INSTALLATIONANDMAINTENANCEMANUAL

TRANSLATION OF THE

ORIGINAL DOCUMENT Foradditionalcopiesvisit:

www.frost‐trol.com

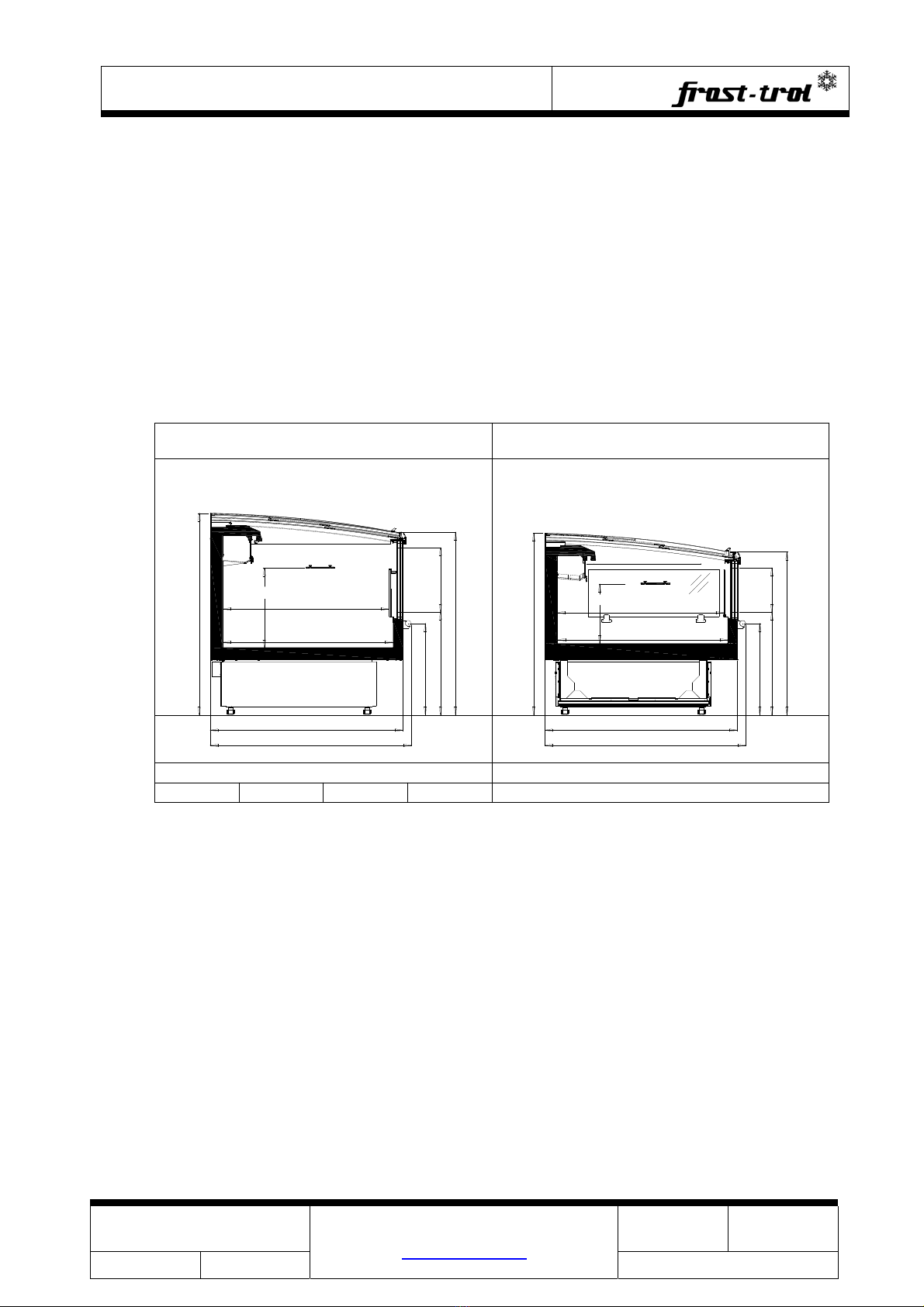

LOMOND

SOLID LINES

D003670 Versión: 3 -1-

Index

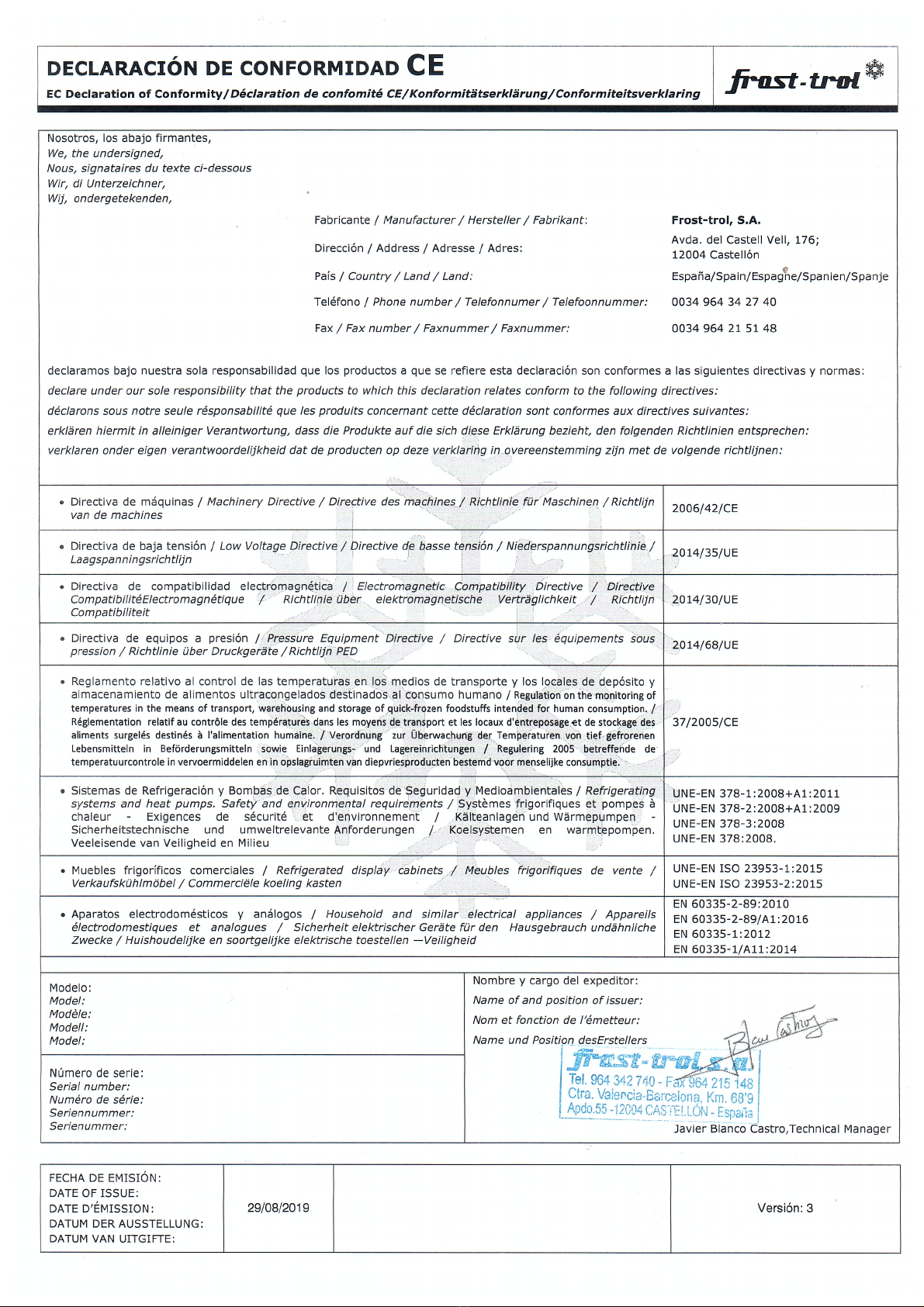

EEC DECLARATION OF CONFORMITY.............................................................. 3

SAFETY ADVICE........................................................................................... 4

1.GENERAL INFORMATION ................................................................. 7

1.1.DESCRIPTION OF REFRIGERATED DISPLAY CABINET........................... 8

1.2.GENERAL CHARACTERISTICS........................................................... 8

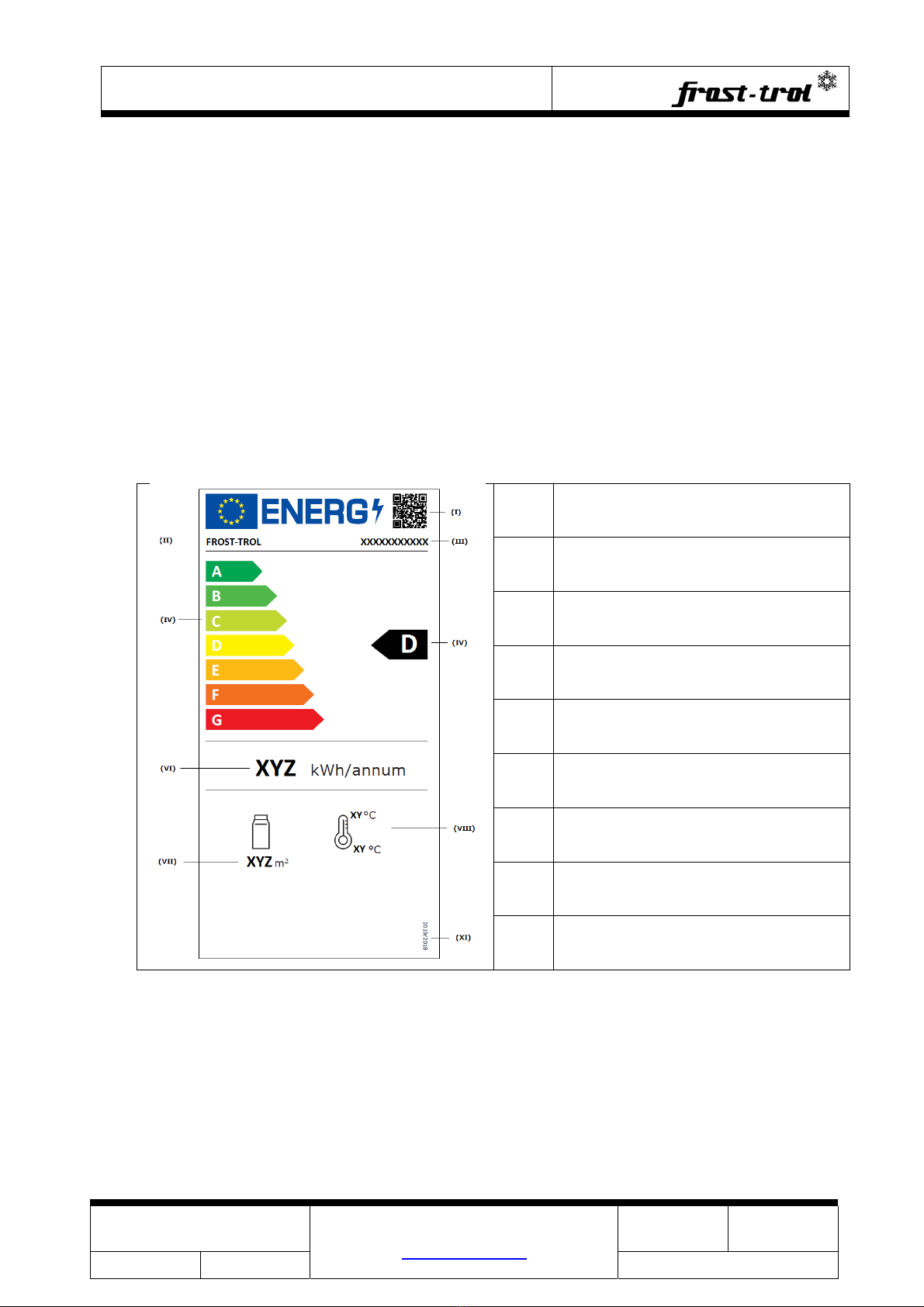

1.3.TECHNICAL INFORMATION AND ACCESS TO EPREL ............................. 9

1.4.SHOP CONDITIONS ........................................................................ 9

