FORTEZA FMC 24 Operating instructions

FORTEZA JSC FORTEZA FMC 24 (50m, 100m, 200m)

Please visit our internet sites: www.forteza.com or www.forteza.eu Page 2

CONTENTS

1. DESCRIPTION AND OPERATION ........................................................... 3

1.1. Purpose.......................................................................................................... 3

1.2. Specifications................................................................................................ 3

1.3. Sensor components........................................................................................ 6

1.4. Operation principle........................................................................................ 6

1.5. Sensor structure............................................................................................. 7

1.6. Adjustment, control and indication parts...................................................... 9

2. INSTALLATION AND ADJUSTMENT PROCEDURE............................ 10

2.1. Requirements for the protected sector and Rx and Tx arrangement ............ 10

2.2. TX and RX mounting.................................................................................... 11

2.3. Sensor connection ......................................................................................... 15

2.4. Sensor adjustment with the buildin adjustment control and indication parts 17

2.5. Software installation and detector adjustment.............................................. 19

2.6. Trial operation............................................................................................... 30

2.7. Creation and saving of the report…………………………………………. 30

3. MAINTENANCE ......................................................................................... 30

3.1. Performance check........................................................................................ 30

3.2. Maintenance check........................................................................................ 30

3.3. Safety measures............................................................................................. 31

4. TROUBLESHOOTING GUIDE .................................................................. 31

5. STORAGE .................................................................................................... 33

6. TRANSPORTATION................................................................................... 33

Certificate...................................................................................................... 34

FORTEZA JSC FORTEZA FMC 24 (50m, 100m, 200m)

Please visit our internet sites: www.forteza.com or www.forteza.eu Page 3

1. DESCRIPTION AND OPERATION

The present description manual and service instruction contains information about the

operation of the local microwave protective detectors series FMC 24 (50m 100m 200m)

below the detector. In this document there is information required for the correct operation

(use, transportation, storage and maintenance) of the detector.

The following abbreviations are used in the present document:

Tx - transmitter

Rx - receiver.

MK - mounting kit;

1.1. Purpose

1.1.1. The purpose of the sensors is to protect the perimeter sectors and to detect an

intruder crossing this sector at his “full height” or “bent”. An alarm is generated by

breaking the individual point relay contacts. Then it is transmitted on the receiver.

1.1.2. The detector is intended for continuous round-the-clock outdoor operation at an

ambient temperature -40ºC…+60С and relative humidity up to 98% at the temperature

+35С.

1.1.3. When the sensor operates with the alarm complex, you can control the sensor

with RS-485 interface.

1.2. Specifications

1.2.1. The recommended length (L) of a sector for modifications:

FMC 24 (200m) –10…200 m

FMC 24 (100m) –10…100 m

FMC 24 (50m) –5…50 m

The detection zone height, h:

FMC 24 (200m) 1,8 m* maximum

FMC 24 (100m) 1,6 m* maximum

FMC 24 (50m) 1,4 m* maximum

The detection zone width, b :

FMC 24 (200m) 2,1 m* maximum

FMC 24 (100m) 1,5 m* maximum

FMC 24 (50m) 1,0 m* maximum

* in the middle of a sector at the maximum length

The cross speed: 0,1 up to10 m/sec

The quantity of the frequency channels 4

Supply voltage 9…30 V

FORTEZA JSC FORTEZA FMC 24 (50m, 100m, 200m)

Please visit our internet sites: www.forteza.com or www.forteza.eu Page 4

Current consumption 45 mA maximum

-Tx 10 mA maximum

-Rx 35 mA maximum

Individual point relay parameters:

Switching voltage 30 V maximum

Switching current 0,1 A maximum

Alarm contact resistance 100 Ohms maximum

“dead” zones 2…3 m

Readiness time

switch ON 30 sec maximum

switch OFF 1 sec maximum

The parameters of TAMPER button:

