FPZ S.p.A.

Via F.lli Cervi 16

20863 Concorezzo (MB), ITALIA

Tel. +39 039 69068 1

FPZ-MI-K TS-MOR-USA-15-R03

1GENERAL INFORMATION .............................................................................................................................................................11

PURPOSE OF THE MANUAL..................................................................................................................................................111.1

UNIT AND MANUFACTURER'S IDENTIFICATION .................................................................................................................111.2

TESTING, WARRANTY AND LIABILITY..................................................................................................................................111.3

2SAFETY RULES .............................................................................................................................................................................12

GENERAL NOTES ON SAFETY AND FOR THE USER..........................................................................................................122.1

CONDITIONS OF INSTALLATION AND NORMAL OPERATION ............................................................................................122.2

FAULT CONDITION AND MAINTENANCE..............................................................................................................................132.3

RESIDUAL RISKS...................................................................................................................................................................132.4

3FORESEEN USE............................................................................................................................................................................14

CONDITIONS OF USE............................................................................................................................................................143.1

SPECIAL VERSIONS..............................................................................................................................................................153.2

PROHIBITIONS.......................................................................................................................................................................153.3

REASONABLY FORESEEABLE IMPROPER USE..................................................................................................................153.4

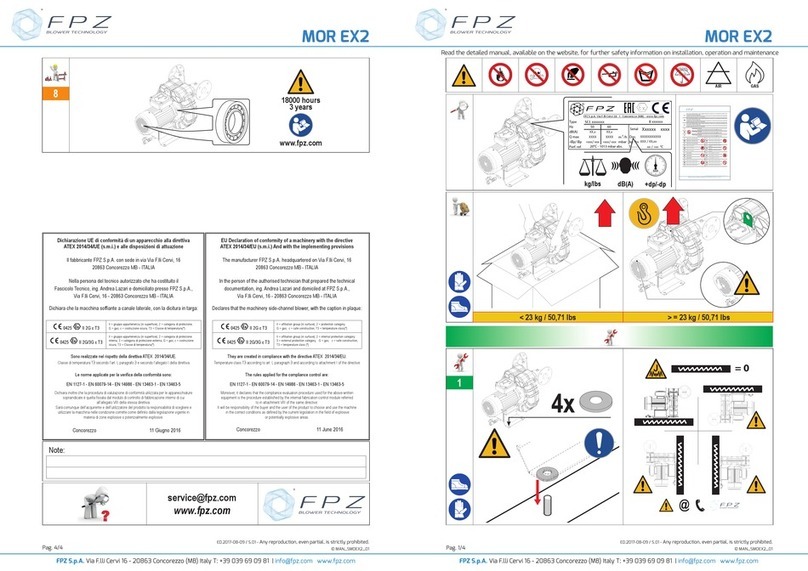

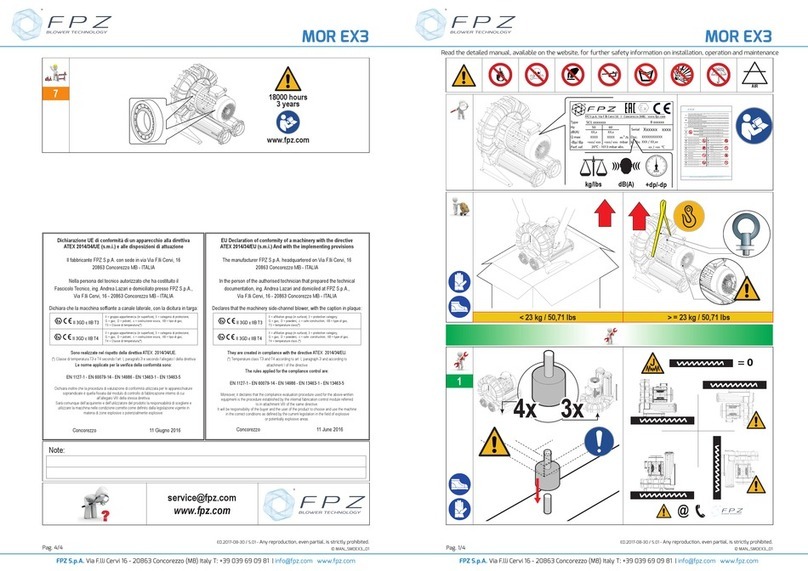

4STORAGE AND TRANSPORT........................................................................................................................................................16

RECEPTION AND CHECK OF CONTENTS............................................................................................................................164.1

PACKING ................................................................................................................................................................................164.2

TRANSPORT AND HANDLING...............................................................................................................................................174.3

STORAGE...............................................................................................................................................................................174.4

5INSTALLATION...............................................................................................................................................................................17

INSTALLATION CONDITIONS................................................................................................................................................175.1

HORIZONTAL INSTALLATION................................................................................................................................................195.2

INSTRUCTIONS FOR REPOSITIONING SILENCER HOUSINGS ..........................................................................................195.3

5.3.1 90° MANIFOLD (accessory) USE...................................................................................................................................20

VERTICAL INSTALLATION ON THE COVER .........................................................................................................................205.4

ELECTRIC MOTOR.................................................................................................................................................................205.5

5.5.1 CONNECTION...............................................................................................................................................................21

5.5.2 INVERTER POWERED ELECTRIC MOTOR .................................................................................................................21

5.5.3 ROTATION DIRECTION................................................................................................................................................21

6STARTUP .......................................................................................................................................................................................22

PRELIMINARY CHECKS.........................................................................................................................................................226.1

OPERATION............................................................................................................................................................................226.2

STOPPING..............................................................................................................................................................................226.3

7MAINTENANCE..............................................................................................................................................................................23

PERIODICAL CHECKS ...........................................................................................................................................................237.1

PERIODICAL MAINTENANCE AND TROUBLESHOOTING....................................................................................................247.2

REPLACING THE SOUND ABSORBING MATERIAL..............................................................................................................247.3

LIFE OF BEARINGS................................................................................................................................................................257.4

OPERATION PROBLEMS.......................................................................................................................................................257.5