Fostex 5042 User manual

Service Manual

Model

16TRACK DIGITAL RECORDER

8TRACK DIGITAL RECORDER

&

MODEL 8345 TC/SYNC CARD

MODEL 5042 / 5043 BALANCE I/O CARD

MODEL 8350 AES/EBU CARD

SAFETY INSTRUCTIONS

Read instructions - All the safety and operating instruc-

tions should be read before the appliance is operated.

Retain instructions - The safety and operating instructions

should be retained for future reference.

Heed warnings - All warnings on the appliance and in the

operating instructions should be adhered to.

Follow instructions - All operating and use instructions

should be followed.

Water and Moisture - The appliance should not be used

near water - for example, near a bathtub, washbowl,

kitchen sink, laundry tub, in a wet basement, or near a

swimming pool, and the like.

Carts and Stands - The appliance should be used only

with a cart or stand that is recommended by the manufac-

turer.

An appliance and cart combination should be moved with

care. Quick stops, excessive force, and uneven surfaces

may cause the appliance and cart combination to over-

turn.

Wall or Ceiling Mounting - The appliance should be

mounted to a wall or ceiling only as recommended by the

manufacturer.

Ventilation - The appliance should be situated so that its

location or position does not interfere with its proper ven-

tilation. For example, the appliance should not be situ-

ated on a bed, sofa, rug, or similar surface that may block

the ventilation openings; or, placed in a built-in installa-

tion, such as a bookcase or cabinet that may impede the

flow of air through the ventilation openings.

Heat - The appliance should be situated away from heat

sources such as radiators, heat registers, stoves, or other

appliances (including amplifiers) that produce heat.

Power Sources - The appliance should be connected to a

power supply only of the type described in the operating

instructions or as marked on the appliance.

Grounding or Polarization - The precautions that should

be taken so that the grounding or polarization means of

an appliance is not defeated.

Power Cord Protection - Power supply cords should be

routed so that they are not likely to be walked on or

pinched by items placed upon or against them, paying

particular attention to cords at plugs, convenience recep-

tacles, and the point where they exit from the appliance.

Cleaning - The appliance should be cleaned only as rec-

ommended by the manufacturer.

Nonuse Periods - The power cord of the appliance should

be unplugged from the outlet when left unused for a long

period of time.

Object and Liquid Entry - Care should be taken so that

objects do not fall and liquids are not spilled into the en-

closure through openings.

Damage requiring Service - The appliance should be ser-

viced by qualified service personnel when:

A.

B.

C.

D.

E.

Servicing - The user should not attempt to service the ap-

pliance beyond that described in the operating instruc-

tions. All other servicing should be referred to qualified

service personnel.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK).

NO USER-SERVICEABLE PARTS INSIDE.

TO PREVENT ELECTRIC SHOCK, MATCH

WIDE BLADE OF PLUG TO WIDE SLOT,

FULLY INSERT.

POUR ÉVITER LES CHOCS ÉLECTRIQUES,

INTRODUIRE LA LAME LA PLUS LARGE DE

LA FICHE DANS LA BORNE CORRE-

SPONDANTE DE LA PRISE ET POUSSER

JUSQU' AU FOND.

CAUTION:

ATTENTION:

The exclamation point within an equilateral

triangle is intended to alert the user to the

presence of important operating and mainte-

nance (servicing) instructions in the literature

accompanying the appliance.

The lightening flash with arrowhead symbol,

within an equilateral triangle, is intended to

alert the user to the presence of uninsulated

“dangerous voltage” within the product's en-

closure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

“WARNING”

“TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK,

DO NOT EXPOSE THIS APPLIANCE TO RAIN OR MOIS-

TURE.”

1.

2.

3.

4.

5.

6.

7.

8.

The power supply cord or the plug has been damaged;

or

Objects have fallen, or liquid has been spilled into the

appliance; or

The appliance has been exposed to rain; or

The appliance does not appear to operate normally or

exhibits a marked changed in performance; or

The appliance has been dropped, or the enclosure

damaged.

9.

10.

11.

12.

13.

14.

15.

16.

17.

3

D1624 / D824

Parts marked with this sign are safety critical components. They must always be replaced with identical

components. Refer to the Fostex Parts List and ensure exact replacement.

CAUTION

TABLE OF CONTENTS

D1624 / D824 English owner's manual : 8288461000

D1624 / D824 Japanese owner's manual : 8288462000

D1624 / D824 English quick guide : 8288463000

D1624 / D824 Japanese quick guide : 8288464000

Service mode, exploded view, PCB assembly, parts list and circuit diagrams are given in this manual

to assist the service technician in maintaining the Model D1624 / D824.

NOTES

The following accessories are supplied with D1624 / D824 as the standard accessories.

*

*

Following is the packing material for the Model D1624 / D824.

*

Carton, inner, D1624 : 8228731000

Carton, outer, D1624 : 8228910000

Carton, inner, D824 : 8228736000

Carton, outer, D824 : 8228914000

Packing, side, L, D1624 / D824 : 8228430001

Packing, side, R, D1624 / D824 : 8228430002

Packing, case, D1624 / D824 : 8228435000

!

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. CONTROLS, INDICATORS & CONNECTORS . . . . . . . . . . . . . . .

3. SOFTWARE UPDATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. SERVICE MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. ERROR CODE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. MODEL 8345/5042/5043/8350 INSTALLING PROCEDURES . . . . .

7. EXPLODED VIEW, PCB ASSEMBLY & PARTS LIST . . . . . . . . . .

8. CIRCUIT & BLOCK DIAGRAMS . . . . . . . . . . . . . . . . . . . . . .

4

8

11

12

22

23

30

58

4

D1624 / D824

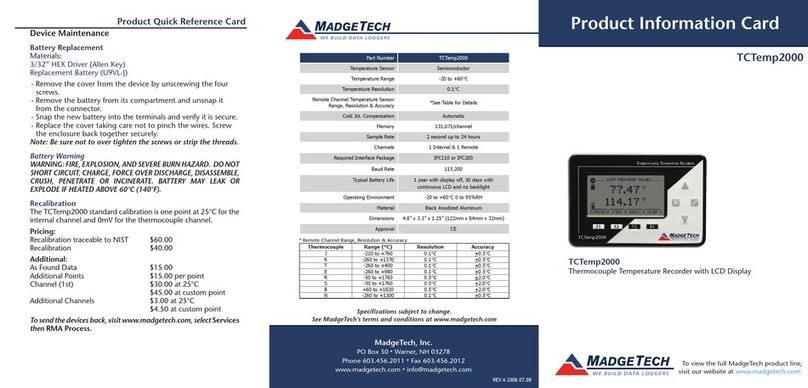

1. SPECIFICATIONS

D824 / D1624

INPUT & OUTPUT

INPUT (1 ~ 8)

Connector RCA pin jack (x 8)

Input Level -10 dBV

Input Impedance 10 kΩor more

OUTPUT (D824: 1 ~ 8, D1624: 1 ~ 16)

Connector RCA pin jack (x 8: D824, x 16: D1624)

Output Level -10 dBV

Load Impedance 10 kΩor more

DATA IN / OUT (D824: 1 ~ 8, D1624: 1 ~ 8 & 9 ~ 16)

Connector Square shape optical

Format IEC consumer optical standard (IEC 60958 Part 3)

Alesis Proprietary Multichannel Optical Digital Interface

(ADAT format does not comply to 96 kHz sampling frequency.)

MIDI IN / OUT /THRU

Connector DIN 5-pin

Format Comply to MIDI standard

WORD IN / OUT

Connector BNC

Level TTL level

REMOTE IN /THRU

Connector D-SUB 9-pin

Transfer Format RS-422

Protocol Sony 9-pin (P2) protocol, ES bus

SCSI

Connector D-SUB 50-pin (half pitch)

Protocol SCSI-2, unbalanced transfer method

Transfer Type Asynchronous

Number of Unit Connected 1

PUNCH IN / OUT

Connector Ø6 mm phone jack

Level CMOS (HIGH: 3.5 ~ 5 V, LOW: 0 ~ 1.5 V)

RECORD & PLAYBACK

Recording Medium Internal 3.5” E-IDE hard disk drive (optional)

Backup Medium External fixed / removable SCSI-2 SCSI device (backup only)

Standard SCSI-2 or better

Sampling Frequency 44.1 kHz, 48 kHz, 96 kHz (Switchable by Disk Format)

Quantization 16-bit linear, 24-bit linear (Switchable by Disk Format)

A-to-D Converter 24-bit delta-sigma 128 times over sampling

D-to-A Converter 24-bit delta-sigma 128 times over sampling

Recording Format FDMS-3Version 2

Emphasis Not available

RecordingTime (mono track min.) About 18 min. / 100 MB at maximum (at 44.1 kHz)

Number ofTracks 24tracks(D824:8+16additionaltracks,D1624:16+8additionaltracks)

Number of RecordingTracks at a Time

D824 8

D1624 16 (when using DATA IN), 8 (Analog only or at 24-bit / 96 kHz)

5

D1624 / D824

Number of playback tracks at a time

D824 8

D1624 16, 8 (at 24-bit / 96 kHz)

No. of Programs 99

Pitch Control ± 6.0 % (0.1 % step)

Crossfade 10 msec (at 44.1 / 48 kHz), 5 msec (at 96 kHz)

Overall Frequency Response 20 ~ 20 kHz ± 1 dB (at 44.1 / 48 kHz)

20 ~ 43 kHz ± 2 dB (at 96 kHz)

Signal to Noise Ratio 100 dB or more (betweenADC and DAC, 24-bit)

Dynamic Range 100 dB or more (betweenADC and DAC, 24-bit)

T.H.D. 0.01 % or less (at 1 kHz, -10 dBV, 24-bit)

Channel Separation 80 dB or more (at 1 kHz, 0 dB, 24-bit)

Phase difference between channels 20 º or less (at 20 kHz)

OPERATION

Shuttle Speed 8 steps (7 steps for FWD direction)

CUE ON ± 1 ~ 8 times (FWD: ± 1 ~ 7 times)

CUE OFF ± 1 ~ 64 times

FFWD / REW Speed

CUE ON ± 3 times

CUE OFF ± 32 times

Digital Scrubbing (JOG) 0~1times(Envelopecanbedisplayedwhenselectingonlyonetrack.)

