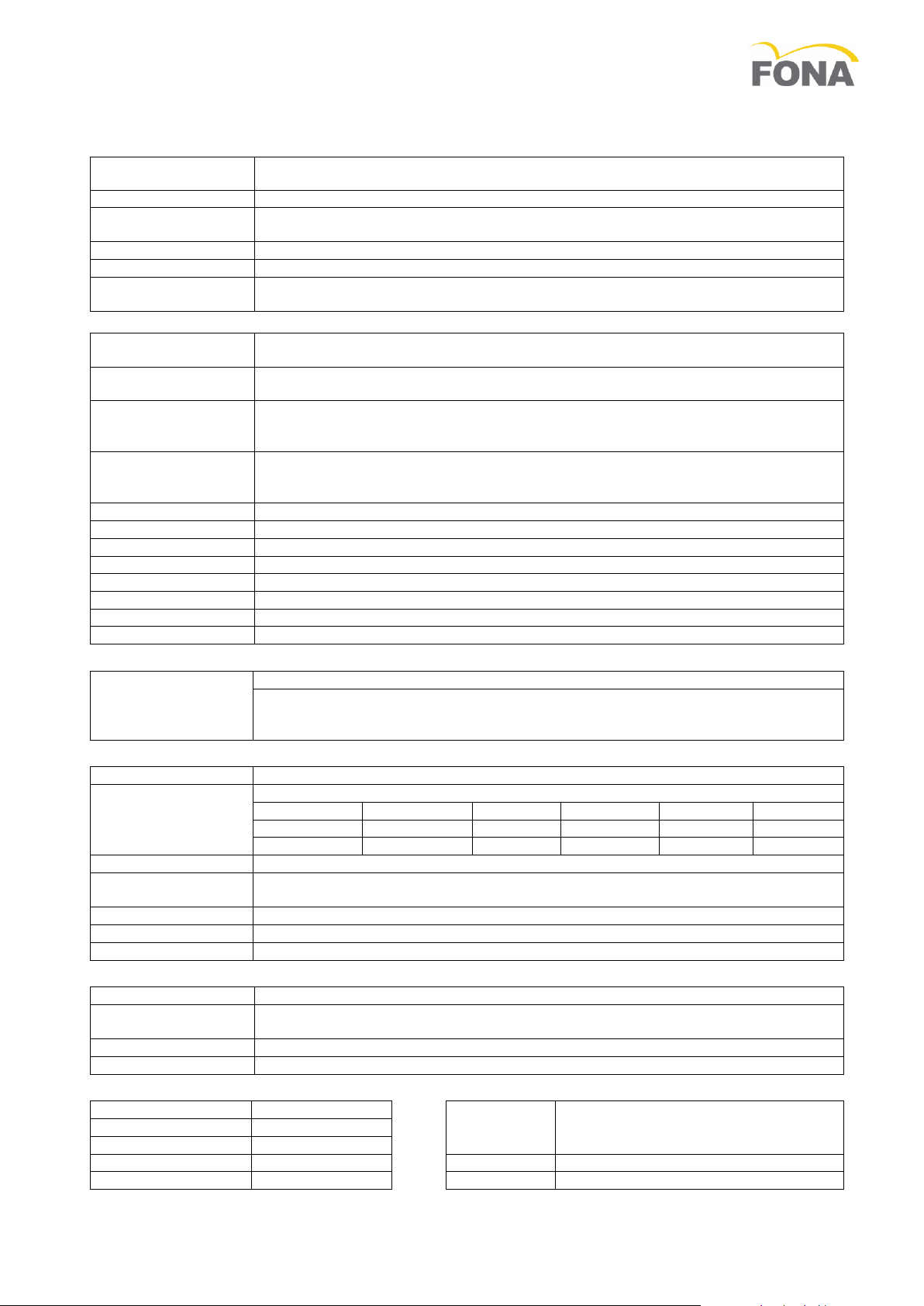

The wall adaptor is provided with a common bolt for bonding and grounding blocked in place

with a nut which has not to be removed.

The grounding conductors to be connected as indicated below.

First the conductor to ground provision in the connecting block of the timer (flat washer, ground

provision, flat washer, lock-washer, nut).

Second the bonding conductor of support arm plus, in case, the one of the cable in the scissor arm

(flat washer, bonding conductors, flat washer, lock-washer, nut).

NUT

NUT

BLOCKING NUT DO

NOT REMOVE

FLAT WASHER

FLAT WASHER

LOCK-WASHER

GROUND PROVISION

TO TIMER

LOCK-WASHER

BONDING

CONDUCTOR OF

SUPPORT ARM

BONDING CONDUCTOR

OF SCISSOR ARM

(IN CASE)