-voltage 30 V maximum

-current consumption 0,1 A maximum

Protection class IP55

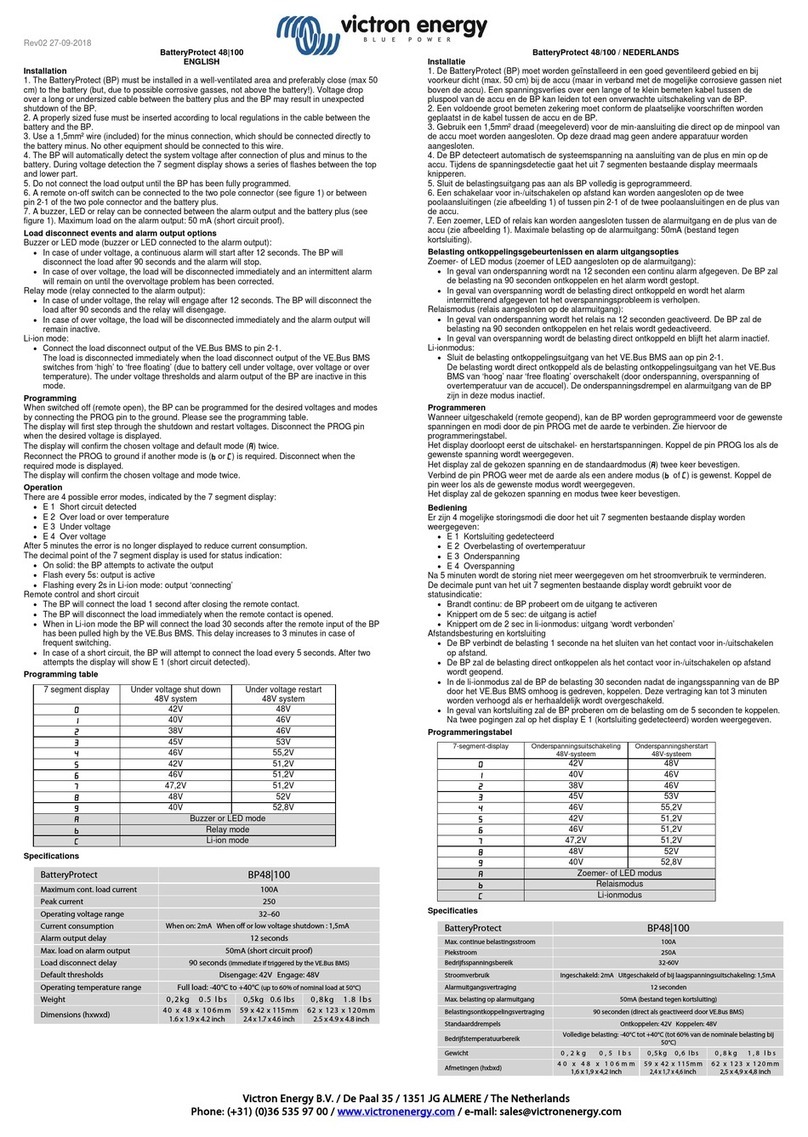

The configuration and the dimensions of the detection zone are given in fig.1.1. and

table 1.1

Table 1.1

Length of a sector, L, m

10

25

50

100

200

Detection zone width, b, m, max

0,5

0,7

1,0

1,5

2,1

Detection zone height, h, m,

max

1,4

1,4

1,4

1,6

1,8

1.2.2. The detection zone is a volumetric part of a sector that being the very specialty

in the kind of detection, and any movement within this sector will generate an alarm.

FORTEZA JSC FORTEZA FMC 24 (50m, 100m, 200m)

Please visit our internet sites: www.forteza.com or www.forteza.eu Page 5

Fig.1.1. Detection zone

L- Length of a sector h- Height of detection zone b- Width of detection zone

1.2.3. In Fig.1.1 and Table 1.1 the height (h) and the width (b) of the detection zone

are given for the middle of the sector. Moving towards the receiver or transmitter these

dimensions decrease evenly, given the geometry of positioning the receiver and transmitter.

1.2.4. The recommended distance from the axis of the detection zone up to fences,

building walls and other motionless objects at the sector length:

80…200m - 1, 1 m minimum

25…80m - 0, 8 m minimum

10…25m - 0, 4 m minimum

1.2.5. The sensor generates an alarm when:

-an intruder crosses the detection zone. Detection probability is 98 % when an

intruder crosses the detection zone at his “full height” or “bent”;

-external electromagnetic field influences on Rx for its masking. There may be

no alarm signal, but in this case the sensor should save its operability.

An alarm is generated by breaking the contacts of optoelectronic individual point relay

(standby mode) for 3 sec minimum. Orange and brown wires marked «NC» (normally

closed) and this alarm is transmitted over RS-485 interface.

Note. At the distance of 3-5 m from the supports with Tx and Rx the probability of the

intruder’s detection, who is moving stooping down (crawling through) in the detection

zone, is less than 98 % as an intruder can stoop down and pass below the detection zone.

1.2.6. The sensor generates a fault signal at:

- the absence of Tx signal;

- the absence of supply voltage or at its reduction lower than 8 mV;

- Rx or Tx failure.

When a fault signal is generated, the individual point relay contacts are broken, and a

fault signal is transmitted over RS-485 interface up to the malfunction repair.

1.2.7. When the exchange is interrupted over RS-485 interface, a fault signal is

generated by the alarm complex.

1.2.8. The sensor generates an alarm at the opening of Rx cover, under which there are

adjusters. The contacts of the tamper button (TAMPER) are open at the cover opening. This

alarm is transmitted to Rx by the separate pair of cables.

1.2.9. The sensor doesn’t generate false alarms at:

- rain, snow, thick fog;

- solar radiation;

- wind speed up to 30 m/sec;

- objects moving with the linear dimensions up to 0,2 m (birds or small animals);

- irregularities up to ± 0,3 m;

FORTEZA JSC FORTEZA FMC 24 (50m, 100m, 200m)

Please visit our internet sites: www.forteza.com or www.forteza.eu Page 6

- snow up to 0,5 m (without additional adjustment);

- grass up to 0,3 m;

- the influence of ultra-short waves emissions of the range 150-175 MHz and the

power up to 40 W at the distance 6 m maximum.