Locate Memory 6 (7 including [LOCATE] key temporary memory) + 99

Level Indication

Type FL Bargraph

Number of Indicated Levels 11 dots (-∞, -42, -30, -24, -18, -12, -9, -6, -3, 0, OVER)

Reference Level (-10 dBV) Indication - 12 dB

Full Scale Output Level + 2 dBV ± 1 dB

GENERAL

Dimensions 482 (W) x 148 (H) x 381 (D) mm

Weight 7.0 kg

Power Supply

JPN 100VAC

USA / CND 120VAC

EUR / UK 230VAC

Power Consumption

D824 Approx. 30 W

D1624 Approx. 35 W

Standard Environment

StandardTemperature 20 ± 2 ºC

Standard Humidity 65 ± 5 %

ENVIRONMENT CONDITION (W/O HD)

Characteristics Guaranteed

Temperature + 5 ~ + 40 ºC

Humidity 30 ~ 70 %

AC voltage deviation ± 5 % or less

Operation Guaranteed

Temperature 0 ~ + 45 ºC

Humidity 85 % or less

AC voltage deviation ± 10 % or less

6

D1624 / D824

8345

INPUT & OUTPUT

TIME CODE INPUT

Format SMPTE/EBU

Connector XLR-3-31 type (Pin 1: GND, Pin 2: HOT, Pin 3: COLD)

Standard Input Level 2V p-p

Minimum Input Level 0.25V p-p

Input Impedance 20 kΩor more

TIME CODE OUTPUT

Format SMPTE/EBU

Connector XLR-3-32 type (Pin 1: GND, Pin 2: HOT, Pin 3: COLD)

Standard Output Level 2V p-p

Minimum Output Level 0.25V p-p

Load Impedance 20 kΩor more

VIDEO INPUT

Format Composite (Applied video signal must comply to PAL or NTSC

standard and be interlace type.)

Connector BNC

Frame Pulse 24, 25, 29.97, 30 Hz (± 1000 ppm)

Field Pulse 48, 50, 59.94, 60 Hz (± 1000 ppm)

Standard Input Level 1V p-p

Input Impedance 75 Ω(ON / OFF by terminator SW)

VIDEOTHRU

Connector BNC

Output Level Direct output of signal fed toVideo Input connector

WORD INPUT

Connector BNC

Frequency 44.1 kHz, 48 kHz

Standard Input Level TTL level

Input Impedance 75 Ω(ON / OFF by terminator SW)

WORD OUTPUT

Connector BNC

Standard Output Level TTL level

Load Impedance 75 Ω

GENERAL

Dimensions 215 (W) x 80 (D) mm

Power Supply Supplied from main unit

Digital DC + 5V

Analog DC + 19V / - 15 V

7

D1624 / D824

5042 / 5043

INPUT & OUTPUT

INPUT (1 ~ 8)

Connector D-SUB 25-pin

Standard Input Level + 4 dBu

Input Impedance 10 kΩor more

OUTPUT (1 ~ 8)

Connector D-SUB 25-pin

Output Level + 4 dBu

Load Impedance 600 Ωor more

OUTPUT (9 ~ 16, Model 5043 only)

Connector D-SUB 25-pin

Output Level + 4 dBu

Load Impedance 600 Ωor more

GENERAL

DIMENSIONS 270 (W) x 70 (D) mm

POWER SUPPLY DC + 15V (Supplied from main unit)

8350Connector D-SUB 25-pin

Format IEC958 PART 3 (AES/EBU)

Pin assignment Indicated below

Recommended cable AES/EBU digital audio transfer cable from Hosa Technology Inc.

DBK-258 (DB-25 (male) ↔4 x XLR (male) & 4 x XLR (female))

13 1

1425

[D-SUB 25-pin Assignment ]

(Seen from rear panel side)SIGNAL

Input 1/2

Input 3/4

Input 5/6

Input 7/8

Output 1/2

Output 3/4

Output 5/6

Output 7/8

HOT

1

2

3

4

5

6

7

8

COLD

14

15

16

17

18

19

20

21

Frame GND 10, 12, 13, 22,

23, 24, 25

Open 9, 11

8

D1624 / D824

2. CONTROLS, INDICATORS & CONNECTORS

Front Panel Section:Main Unit (D1624 / D824)

1. Detachable Controller connector

2. Controller mounter

3. Removable hard disk cartridge slot

4. Lock/Unlock key

5. Hard disk power LED

6. Access LED

7. Power switch

1. Controller Connection Cable

2. Record Track Select / Envelope key

3. Track Shift / All Input key

4. Auto Play/Auto Return key

5. Clipboard In / Preview key

6. Clipboard Out / Preview key

7. Auto Return Start / Preview key

8. Auto Punch In / Preview key

9. Auto Punch Out / Preview key

10. Auto Return End / Preview key

11. Display Select key

12. Program select key

13. Store key

14. Exit/No / Eject key

15. Execute/Yes / Chase key

16. Recall key

17. NEXT key

18. Previous key

19. Jog/Shuttle dial

20. Vari-pitch / Pitch Edit key

21. Fast Forward key

22. Locate key

23. Rewind key

24. Undo/Redo / Multi Undo key

25. Play key

26. Setup / TC Generator Setup key

27. Stop key

28. Edit / TC Ready key

29. Record /All Ready key

30. Auto Punch Mode On/Off key

31. Shift key

32. TC ready LED

33. Access LED

34. All Input LED

35. Punch In/Out jack

36. Meter display

Front Panel Section: Controller (D1624 / D824)

12 3 42

567

12

3

45 678910

11

12

13 14 1516

1718

19

212325272931 202224

26

2830323334

35

36

9

D1624 / D824

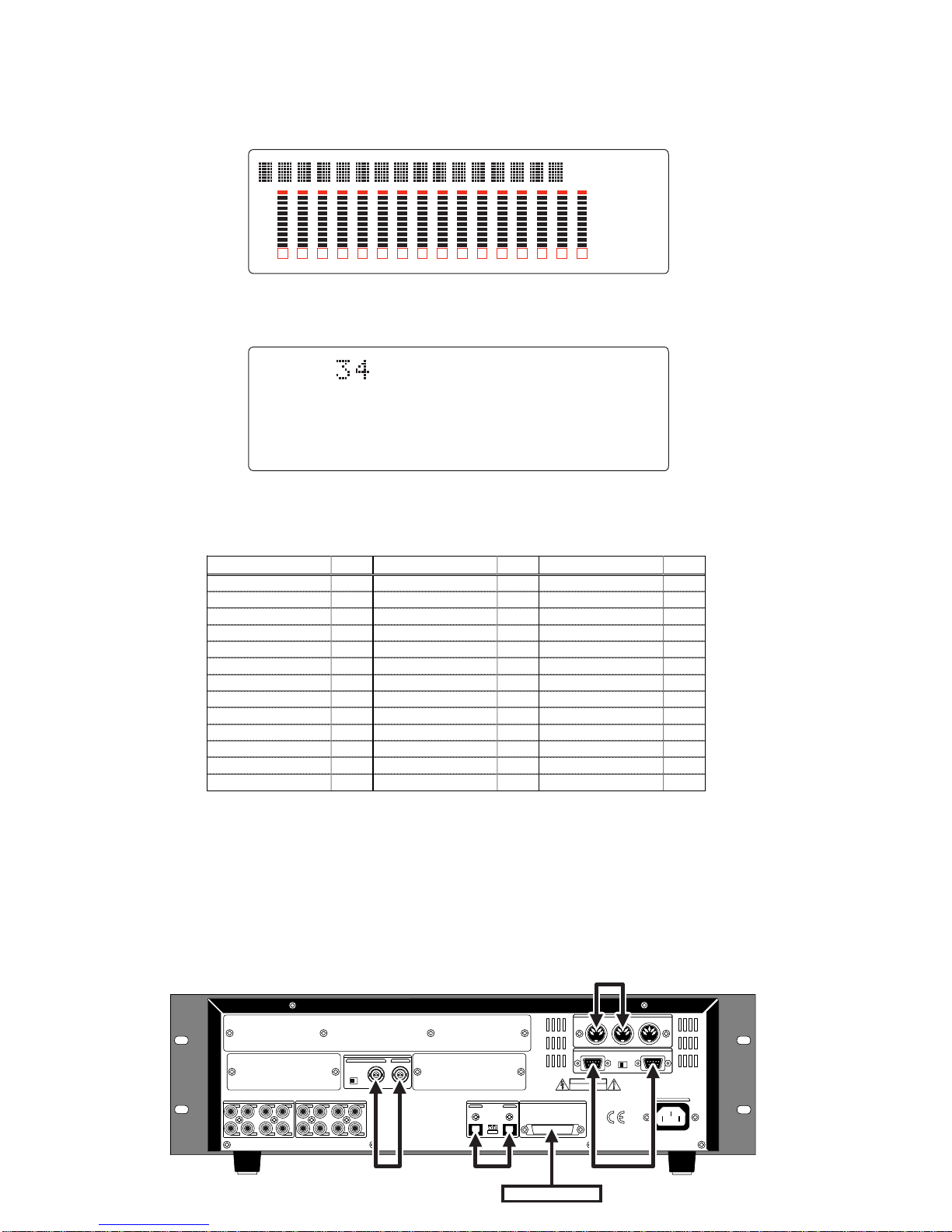

Rear Panel Section (D824)