COMMON BOLT

METAL BODY OF WALL SUPPORT

FLAT WASHER

FLAT WASHER

FONA XDG –Service & Installation Manual

8/32 69 550 70210 150715

3.1.5 Mounting and Connecting Sequence

Step 1

Mount the Wall Adaptor

Step 7

Connect the Hand-Switch

Step 2

Mount the Timer

Step 8

Optional Remote Hand-Switch

Step 3

Mount the Support Arm

Step 9

Mount and connect X-ray head

Step 4

Mount the Scissor Arm

Step 10

Mount the collimator

Step 5

Connect the Wall Adaptor

Step 11

Final Tuning and Set-Up

Step 6

Connect the Timer

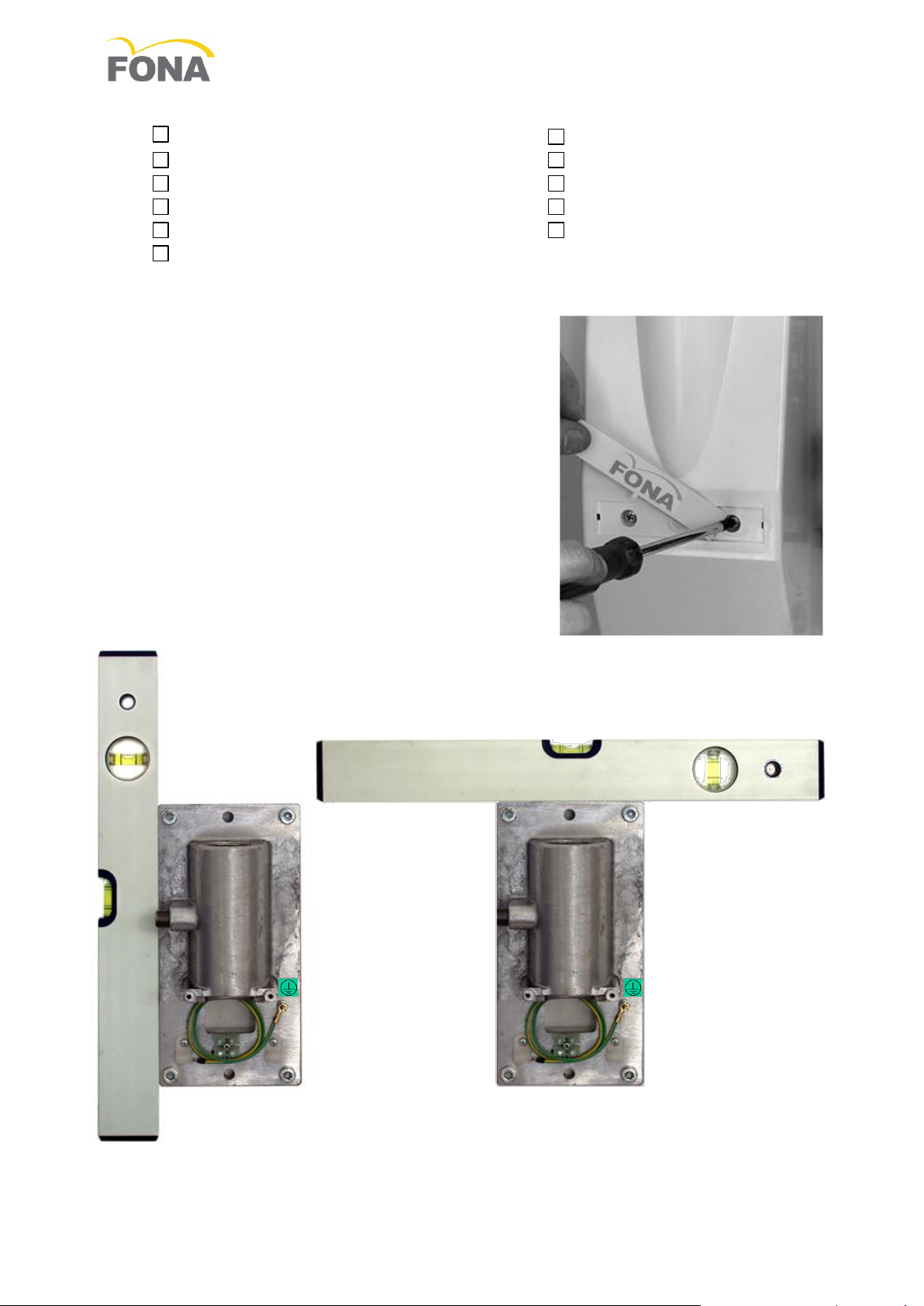

3.1.6 Mounting the Wall Adaptor

ATake away the plastic cover removing the screws under the

logo label.

BUse the Wall Adaptor plate or a template to mark the holes on

the wall.

Please note that the timer can be mounted close to the Wall

Adaptor on the right side or in a remote position. Cabling

should have been laid out accordingly.

CMake the holes in the wall according to the applicable type of

mounting with two, four bolts, or six bolts, with or without

reinforcing plate.

DSlide the logo-strip out from the plastic cover to access the

screws and remove it from the metal frame.

EMount the metal frame on the wall using proper heavy-duty

metal anchors and make sure that the power cable enters

from behind.

FSecure it to the wall ensuring it is leveled. Improper leveling

might cause the arm to move and swing out of position.

GPerform wire connection and final set-up complying with

recommended sequence of actions reported in the following.

FONA XDG –Service & Installation Manual

150715 69 550 70210 9/32

3.1.7 Mounting the Timer

AUse the mounting plate or the template to mark the

holes on the wall.

BRemove the plastic cover after having taken away the

blocking screws behind the logo strip. Pay attention

when disconnecting the flat cable of the control panel

from the control board.

CDrill the four holes in the wall and secure the timer

making sure it is leveled. Cabling should have been laid

out in accordance to mounting requirements.

DPerform wire connection and final set-up complying with

recommended sequence of actions reported in the

following.

3.1.8 Mounting the Support Arm

AUnpack the support arm and check for completeness of parts.

BDo not remove the rope to pull the cable of the Scissor Arm to the Wall Adaptor through the Support

Arm.

CPush back the cylinder of the side friction not to interfere, lightly grease the shaft of the extension arm

and insert it into the wall adaptor.

DMount the rotation end-stop spacer and close the side friction without tightening.

FONA XDG –Service & Installation Manual

10/32 69 550 70210 150715

3.1.9 Mounting the Scissor Arm

WARNING. THE SPRINGS IN

THE SCISSOR ARM MAY CAUSE

INJURY TO THE INSTALLER AS

WELL AS DAMAGE TO THE ARM

ITSELF IF NOT HANDLED

PROPERLY. DO NOT REMOVE

THE BINDING STRING UNTIL

WHEN NECESSARY

ALight grease the shaft at the base of the arm and make sure

the ring spacer is in place; push back the cylinder of the

friction into the support arm not to interfere during the

insertion of the shaft.

BSecure the trailing rope to the end of the electrical cable of

the Scissor Arm.

CPull the other end of the trailing rope to drive the electrical

cable of the Scissor Arm through the Support Arm out into

the Wall Adaptor.

DHold the opening section of the Scissor Arm, carefully

remove the safety string and allow the arm to open slowly,

away from people.

EPerform final set-up complying with recommended sequence

of actions reported in the following.

FONA XDG –Service & Installation Manual

150715 69 550 70210 11/32

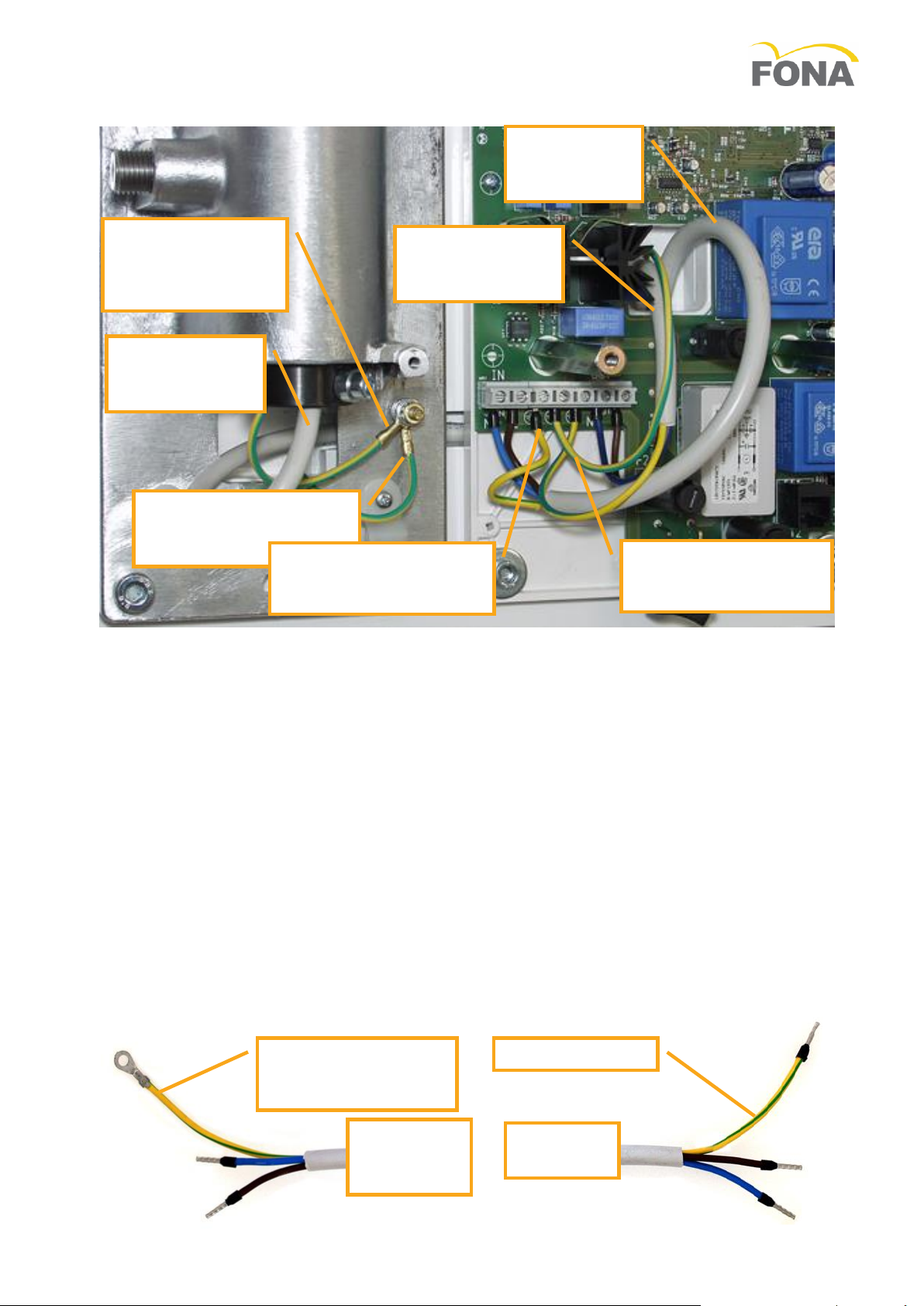

3.1.10 Connecting the Wall Adaptor with Timer at side

APass the conductor of the grounding provision (already connected to the common bolt) into the timer

for connection to the central ground point in the connecting block (protective earthing).