1.2.10. The sensor is immune to electromagnetic interferences (voltage impulses in

supply circuits, breaks of mains supply, electrostatic discharges and electromagnetic fields).

1.2.11. The case of the sensor is made of impact-resistant plastic immune to UV

radiation and the temperature changes in all the performance range.

1.2.12. The sensor mean lifetime is 8 years.

1.2.13. Maximum dimensions of the units without a mounting kit, mm:

-transmitter - 207x133x50;

-receiver - 207x133x50.

1.2.14. Maximum weight of Rx +Tx units with a mounting kit -1.7 kg:

1.3. Sensor components

Receiver –1 pc

Transmitter –1 pc

Mounting kit (MK) including:

- bracket –2 pcs

- buckle –4 pcs

Kit of tools and accessories including:

-screwdriver;

- spanner 8x10.

User manual and USB flash drive with software/ additional information.

Package.

The protocol converter USB/RS-485 with the port isolation cable for PC connection

USB2.0 A –miniB are supplied at the customer order.

1.4. Operation principle

1.4.1. The sensor is a bistatic microwave device.

The sensor principle of operation is to generate an electromagnetic field between Tx

and Rx. This field forms a volumetric detection zone in the form of a long ellipsoid of

rotation. The sensor registers changes of the field when an intruder crosses a protected area.

1.4.2. An intruder crossing the detection zone causes some changes of the signal

amplitude in Rx. The signal passes through the amplifier and is compared with the thresholds

value according to the algorithm. If the signal change on Rx input is provoked by a person

passage, then Rx generates an alarm, breaking actuating relay contacts. The signal changes

FORTEZA JSC FORTEZA FMC 24 (50m, 100m, 200m)

Please visit our internet sites: www.forteza.com or www.forteza.eu Page 7

depend on: height and weight of the intruder, place of the sector crossing, its relief and speed

of the movement.

1.4.3. The signal on Rx input can be changed under the influence of other interference

factors: precipitations, vegetations, small animals, electromagnetic interference, swinging of

tree branches or gates, crossing the detection zone and which are commensurable with

intruder movements.

Other reasons, e.g. location of extensive constructions in the detection zone or near it

(fences, walls), irregularities and snow can influence on the Rx input signal. In these cases

the detection zone form is distorted because of re-reflections and interferences.

Multi thresholds operation algorithm permits to reduce the number of false alarms.

That’s why one should observe the recommendations of the subsection 2.1.

1.4.4. The alarms reception and indication are performed with the security system

controlled by the relay contacts, and with the security systems operating with RS-485

interface. When an alarm is generated, the normally closed contacts are broken.

1.4.5. You can use laptop to adjust and control the sensor operation. The remote

adjustment is also possible; you can control the sensor with the alarm complex over RS-485

interface.

1.5. Sensor structure

1.5.1. The detector consists of separate units (Rx, Tx) placed in dust-, splash-proof

enclosures.