Rear Panel Section (D1624)

1. PanelA for an optional card

2. Panel B for an optional card

3. WORD IN terminating switch

4. WORD INPUT connector [BNC]

5. WORD OUTPUT connector [BNC]

6. MIDI Input/Output/Thru connector

7. AC IN connector

8. REMOTE THRU connector

9. REMOTE INPUT terminating switch

10. REMOTE INPUT connector

11. SCSI connector [half-pitch 50-pin]

12. Digital/Data Output connector [OPTICAL]

13. Digital/Data Input connector [OPTICAL]

14. Analog Output jack [RCA pin]

15. Analog Input jack [RCA pin]

100

ON OFF

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

AVIS:

RISQUE DE CHOC ELECTRIQUE NE PAS OUVRIR

WARNING:

TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, DO NOT EXPOSE THIS EQUIPMENT

TO RAIN OR MOISTURE.

REMOTE

THRU

MIDI

INPUT OUTPUT THRU

INPUT

OFFON

WORD

OUTPUTINPUT

SCSI

8 - 116 - 9 8 - 1 16 - 9

OUTPUTINPUT

DIGITAL/DATA AC INANALOG OUTPUT

ANALOG INPUT

5

1

678

234

13

5

141516

678

9

1

101112

234

OPTICAL

75Ω

12 234 5 6

789101112

131415

REMOTE

THRU

MIDI

INPUT OUTPUT THRU

AC IN

INPUT OUTPUT

WORD

ON OFF

43

ANALOG INPUT

2

87 6

1

5

43

ANALOG OUTPUT

2

87 6

1

5

OUTPUTINPUT

SCSIDIGITAL/DATA

100

ON OFF

OPTICAL

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

AVIS:

RISQUE DE CHOC ELECTRIQUE NE PAS OUVRIR

WARNING:

TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, DO NOT EXPOSE THIS EQUIPMENT

TO RAIN OR MOISTURE.

75Ω

12 234 5 6

789101112

131415

10

D1624 / D824

Rear Panel Section (D824 with Model 5042, 8345 and 8350)

Rear Panel Section (D1624 with Model 5043 and 8345)

[ MODEL 5043 ]

1. Balanced input connector

2. Balanced output connector (9 - 16)

3. Balanced output connector (1 - 8)

[ MODEL 8345]

4. Video input terminating switch

5. Video input connector

6. Video thru connector

7. Word input terminating switch

8. Word input connector

9. Word output connector

10. Time code input connector

11. Time code output connector

[ MODEL 5042 ]

1. Balanced input connector

2. Balanced output connector

[ MODEL 8350 ]

3. Digital input & output connector

[ MODEL 8345 ]

4. Video input terminating switch

5. Video input connector

6. Video thru connector

7. Word input terminating switch

8. Word input connector

9. Word output connector

10. Time code input connector

11. Time code output connector

REMOTE

THRU

MIDI

INPUT OUTPUT THRU

AC IN

INPUT OUTPUT

WORD

75Ω

ON OFF

43

ANALOG INPUT

2

87 6

1

5

43

ANALOG OUTPUT

2

87 6

1

5

OUTPUTINPUT

SCSIDIGITAL/DATA

100

ON OFF

OPTICAL

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

AVIS:

RISQUE DE CHOC ELECTRIQUE NE PAS OUVRIR

WARNING:

TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, DO NOT EXPOSE THIS EQUIPMENT

TO RAIN OR MOISTURE.

INPUT

OUTPUT

INPUT THRU

VIDEO

75Ω

ON OFF

+4dBu INPUT

ANALOG BALANCE I/O

+4dBu OUTPUT

TIME CODE

3

2

1

COLD

GND

HOT

8-1 I/O

AES/EBU

123

45 9

810

76 11

100

ON OFF

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

AVIS:

RISQUE DE CHOC ELECTRIQUE NE PAS OUVRIR

WARNING:

TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, DO NOT EXPOSE THIS EQUIPMENT

TO RAIN OR MOISTURE.

REMOTE

THRU

MIDI

INPUT OUTPUT THRU

INPUT

OFFON

75Ω

WORD

OUTPUTINPUT

SCSI

8 - 116 - 9 8 - 1 16 - 9

OUTPUTINPUT

DIGITAL/DATA AC INANALOG OUTPUT

ANALOG INPUT

5

1

678

234

13

5

141516

678

9

1

101112

234

OPTICAL

HOT

GND

COLD

1

2

3

TIME CODE

OFFON

75Ω

VIDEO

THRUINPUT OUTPUT

INPUT

+4dBu OUTPUT 8-1+4dBu OUTPUT 16-9

ANALOG BALANCE I/O

+4dBu INPUT 8-1

123

45 9

810

76 11

11

D1624 / D824

3. SOFTWARE UPDATE

Since the 8Mbit flash ROM is mounted on the MAIN PCB assy, the D1624/D824 software can be updated through the

SCSI port. Please refer to the following explanation for correct software updating procedures.

3-1. Required Tools

The following tools/equipment are required to update the D1624/D824 software.

1. IBM PC/AT compatible computer with SCSI board

2. Removable type SCSI drive

3. Cable between the removable type SCSI drive and the SCSI board

4. Cable between the removable type SCSI drive and the D1624/D824 (D-SUB half-pitch 50-pin)

5. A Utility software to extract the WinZip compressed file

3-2. Software Updating Procedures

Presuming that the updated software is correctly sent to you via email and is copied into your computer.

1. Connect the removable type SCSI drive to the IBM PC/AT compatible computer SCSI port.

2. Insert the diskette to the removable type SCSI drive and format it by the computer on which Windows 95/98 is

running.

3. Using the utility software, extract the WinZip compressed software file. The extracted file name is “d1624mvX.XX”.

(X.XX indicates the version number. For example, if the software version number is V1.06, the file name is

d1624mv1.06.)

3. Copy the updated software file “d1624mvX.XX” to the removable type SCSI drive (diskette).

4. Set the removable type SCSI drive ID to 6 and connect to the D1624/D824 SCSI port (D-SUB half-pitch 50-pin).

5. Turn on the power of removable drive and then D1624/D824.

6. Insert the diskette with updated software file.

7. The D1624/D824 automatically finds the software update file in the SCSI drive/disk and is put into the software

update mode. In this condition, “SystemUp” is displayed and “SURE?” is blinking on the FL display.

44.1kHz

SURE?

42

_

OL

0

30

24

18

12

9

6

3

12345678910111213141516

8. Press the [EXECUTE/YES] key to start updating the software.

9. The D1624/D824 FL display shows “Loading !”, “Writing !”, etc and after a while, “SystemUp” appears on the

FL display again. This indicates that the software is correctly updated. Press the [STOP] key or [EXIT/NO] key to

eject the disk.

10. Turn off the D1624/D824 and the connected SCSI drive.

11. Disconnect the SCSI drive from the D1624/D824 and power on the D1624/D824 again.

12. Confirm the software version number and the programming date while in the boot up procedures. For your

information, they can also be checked by the Service Mode explained later.

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910 11 12 13 14 15 16

SETUP

: Blinking

[CAUTION]

In case the D1624/D824 does not find the software update file in the external SCSI drive by itself, please follow the

procedures below.

1..6. Same as the before mentioned procedures.

7. Press the [SETUP] key.

8. Rotate the jog wheel, select the “Drive Sel?” menu and press the [EXECUTE/YES] key.

12

D1624 / D824

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910111213141516

SETUP

: Blinking

4. SERVICE MODE

There are various optional modes available in the D1624/D824 Service Mode. Please utilize them when servicing the unit.

4-1. Putting D1624/D824 into Service Mode

The way of putting the D1624/D824 into Service Mode is as follow.

1. Plug a 3.5” E-IDE HDD caddy into the D1624/D824 HD bay and lock it using the HD key.

2. Power on the D1624/D824.

3. While holding down the [STOP] key and [TRACK SHIFT/ALL INPUT] key, press the [SETUP] key.

As shown below, by rotating the jog dial C.W. or C.C.W., various optional modes will be displayed in addition to the

general SETUP menus. In order to select a certain optional mode, press the [EXECUTE/YES] key while the menu is

displayed.

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910 11 12 13 14 15 16

SETUP

: Blinking

Tempo Map Set? Delete PGM? Preroll Time? Frame Rate? Offset Mode? Slave Type?

