pulverisette 5 page 1

FRITSCH

ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN

Table of contents page

1General Information / Introduction..............................................2

1.1 Notes about Operating Instructions........................................................... 2

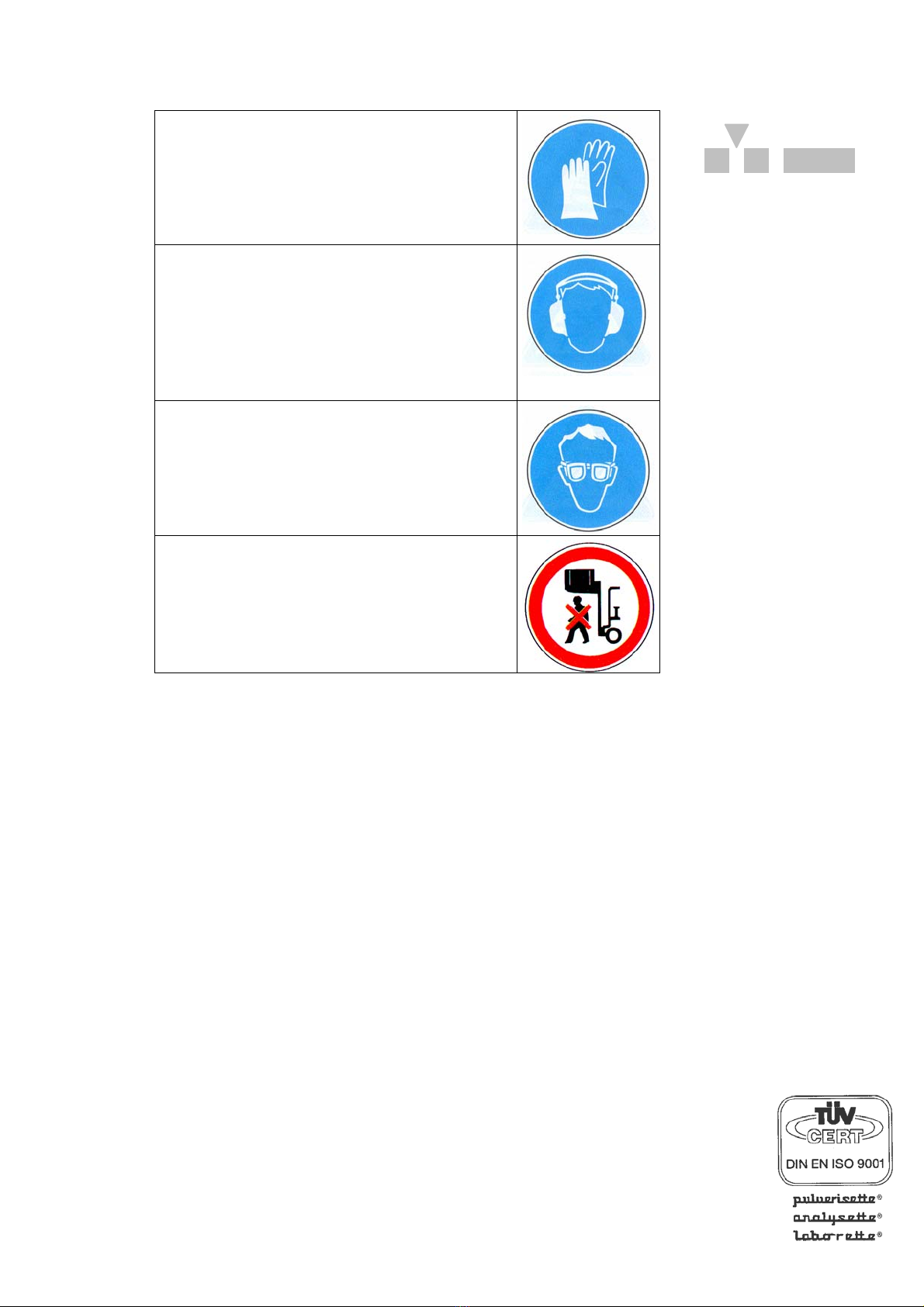

1.2 Explanations of the signs at the instrument and

in the operating instructions....................................................................... 2

1.3 Short Description of the Machine .............................................................. 3

1.3.1 Applications ........................................................................................................... 3

1.3.2 Method of Operation.............................................................................................. 4

1.3.3 Drive Motor and Speed Control ............................................................................. 4

1.4 Technical Data........................................................................................... 4

2Operating Safety ...........................................................................6

2.1 General Safety Instructions ....................................................................... 6

2.2 Operators................................................................................................... 7

2.3 Protective Devices..................................................................................... 7

2.4 Danger Points............................................................................................ 8

2.5 Electrical Safety......................................................................................... 8

2.5.1 General.................................................................................................................. 8

2.5.2 Protection against Restarting................................................................................. 8

2.5.3 Overload Protection (see 8 Troubleshooting Checklist)......................................... 8

2.5.4 Unbalance Detection (see 8 Troubleshooting Checklist) ....................................... 8

3Installation.....................................................................................9

3.1 Unpacking.................................................................................................. 9

3.2 Transport ................................................................................................... 9

3.3 Erection...................................................................................................... 9

3.4 Ambience conditions ................................................................................. 9

3.5 Electrical Connection............................................................................... 10

3.6 Adaptation to Mains Supply Voltage, Changing Timer and

Unbalance Detection in setup mode ....................................................... 10

3.7 Switching On for the First Time / Test for Correct Functioning ............... 11

4Working with the mill..................................................................12

4.1 Choice of Grinding Bowls and Grinding Balls.......................................... 12

4.1.1 Size of the Grinding Balls .................................................................................... 12

4.1.2 Number of Balls per Grinding Bowl...................................................................... 13

4.2 Filling the Grinding Bowl.......................................................................... 13

4.3 Influencing Quantities During Grinding.................................................... 14

4.3.1 Dry Grinding ........................................................................................................ 14

4.3.2 Wet Grinding (Grinding in Suspension) ............................................................... 14

4.4 Clamping the grinding bowls ................................................................... 15

4.4.1 Clamping with the "Safe Lock" Holder ................................................................. 15

4.4.2 Clamping the 80 ml grinding bowl........................................................................ 15

4.4.3 Clamping with Additional Clamping System......................................................... 16

4.5 Mass Balance .......................................................................................... 17

4.6 Grinding Time .......................................................................................... 17

4.7 Control Panel........................................................................................... 18

4.7.1 Setting the Speed................................................................................................ 18

4.7.2 Setting the Running Time .................................................................................... 18

4.7.3 Reversing Operation............................................................................................ 18

4.7.4 Repetition of the Grinding / Break Cycles............................................................ 18

4.8 Performing a Grinding Operation ............................................................ 19

4.9 Cooling the Grinding Bowls ..................................................................... 19

4.10 Standby.................................................................................................... 19

4.11 Grinding under protective gas with gas lid .............................................. 20

4.12 GTM System............................................................................................ 22

5Cleaning.......................................................................................22

6Maintenance ................................................................................23

7Warranty ......................................................................................24

8Troubleshooting Checklist ........................................................24

9Examples of Comminution Tasks .............................................25

10 List of Keywords.........................................................................27

11 Spare part list and circuit diagrams..........................................27