BConnect the grounding provision of the extension arm to the common bolt on the wall plate (flat

washer, ground provision, lock-washer, nut).

CPass through the supply cable of the arm into the timer for connection to the OUT positions (supply

cable output to X-ray head).

3.1.11 Connecting the Wall Adaptor with Timer remote

AIn case the connection to the mains is done starting from the wall adaptor a 5 position connection

block has to be mounted. This approach is recommended allowing for a lower ground resistance.

a The ground wire of the mains has to be connected in first position on the common bolt and

blocked with a nut.

b The mains line goes to the remote timer and back through the connection block to the X-ray head.

c The other grounding provisions for support arm and of cable returning from the timer to be

connected to the common bolt and blocked with a second nut.

d The ground resistance to consider is actually the one of the cable in the scissor arm.

BIn case the connection to the mains is done through the timer box, the ground resistance to consider

includes the wire from the timer to the wall adaptor.

a Prepare the terminations of the cable for remote connection of timer with tips to fit the connecting

blocks in timer and connecting blocks plus the common bolt for grounding in wall adaptor.

Make sure the copper section of the yellow green wire is large enough (see section 0,

Electrical Requirements, at page 7).

WALL

ADAPTOR

SIDE

TIMER

SIDE

YELLOW-GREEN TO

COMMON BOLT ON

WALL ADAPTOR

YELLOW-GREEN

SUPPLY CABLE

FROM TIMER

TO TUBE HEAD

YELLOW-GREEN

GROUND PROVISION

TO TIMER

YELLOW-GREEN

BONDING

CONDUCTOR OF

SUPPORT ARM

SUPPLY CABLE

OUTPUT TO

TUBE HEAD

YELLOW-GREEN

GROUND PROVISION

ON TIMER

MAINS LINE

INPUT TO

TIMER

YELLOW-GREEN

GROUND PROVISION

FROM MAINS

FONA XDG –Service & Installation Manual

12/32 69 550 70210 150715

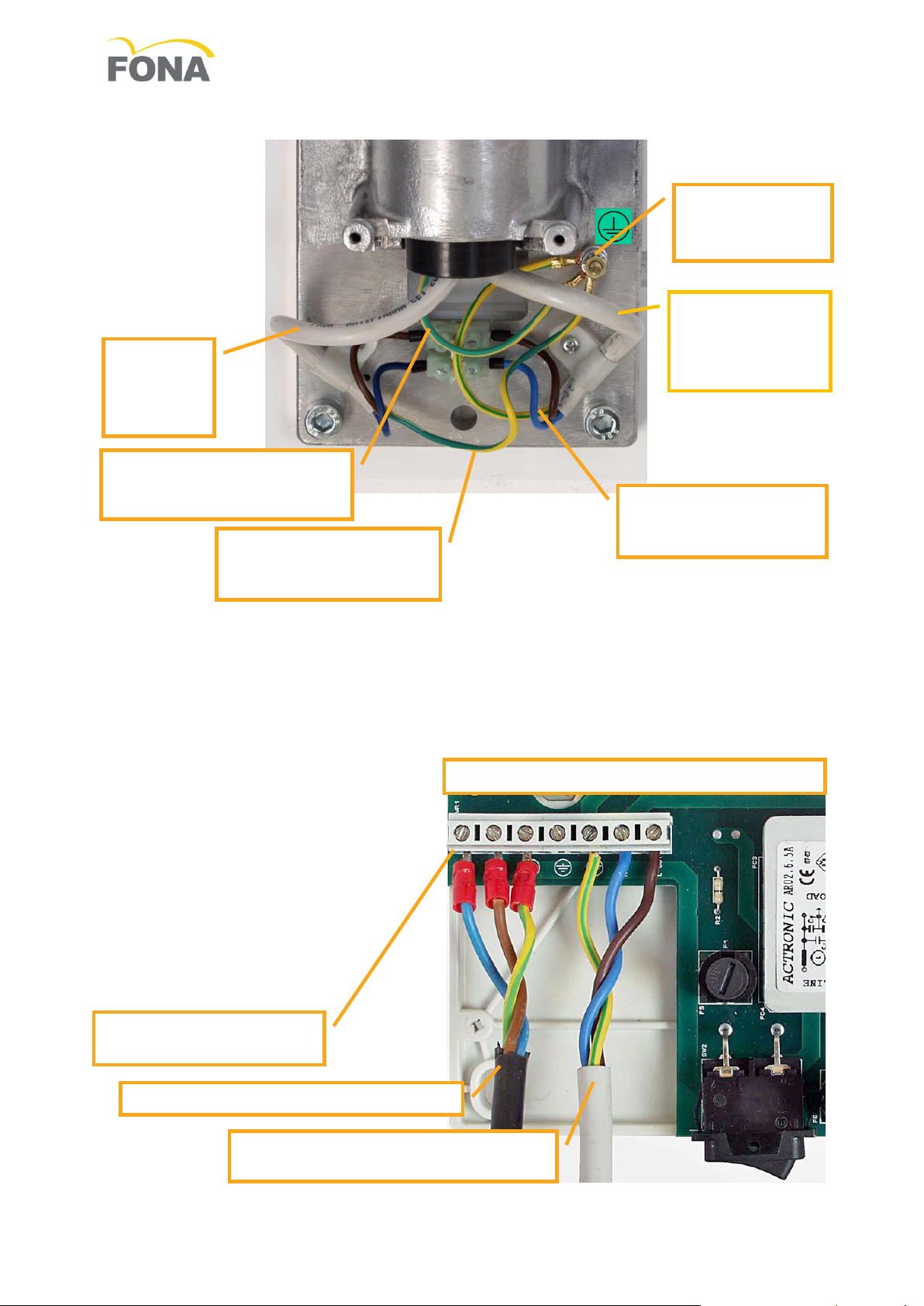

CRemove from the common bolt for bonding and grounding on the wall adaptor the existing cable for

ground provision.

DConnect the cable for remote connection of the timer by placing the ground wire as first conductor on

the common bolt for bonding and grounding; block with washers and nut.

EPlace the phase and neutral wires to the connecting block.

FConnect to the common bolt for bonding and grounding the bonding conductor of the extension arm

and the one of the cable of the arm.

GConnect the phase and neutral conductors of the supply cable in the arm to the connecting block.

See section 0,

HElectrical Requirements, at page 7 to determine cable length and maximum distance.

SUPPLY CABLE FROM REMOTE

TIMER TO TUBE HEAD

MAINS SUPPLY INPUT TO TIMER

CONNECTING BLOCK

IN THE TIMER

CONNECTIONS IN THE REMOTE TIMER

BOLT FOR

BONDING AND

GROUNDING

SUPPLY

CABLE

TO TUBE

HEAD

YELLOW-GREEN

GROUND PROVISION

FROM/TO TIMER

YELLOW-GREEN

BONDING CONDUCTOR

SUPPORT ARM

SUPPLY CABLE

FROM REMOTE

TIMER TO TUBE

HEAD

YELLOW-GREEN

BONDING CONDUCTOR

SCISSOR ARM

FONA XDG –Service & Installation Manual

150715 69 550 70210 13/32

3.1.12 Connecting the Timer

ATurn-off the voltage supply line. Connect the three wires from the voltage supply to the terminal

block (IN on the left) but do not connect any outgoing wire (OUT on the right) to Wall Adaptor.

BMake sure that the “live” conductor is the “hot” one:

a Connect an AC voltmeter or a test light between the block terminal “live in” and “ground”.

b Turn line voltage supply “ON”. If full line voltage is measured (test lamp lights) the wiring is

correct. If not turn line voltage supply “OFF”, reverse “live in” and “neutral in” wires and repeat the

measurement; eventually the full line voltage should be read between “line” and “ground” (test

lamp lights).

c Make sure no voltage is read between “neutral in” and “ground”; if not check line voltage

distribution.