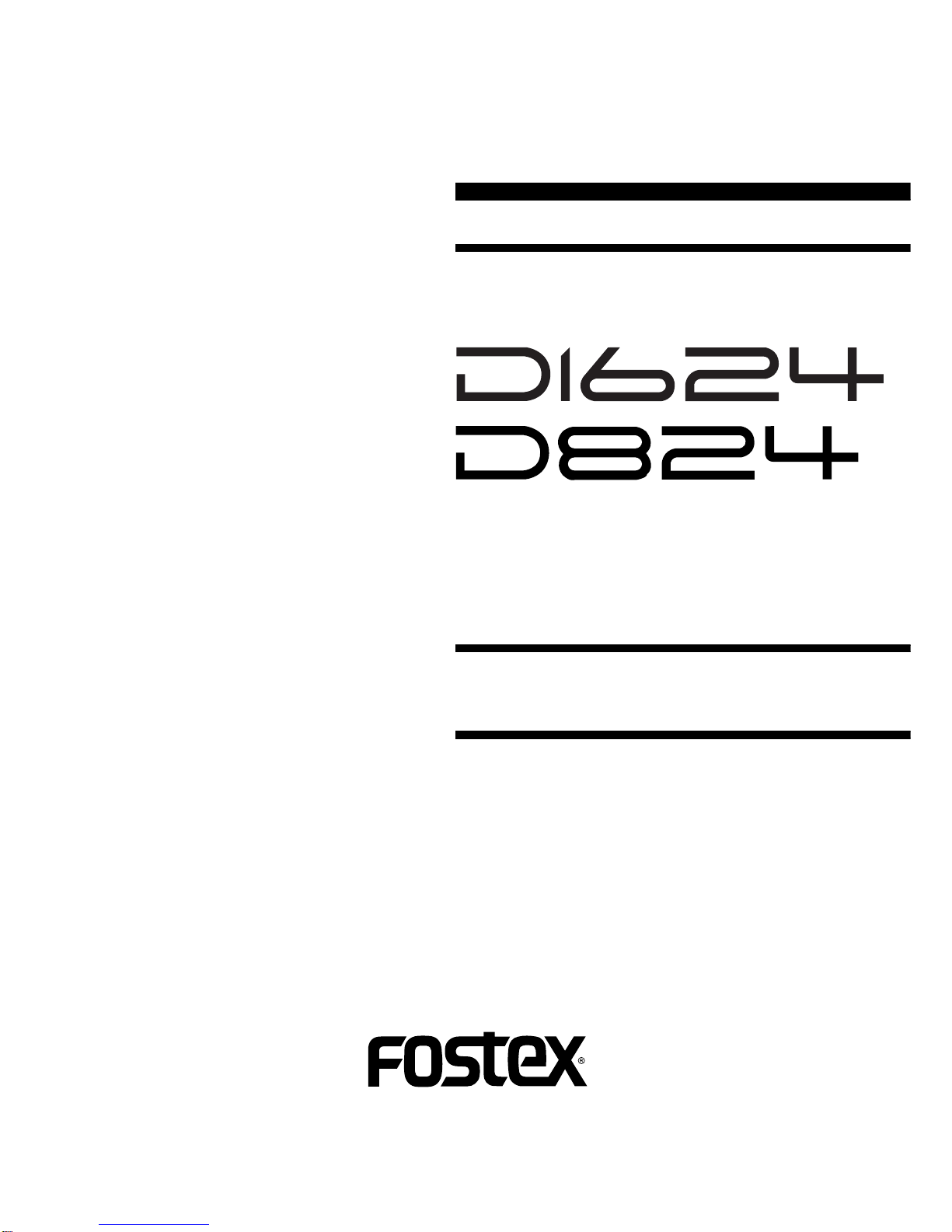

Signature Set? Title Edit? Click ? Midi Sync Out?

Version?DA Test?

Standby Disk?

Display Test?

Self Check?

Offset Disp?

Initial Disk?

Flash ROM?

MTC offset? Ref. TC?

Drive Info? Offset Disp?

Virtual LTC?

Reserved

Rec Protect?Disk Format?

Digital In?

Digital Out?

Resolution?

Device ID?

Clock Sel?

Sync Preset?

NOs Of Event?

Reserved

Disk Optimize?

Reserved

Date & Time set?

Save PGM?

Load pGM?

Drive Sel?

Freeblock Check?

9. Select “SCSI-6” and press the [EXECUTE/YES] key.

10. The D1624/D824 recognizes the software file in the connected SCSI drive/diskette and is automatically put into

the software update mode.

11. Press the [EXECUTE/YES] key to start updating the software.

12. The D1624/D824 FL display shows “Initial...”, name of the drive, “Loading...” and “Writing...” in order and after

a while, “SURE?” will start blinking again. This indicates that the software is correctly updated. Press the [STOP]

key or [EXIT/NO] key to eject the disk.

13. Turn off the D1624/D824 and the connected SCSI drive.

14. Disconnect the SCSI drive from the D1624/D824 and power on the D1624/D824 again.

15. Confirm the software version number and the programming date while in the boot up procedures. They can also

be checked by the Service Mode explained later.

4-2. Flash ROM (software) version

This mode is used to check the Flash ROM (software) versions currently installed in the unit.

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

1234567891011 12 13 14 15 16

: Blinking

13

D1624 / D824

44.1kHz

42

_

OL

0

30

24

18

12

9

6

3

12345678910111213141516

4-3. DA Test

This mode tests the signal flow from the DATA INPUT jack to the D/A converter. A S/P DIF digital signal (Fs:

44.1kHz) must be input to the DATA INPUT jack to execute this test. Then, press the [EXECUTE/YES] key while “?”

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910 11 12 13 14 15 16

: Blinking

44.1kHz

EXT SYNC

DIGITAL

42

∞

_

OL

0

30

24

18

12

9

6

3

1234567891011 12 13 14 15 16

is blinking. If the D1624/D824 is in a normal condition, “44.1kHz” and “DIGITAL” will be lit solid. The odd (1, 3, 5,

7, 9, 11, 13, 15) and even (2, 4, 6, 8, 10, 12, 14, 16) channels indicate the left and right input level of S/P DIF digital

signal fed to the DATA INPUT jack respectively.

If the D1624/D824 is not in a normal condition, “DIGITAL” and “EXT SYNC” on the display will blink and the

bargraph meter will not indicate any level.

In order to check the version number, press the [EXECUTE/YES] key while “?” is blinking.

The example on the above indicates that the Flash ROM version is V1.05 and its programming date is April 3, 2000.

4-4. Standby Disk

This mode stops spinning the internal hard disk for purposes such as “shock” test. If the [EXECUTE/YES] key is

pressed when “?” is blinking, “SURE?” will start blinking. If you would like to go on, press the [EXECUTE/YES] key

once again. The internal hard disk will stop spinning.

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910 11 12 13 14 15 16

: Blinking

4-4. Display/Key Test

This mode tests if all the segments on the FL display, LEDs and keys (switches) on the D1624/D824 controller are

correctly working or not. To execute this test, press the [EXECUTE/YES] key while “?” is blinking.

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910 11 12 13 14 15 16

: Blinking

14

D1624 / D824

44.1kHz

SETUP

MTC IN OFFSET

CHASE

LOCATE

PGM

REMAIN FORMAT

SIGNATURE

TEMPO

48kHz

-0.1%

COMPLETED!

SURE?

