5

1.

2.

3.

1.

2.

3.

Invoice

Flyer

Brochure

CONTROL PANEL - Home Screen Interface

No.NAME FUNCTION

1 Form Size Display Shows the size of the forms loaded in the pressure sealer

2 Resettable Counter Displays the number of forms processed, can be reset between each job

3 Counter Reset Icon Resets the counter to “0”

4 Fold Selection Icon Press to advance to fold selection screen

5 Custom Fold Access Press to select or edit previously saved custom folds

6 Operator Settings Icon Press to enter to the operator settings screen

7 Start / Stop Icon Press to start the pressure sealer. Press to stop the pressure sealer.

57

6

4

1

2 3

Any icon with a blue frame around it (i.e. #4 above) can be adjusted by pressing the icon.

Icons without a blue frame (i.e. #1 above) provide status, and cannot be pressed.

In any other screen, use the icon after choosing a setting or entering information.

To return to the home screen from any other screen, press the home icon.

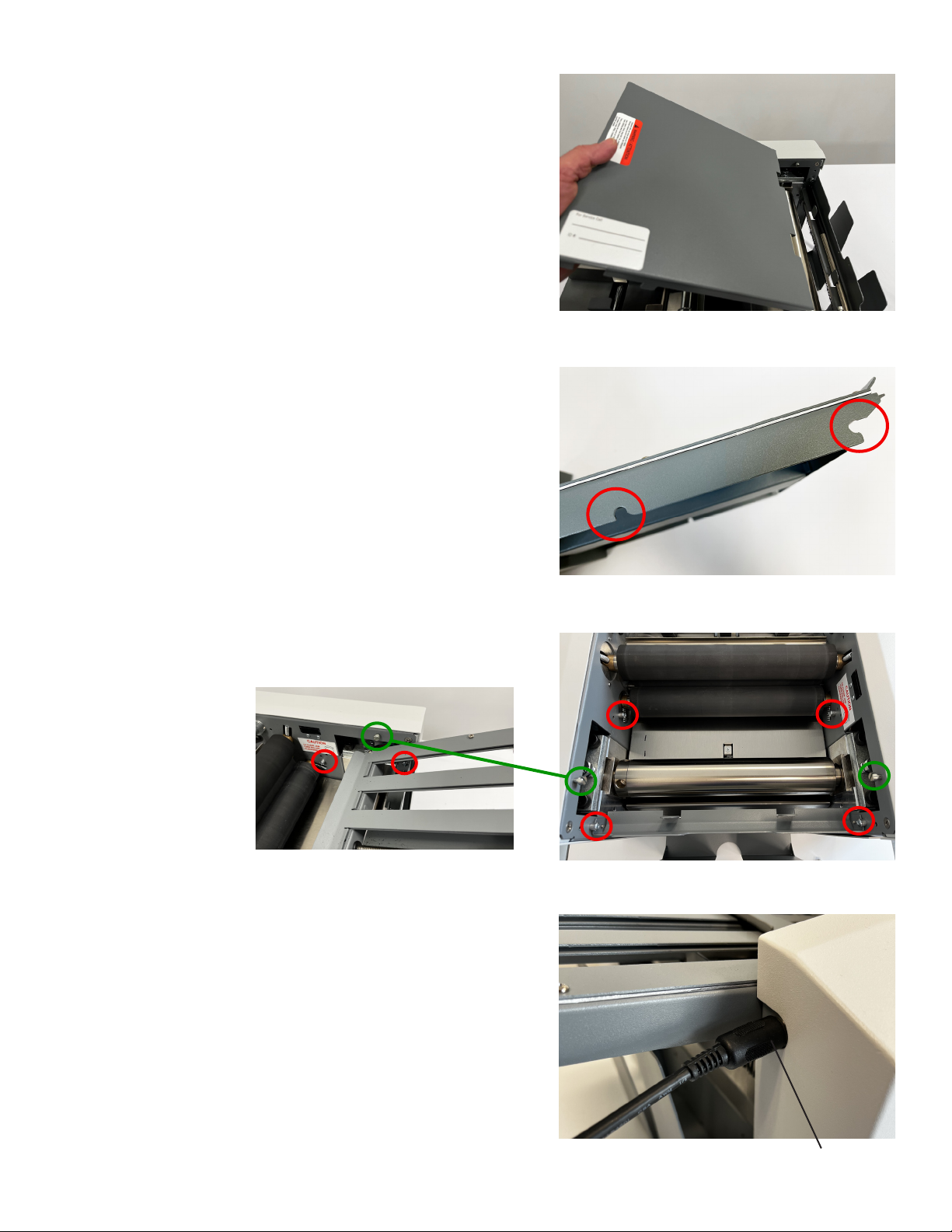

Install Form Knock Down Strap

1. To improve the stacking of folded forms attach the

magnetic form knock down strap to the support bar

below the upper fold table (Fig. 3). The strap can be

adjusted up or down or left to right for best results.

Fig. 3