CTest the timer for full functionality keeping the output cables disconnected not to supply the load.

DConnect the load.

a Turn OFF the line voltage supply line,

b Connect the three wires of additional cable outgoing to the Wall Adaptor, Arm, Tube Housing

Assembly. Live and neutral wires to the arm (X-ray head) can be interchanged.

Fuses of FONA XDG Timer

Ref.

115 V

230 V and 240 V

F1

6.3 AT 5x20

4 AT 5x20

F2

6.3 AT 5x20

4 AT 5x20

F3

315 mAT 5x20

315 mAT 5x20

F4

80 mAT 5x20

50 mAT 5x20

3.1.13 Connecting the Hand-Switch

AThe hand-switch is provided with a 3 m coiled cord to be plugged one side in the hand-switch, the

other side in the lower left corner of the timer’s board, either externally (connector TST1) or internally

to the timer (connector TST2). Internal connection is for remote hand-switch or for additional control

safety switches.

LIVE

FUSE F1

IN

HAND-SWITCH

CONNECTION

JUMPERS

HAND-SWITCH

SOCKET TST2

HAND-SWITCH

SOCKET TST1

FUSE F2

FUSE F4

ZERO OHM

RESITOR

OUT

GROUND

NEUTRAL

FONA XDG –Service & Installation Manual

14/32 69 550 70210 150715

BJumpers are available to activate properly the hand-switch connection:

a Position TST1 to enable external socketTST1,

b Position TST2 to enable the internal socket TST2,

c Position TST1/2 f to enable the internal and the external sockets.

3.1.14 Optional Remote Hand-Switch

The hand-switch can be remotely mounted by making use of the optional kit made of a remote box (wall

holder) and connection cable 10 m long.

The connection of the wires is here indicated.

The wires of the switch are number 3 and 4

(those in the middle of the connector).

3.1.15 Mounting and Connecting the X-ray Head

ARemove the handgrip pipe

from the arm and place it onto

the tube-head shaft of the

coupling yoke.

BLubricate the shaft, insert it

into the arm passing the

cables into the coupling yoke,

then hold it in place with the

retaining fork.

CAttach the connectors of the

supply and grounding wires

and push them into the side

opening of the coupling yoke.

DPull down the O-ring and

push-up the handgrip pipe,

then fix it in place with the

screw at bottom.

EVerify smooth movement of

the tube head around its

vertical and horizontal axis.

Tune side friction if necessary

referring to section 4.4,

Maintenance of X-ray Head, at

page 22 for details.

FMount the cover on the yoke opening eventually.

HANDGRIP

PIPE

RETAINING

FORK

COUPLING

YOKE

FONA XDG –Service & Installation Manual

150715 69 550 70210 15/32

3.1.16 Beam Limiting Device

AMount the beam limiting device on the tube-head and lock it close with a clock-wise rotation.

3.1.17 Final Tuning and Set-Up

ARemove the line voltage fuse(s) from the timer (Fuse 1 and Fuse 2).

BTune friction screw in Wall Adaptor for rotation of Support Arm (see section 4.1, Maintenance of Wall

Adaptor at page 20 for details).

CTune friction screw in Support Arm for rotation of Scissor Arm around it vertical axis (see section 4.2,

Maintenance of Support Arm at page 20).

DThe friction points in the scissor arm and those for the rotation of the X-ray head around its horizontal

axis are tuned in factory. Should you need to repeat the procedures refer to sections 4.3, Maintenance

of Scissor Arm, at page 21 and 4.4, Maintenance of X-ray Head, at page 22, respectively.

EMake sure the Timer switch is in the “OFF” position.

FSet the dip switches SW2 as indicated in the following to define:

a Enable/disable function for correction of exposure in presence

of line voltage fluctuations.

b The nominal line voltage of the X-ray head (see label).

c Set dip switch 4 to the anode current set in the X-ray head

label, which is 3.5 mA for FONA XDG.

d Set the pre-heating time according to type of X-ray insert used

in the X-ray head assembly; the measured value is marked on

the X-ray head.

e Select the technique factor on display as mAs (always mAs for

the timer of FONA XDG).

GPut back the line voltage fuse(s).

HPut back all plastic covers and logo strips.

IConnect the system to the line voltage by switching the general line

voltage switch on and/or plug the power cord into the wall socket.

JSwitch the timer “ON”.

The system is now ready for functional checks.