MIDI CHASE

SAVE LOAD

EXT SYNC

DIGITAL

MTC INTC

ABS

42

∞

_

OL

0

30

24

18

12

9

6

3

1234567891011 12 13 14 15 16

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910111213141516

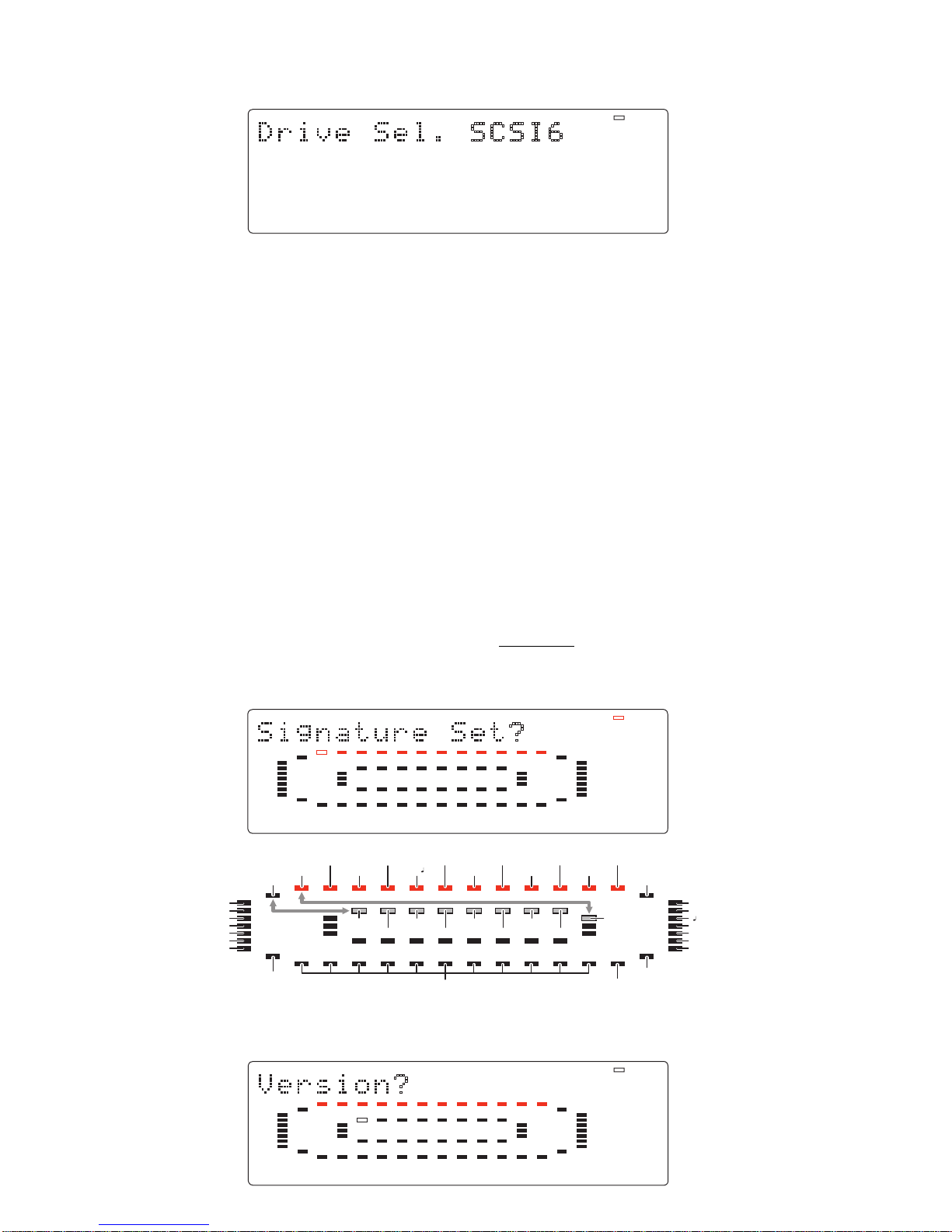

If the D1624/D824 is in a normal condition, all the segments on the FL display will be lit solid, dot matrix and bargraph

meter sections on the FL display and all the LEDs on the top panel will start blinking. If the D1624/D824 is not in a

normal condition, faulty segments on the LCD display, dot matrix and/or LEDs on the top panel will remain unlit.

In this condition, if the [EXECUTE/YES] key is pressed one more time, the Key Test can be executed. The Key Test

checks if each key and jog dial are working properly or not. The display below indicates that the [PLAY] key is pressed

and held down.

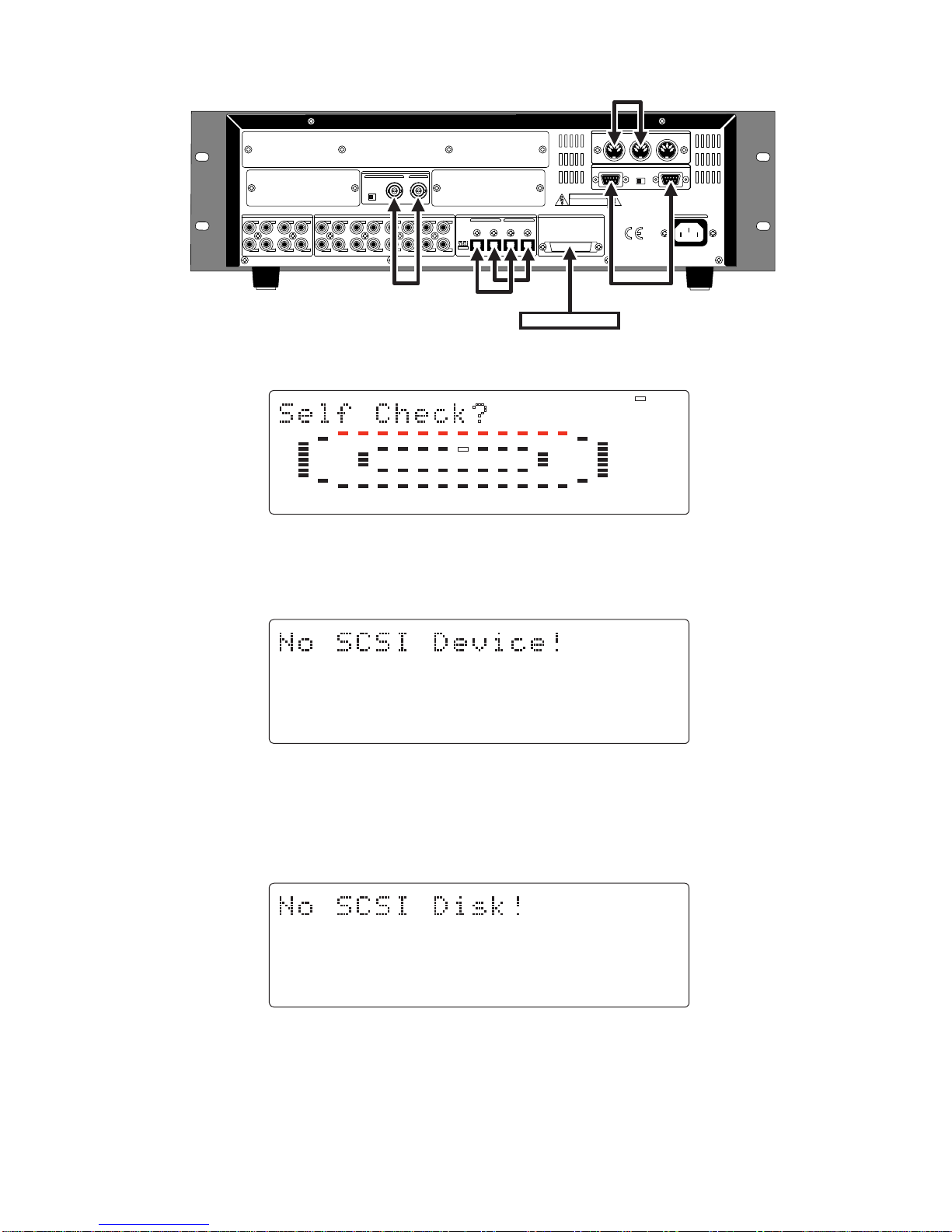

4-5. Self Check

This mode automatically tests the following points in order.

1. SCSI port →2. ATA (E-IDE) bus →3. Option (Model 8345) bus →4. MIDI in/out circuit

→5. S/P DIF digital signal in/out →6. ADAT digital signal in/out →7. 8345 vari-pitch circuit

→8. Vari-pitch circuit →9. External Time Clock Check →10. Internal Time Clock Check →

11. Remote in/out circuit →12. Word In/Out circuit →13. A/D and D/A circuit (Input Monitor)

REMOTE THRU

MIDI

INPUT OUTPUT THRU

AC IN

INPUT OUTPUT

WORD

75Ω

ON OFF

43

ANALOG INPUT 2

87 6

1

5

43

ANALOG OUTPUT 2

87 6

1

5

OUTPUTINPUT SCSIDIGITAL/DATA

100Ω

ON OFF

OPTICAL

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

AVIS:

RISQUE DE CHOC ELECTRIQUE NE PAS OUVRIR

WARNING:

TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, DO NOT EXPOSE THIS EQUIPMENT

TO RAIN OR MOISTURE.

DIGITALWORD

MIDI

REMOTE

External SCSI Device

Cable connection in “Self Check” mode : D824

Key/Button No. Key/Button No. Key/Button No.

AUTO RTN/PLAY 01 ERASE 14 RECORD TRACK 5 27

CLIPBOARD IN 02 UNDO 15 RECORD TRACK 6 28

CLIPBOARD OUT 03 REDO 16 RECORD TRACK 7 29

AUTO RTN START 04 HOLD/ 17 RECORD TRACK 8 30

AUTO PUNCH IN 05 STORE 18 SHIFT 31

AUTO PUNCH OUT 06 RECALL 19 RECORD 32

AUTO RTN END 07 AUTO PUNCH 20 STOP 33

DISP SEL 08 LOCATE 21 PLAY 34

EXECUTE/YES 09 VARI PITCH 22 REWIND 35

EXIT/NO 10 RECORD TRACK 1 23 F. FWD 36

COPY 11 RECORD TRACK 2 24 SHUTTLE 00~07

MOVE 12 RECORD TRACK 3 25 JOG (C.W.) 51

PASTE 13 RECORD TRACK 4 26 JOG (C.C.W.) 49

The table below shows the relationship between the key/button/jog dial and the corresponding numbers appear on the

FL display.

In order to quit the Button Test, turn the jog dial C.W. or C.C.W. further after “51” or “49” is displayed respectively.

15

D1624 / D824

CAUTION: In order not to form a MIDI signal loop, connect the MIDI cable after putting the D1624/D824 into the

Service Mode.

100Ω

ON OFF

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

AVIS:

RISQUE DE CHOC ELECTRIQUE NE PAS OUVRIR

WARNING:

TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, DO NOT EXPOSE THIS EQUIPMENT

TO RAIN OR MOISTURE.

