Page 3

MT04-001 AquariTherm Tap (Manual) www.dartvalley.co.uk

Revision No. MAQTIN16071301

Page 2

MT04-001 AquariTherm Tap (Manual) www.dartvalley.co.uk

Revision No. MAQTIN16071301

4.5

50

30

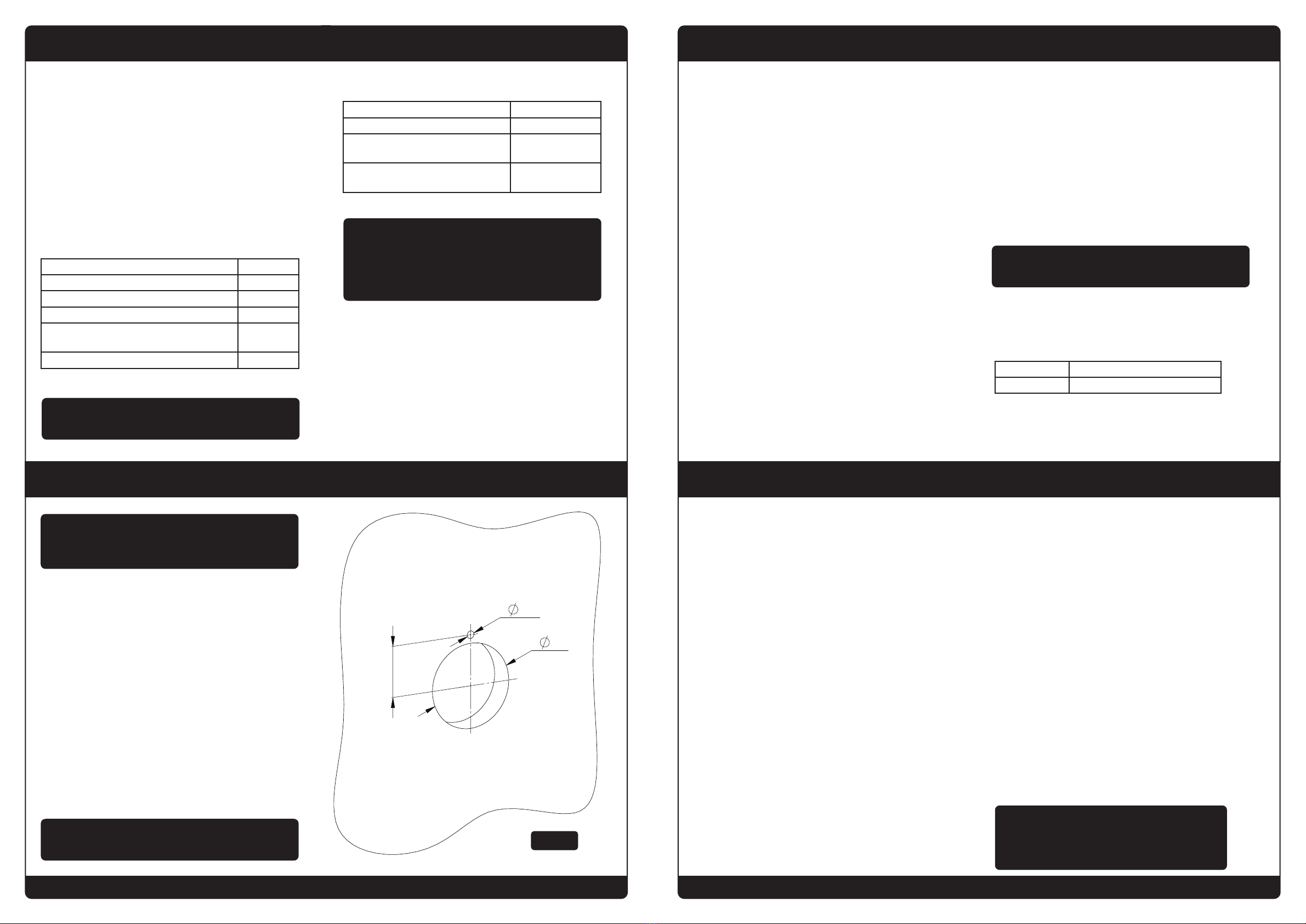

Step 4 : Preparation and Drilling

Step 3 : Introduction

The tap incorporates a thermoregulating cartridge to ensure users

of consistent water temperatures.

The tap is suitable, without modification, for all types of installation,

including pump boosted systems and mains pressure.

The valve has been designed and manufactured to comply with

NHS D08 requirements for washbasin applications up to 41ºC high

and high pressure designations.

The valve has been independently tested and approved as a Type 3

valve under the TMV3 scheme with the HP-WE designation of use.

Table 1: Technical Specification / Condition of Use for

Type 3 valves

Table 2: Mixed Water Temperature Approvals

NOTE: For washbasins, washing under running water

is assumed. The fitting of isolation valves is required as

close as is practicable to the water supply inlets of the

AquariTherm. Non-return valves and strainers are fitted

internally- see fig.13.