1.5.FIXATION OF THE RECOMMENDED TEMPERATURE IN EACH

COMPARTIMENT ........................................................................................ 10

1.6.OPERATING THE COOLING SYSTEM................................................. 10

1.7.RECEIPT OF REFRIGERATED CABINET ............................................. 10

1.8.DAMAGE SUSTAINED IN TRANSIT................................................... 10

1.9.TECHNICAL ASSISTANCE............................................................... 11

1.10.STORAGE.................................................................................... 11

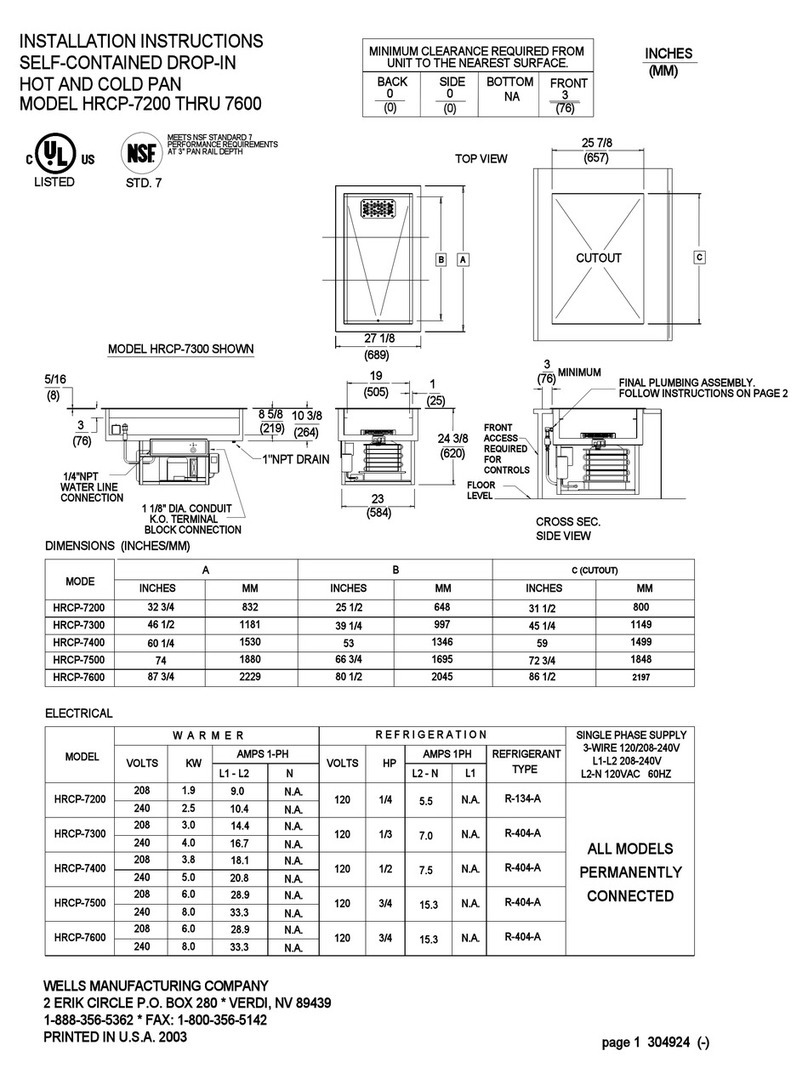

2.INTALLATION OF REFRIGERATED DISPLAY CABINET.......................... 12

2.1.CABINET LOCATION...................................................................... 12