REMOTE

THRU

MIDI

INPUT OUTPUT THRU

INPUT

OFFON

75Ω

WORD

OUTPUTINPUT

SCSI

8 - 116 - 9 8 - 1 16 - 9

OUTPUTINPUT

DIGITAL/DATA AC INANALOG OUTPUT

ANALOG INPUT

5

1

678

234

13

5

141516

678

9

1

101112

234

OPTICAL

DIGITAL

WORD

MIDI

REMOTE

External SCSI Device

Cable connection in “Self Check” mode : D1624

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910 11 12 13 14 15 16

: Blinking

4-5-1. SCSI Port Check

If the D1624/D824 does not recognize a connected SCSI device, the prompt below will be displayed.

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910111213141516

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910111213141516

The following is considered to be the cause of problem.

• Bad cable connection, bad cable contact and / or the power of SCSI device is being turned off.

• SCSI device ID is not set to 6.

• U9, U64, J16, etc and / or surrounding circuit are defective.

• If a removable type SCSI drive is connected and in case a disk is not inserted into the drive, the following prompt

will be displayed.

Fs, DIGITAL IN, DIGITAL OUT and SLAVE MODE settings on the internal hard disk to be used when the Self Check

test is executed should be as follow.

* Fs: 44.1kHz

* DIGITAL IN: OFF (L: -, R: -)

* DIGITAL OUT: ADAT

* SLAVE MODE: OFF

Even if the before mentioned prompt is displayed, pressing the [EXECUTE/YES] key would reach the next test.

16

D1624 / D824

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910111213141516

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910111213141516

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910111213141516

4-5-2. ATA (E-IDE) Bus Check

This test checks if data can be properly read out from the preformatted internal hard disk.

If the “ALTERNATE STATUS” which indicates the hard disk condition cannot be read out, the prompt below will be

displayed.

If the data (SYSTEM ID) written by formatting the disk cannot read out correctly, the prompt below will be displayed.

The following is considered to be the cause of problem.

• Breaking, shortage and / or bad contact of flat cable W12.

• U1, U9, etc and / or surrounding circuit are defective.

Fs, DIGITAL IN, DIGITAL OUT and SLAVE MODE settings on the internal hard disk to be used when the Self Check

test is executed should be as follow.

* Fs: 44.1kHz

* DIGITAL IN: OFF (L: -, R: -)

* DIGITAL OUT: ADAT

* SLAVE MODE: OFF

Even if the before mentioned prompt is displayed, pressing the [EXECUTE/YES] key would reach the next test. If the

[EXECUTE/YES] key is pressed with the “ATA Bus Check” message displayed, checking the SYSTEM ID on the

SCSI device will be executed. The current drive setting after the Self Check test will become “SCSI”.

4-5-3. Option (Model 8345) Bus Check

This test checks if the option bus (J18 on the MAIN PCB) to which the Model 8345 is connected is working properly

or not. If reading out and / or writing in data are not correctly executed, the prompt below will be displayed.

The following is considered to be the cause of problem.

• Bad connection and / or wrongly connected J18.

• J18, U67, U75, etc and / or surrounding circuit are defective.

Even if the before mentioned prompt is displayed, pressing the [EXECUTE/YES] key would reach the next test.

17

D1624 / D824

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910111213141516

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910111213141516

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910111213141516

4-5-4. MIDI In/Out Check

By connecting the MIDI IN and OUT ports, this test checks if the replyagainst the ID inquiry is correctly received. If

not, the prompt below will be displayed.

The following is considered to be the cause of problem.

• J7, U28, U29 (MAIN PCB), J201, J202 (MIDI PCB), J301, J304 (RS422 PCB), etc and / or surrounding circuit are

defective.

Even if the before mentioned prompt is displayed, pressing the [EXECUTE/YES] key would reach the next test.

4-5-5. S/P DIF In/Out Check

By connecting the DATA IN and OUT terminals, this test checks if the S/P DIF signal output by itself is correctly

received. If the PLL circuit is not in a “LOCKED” condition, the prompt below will be displayed.

The following is considered to be the cause of problem.

• No oscillation of resonator X1.

• J11, J12, J20, J21, U4, U5, U17, U19, U24, U62, etc and / or surrounding circuit are defective.

Even if the before mentioned prompt is displayed, pressing the [EXECUTE/YES] key would reach the next test.

4-5-6. Adat In/Out Check

By connecting the DATA IN and OUT terminals, this test checks if theADAT digital signal output by itself is correctly

received. If the PLL circuit is not in a “LOCKED” condition, the prompt below will be displayed.

The following is considered to be the cause of problem.

• No oscillation of resonator X2.

• J11, J12, J20, J21, U4, U5, U17, U19, U24, U62, etc and / or surrounding circuit are defective.

Even if the before mentioned prompt is displayed, pressing the [EXECUTE/YES] key would reach the next test.

18

D1624 / D824

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910111213141516

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910111213141516

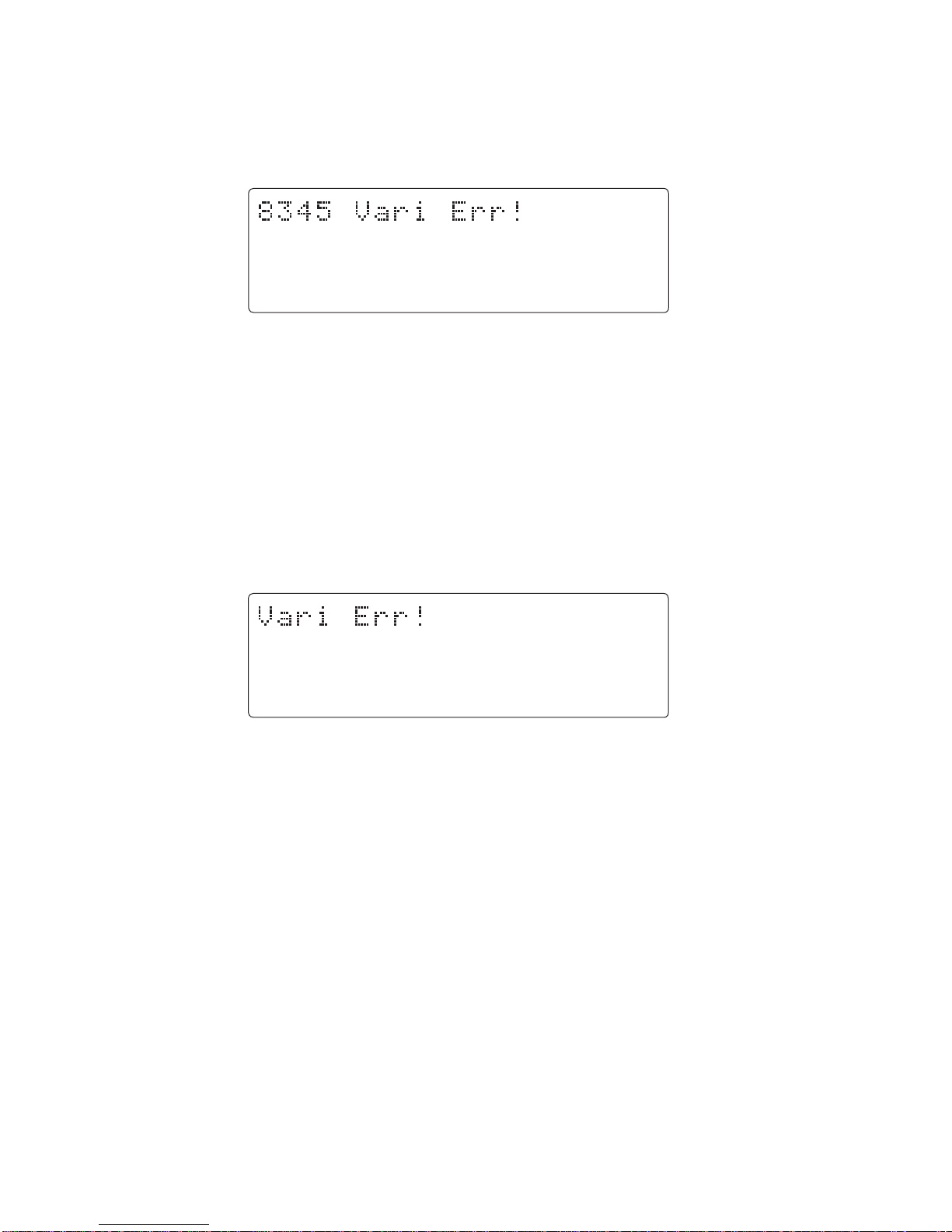

4-5-7. 8345 Vari-Pitch Circuit Check

The master clock is generated using the Model 8345 LRCK (J1 pin-24: EXT_LRCK). In the meantime, the adat digital

signal is generated based on this master clock. This test checks if the adat digital signal output by itself is correctly

received. If not, it means that the vari-pitch circuit does not work correctly. As a result, the prompt below will be

displayed.

If “adat error” is displayed in the before mentionedAdat In/Out Check test, the above error prompt will be displayed.

If the Model 8345 is not installed in the D1624/D824, this test will be skipped.

The following is considered to be the cause of problem.

• Wrongly connected flat cable to J18 on the MAIN PCB.

• J18, U67, U75, etc and / or surrounding circuit are defective.

Even if the before mentioned prompt is displayed, pressing the [EXECUTE/YES] key would reach the next test.

4-5-8. D1624/D824 Vari-Pitch Circuit Check

Using the master clock generated through the D1624/D824 vari-pitch circuit on the MAIN PCB, the adat digital signal

is output. This test checks if the adat digital signal output by itself is correctly received. If not, it means that the vari-

pitch circuit does not work correctly. As a result, the prompt below will be displayed.

