PRE-INSTALLATION REQUIREMENTS

Tools and Materials Required for Installation:

1. Phillips head screwdriver.

2. Channelqock adjustable pliers.

3. Carpenter's level.

4. Flat or straight blade screwdriver.

5. Duct tape.

6. Rigid or flexible metal 4 inch (10.2 cm) duct.

7. Vent hood.

8. Pipe thread sealer (Gas).

9. Plastic knife.

10. I/2 inch open end wrench.

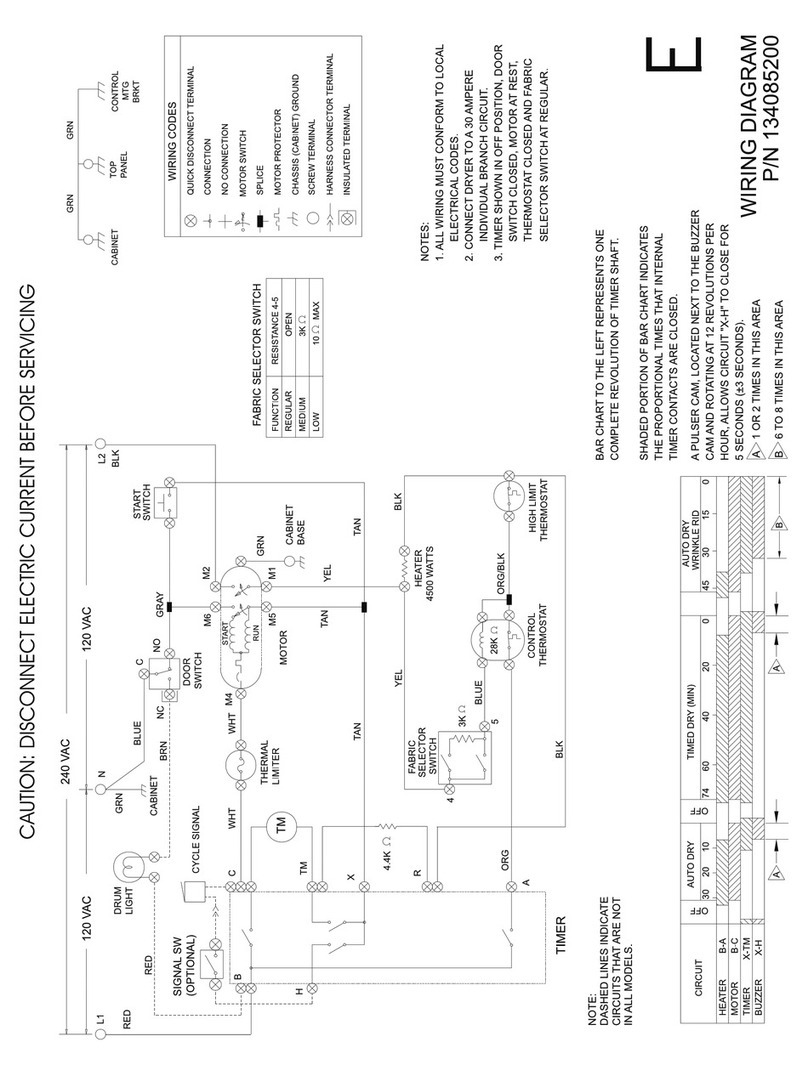

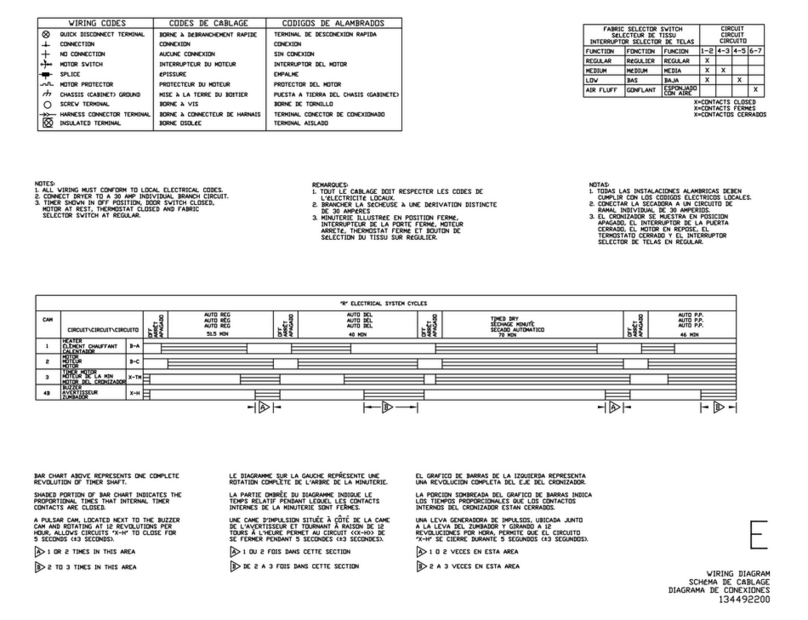

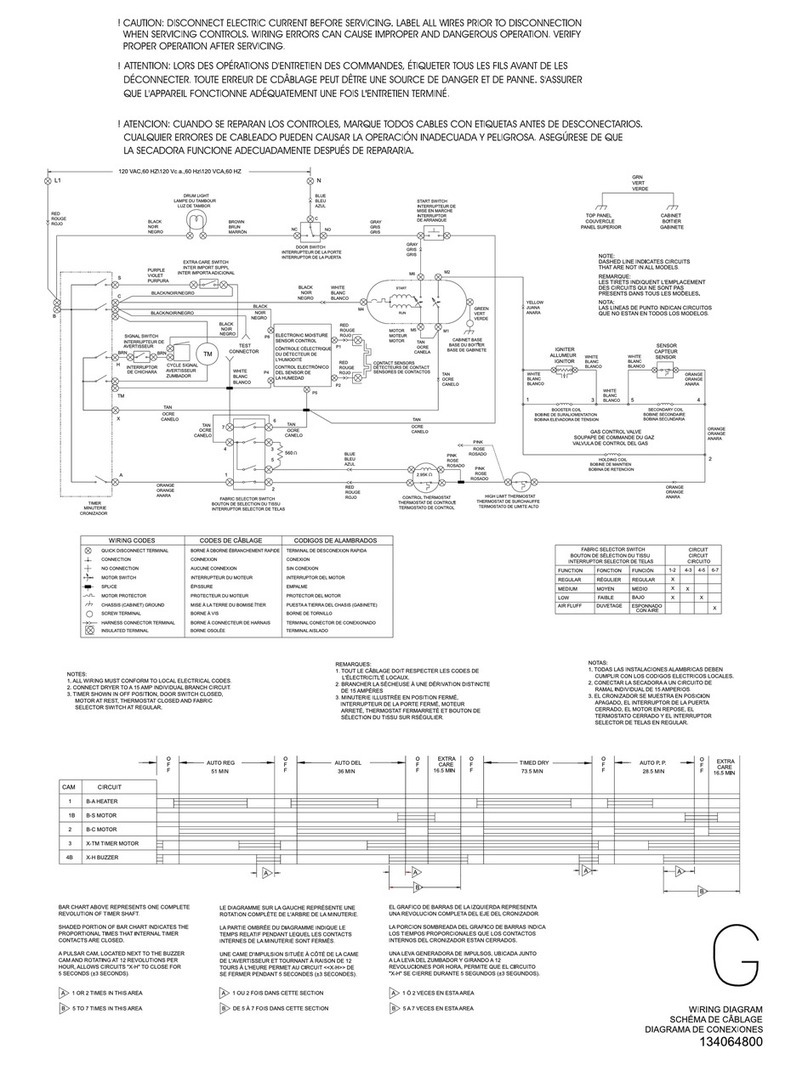

ELECTRICAL REQUIREMENTS

ELECTR/CDryer ]

CIRCUIT- Individual 30 amp. branch circuit fused with 30 amp.

minimum time delay fuses or circuit breakers.