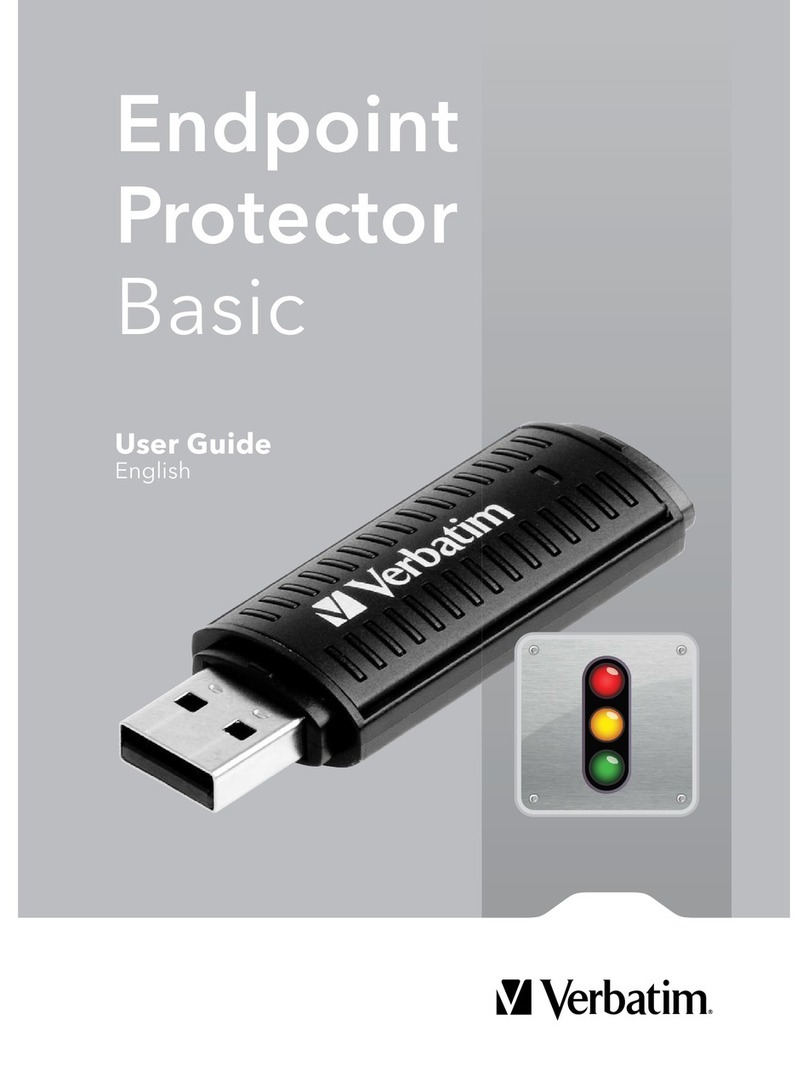

1.5.2. Rx Construction and its fastening elements to the support are given in fig. 1.2

The carrier of the unit is base 4. Radio transparent enclosure 5 is fixed to the base with fixing

elements. In the heel of the enclosure there are two holes preventing condensed fluid

accumulation within the unit. The access to the controls, adjustment, indication elements and

clamps for the connection of the terminal element is open when the cover 6 is removed. Rx

is connected to the alarm control device with eight wires cable 8. Rx is mounted on the

support 1 using the bracket 2 and two buckles 13. Mounting provides the rotation of the unit

horizontally at angle +65minimum; vertically: upward - at angle 30minimum, downward

–at angle 45minimum (if the bolt 12 is eased). Location and marking of the clamps,

controls, and adjustment and indication elements located under the cover 6 are shown in fig.

1.3(a).

1.5.3. Tx construction and its bracket are the same as the Rx construction (see fig.

1.2). The difference is in internal elements: under cover 6 are shown in fig. 1.3 (b); six wires

cables are used instead of cable 8.

1.5.4.Mounting kit includes two brackets and four buckles for the mounting on the

support of Rx and Tx.

FORTEZA JSC FORTEZA FMC 24 (50m, 100m, 200m)

Please visit our internet sites: www.forteza.com or www.forteza.eu Page 8

Fig.1.2

1-support - 1 item

2- bracket - 1 item

3- figured washer - 2 items

4-base -1 item

5-enclosure - 1 item

6-cover -1 item

7- corrugated tube - 1 item

8-cable - 1 item

9-ring - 1 item

10-nut M6 - 1 item

12-bolt M6*16 –1 item

13-buckle- 2items

Notes.

1. The support mounting on the ground is given in fig. 1.2 (item 2.2).

2. The dimensions are given in mm.

FORTEZA JSC FORTEZA FMC 24 (50m, 100m, 200m)