If “adat error” is displayed in the before mentionedAdat In/Out Check test, the above error prompt will be displayed.

If the Model 8345 is not installed in the D1624/D824, this test will be skipped.

The following is considered to be the cause of problem.

• U1, U2, U17, etc and / or surrounding circuit are defective.

Even if the before mentioned prompt is displayed, pressing the [EXECUTE/YES] key would reach the next test.

4-5-9. External Time Clock Check

This mode checks the internal RTC (Real Time Clock) controlling circuit when the power is at OFF condition.

The following is considered to be the cause of problem.

• Defects on the U86.

Even if the before mentioned prompt is displayed, pressing the [EXECUTE/YES] key would reach the next test.

4-5-10. Internal Time Clock Check

This mode checks the internal RTC (Real Time Clock) controlling circuit when the power is at ON condition.

The following is considered to be the cause of problem.

• Defects on the U1.

Even if the before mentioned prompt is displayed, pressing the [EXECUTE/YES] key would reach the next test.

19

D1624 / D824

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910111213141516

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910111213141516

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910 11 12 13 14 15 16

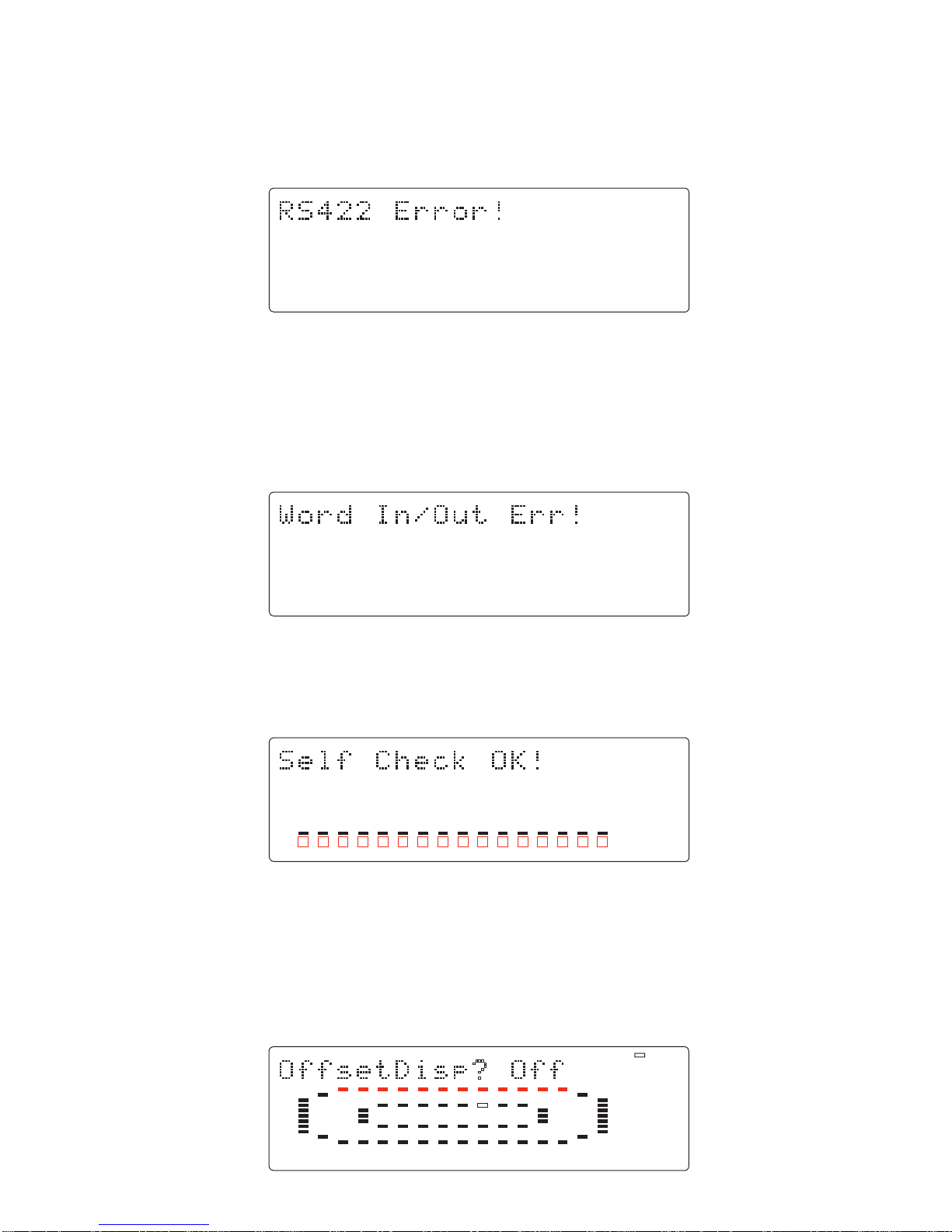

4-5-13. A/D and D/A Circuit Check (Input Monitoring)

The D1624/D824 automatically checks the before mentioned points in the Self Check mode. If the D1624/D824 is

working properly, the following appears on the display with REC LED blinking.

In order to go back to the normal display, press the [EXIT/NO] key or STOP button.

4-6. Offset Display

This mode determines if the offset value against a master machine should be displayed when the D1624/D824 is

working as a slave machine. If you would like to turn ON the offset display, press the [EXECUTE/YES] key while “?”

is blinking. (The default setting is “off”.) Then, turn the jog dial C.W. to change the display to “ON” and press the

[EXECUTE/YES] key.

44.1kHz

SETUP

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910 11 12 13 14 15 16

: Blinking

4-5-11. Remote

This mode checks the remote circuit.

The following is considered to be the cause of problem.

• Defects on the U86.

Even if the before mentioned prompt is displayed, pressing the [EXECUTE/YES] key would reach the next test.

4-5-12. Word In/Out

This mode can be checked only when the Model 8345 is not installed. In other words, if this test is executed with the

Model 8345 installed, the following error message will be displayed.

The following is considered to be the cause of problem.

• Defects on the U1.

Even if the before mentioned prompt is displayed, pressing the [EXECUTE/YES] key would reach the next test.

20

D1624 / D824

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

1234567891011 12 13 14 15 16

: Blinking

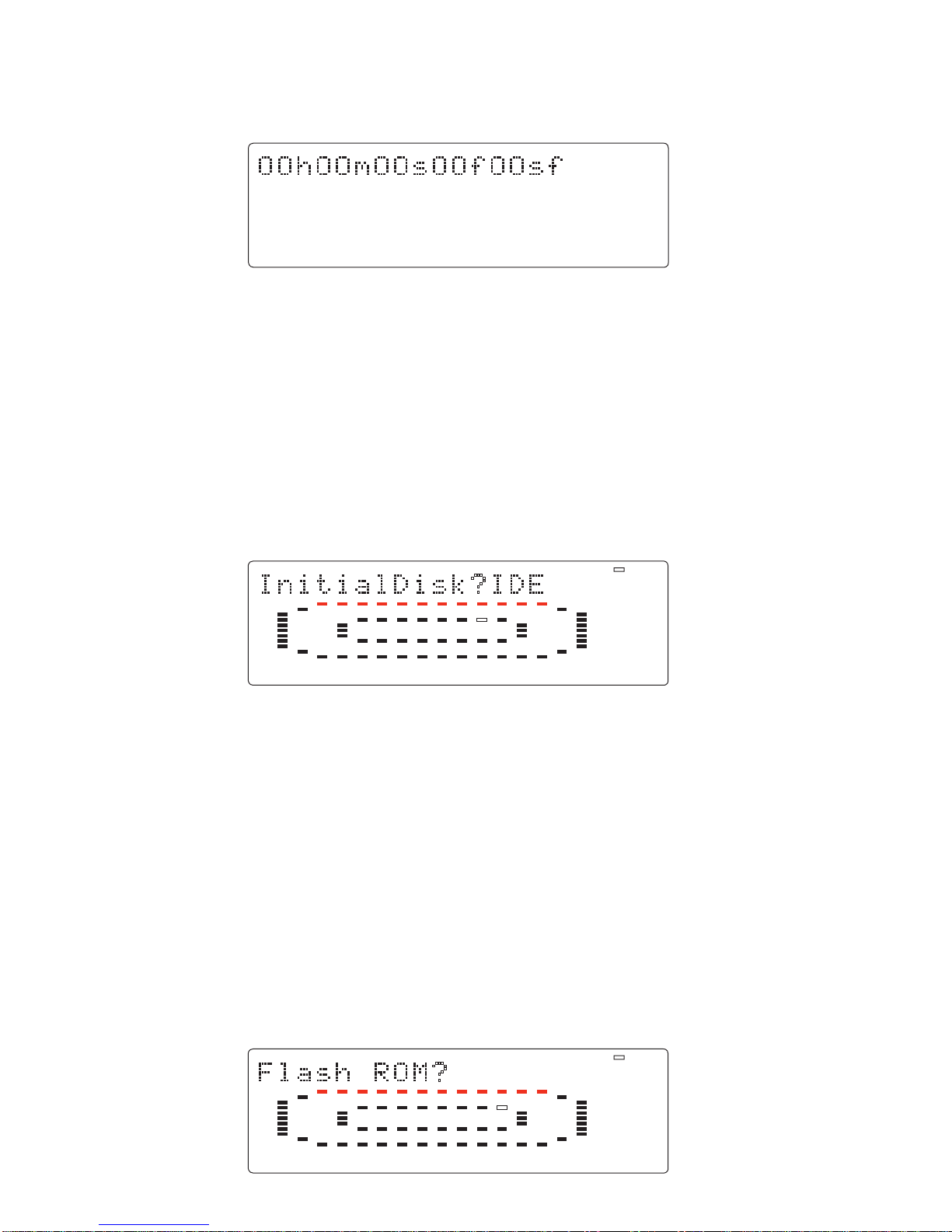

4-8. Flash ROM

This mode is used when copying the system software from EPROMs to Flash ROM. As mentioned in the section “3.

