2 - Safety Precautions

The following instructions must be adhered to, in order to ensure a safe working environment and the

safety of the user.

Note: When unpacking or manoeuvring the searchlight into its fixing position, suitable lifting

points must be used in order to prevent damage to the equipment or personal injury.

◼The high luminance of the LED can cause severe damage to the eye if viewed directly. ALWAYS wear

suitable protective goggles when viewing the LED;

◼Searchlights get hot. Never touch the unit when lit and always allow 15 to 20 minutes for cooling down

after turning the searchlight off;

◼Never place anything on or cover the searchlight when in use;

◼Ensure the LED has cooled sufficiently before removal;

◼Due to the vast range of LED modules available it may appear possible that more powerful LED’s can

be used in the equipment than for which it was designed. Even when the unit will physically accept a

higher wattage LED, this substitution is not recommended and is dangerous. This action will also void

any warranties on the equipment.

3 –Technical Information

This product has been designed to operate in accordance with the product specification.

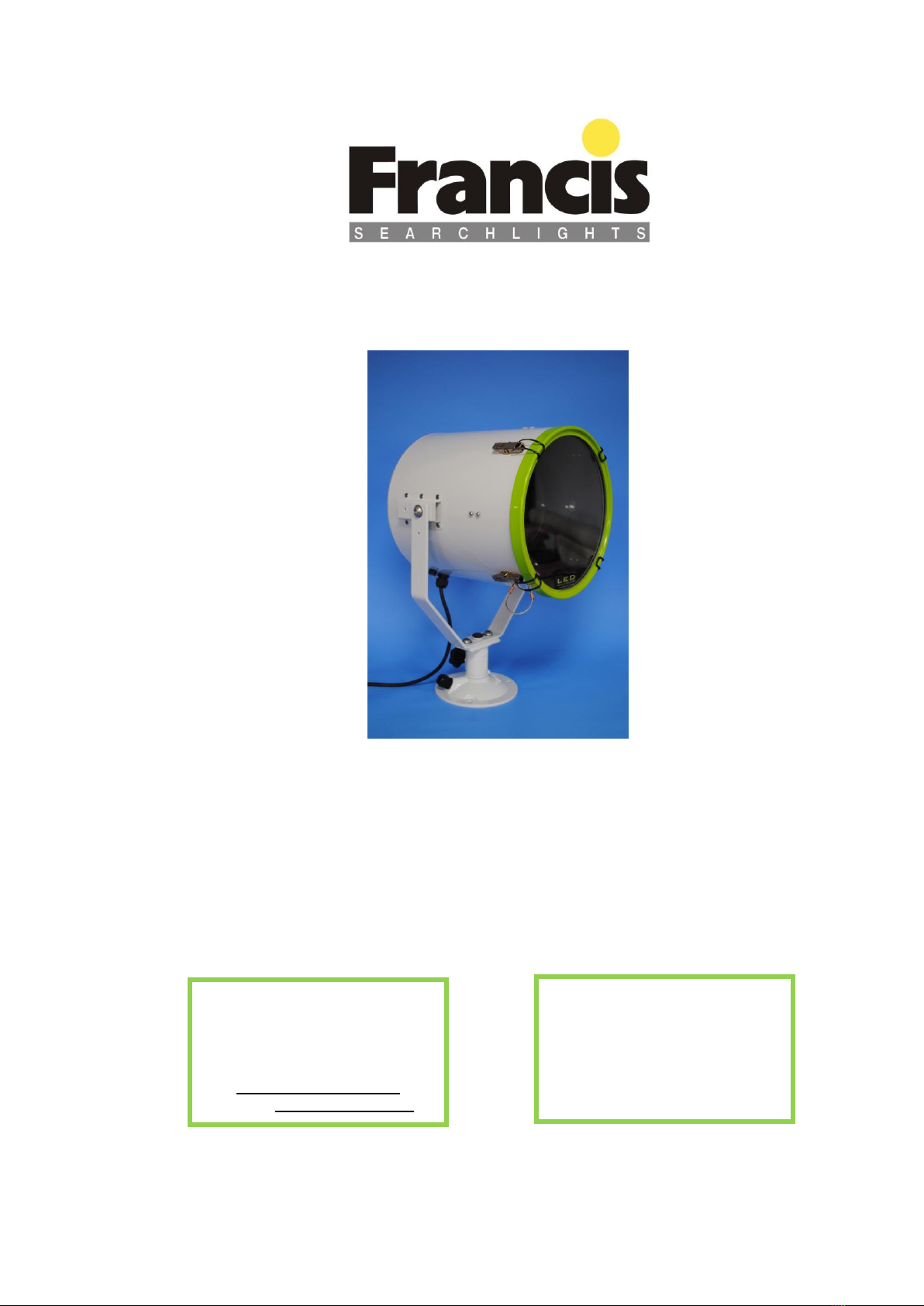

The L300 110W LED searchlight has the following features:

◼All marine grade materials and fixings;

◼Powder coated finish;

◼Full 450° horizontal rotation;

◼Vertical movement ±40˚ (Deck & Deck Pedestal;

◼Vertical movement +30˚ to -25˚ (Cabin & Cabin Pedestal;

◼Instant re-strike. No cooling down time required;

◼Economical 33,000 hour LED life;

◼Toughened super clear Optiwhite front glass;

◼Searchlight & Control Gear protected to IP66;

◼Searchlight weight 12 Kgs, PSU weight 2.5 Kgs;

The searchlight also performs to the following optical data:

◼Supply voltage –90 to 250v;

◼Luminous flux 13,900;

◼Colour temperature 6500K;

◼Range –1129 metres;

◼Divergence –7° spot 20˚flood;

◼Temperature range: -50 to +50

In order that the searchlight operates correctly it is imperative that competent personnel are responsible

for the installation, operation and servicing of this equipment. Failure to adhere to this advice may cause

premature failure or incorrect operation of the searchlight, which may damage the equipment or cause

personal injury.

Back To Top