1

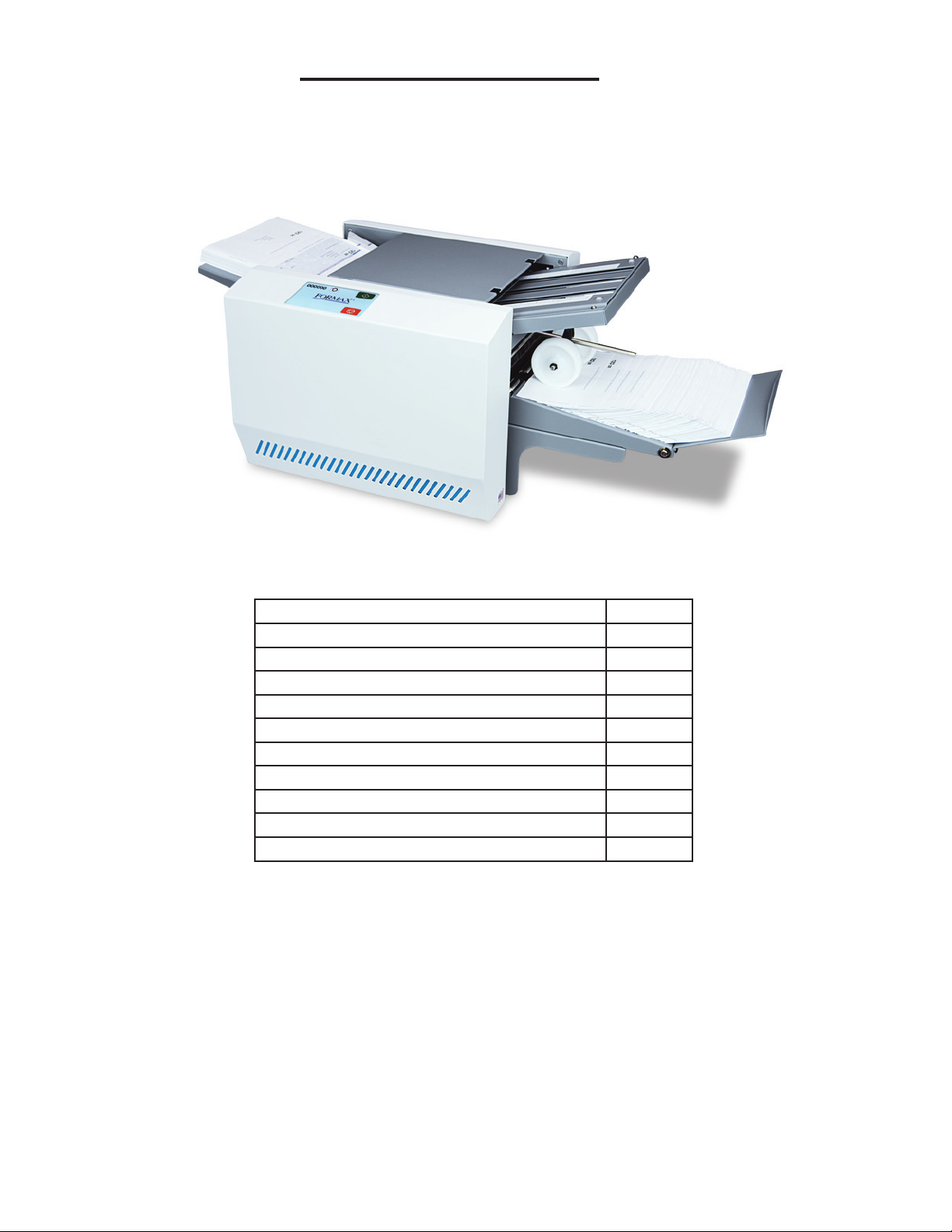

DESCRIPTION

Lower Fold Plate

Touchscreen

Control Panel

Top Cover

Upper Fold Plate

In-feed Table

Paper Side Guides

Stacking Rollers

Integrated Conveyor

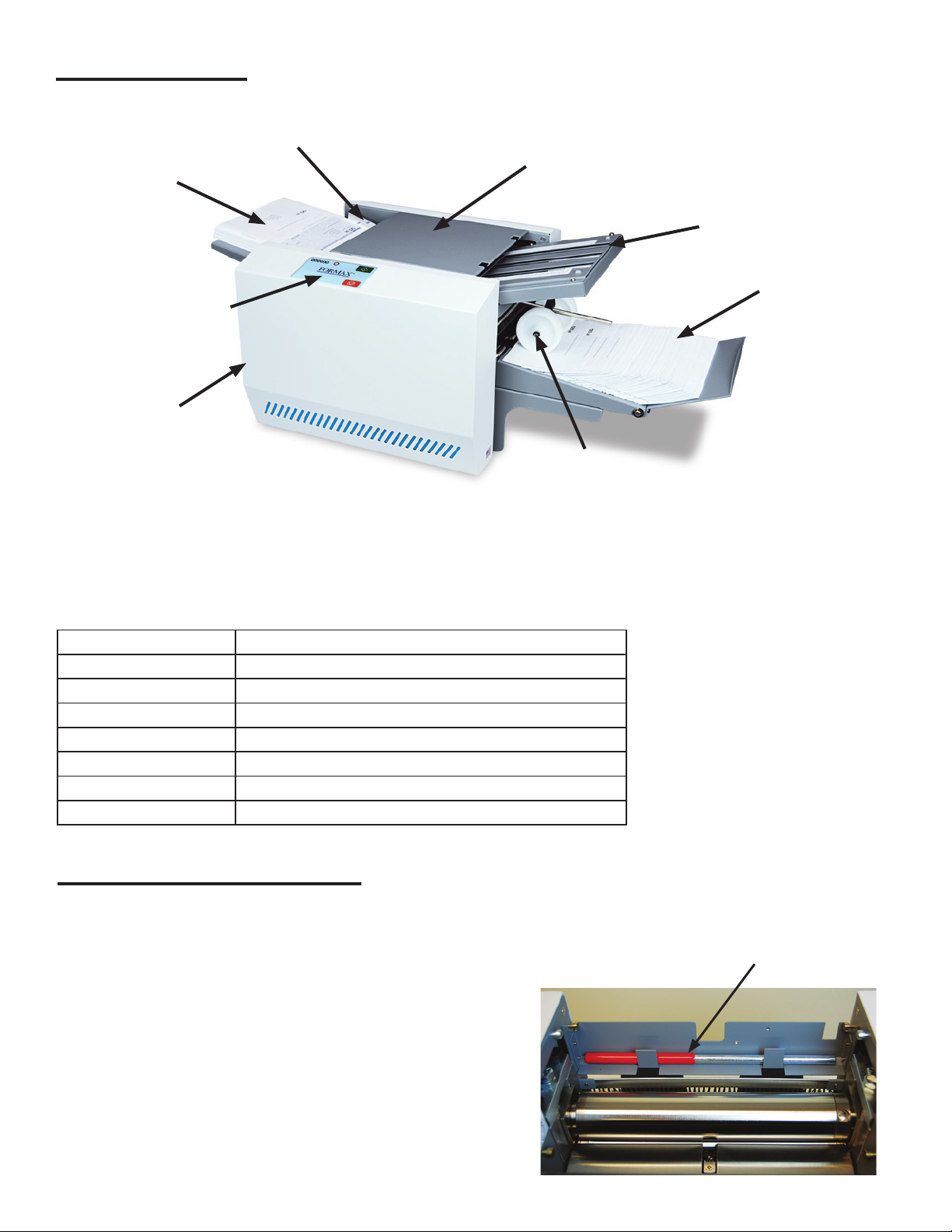

1. Check package for shipping damage. If there is shipping damage, do not discard the box.

2. CAUTION: Two people are required to lift the machine out of the box.

3. Place the jam clearing handle into the the holder

which is mounted to the machine. This is the jam

clearing tool’s proper location (see picture, right).

4. Install upper fold plate (refer to pages 4 and 5

for proper installation).