NOTE: Balanced pressures are desirable, but must be

maintained within the ranges above.

Maximum Static Pressure 10 Bar

Dynamic Pressure 1 to 5 Bar

Hot Supply Temperature 55-65 ºC

Cold Supply Temperature 5-20 ºC

Minimum Temperature Differential (Mix to Hot)

for Fail-Safe

10 ºC

Temperature Stability +/- 2 ºC

Code HP-WE

Application Washbasin

Mixed Water Temperature (at point of

discharge)

41 ºC

Operating Pressure High Pressure (1-5

Bar)

c) record the temperature of the mixed water at a smaller

draw-off flow rate, which shall be measured

d) isolate the cold water supply to the mixing valve and

monitor the mixed water outlet. If there is a flow stream

after 5 seconds then collect any water discharging into a

suitably graduated measuring vessel for 60 seconds; if the

volume of water collected is greater than 120ml then further

investigation is needed.

e) If there is no flow or the volume of water collected is less

than or equal to 120ml, then restore the cold water supply;

after 15 seconds, record the mixed water temperature.

f) record the equipment, thermometer etc. used for the

measurements

Table 3: Guide to maximum stabilised temperatures

recorded during site tests

Step 12 : In-Service Testing

11.1 Purpose

Since the installed supply conditions are likely to be different

from those applied in the laboratory tests it is appropriate, at

commissioning, to carry out some simple checks and tests on

each mixing valve to provide a performance reference point for

future in-service tests.

11.2 Procedure

Check that:

a) the designation of the thermostatic mixing valve matches

the intended application

b) the supply pressures are within the range of operating

pressures for the designation of the valve

c) the supply temperatures are within the range permitted for

the valve and by guidance information on the prevention of

legionella etc.

Adjust the temperature of the mixed water in accordance with

the manufacturer’s instructions and the requirement of the

application and then carry out the following sequence:

a) record the temperature of the hot and cold water supplies

b) record the temperature of the mixed water at the largest

draw-off flow rate

Step 11 : Method for Commisioning Thermostatic Cartridge

NOTE: The final stabilised mixed water temperature should

not exceed the values in Table 3

Application Mixed Water Temperature

Washbasin 41 ºC

7

We recommend the fitting of local hot & cold full flow isolation

valves prior to the tap if not already fitted.

Turn off hot & cold water supply. Cut pipework using a suitable

plumbers cutting tool, remove any sharp edges, locate isolation

valves on to pipes and tighten, make sure the new valves are in

the off position then turn the water back on, test for any leaks.

Using a bucket open each valve individually and purge water

through into the bucket this will remove any dirt left in the

pipework.

Refer to current HTM guidelines for tap positioning information,

also ensure adequate access is given under the Spigot to

operate integrated isolation valves.

Mark and drill a 50mm diameter hole in the wall panel where

the tap is to be located and a 4.5mm hole for the anti-rotation

pin (Fig. 1).

IMPORTANT: The tap is supplied with an anti-rotation pin.

Failure to fit the pin will result in void of warranty. Fig 1

IMPORTANT: Plumbing compound should not be used to

seal the pipework as oils leaching from the compound will

prevent the TMV from functioning correctly.

12.1 Purpose

The purpose of in-service tests is to regularly monitor and record

the performance of the thermostatic mixing valve. Deterioration in

performance can indicate the need for service work on the valve

and/or the water supplies.

12.2 Procedure

Using the same measuring equipment or equipment to the same

specification as used in the commissioning of the valve, adjust

the temperature of the mixed water in accordance with the

manufacturer’s instructions and the requirement of the application.

Carry out the following sequence:

a) record the temperature of the hot and cold water supplies.

b) record the temperature of the mixed water at the largest

draw-off flow rate.

c) record the temperature of the mixed water at a smaller draw-off

flowrate, which shall be measured.

If the mixed water temperature has changed significantly from the

previous test results (e.g.>1 K) 5), record the change and before

re-adjusting the mixed water temperature check:

a) that any in-line or integral strainers are clean.

b) any in-line or integral check valves or other anti-back siphonage

devices are in good working order.

c) any isolating valves are fully open.

With an acceptable mixed water temperature, complete the

following procedure:

a) record the temperature of the hot and cold water supplies

b) record the temperature of the mixed water at the largest

draw-off flow rate.

c) record the temperature of the mixed water at a smaller draw-off

flow rate, which shall be measured.

d) isolate the cold water supply to the mixing valve and monitor the

mixed water temperature.

e) record the maximum temperature achieved as a result of (d) and

the final stabilised temperature.

f) record the equipment, thermometer etc. used for the

measurements.

If at step (e) the final mixed water temperature is greater than the

values in Table 1 (Step 3) and / or the maximum temperature

exceeds the corresponding value from the previous results by more

than about 2 K, the need for service work is indicated.

NOTE: In-service tests should be carried out with a frequency,

which identifies a need for service work before an unsafe water

temperature can result. In the absence of any other instruction

or guidance, the procedure described in Annex Fof D 08 may be

used - Annex F of D 08 (informative)