FONA XDG –Service & Installation Manual

16/32 69 550 70210 150715

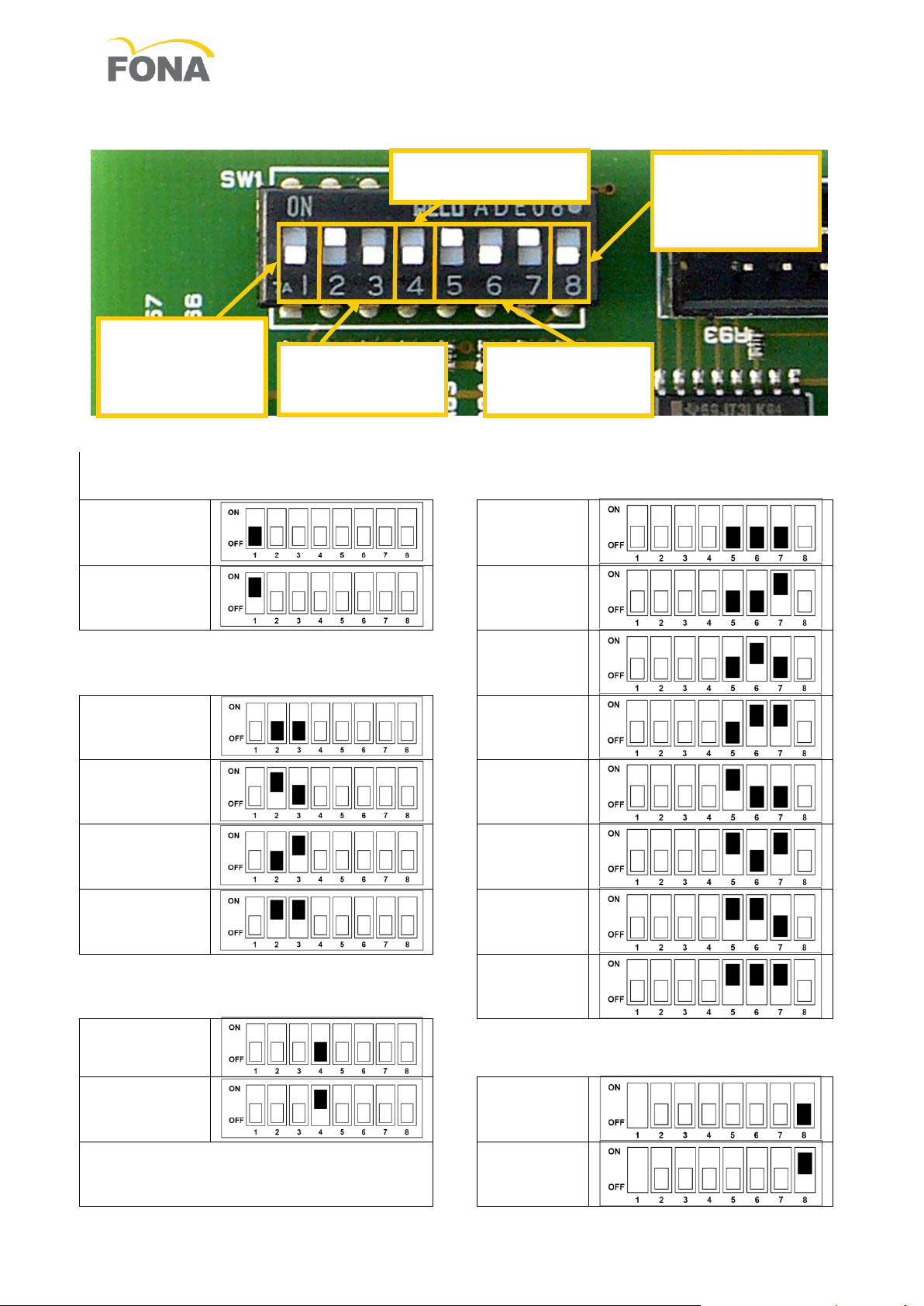

3.2 Dip Switch Setting

DIP 1

Technique Factor Correction

DIPS 5 –6 –7

Pre Heating Time

Disabled

100 ms

Enabled

120 ms

DIPS 2- 3

Tube Head Type

140 ms

110 or 220

VAC

160 ms

115 or 230

VAC

180 ms

120 or 240

VAC

200 ms

127 or 250

VAC

220 ms

DIP 4

Tube Head Anode Current

240 ms

3.5 mA

DIP 8

Technique Factor Displayed

7 mA

s

mAs

DIPS 2-3

TUBE HEAD

TYPE

DIP 4

ANODE CURRENT

DIPS 5-6-7

PRE HEATING

TIME

DIP 8

TECHNIQUE

FACTOR

DISPLAYED

DIP 1

TECHNIQUE

FACTOR

CORRECTION

FONA XDG –Service & Installation Manual

150715 69 550 70210 17/32

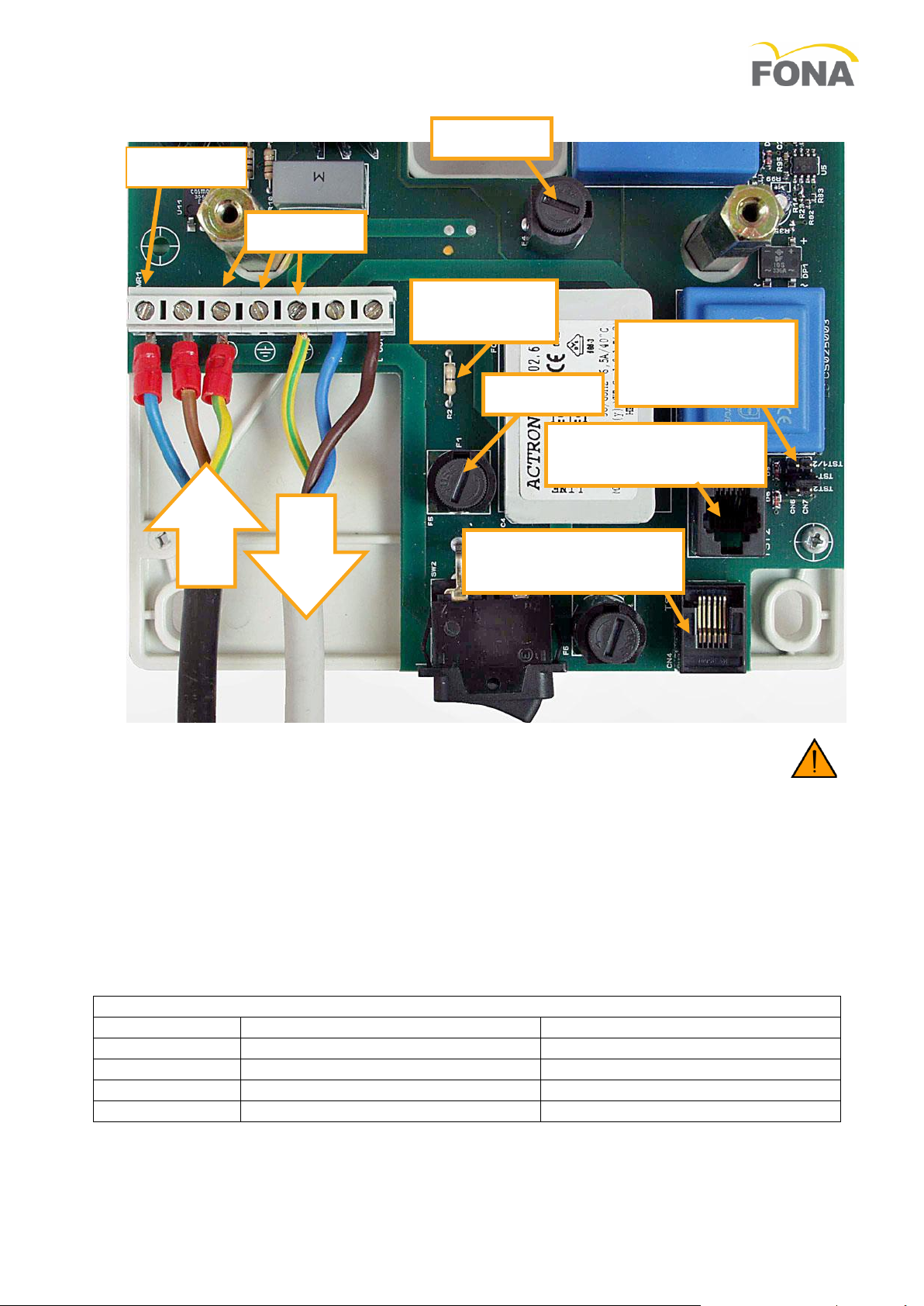

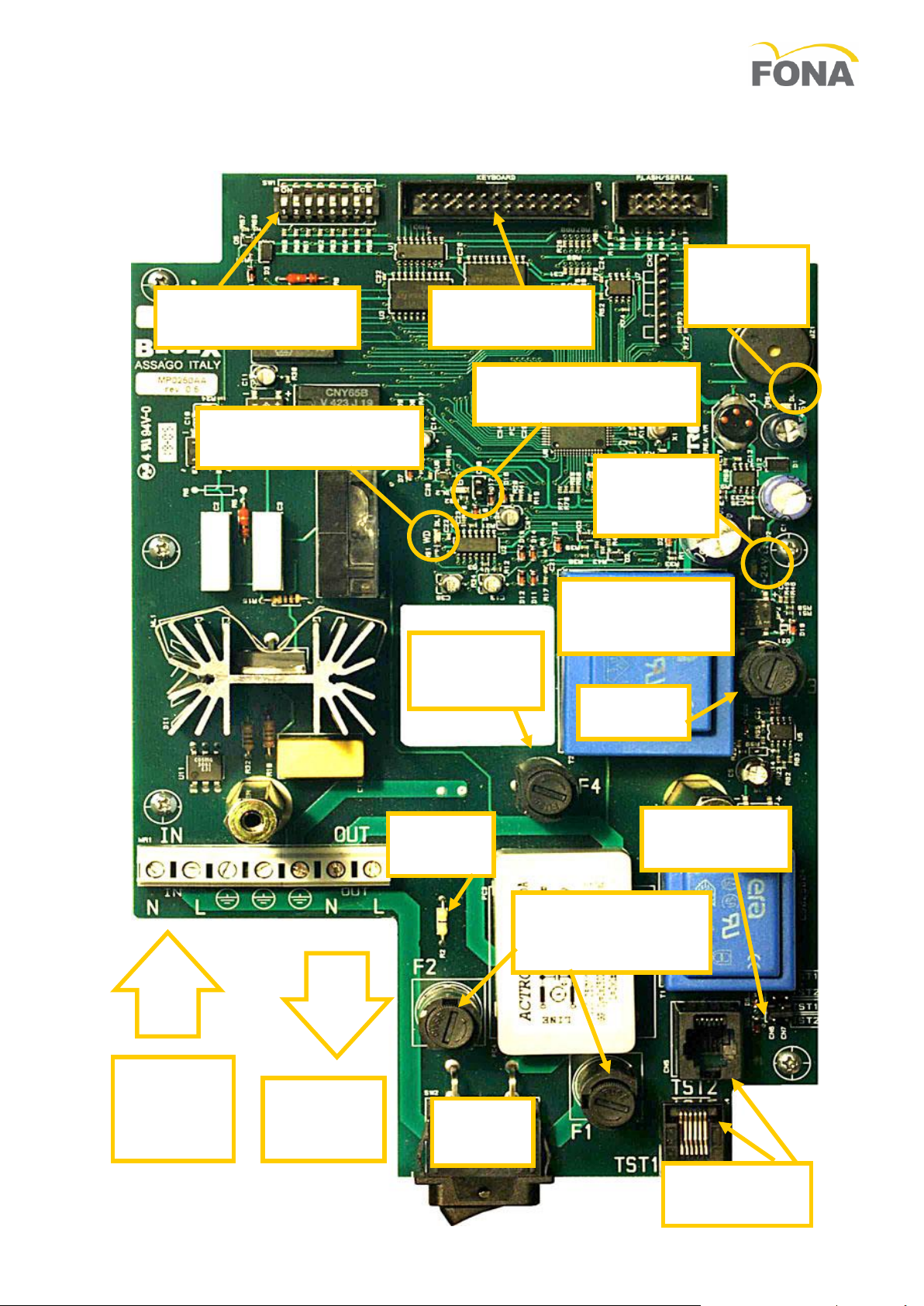

3.3 Layout Power Board Timer

SET-UP

MICROSWITCHES

KEYBOARD

CONNECTOR

POWER

SUPPLY

5 V LED

BACK UP TIMER

TEST POINT & LED

MICROPROCESSOR

WATCH DOG LED

FUSE 4

T50mA @230V

T80mA @115V

POWER

SUPPLY

24 V LED

FUSE 3

T 315 mA

OUTPUT

LINE TO

TUBEHEAD

INPUT

MAINS LINE

NEUTRAL

& LIVE

JUMPER

FUSE 2

HANDSWITCH

SOCKETS

MAINS

SWITCH

HANDSWITCH

JUMPERS

FUSE 1 & FUSE 2

T4A @230V

T6.3A @115V

5VA TRANSFORMER

PRIMARY 115/230 V

SECONDARY 18 V

FONA XDG –Service & Installation Manual

18/32 69 550 70210 150715

3.4 Mobile Systems

3.4.1 Unpacking

Unpack the components of the system and check the following:

AEach item is in good conditions and was not damaged during transportation.

BAll the items for the desired system configuration are available.

CThe line voltage on the labels of timer and X-ray head correspond to the existing local

line voltage.

3.4.2 Room Preparation

Make sure that a wall socket is available close to the dental chair in reach of the mobile X-

ray equipment.

Such a socket has to be provided with connection to the protective grounding.

