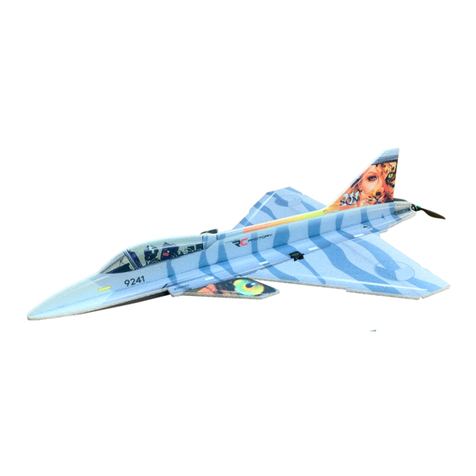

F-15 Eagle

InstructionsF-15Eaglewww.freeair.cz Page .:1/3

Dearcustomer,

congratulationsonyourpurchaseof ourmodelof thefamous F-15 Eagle fighter.Beforecommencingitsbuilding,pleasestudythe

assemblyinstructionscarefullyandmakesureyouunderstand thebuilding process. Ifneedbe, contactthemanufactureroryour

dealer Seznamdíl :

Názevdílu kus

Názevdílu kus

Fuselageof EPP 1 Elevatorsafetyring 2

Elevatorcontrolrod 2 Elevatorshaft(carbon5x100mm)) 2

Wingof EPP 2 Elevatorlever 2

Elevatorof EPP 2 Instructions 1

Verticaltailof EPP 2 Self-adhesivestickerset 1

Enginenacelles1 Wingspars(carbon500x1mm) 2

Elevatorshaftbushing 4 Fuselagecentralpanelof EPP 1

Motorbulkhead 1 Doublerof thefuselagemotorsection(Al

1,6x100) 2

Youwill needalsothe:

CAglue, CAglueactivator, sharp(modelling) knife, 150mmextensioncableforservo???. Tocompletethemodelyouwill need:a

receiver(MZK), servos(WipontW-060),acontroller(TMM-1210-3orJeti 12),anaccumulatorbattery(3 LiPolcellsof 640-1200

mAh),amotor(HCS-80/2Eorsimilarof about80 Woutput).

Descriptionofthemodel:|

ThemodeliscompletelymadeofEPP andhassomecarboncomponents. Withitsweightbeginning at 250 gramsit isanideal

modelforflyinginanysuitablespot(e.g. aschoolplaygroundorinthestreet).Itisintendednotonlyforexperiencedpilots,butalso

fortheadvancedmodellers.Topowerit youmayuseamotorfromourproduction,e.g.theHCS-80/2E,andthree LithiumPolymer

cells. Thankstoawell thought-outdesigntheconstructionwouldtakeonlyabout90 minutes.

Buildingprocess:

Unless otherwisestated,alljointsshouldbegluedwiththerapidCyAglue. Startthebuildingbyassemblingtheengine

nacelles(Fig. 1,2). Thengluethewingstothefuselagecentralpart,and,using asharpmodelling knife, cuta1-2mm

deepslitintothewingfrombothupperandlowerside. Press thecarbonspar(rod) intotheslitandgluetherefromboth

sides, using thinCyAglue(Fig.3).Workonaflatsurface toensurethecompleteassemblyisnotdistorted.

Cuttheopeningsforservosintothefuselagecentresectionandgluethecentresectioninplace (Fig.4).

Gluethesecuringring totheendof thecarbonshaftof theelevators. UsingtheFig. 5asaguide,cutthegroovesinthe

fuselagecentralpartand,according totheFig.6,gluethemechanismof theslabelevatorsinplace.

Insertthecarbontubethroughthelocationgroovesandslideontoittheelevatorlever, thenthetwosecuringrings,two

fromeachside, respectively(Fig. 3).Inthefuselagepart, cutthegroovesfortheelevatorshaftbushings.Movethe

securingringstotheirextremeexternalpositionstoeliminateanyplayinthecarbontube. Thencarefullygluethe

rings,ensuringatthesametimethefreedomofmovementofthecarbontube. UsingtheFig. 4asaguide,glueinplace

thebushingsfortheslabelevator. Pierce/drillaholethroughacubeofEPP and slideitontothecontrolrod,toserveas

thecontrolrodguide.Gluetheelevatorservo inplace (Fig.5), settingthecorrectdistance accordingtothepositionof

thecut-outinthenacelle,andinstalltheelevatorcontrolrods(Fig. 6).

Checktheneutralpositionof theservo andgluetheelevatorleverinplace (Fig.7).Ensurethewingandrightandleft

elevatorplanesareparallel andthattheyareatthesameangle relativetothewings. Gluetheenginenacellestothe

fuselage(Fig.8).Gluethefuselagemainpart(Fig.9)and theverticaltailsurfaces(Fig.10). Using theFig.11 asa

guide,gluethemotorbulkheadandtherearfuselagealuminiumdoubler, screw-onthemotorbearers(Fig.12)and

securethemotorinplace.

InstallthespeedcontrollerasperFig.13.Gluetheenginenacelleupperpartinplace (Fig. 14).Thelocationof

theaccumulatorbatteryisshownof theFig.15.Usingahand-heldsolderinggun, cutaholeforthereceiverintothe

fuselage(place theholesothattheservo cableswouldreachit). Ifthecontroller’sservo cableislongenough,thereisno

needtouseanextensionone.Connectcableextensionstothepowercablesofthecontroller,orcuttheoriginalcables

shortandsplice themwithnewcablesaslongasnecessary. Themodelisnowreadyforbalancing. Byshiftingthe

batteries, setthepositionof thecentreof gravitytosome320mmfromthemotorbulkhead.Thencut,usingasoldering

gun,anopening forthebatterypack;thedimensionsof thebatteryopening shallbesome2to3mmless thantheouter

dimensionsof thebatterypack, sothatthebatterieswouldholdinplace withoutanyextrafixation.

Nowthemodeliscomplete. Forthefirstflight,setthedeflectionof thecontrolstothehalfof theirtravel. As

themodel,thankstothepropellertorque,tendstorolltotheleft, setthetrailingedgeof therighthalfof theelevator

some4mmup.Themodelhasspecificflightcharacteristics–thankstoitslayoutitcanflynotonlyfast, butalsovery

slow. Bearinmindthatthepropellertorqueeffectismuchmorepronouncedduring slowflight,especiallyafterthe

launch,andthemodelrollsslightlytoleft.

Thismodelisnotoy–thereforeavoidflyingincrowdedorsuchplaceswherehealthorpropertynotonlyof

yourselves, butalsoof thirdpersonscouldbejeopardised..

LotsoffunandmanyhappylandingswishesFreeAir.

PDFcreated withpdfFactorytrialversion www.pdffactory.com