2/37 Item no.: HAB 100177146 - 000 · ENU · Change 1.1 · Approved 2023-02-21

Control electronicsControl electronics

VTD-60.XX-K5C-SVTD-60.XX-K5C-S

Contents

1 Introduction ............................................................................................................... 5

1.1 Foreword........................................................................................................................................................5

1.2 Target group ..................................................................................................................................................5

1.3 Written styles in this document ...................................................................................................................5

1.4 Warning notices and notices ........................................................................................................................5

2 Safety information..................................................................................................... 5

2.1 General safety information ...........................................................................................................................6

2.2 Documentation ..............................................................................................................................................6

2.3 Mechanical safety..........................................................................................................................................6

2.4 Standards and directives..............................................................................................................................6

...............................................................................................................................7

2.6 Safety of persons ..........................................................................................................................................7

2.7 Electric/electromagnetic safety....................................................................................................................7

2.8 Intended use ..................................................................................................................................................8

2.9 Improper use..................................................................................................................................................8

...................................................................................................................9

2.11 Transport and storage...................................................................................................................................9

2.12 What to do in the event of malfunctions and irregularities........................................................................9

3 Description ................................................................................................................ 10

3.1 Description of VTD-60.XX-K5C-S..................................................................................................................10

3.2 Nameplate ......................................................................................................................................................10

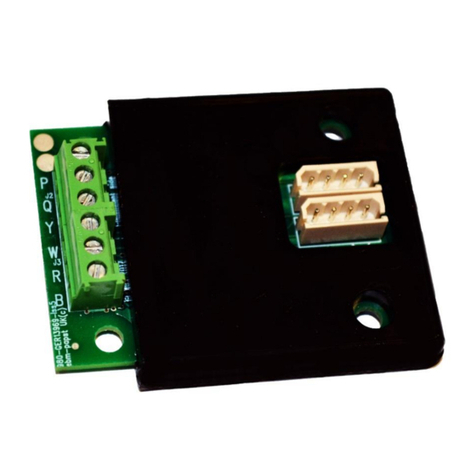

3.3 Device view ....................................................................................................................................................13

3.4 Status LED .....................................................................................................................................................15

4 Technical data............................................................................................................ 16

4.1 Power .............................................................................................................................................................16

4.2 Motor types ....................................................................................................................................................16

4.3 Mechanical data.............................................................................................................................................16

4.4 Environment ..................................................................................................................................................17

4.5 Controller cycle times ...................................................................................................................................17

4.6 CAN bus .........................................................................................................................................................17

4.7 Encoder supply (rotary encoder/Hall)..........................................................................................................17

4.8 Rotary encoder ..............................................................................................................................................17

4.9 Hall sensors ...................................................................................................................................................18

4.10 Digital inputs..................................................................................................................................................18

4.11 Digital outputs ...............................................................................................................................................18