Fresh Breeze Monster Operation instructions

Other Fresh Breeze Aircraft manuals

Fresh Breeze

Fresh Breeze APAX User manual

Fresh Breeze

Fresh Breeze XCitor User manual

Fresh Breeze

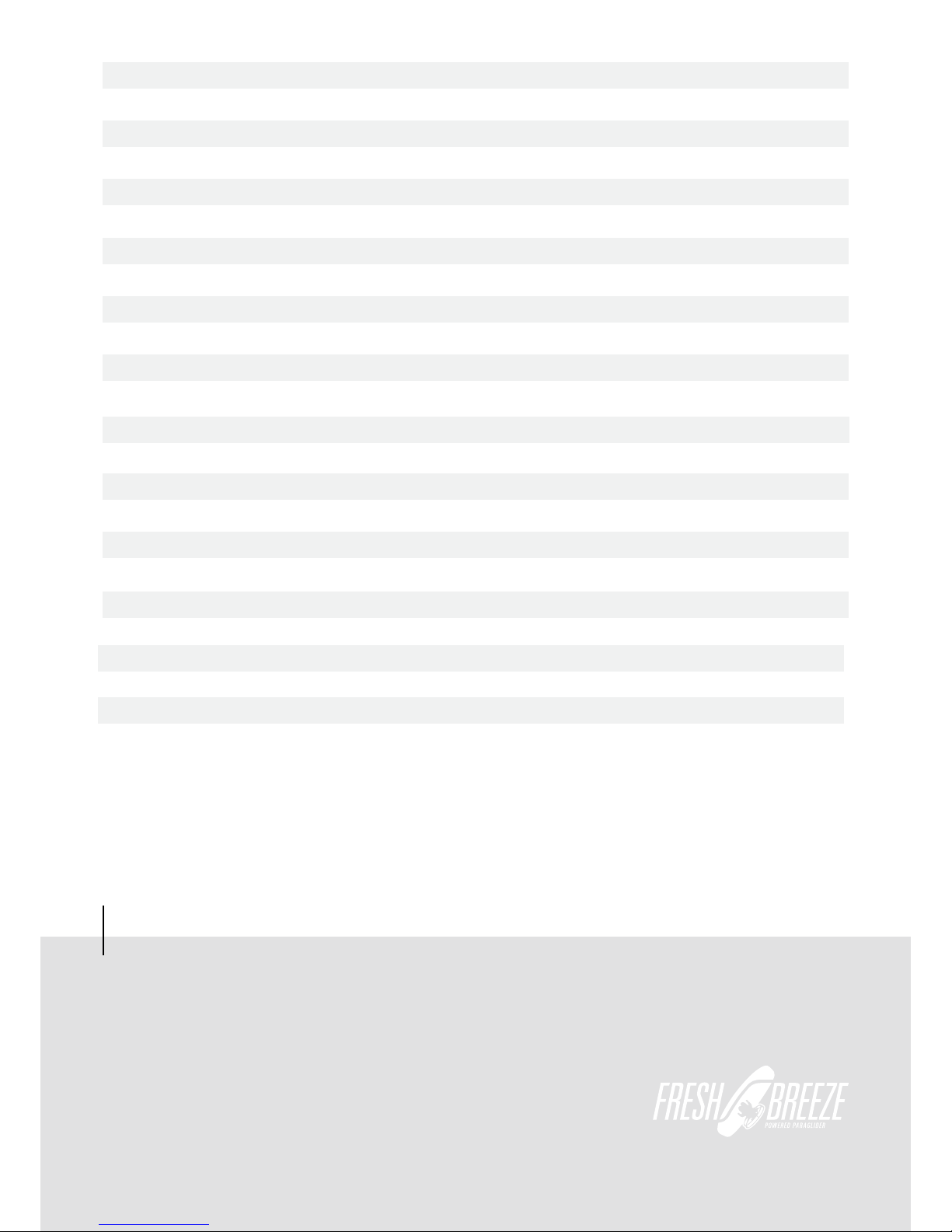

Fresh Breeze Flyke User manual

Fresh Breeze

Fresh Breeze Relax 22 User manual

Fresh Breeze

Fresh Breeze APAX evo User manual

Fresh Breeze

Fresh Breeze SilexX User manual

Fresh Breeze

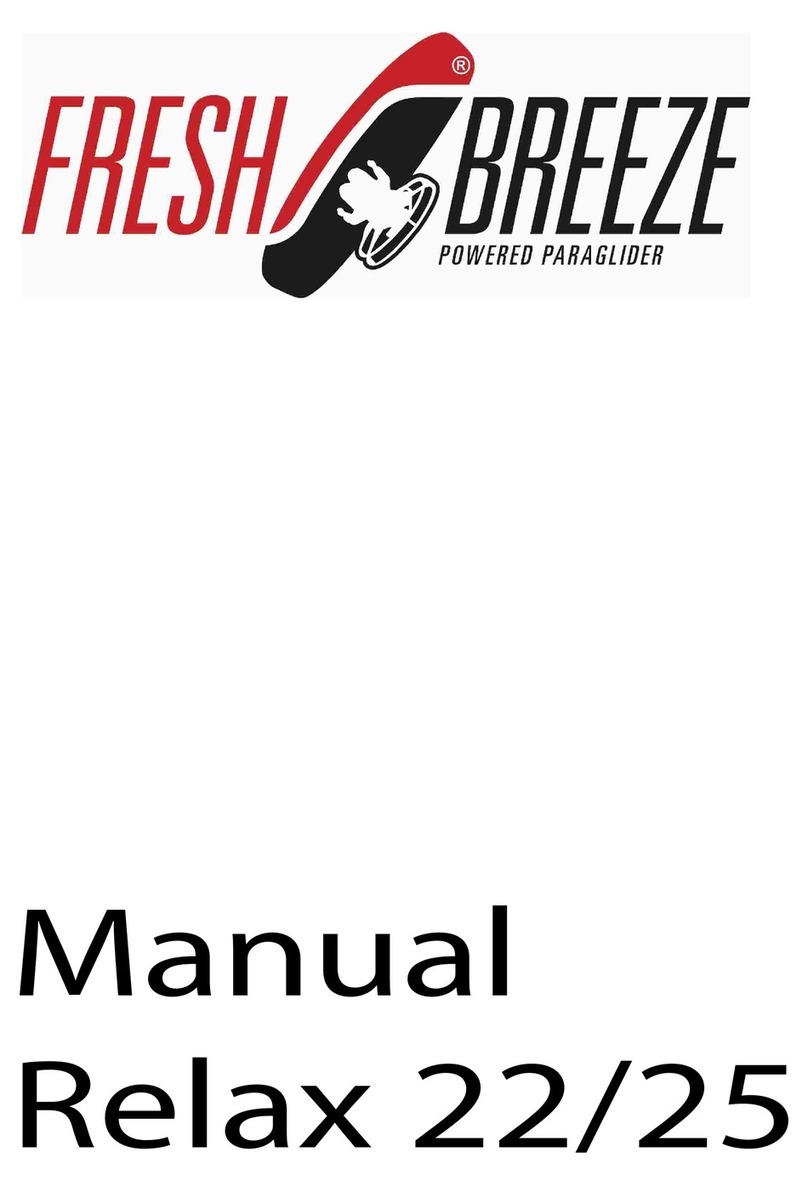

Fresh Breeze Super Throxi User manual

Fresh Breeze

Fresh Breeze X-Light F 23 Technical specifications

Fresh Breeze

Fresh Breeze SKIP ONE Owner's manual