POWER SUPPLY- 3 wire, 240 volt, single phase, 60 Hz,

Alternating Current. (Canada - 240 volt, single phase, 60 Hz,

Alternating Current.)

POWER SUPPLY CORD KIT - Tile dryer MUST employ a 3-

conductor power supply cord NEMA 10-30 type SRDTrated at

240 volt AC minimum, 30 amp., with 3 open end spade lug

connectors with upturned ends or closed loop connectors and

marked for use with clothes dryers. If being installed in a

manufactured (raobile) horse, the dryer MUST employ a 4-

conductor power supply cord NEMA !4-30 type SRDTor ST(as

required) rated at 240 volt AC minimum, 30 amp., with 4 open

end spade lug connectors with upturned ends or closed loop

connectors and marked for use with clothes dryers. See

ELECTRICALCONNECTIONSFORA 4-WIRE SYSTEM.

(Canada - 4-wire power supply cord isinstalled on dryer.)

OUTLETRECEPTACLE- NEMA 10-30R receptacle to be located

so the power supply cord is accessiblewhen the dryer is in the

installed position. (Canada - NEMA 14-30R receptacle.)

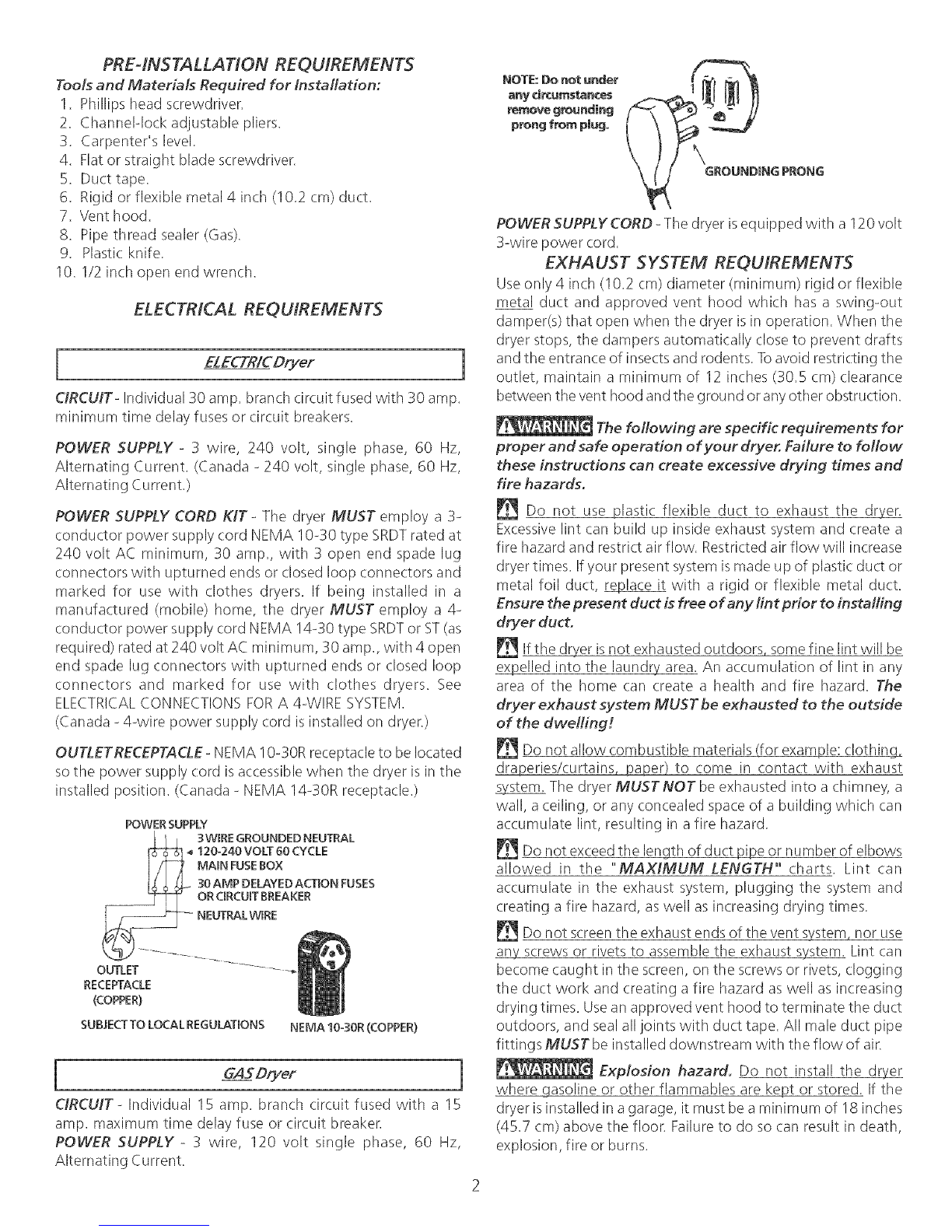

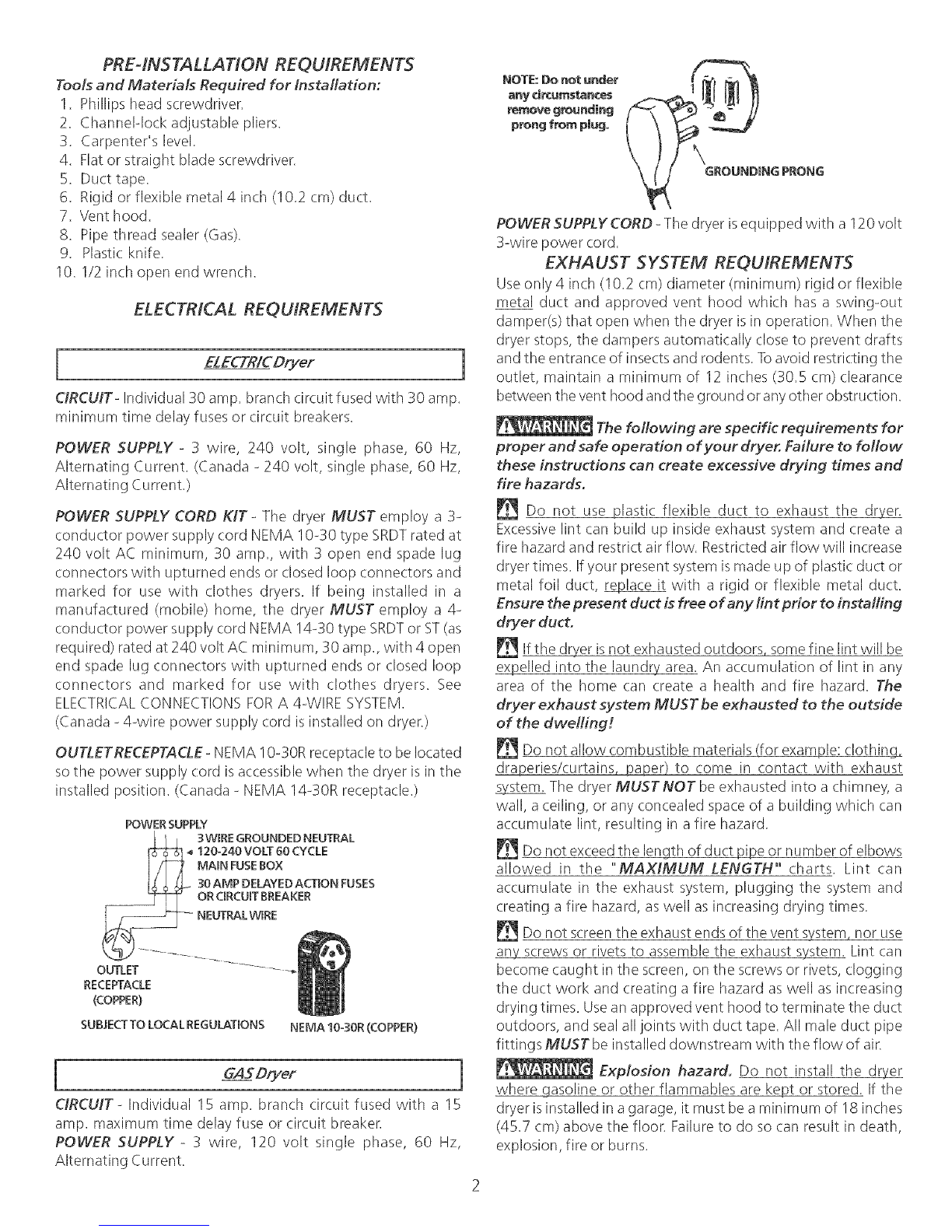

POWER SUPPLY

OUTLET

RECEPTACLE

(COPPER)

SUBJECTTO LOCAL REGULATIONS NEMA 1O-3OR(COPPER)

I GASDd/ef 1

CIRCUIT - Individual 15 amp. branch circuit fused with a 15

amp. maximum time delay fuse or circuit breaker.

POWER SUPPLY - 3 wire, 120 volt single phase, 60 Hz,