The line voltage cable can come without plug to be added according to the local standard.

3.4.3 Mounting and Connecting Sequence

Step 1

Assemble the Mobile Stand

Step 2

Mount the Scissor Arm

Step 3

Mount the Scissor Arm

Step 4

Mount the Timer

Step 5

Connect the Line Voltage Cable

Step 6

Connect the Timer

Step 7

Activate second Fuse

Step 8

Mount and connect X-ray head

Step 9

Mount the collimator

Step 10

Final Tuning and Set-Up

3.4.4 Assembling the Mobile

Stand

AMount the legs below the central base.

BMount rear wheels and front wheels with brakes.

CAttach the pole with timer plate.

DComplete the stand with cable holder and

handles

3.4.5 Mounting the Arm

ALoosen the friction and push back the cylinder of

the same not to interfere during shaft insertion.

BInsert the arm. Refer to section 3.1.9 at page 10

for details.

FONA XDG –Service & Installation Manual

150715 69 550 70210 19/32

POWER

SUPPLY

CORD

BONDING

CONDUCTOR

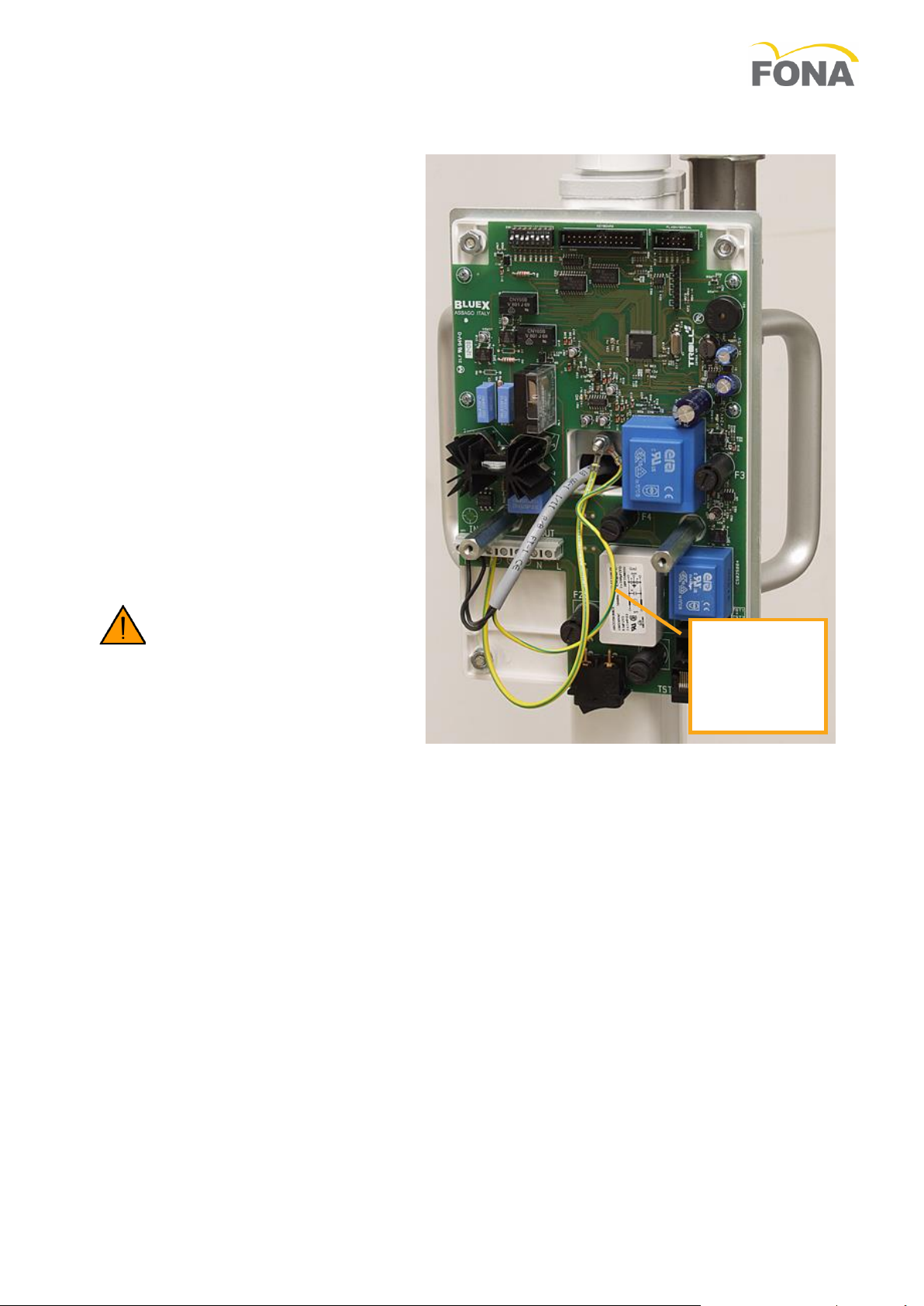

3.5 Mounting the Timer

The timer is blocked in place with four bolts.

3.5.1 Connecting the Line

voltage cable

AThe line voltage cable for the mobile has

to be completed with local plug.

BThe power supply cord bonding

conductor has to be blocked (first) to the

common bolt for bonding and grounding

using lock-washer and nut.

CThe grounding wire for the timer is then

placed on the same common bolt and

blocked (second) with lock- washer and

nut.

DConnect the grounding wire for the timer

to the ground provision on the terminal

block of the timer and the two line wires

of the power cord to the input points of

the terminal block of the timer.

3.5.2 Connecting the Timer

For the connection of the output cable to the

timer please refer to section 3.1.11 at page

13.