Please visit our internet sites: www.forteza.com or www.forteza.eu Page 9

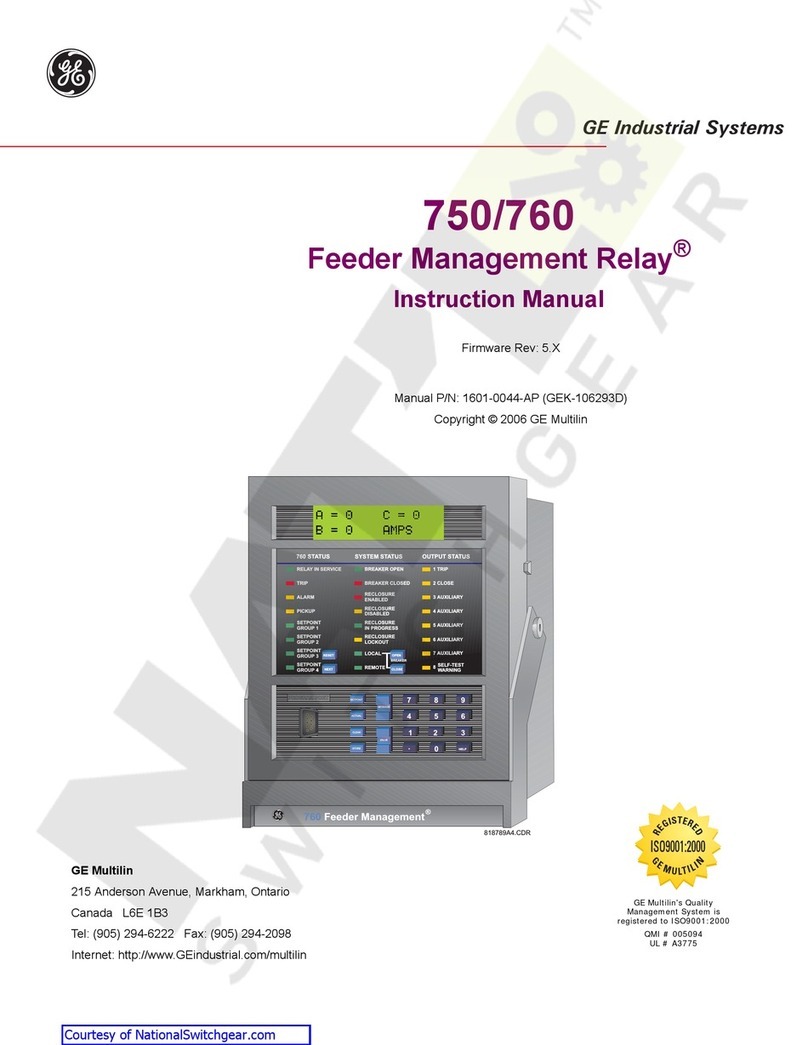

TX

RX

1 –frequency channels switches

2 –tamper circuit "TAMPER"

3 –indicator "LED"

4 –marking of cable cords

1 –frequency channels switches

2 –tamper circuit "TAMPER"

3 –socket "RS 485"

4 –button "AGC"

5 –sensitivity switches

6 –indicator "LED"

7 –marking of cable cords

Fig.1.3

Note. Dear user! The manufacturer of the detector constantly upgrades their quality and

reliability. That’s why in some lots of detectors one can find design modifications

unspecified in the documents delivered with the detectors. Nevertheless, the main

specifications are valid.

1.6. Adjustment, control and indication parts

1.6.1. The micro channels switches provided the frequency channels switch are set on

the transmitter and the receiver. Only one of four switches can be set with the same number

on the receiving and the transmitting side when the power supply is ON.

CAUTION! Set the frequency channels only when the power supply is OFF!

FORTEZA JSC FORTEZA FMC 24 (50m, 100m, 200m)

Please visit our internet sites: www.forteza.com or www.forteza.eu Page 10

If you switch a frequency channels on the operating sensor, the channels is not

changed, but after the power supply is switched ON/OFF the channels number is

changed.

1.6.2. The adjustment, the control and the sensor indication is performed by the

controls of the receiver LED indication and BUZZER sound, software FORTEZA FMC

oftware on PC.

1.6.3. Manual adjustment: calibration of detector signal using LED indication and

Buzzer; Sensitivity adjustment.

1.6.4. Adjustment using PC: calibration visualization; selection of detection zone

length; AUTO or MANUAL sensitivity adjustment modes.

1.6.5. To prevent unauthorized openings of the cover 6 (fig.1.2), a tamper button 2 is

placed in the receiver (fig.1.3). The button contacts are closed in the operating state. When

the cover is opened, the contacts are broken providing the circuit opening TAMPER.

2. INSTALLATION AND ADJUSTMENT PROCEDURE

The preparation to the sensor operation is the following:

- preparation of the sector;

- signal cables and power supply laying;

- Tx and Rx installation;

- sensor connection (connection of power supply and intruder alarm loops);

- alignment of Tx and Rx antennas

- Rx thresholds setting.

The principles and methods of these steps are given in i. 2.1-2.8.

2.1. Requirements for the protected sector of Rx and Tx alignment

2.1.1. The sector where Tx and Rx are located should meet the following

requirements:

a) The height of irregularities should not exceed +0,3m. If irregularities of the sector

surface from the plane exceed +0,3m, the specifications of the detector can worsen. In this

case the issue of the use of the detector under these conditions is defined by the trial

operation.

b) The height of the grass should not exceed 0,3m;

c) The height of the snow should not exceed 0,5m;

d) The maximum incline of the sector is 45˚;

e) Single fixed objects (e.g. posts, trees without lower branches) can be situated in the

detection zone at the distance of 0,5 m minimum from the axis;

f) The width of the sector should meet item 3.3.

FORTEZA JSC FORTEZA FMC 24 (50m, 100m, 200m)

Please visit our internet sites: www.forteza.com or www.forteza.eu Page 11

2.1.2. The detector can be mounted if the width of the sector is less. In this case if

“Calibration mode” voltage is less than 10 mV, it is necessary to change Rx and Tx position

relative to the support. For example, if Rx and Tx are at the left from the support, turning the

wall bracket relative to the support at 180º, fix Rx and Tx at the right from the support. If it

is not successful and “Calibration mode” voltage is less than 10 mV, it is necessary to realize

the trial operation and according to its results to make a decision about the possibilities of the

detector operation in these conditions.

2.1.3. Moving objects influenced by wind: wings of gate, bushes, trees branches, etc.

should not be situated in the detection zone and at the distance of:

± 1,7 m from the axis connected Rx and Tx at the perimeter length from 10 to 50 m;

± 2,2 m from the axis connected Rx and Tx at the perimeter length from 50 to 100 m;

± 2,6 m from the axis connected Rx and Tx at the perimeter length from 100 to 200 m.