Alternating Current.

NOTE: Do not under

any d_:umstances

remove grounding

prong from plug.

POWER SUPPLYCORD - The dryer isequipped with a 120 volt

3-wire power cord.

EXHAUST SYSTEM REQUIREMENTS

Useonly 4 inch (10.2 cm) diameter (minimum) rigid or flexible

metal duct and approved vent hood which has a swing-out

damper(s) that open when the dryer is in operation. When the

dryer stops, the dampers automatically close to prevent drafts

and the entrance of insects and rodents. Toavoid restricting the

outlet, maintain a minimum of 12 inches (30.5 cm) clearance

between the vent hood and tile ground or anyother obstruction.

The following are specific requirements for

proper and safe operation of your dryer Failure to follow

these instructions can create excessive drying times and

fire hazards.

Do not use plastic flexible duct to exhaust the dr,e/_£_.

Excessivelint can build up inside exhaust system and create a

fire hazard and restrict air flow. Restricted air flow will increase

dryer times. If your present system ismade up of plastic duct or

metal foil duct, _)lace it with a rigid or flexible metal duct.

Ensure the present duct is free of any lint prior to instal/ing

dryer duct.

If the dryer isnot exhausted outdoors somefine lint will be

expelled into the laundry area. An accumulation of lint in any

area of the home (:an create a health and fire hazard. The

dryer exhaust system MUST be exhausted to the outside

of the dwel/ing r.

Do not allow combustible materials (for example: clothing_

draperies/curtains, paper) to come in contact with exhaust

s_stem. Tile dryer MUSTNOT be exhausted into a chimney, a

wall, a ceiling, or any concealed space of a building which can

accumulate lint, resulting in a fire hazard.

Do not exceed tile length of duct F£)eor number of elbows

allowed in the "MAXIMUM LENGTH" charts. Lint can

accumulate in the exhaust system, plugging the system and

creating a fire hazard, as well as increasing drying times.

_Do not screen the exhaust ends of the vent system, nor use

any screws or rivets to assemble the exhaust system. Lint can

become caught in the screen, on the screws or rivets, clogging

the duct work and creating a fire hazard as well as increasing

drying times. Usean approved vent hood to terminate the duct

outdoors, and sealall joints with duct tape. All male duct pipe

fittings MUST be installed downstream with tile flow of air.

Exp/osion hazard. Do not install the dryer

where gasoline or other flammables are kept or stored. If the

dryer isinstalled in a garage, it must be a minimum of 18 inches

(45.7 cm) above the floor. Failure to do so can result in death,

explosion, fire or burns.