UNPACKING & SET-UP

Jam clearing tool

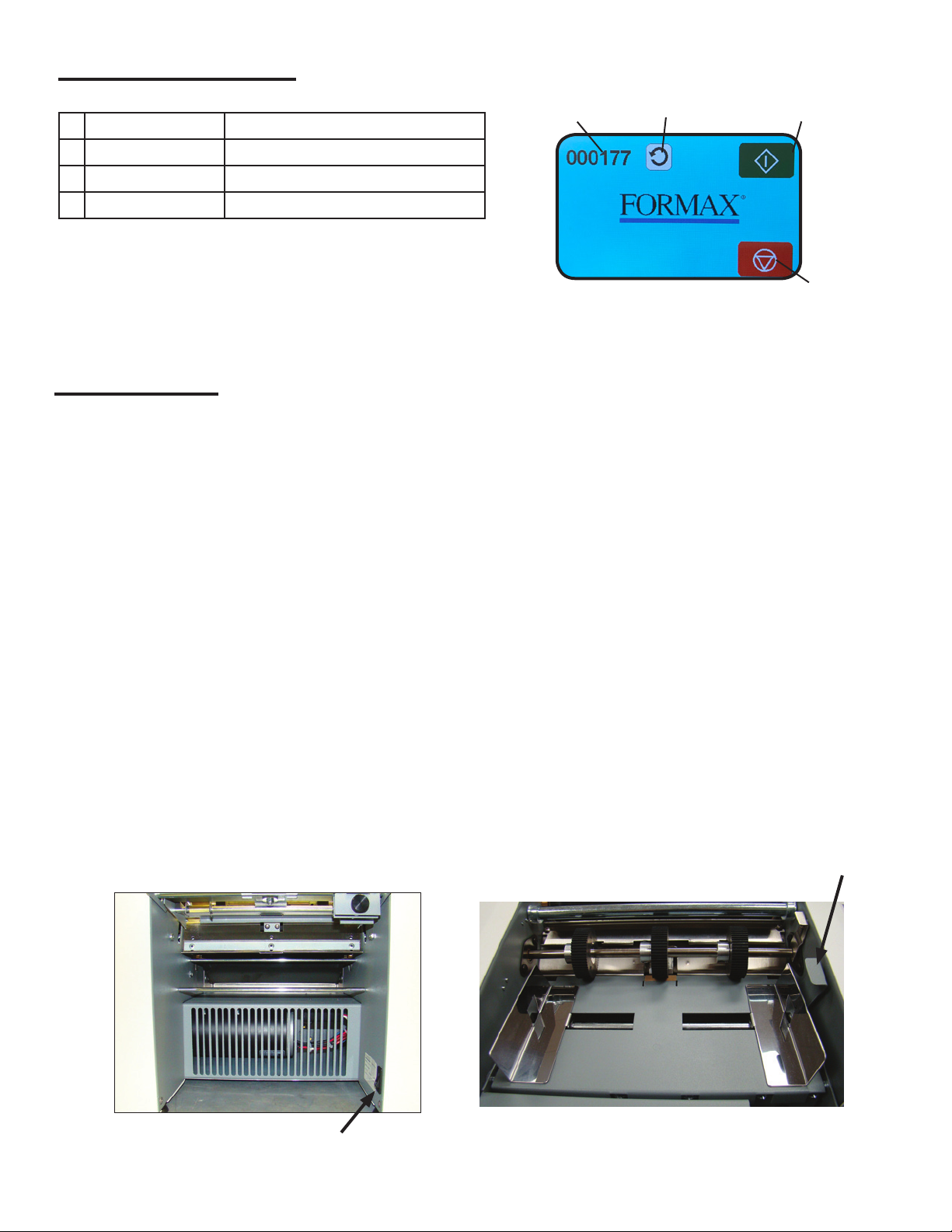

FUNCTION:

The 1506Plus Pressure Sealer folds and seals many different congurations, including “C”, “Z”, “V” and

custom folds. It also accommodates several different sizes of forms. For congurations and/or paper

sizes specications below.