3.5.3 Activation of Fuse 2

Units provided with supply cord and

plug must be equipped with fuses

on both line phases. The activation

on the second fuse is done by cutting the

Jumper Fuse 2 (zero Ohm resistor) close to

Fuse F2. See position on layout in section 0

at page 17.

3.5.4 Mounting and Connecting the X-ray Head

Refer to section 3.1.15 at page 14.

3.5.5 Mounting the Beam Limiting Device

Refer to section 3.1.16 at page 15.

3.5.6 Final Tuning and Set-Up

Refer to section 3.1.17 at page 15.

FONA XDG –Service & Installation Manual

20/32 69 550 70210 150715

FRICTION

SCREW

4. MAINTENANCE

Here in the following the list of recommended maintenance actions to keep the FONA XDG system in

compliance with the Performance Standard.

It is the responsibility of the User to maintain the equipment in compliance with the standard. Failure of

the User to properly maintain the equipment may relieve the Manufacturer, or its Agent, from responsibility

for any injury, damage or non compliance which may result.

Maintenance for the FONA XDG system to be done regularly by a service technician at least once every 24

months, with regular checks performed by the operator every year.

Any defect or malfunction should be corrected immediately by qualified personnel with adequate training.

WARNING.

Any defective item affecting A safe use must be repaired or replaced

Only original certified components and spare parts must be used for repairs or replacements.

Correction of damages to the identification labels to be handled with the Manufacturer. Any defect or

non-compliance must be reported promptly to the Manufacturer or to its Local Agent.

Always disconnect the system from the line voltage supply using the general line voltage switch for the

room where the equipment is located before performing any maintenance activity

Avoid using liquid or spray detergents which may enter into the equipment and cause corrosion.

Avoid the use of solvents or corrosive detergents which can damage painted surfaces and plastic

covers.