SOFTWARE UPDATE” (page 11), the D1624/D824 software inside the Flash ROM can be updated through the SCSI

port. However, if something wrong happens when updating the software (e.g. A blackout occurred while updating the

software.), the D1624/D824 might not be able to boot up using the system software inside the Flash ROM.

In this case, the following procedures must be taken.

1. Turn off the power of D1624/D824 and disconnect the AC cable from the AC IN socket.

2. Plug the D1624/D824 EPROMs into the ROM CARD PCB assy sockets (U1 and U2). The SW on the ROM

CARD PCB assy must be set to “EPROM” side.

3. Open up the top cover, loosen 4 screws fixing the HD bay to the HD bracket and move the bay to the front side,

so that the ROM CARD PCB assy can be plugged into the 50-pin connector J5 on the MAIN PCB assy vertically.

4. Connect the AC cable and turn on the power of D1624/D824.

In this condition, the D1624/D824 is booted up using the system software inside the EPROMs. The next procedures to

take are as follows.

4-7. Initializing Disk

This is the mode to initializes a 3.5” internal E-IDE hard disk drive or an external SCSI device connected to the SCSI

port.

CAUTION: If both the external SCSI drive and the internal 3.5” E-IDE hard disk drive are connected at the same time,

currently selected drive by the SETUP menu “Drive_Sel?” will be initialized.

After pressing the [EXECUTE/YES] key, “SURE?” will start blinking on the FL display. In this condition, pressing

the [EXECUTE/YES] key one more time would initialize the recognized disk drive. This mode puts the disk back to

the condition originally formatted. This mode is exclusively designed for our manufacturer. To initialize the disk, use

the ERASE function in the Format SETUP menu.

44.1kHz

42

∞

_

OL

0

30

24

18

12

9

6

3

1234567891011 12 13 14 15 16

: Blinking

44.1kHz

OFFSET

42

∞

_

OL

0

30

24

18

12

9

6

3

12345678910111213141516

In order to check the offset value, select the “MTC” time base and the “REMAINING TIME” display. The display

below is an example of offset display. This mode is identical to the one when the normal SETUP menu “Offset Disp?”

is selected.

This manual suits for next models

5

Table of contents

Other Fostex Voice Recorder manuals

Fostex

Fostex D-15 User manual

Fostex

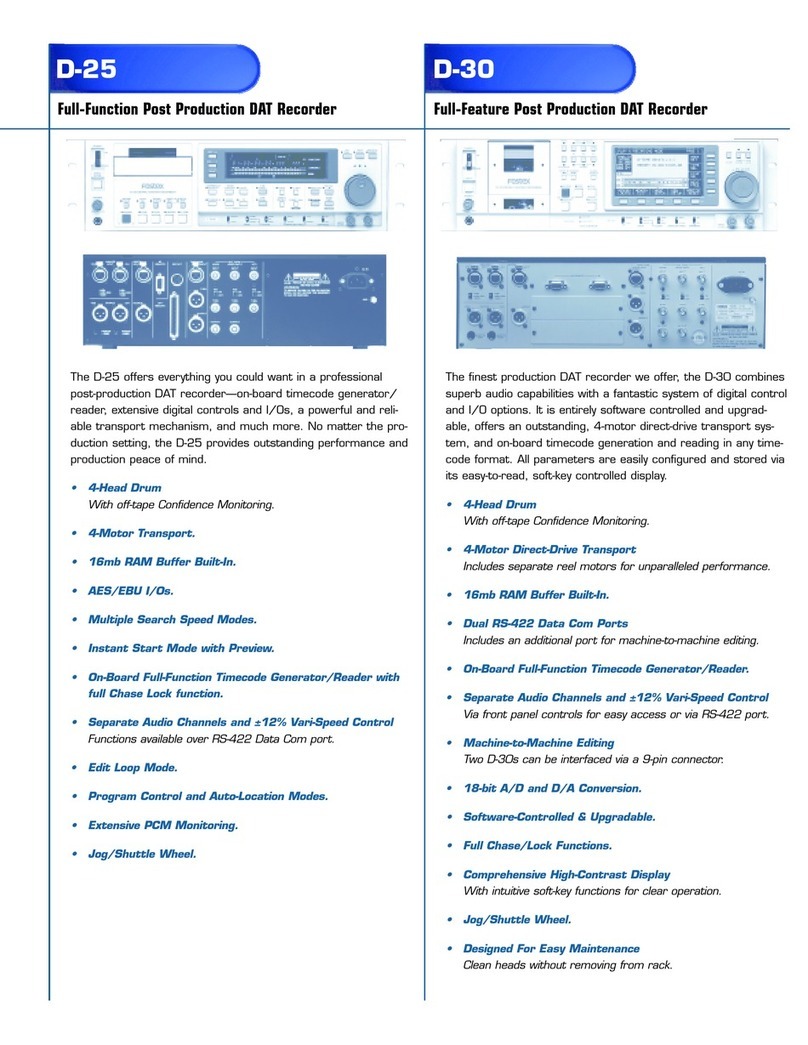

Fostex D-25 User manual

Fostex

Fostex DP-8 User manual

Fostex

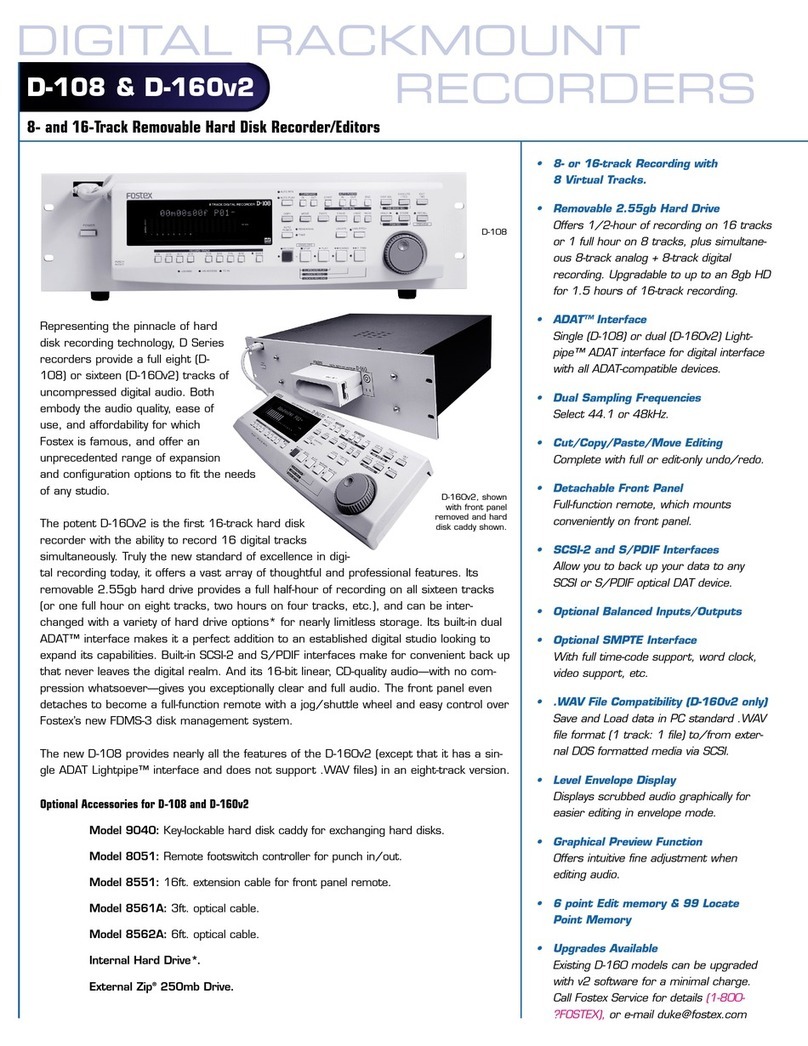

Fostex D-108 Owner's manual

Fostex

Fostex FR-2 User manual

Fostex

Fostex VF-160 User manual

Fostex

Fostex MR-8 MKII User manual

Fostex

Fostex VF80 User manual

Fostex

Fostex VF80 User manual

Fostex

Fostex D-10 User manual

Fostex

Fostex D-25 User manual

Fostex

Fostex D2424LV MKII User guide

Fostex

Fostex D-20B User manual

Fostex

Fostex D2424LVMKII User guide

Fostex

Fostex XR-5 User manual

Fostex

Fostex PD-2 User manual

Fostex

Fostex MR-8HD/CD User manual

Fostex

Fostex GT10 User manual

Fostex

Fostex D-160 User manual

Fostex

Fostex D-160 User manual