Paper size: Up to 8.5” W x 14” L

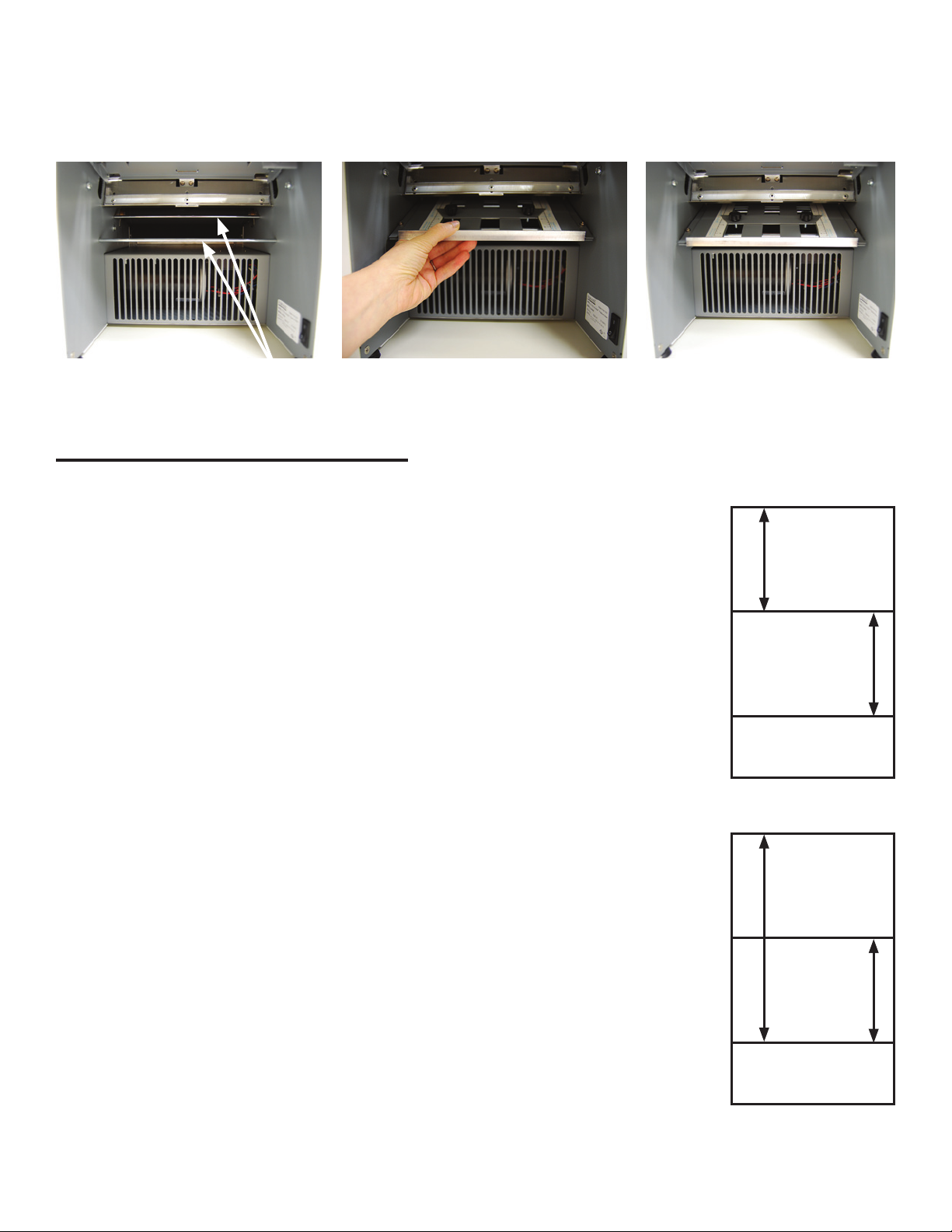

Fold styles: C, Z, V uneven Z, uneven C, custom folds

Fixed speed: Up to 6,250 sheets per hour

Hopper capacity: Up to 200 sheets 20#

Weight: 90 lbs.

Dimensions: 37” L x 17” W x 13” H

Power supply: 120V, 50/60 Hz

Certications: UL Approved