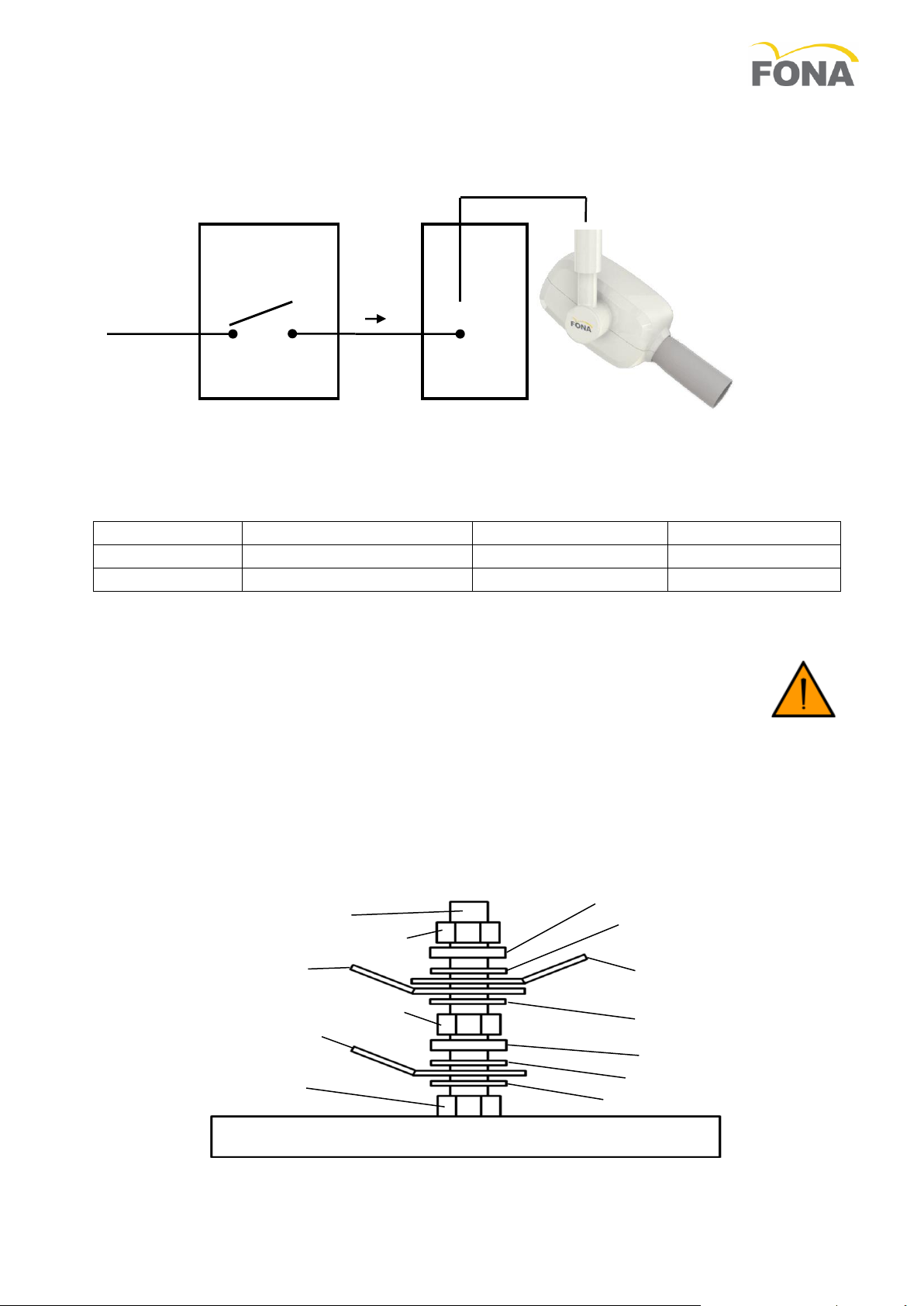

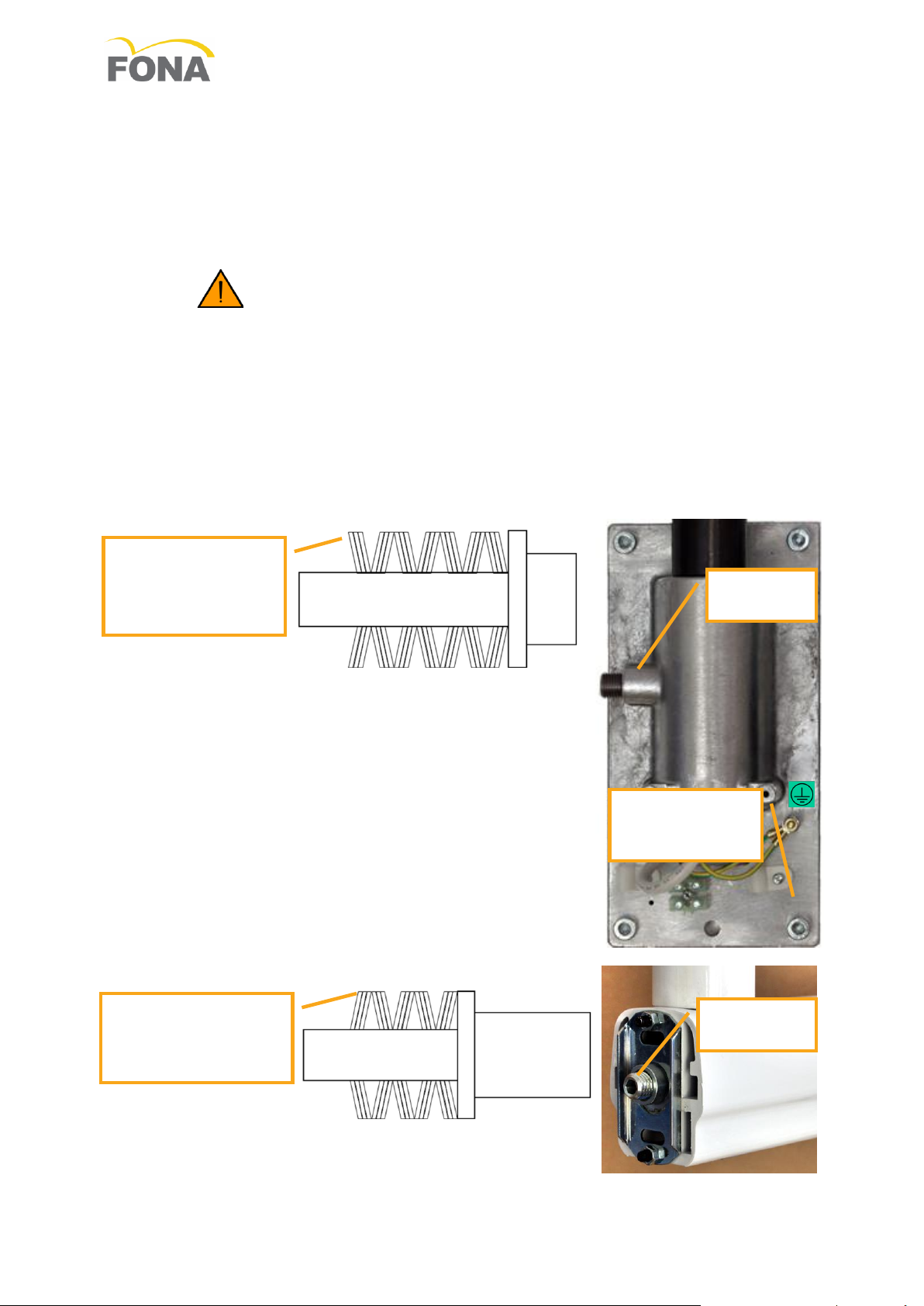

4.1 Maintenance of Wall Adaptor

ARemove the cover and verify that the mounting is closely

connected to the wall and stays firm and steady during the

movements of the system.

BVerify for proper connection of grounding wires to the common

bolt.

CCheck friction during rotation of Extension Arm and adjust if

needed.

DVerify that the technical label with identification data outside the

plastic cover at bottom is in place and is readable.

4.2 Maintenance of Support Arm

ASlide partially out the extension arm from wall mount, inspect for

wear of the joint and lubricate for smooth rotation.

BCheck friction during rotation of Arm and adjust relevant screw if

needed.

CVerify that the technical label with identification data is in place and is readable.

POSITION OF 21

DISK SPRINGS IN

FRICTION SCREW

7 GROUPS OF 3

BOLT FOR

BONDING AND

GROUNDING

FRICTION

SCREW

POSITION OF 15

DISK SPRINGS IN

FRICTION SCREW

5 GROUPS OF 3

Other manuals for XDG

1

Table of contents

Other Fona Dental Equipment manuals

Popular Dental Equipment manuals by other brands

Belmont

Belmont IO 5000TA Installation and operation instructions

Straumann

Straumann Novaloc technical information

KaVo

KaVo MASTERmatic LUX M10 L Instructions for use

Intensiv

Intensiv Ortho-Strips Opener Instructions for use and safety recommendations

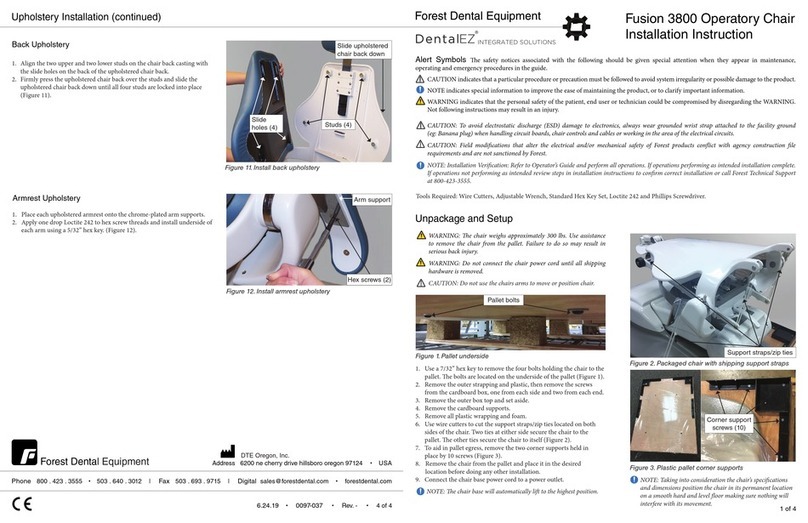

Forest Dental

Forest Dental Fusion 3800 Installation instruction

VHF

VHF S5 operating instructions

AcceleDent

AcceleDent Optima Quick reference guide

Carestream DENTAL

Carestream DENTAL CS 8200 3D user guide

ETEKCITY

ETEKCITY EWF-32 user manual

Acteon

Acteon SOPRO 717 FIRST user manual

Bien Air

Bien Air OPTIMA INT installation instructions

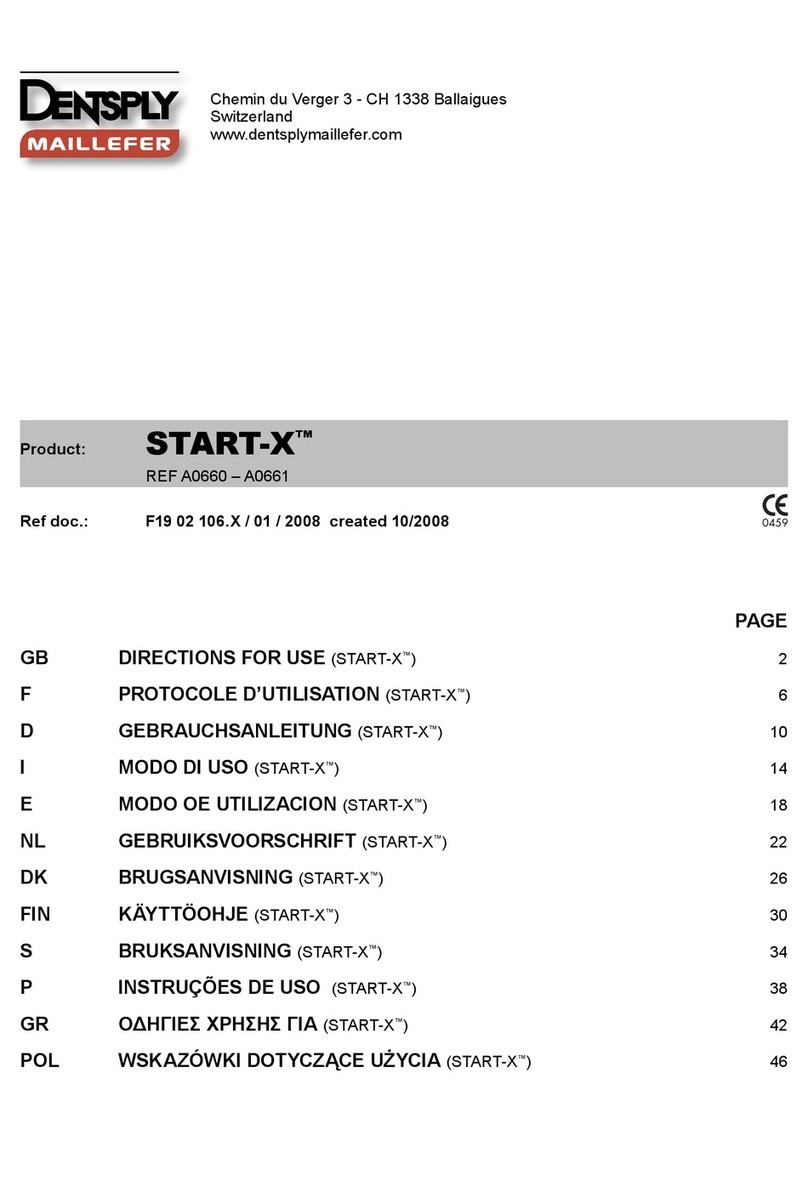

Dentsply Maillefer

Dentsply Maillefer START-X A0660 Directions for use