2.2.UPACKING................................................................................... 13

2.3.LEVELLING .................................................................................. 13

2.4.ASSEMBLY................................................................................... 14

2.4.1.REAR BACKSTOPPERS MOUNTING: ................................................. 15

2.4.2.SIDE KIT MOUNTING .................................................................... 16

2.4.3.WALL AHEAD KIT MOUNTING......................................................... 17

2.4.4.BACK TO BAK KIT MOUNTING ........................................................ 18

2.4.5.HEAD MODULE ASSEMBLY KIT........................................................ 19

2.5.ELECTRICAL CONNECTION............................................................. 20

2.6.CLEANING................................................................................... 20

3.OPERATION................................................................................. 21

3.1.INITIAL START-UP........................................................................ 21

3.2.HOW TO SET THE SET POINT (DESIRED TEMPERATURE VALUE).......... 21

3.3.HOW TO ACCESS AND SET PARAMETERS......................................... 22

3.4.ACCESSING THE PARAMETERS BY SELECTING CATEGORY.................. 22

3.5.ALARMS WITH MANUAL RESET ....................................................... 23

3.6.MANUAL DEFROST........................................................................ 23

3.7.PRODUCT LOADING AND PRESERVATION......................................... 23

4.MAINTENANCE AND CLEANING....................................................... 25

4.1.GENERIC CLEANING ROUTINE........................................................ 25