2.1.4. Sector width should not be less than the detection zone one (see Table 1.1).

The sensor can be mounted if the sector width is less. In this case the sensor application is

determined by trial operation.

2.1.5. The range of the sector’s slope is 40˚ maximum.

2.1.6. The sensors with different channels should be mounted on the neighbor sectors.

When the sensor is mounted one after another on the sectors, a number of the channels

should be repeated successively from 1 to 4 providing the maximum distance of the sensors

with the same letter.

2.1.7. To increase the detection zone in the height, it is possible to align the sensors in

two tiers. The sensors should have different channels; two transmitters should be installed

from one side of the protected area, two receivers –from another one. The sectors lengths

should be identical.

2.1.9. The sensor can limit the maximum intruder’s speed. If the maximum intruder’s

speed is reduced, the interference immunity will be increased. The manufacture produces the

sensors with the maximum intruder’s speed of 10 m/sec (“high”). You can reduce the

maximum intruder’s speed up to 4 m/sec (“middle”) and up to 1 m/sec (“low”)*. You can

change the intruder’s speed with PC. After that it is necessary to set the alarm sensetivity

again.

e.g. open perimeter area –high intruder’s speed; the zone between a fence and an

auxiliary one (an intruder can’t rush) – middle intruder’s speed; sensor mounting on the

top of the fence –low intruder’s speed.

2.2. TX and RX mounting

2.2.1. Mark the perimeter area for the places where the supports will be mounted. To

generate a continuous protected boundary, the installation of Tx and Rx isn’t permitted on

adjacent perimeter sectors. The right installation on adjacent perimeter sectors is Tx and Tx,

Rx and Rx. To generate the continuous protected boundary, it is necessary to provide the

FORTEZA JSC FORTEZA FMC 24 (50m, 100m, 200m)

Please visit our internet sites: www.forteza.com or www.forteza.eu Page 12

overlapping of the sectors detection zones (see fig. 2.1 and 2.2). The overlapping is

necessary to eliminate the possibility of the sector overcoming under or above Tx (Rx)

unit near the support.

Fig. 2.1

Fig. 2.2

Note: To avoid co-interference between neighboring detectors, you can adjust them

to different operation channels (don’t forget to change receiver’s and transmitter’s

operation channels too with the mentioned way in the manual).

Note: Avoid installation in a way where the reflected microwave signals (by metal

fences and other metal objects or by wet surfaces after rain and snow) may cause

interference and false alarms.

2.2.2. Mount the supports. It is recommended to use metal or asbestos-cement tube as

supports of 70…90 mm diameter. The height of the support above the surface of the ground

is given in fig. 2.3. In the places where there is a lot of snow, the superstructure of the

support should be 1500 mm minimum. As for the support construction, it is necessary to

provide some dowels for concreting and some holes for the cable gland. The example of the

Tx2

Tx1

Rx1

Rx2

2…3 m

2…3 m

Rx1

Rx3

Tx2

Tx1

Rx2

Tx3

FORTEZA JSC FORTEZA FMC 24 (50m, 100m, 200m)

Please visit our internet sites: www.forteza.com or www.forteza.eu Page 13

support mounting is given in fig. 2.3. In the snowy regions the superstructure of the support

should be 1500 mm minimum.

1 - support;

2 - plastic plug;

3 - hole for the cable input inside the

support;

4 - hole for the main cable and sensor

cable input;

5 - hole for the main cable input;

6 - concrete (gravel);

7-dowels for prevention the

unauthorized dismounting of the

support;

8- ground

Fig. 2.3

Note.

1. For A size the ground should be laid after installation works.

2. Dimensions are given in millimeters (mm).

2.2.3. Other variants of the sensor mounting (for example on the fence or wall) can be

applied according to the protection tactics. If the sensor blocks the top of the fence, it is

recommended to fasten the support with the fence with a solid mechanical or welded joint.

Table 2.1

Sensor

Max detection zone

length (L), m

Max detection zone

width (b), m

Max detection zone

height (h), m

FMC 24 (50m)

40

1,0

1,0

FMC 24 (100m)

75

1,5

1,5

FMC 24 (200m)

75

1,5

1,5

FORTEZA JSC FORTEZA FMC 24 (50m, 100m, 200m)

Please visit our internet sites: www.forteza.com or www.forteza.eu Page 14

Fig.2.4

2.2.4. Lay the main cables according to the project of the security system. It is

recommended to use multicore cables with the core screen or metal sheath. The cable core

section is chosen on condition that the supply voltage is not less than 9 V for every sensor

unit. It is not recommended to lay the main cables near heavy electromagnetic interference

sources (power lines, antenna systems, and etc.) and to use free cable cores for impulse

signal transmission. CAUTION! To reduce the level of electromagnetic interferences, it

is recommended to mount the power supply unit at a distance up to 300 m from the

place where the sensors are installed.

