SAFETY INSTRUCTIONS

Hazard Messages

5

SAFETY INSTRUCTIONS

Hazard Messages

This manual includes safety precautions and other important

information in the following formats:

IMPORTANT: Identifies information that controls correct assem-

bly and operation of the product.

NOTE: Identifies helpful or clarifying information.

This symbol alerts the user to the presence of dangerous

voltage inside the product that might cause harm or elec-

trical shock.

This symbol alerts the user to the presence of hot sur-

faces that might cause fire or personal injury.

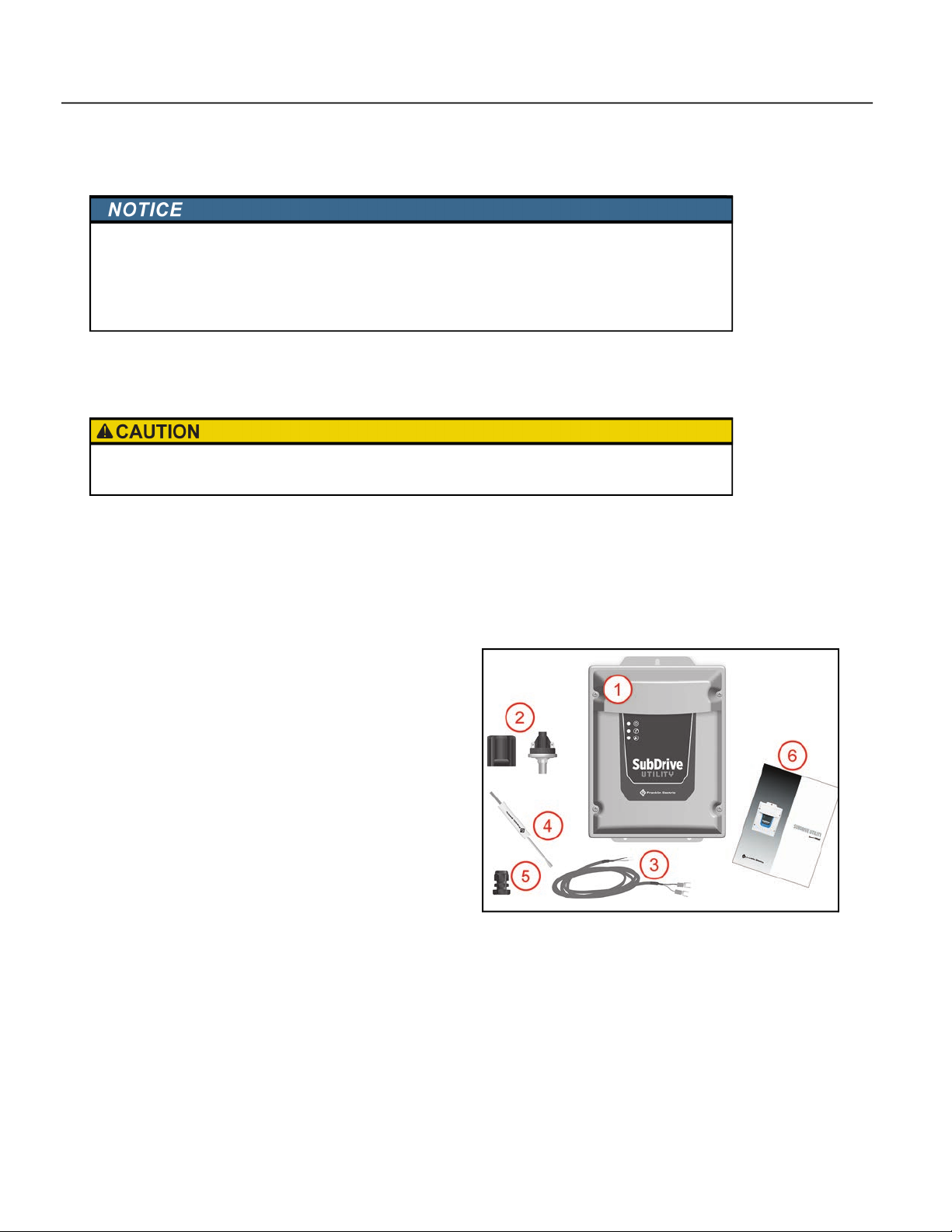

Before Getting Started

This equipment should be installed and serviced by technically

qualified personnel who are familiar with the correct selection

and use of appropriate tools, equipment, and procedures. Failure

to comply with national and local electrical and plumbing codes

and within Franklin Electric recommendations may result in elec-

trical shock or fire hazard, unsatisfactory performance, or equip-

ment failure.

Read and follow instructions carefully to avoid injury and prop-

erty damage. Do not disassemble or repair unit unless described

in this manual.

Failure to follow installation or operation procedures and all

applicable codes may result in the following hazards:

Indicates an imminently hazardous situation

which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation

which, if not avoided, could result in minor or

moderate personal injury.

Indicates a potentially hazardous situation

which, if not avoided could result in damage to

equipment or other property.

High voltages capable of causing severe

injury or death by electrical shock are

present in this unit.

• To reduce risk of electrical shock, disconnect power before

working on or around the system. More than one discon-

nect switch may be required to de-energize the equipment

before servicing.

• Make sure the ground terminal is connected to the motor,

control enclosures, metal plumbing, and other metal near

the motor or cable using wire no smaller than motor cable

wires.

Risk of bodily injury, electric shock, or

equipment damage.

• This equipment must not be used by children or persons

with reduced physical, sensory or mental abilities, or lack-

ing in experience and expertise, unless supervised or

instructed. Children may not use the equipment, nor may

they play with the unit or in the immediate vicinity.

• Equipment can start automatically. Lockout-Tagout before

servicing equipment.

• Operation of this equipment requires detailed installation

and operation instructions provided in this manual for use

with this product. Read entire manual before starting

installation and operation. End User should receive and

retain manual for future use.

• Keep safety labels clean and in good condition.