Mayer GmbH & Co. KG Potting Machine 1018 - Instruction of Use

- 7 -

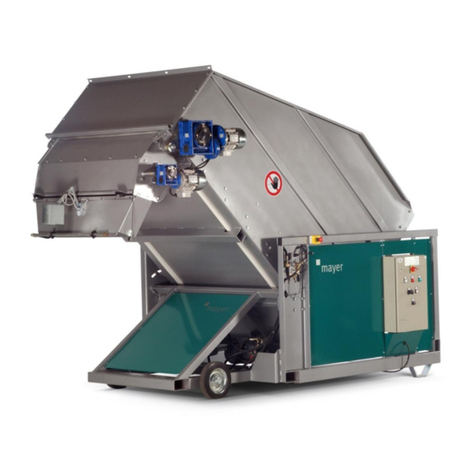

2.0 DATA FOR THE USE OF THE MACHINE

2.1 SCOPE OF USE

Great pots, vessels or containers, as well as plastic foil-bags can be filled up with soil

with this MAYER GREAT CONTAINER FILLING POTTING MACHINE.

2.2 IRREGULAR USE

Other application purposes than those detailed in the capitals "Scope of use" and "Work

with the machine" are not allowed, and make the manufacturer free of any

responsibility.

2.3 FUNCTION OF THE MACHINE (OPERATION PRINCIPLE)

The machine consists of a soil container, an elevator and a transport trough for the

substrate.

Instead of bottom, there is a rubber band mounted on the soil container to transport the

substrate forwards. Thereby the soil can fall through a rhythmical movement into the

elevator.

There are two chains with buckets in which soil is then upwards transported.

The soil mass transported up this way is tilted into a trough made of metal plate, and

two worms moving in contrary to each other, to the left and to the right, deliver and

distribute the substrate.

In front of the machine, on the left and the right side to the elevator, two turntables are

positioned. The empty containers are placed onto the two turntables and are filled up

with soil from the transport though with the help of two soil slides. In order to make filling

up easier and better the turntables can be rotated up to 360°.

The filled containers are manually taken away from the machine, and the new empty

containers are manually placed onto the turntables, as well.

3.0 TRANSPORTATION, HANDLING AND STORAGE OF THE MACHINE

3.1 TRANSPORTATION

When transporting the machine, it is extremely important to take care in order to avoid

any damage caused by use of excess force or imprudent loading and disloading.

Depending on kind and length of time of transport, proper transportation safety

regulations must be taken into account.

During transportation, condensing of water because of great change in temperature,

and bumps must be avoided.

The machine itself must be treated in a normal careful way.