2.2.5. The mounting kit (MK) for mounting on the top of the fence can be delivered on

the customer order to protect the perimeter site from the intruder climbing over the fence and

the intrusion into the window. The example of the sensor installation with the brackets

application 350, 500 mm is given in fig. 2.4. The detection zone sizes are shown in Table

2.1. The angles to turn horizontally the sensor units on the brackets are 180˚, vertically: up –

at the angle of 17˚, down - 45˚.

FORTEZA JSC FORTEZA FMC 24 (50m, 100m, 200m)

Please visit our internet sites: www.forteza.com or www.forteza.eu Page 15

Notes.

1. If the upper part of the fence is protected with physical protection devices, it is necessary

to use the bracket of 500 mm. If the upper part of the fence is not protected with barbed

wire, it is recommended to use the bracket of 350 mm.

2. The height of Rx and Tx units for the protection of the fence upper part is equal to the

fence height ±100 mm.

3. The dimensions and materials of the fence are not specified. It is necessary to provide

the fence rigidity.

4. The detection zone dimensions b and h are given for the correct alignment of the sensor

according to i. 2.4, 2.5.

5.To avoid co-interference between neighboring detectors, you can adjust them to different

operation channels (don’t forget to change receiver’s and transmitter’s operation

channels too with the mentioned way in the manual).

6.Avoid installation in a way where the reflected microwave signals (by metal fences and

other metal objects or by wet surfaces after rain and snow) may cause interference and

false alarms.

2.2.6. Mount Tx and Rx on brackets with bolts 12 (fig.1.2).

2.3. Sensor connection

2.3.1. Connect the necessary power, signal and remote control circuits. Rx and Tx unit

is connected with its own cables. The color or marking of the cable conductors indicate their

purpose.

The information about cable conductors marking, color and purpose is given in Table 2.2.

2.3.2. Set the letter of the sensors with the channels switches of Tx and Rx.

Table 2.2.

Rx

Tx

Circuit

Color

Purpose

Circuit

Color

Purpose

“+”

red

Supply voltage

“+”

red

Supply voltage

“-“

blue

“-“

blue

“TAMPER”

yellow

Tamper button

contacts TAMPER

“TAMPER”

yellow

Tamper button

contacts TAMPER

“TAMPER”

black

“TAMPER”

black

“NC”

orange

Normally closed

contacts of actuating

relay NC

“NC”

brown

“RS A”

white

Contacts of RS-485

connection

“RS B”

green

FORTEZA JSC FORTEZA FMC 24 (50m, 100m, 200m)

Please visit our internet sites: www.forteza.com or www.forteza.eu Page 16

Fig. 2.5

Warning: Do not open the detector’s housing, because it may damage the device!!!

Note: Always use separated cables for the power supply circuit as the cables for the

alarm signal circuit to avoid unexpected alarms.

Note: The alarm contact loading capacity is up to 30 Vdc 0.1 A.

Note: All the electronic connections should be carried out only after power is

disconnected.

2.3.3. The type and the nominal of the terminal element of the security systems loop

(resistor, condenser and diode) are determined by the type of the control device. The detector

is connected to the control device. Usually it is a resistor. The nominal resistance of this

resistor should take into the clamping resistor of the lightning circuit (this resistor - 100

Ohm) and resistance of the security systems loop (depends on the chosen cable type and its

length).

2.3.4. The contacts of the tamper circuit (“TAMPER”) of Rx or Tx can be connected

to the receiver control device by the separate loop. In this case the user receives the

information of the opening of the Rx or Tx terminal covers with the separate signal. The

second variant: the individual point relay is switched ON in series with the contacts of the

individual relay. In this case an alarm will be generated when:

-the individual point relay functions;

-the opening of the Rx or Tx terminal covers on one channel of the control device.

2.4. Sensor adjustment with the built-in adjustment, control and indication parts

2.4.1 Preliminary adjustment of Tx and Rx

2.4.1.1. Loosen the bolts 12 and 9 of Rx and Tx (fig.1.2).

FORTEZA JSC FORTEZA FMC 24 (50m, 100m, 200m)

Please visit our internet sites: www.forteza.com or www.forteza.eu Page 17

2.4.1.2. Direct Rx and Tx against each other using a sight leaf situated on the antennas

sides.

2.4.1.3. Tighten the bolts 12 and 9 of Rx and Tx;

2.4.2. Main adjustment of Tx and Rx

2.4.2.1. Open the cover 6 of Rx (fig.1.2).

TX transmitter

RX receiver

Fig. 2.6

2.4.2.2. Channels set up. The receiver and transmitter should be adjusted to the same

signal frequency. It is necessary to set the different channels to nearby detection zones.

FREQ CH switches

Note: You can check which channel receiver and transmitter in operation by

switches FREQ CH position (table 9.1.)

2.4.2.3. Check the right connection of supply circuits and output circuits of the

detector. Switch ON the power supply.

2.4.2.4. When power is supplied to detector Rx and TX units, the “LED” blinking

indicates the frequency channel.

TX - “LED” blinks once per 2 sec it is means that power is connected and it is

acceptable range.

