FCR-230 1

FCR-230

INSTRUCTION

FCR230

Room controller for controlling fan-coil units

FCR-230 is a room controller intended for controlling fan-coil heaters/

coolers and thermal actuators or 3-point actuators. Installation is

directly on the wall or on an electrical connection box. The fan can be

set to one of three speeds.

FCR-230 has change-over function and can be used for 2-pipe or

4-pipe systems.

For integration into a system, FCR-230 has communication via

RS485 (Modbus, BACnet or EXOline). The device can be congured

using the application Regio tool (version 1.3-1-05 or later), which can

be downloaded from the Regin web site (www.regin.se).

Technical data

Supply voltage 230 V AC ±10 %, 50/60 Hz

Power consumption < 3 W

Ambient temperature 0...50°C

Ambient humidity Max 90 % RH

Storage temperature -20...+70°C

Built-in temperature sensor NTC type, range 0...50°C

Inputs Refer to connection illustrations and

table below

Outputs Relays for fan control, 230 V AC, 3 A

DO4, DO5 for actuators, Triac, 230 V AC,

max. 300 mA

Communication RS485: Modbus, EXOline (using

automatic detection/switching) or BACnet

Modbus 8 bits, 1 or 2 stop bits. Odd, even

(FI) or no parity

Communication speed 9600, 19200, 38400 bps (EXOline, Modbus

and BACnet) or 76800 bps (BACnet only)

Terminal blocks Lift type for a maximum cable area 2.1 mm2

Protection class IP20

Pollution degree 2

Overvoltage category 3

Material casing Polycarbonate, PC

Dimensions 102 x 120 x 29 mm

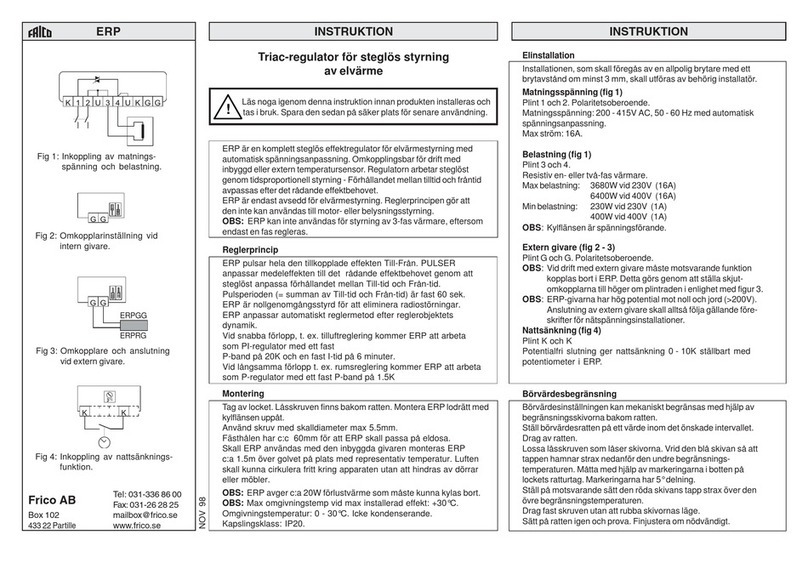

Installation

Place the controller in a location that has a temperature representative for

the room. A suitable location is approx. 1.6 m above oor level in a place

with unobstructed air circulation.

Depress the locking tab in the upper edge of the controller with a

screwdriver. Carefully turn the screwdriver until the bottom plate and the

electronics unit are slightly separated (see gure 1). Then use the cutout

that becomes visible in the edge of the bottom plate to open the upper

edge completely (see gure 2). Do the same thing in the lower edge of the

controller.

Figure 1 Figure 2

Lift the electronics unit up from the bottom plate. The bottom plate with

terminals has a number of hole combinations. Select suitable holes and

fasten the bottom plate on the wall or connection box, so that the arrows

on the bottom plate point upwards. Do not tighten the screws too hard!

Note: FCR-230 does not indicate fan breakdown or overheating of the

heating coil. Therefore, all connections must be made externally. An

overheating protection or similar can be used to disconnect the supply

voltage.

Disconnection

FCR-230 should be connected to a switch or circuit breaker in the

building installation. This switch should be in close proximity to the

controller and within easy reach of the operator, and should be

marked as the disconnecting device for the equipment.

Always use the circuit breaker to disconnect the controller from the

mains supply during maintenance of the fan-coil and actuators.

Settings

Control modes

FCR-230 can control heating and cooling in sequence or be set to

seasonal switching between heating and cooling (change-over, see

below).

Change-over function

FCR-230 has an input for change-over that automatically resets the

output DO4 to operate with heating or cooling function. When the con-

troller is used together with a 3-position actuator, output DO5 is also

aected by the change-over function in accordance with the above. A

sensor of type PT1000 can be connected to the input and be mounted

so that it senses the temperature on the supply pipe to the coil.

When the temperature exceeds 28°C, the output function is set to

heating and when the temperature drops below 16°C, the output is

set to cooling. As an alternative, a potential-free contact can be used.

The input function can be set to NO/NC.

To ensure satisfactory functioning when using a sensor, the system

must have continuous primary circuit circulation. When the change-

over function is not used, the input must be left disconnected.

When using an electric heater and the change-over function is set to

heating, the sequence of operation for FCR-230 will be heating/heat-

ing and DO5 will be activated rst.

If a change-over sensor is not connected, the sequence will be heat-

ing/heating. If cooling is to be used in the sequence, parameter 2

(change-over mode) must be changed manually.

Operating mode

There are four dierent operating modes. Switching between these

modes is performed locally.

Comfort: is shown in the display. Heating and cooling have a

smaller neutral zone NZC. An occupancy detector can be connected

to the DI in order to select between Comfort and Economy. Switching

between Comfort/Economy and O can also be done via the On/O

button. Comfort/Economy is selected via the parameter list.

EN

Instruction for products with software version 1.2.

Read this instruction before installation and wiring

of the product. This product is BTL listed from

software version 1.2-1-00 (BACnet stack 3.0.4).

Consult documentation in all cases where this symbol

is used, in order to nd out the nature of the potential

hazards and any actions to be taken

i