RX - after 1-2 minutes afters tuning the power supply, check the status of “LED”

indicator: the indicator should be off, that informs, detector is in standby mode.

2.4.2.5. After 3-5 sec RX “LED” is switch off which means that detector is in

operation mode.

Note: In situation, if the indicator Rx continuously on, periodically and briefly goes

out or lights up-determine the problem and correct it using table 4.1

2.4.2.6. Aligning is performed incrementally and consists of a set of repetitive actions.

The alignment can be started with both transmitter or receiver. In the alignment mode, the

detector switch, when you press and hold down the button, "AGC" on receiver. The indicator

FORTEZA JSC FORTEZA FMC 24 (50m, 100m, 200m)

Please visit our internet sites: www.forteza.com or www.forteza.eu Page 18

“LED” and BUZZER is switched ON.

2.4.2.7. Tx and Rx are adjusted on the angle of the place and the azimuth according to

the buzzer signals and “LED” blinking’s (on the RX). Two persons are necessary for the

detection zone calibration. One of them is situated next to Rx, the other –next to Tx.

The alignment includes the following order:

a) Loosen the bolts 12 (see fig. 6.1) of Rx; Loosen the nuts 10;

b) Press and hold the button “AGC” on Rx. Rotate Rx horizontally, seeking the

maximum signal, then rotate the Rx vertically, seeking the maximum signal (the

most frequent LED indicator flashes/beeps). Release the „AGC“ button.

Repeat the paragraph b) If during the repeat of paragraph b), rotating the unit vertically the

flashing of LED indicator slows down the adjustment will be complete. Otherwise one more

time repeat articles in the following sequence a) and b).

c) Tighten the bolts 12;

d) Tighten the nuts 10;

Check the buzzer signal speed and “LED” blinking’s as a result of the adjustment.

Rx and Tx must directly at each other for stable operation. Don’t misalign Rx and Tx

down or a side.

2.4.2.8. After commencing the adjustment, wait for the sensor to switch in to working

mode (1-2 minutes), the LED should go out.

2.4.2.9.Complete the described actions for the Tx, controlling the signal level

according to the indicator of Rx. For coordination of actions use the talk set.

2.4.2.10. If the LED shines and rarely turns out - the calibration signal voltage is in the

upper critical point of the allowed diapason - a) the increasing of distance is needed between

Rx and Tx or b) disalig the sensors by turning them up. If the LED rarely flashes - the power

of the signal is in the lower point of the allowed diapason - it is needed to lower the distance

between Rx and Tx or change (with 4-5 cm interval) the placement of Rx or Tx from the

ground down or up.

2.4.3. Sensitivity setting

2.4.3.1. Standard switches SENS in the position PC this means that sensitivity is

set from computer. You can change the sensitivity +10% or -10% percent’s using switches

if it necessary.

2.4.3.2. Sensitivity is adjusted according to the protected sector crossing at the “full

height” or “bent” (crawling) along its whole length. It is recommended to begin doing these

check passages in the middle of the protected area. It is necessary to go out of the detection

zone at a distance of 1-2 m and to pause from 5 to 7 sec. Otherwise, the results of the

previous passage will influence on the next one.

2.4.3.3. When the sensor generates alarms, “LED” indicator shines for 3 sec. After the

switching ON of the indicator “LED”, the following passage can be done.

FORTEZA JSC FORTEZA FMC 24 (50m, 100m, 200m)

Please visit our internet sites: www.forteza.com or www.forteza.eu Page 19

2.4.3.4. Do some check passages in “problem” places of the detection zone: hollows,

hills, near to barriers, buildings, and trees situated in the detection zone. If it is necessary

change the sensor sensitivity.

2.4.3.5. We offer to set switchers in position –10% and cross the detection zone

in different points. In case if the detector is not generated alarm during the investigator

passage, set first switchers to position and after that to position + 10% .

Notes. If switcher’s is in position + 10% the detector is not generated alarm during

the investigator passage, please use computer to adjust the sensitivity.

2.4.3.6. When the adjustment is over, it is necessary to close Rx and Tx terminal

covers.

2.4.3.7. After the sensor adjustment it is recommended to carry out its trial operation

for 2…3 days to reveal and eliminate possible errors of mounting and adjustment.

2.5. Software installation and detector adjustment with PC

2.5.1. The computer allows checking the signal level, change sensitivity parameters,

detection zone length, giving a signal, setting some parameters inaccessible for Preliminary

adjustment.

2.5.2. Software installation

2.5.2.1. You can download the latest version of setup software from our website

download menu http://www.forteza.com or find it on USB FLASH DRIVE which is

included in detector set.

2.5.2.2. Connect the sensor to PC with RS 485 with USB, power to the sensor. The

computer determines the type of USB device and installs the driver on COM-port. If the

driver is not installed automatically, the computer asks to install the driver. Follow IIIIIII

You can find driver in Forteza FMC SOFT file.

This manual suits for next models

1

Table of contents