INSTALLATION AND MAINTENANCE MANUAL

TRANSLATION OF THE

ORIGINAL DOCUMENT

For additional copies visit:

www.frost-trol.com

GREGAL

SOLID LINES

D008270 Versión: 2 -1-

Index

EEC DECLARATION OF CONFORMIT ................................................................ 3

SAFET ADVICE ............................................................................................. 4

1.

GENERAL INFORMATION ................................................................... 7

1.1.

DESCRIPTION OF REFRIGERATED DISPLA CABINET ............................ 8

1.2.

GENERAL CHARACTERISTICS ............................................................. 8

1.3.

SHOP CONDITIONS .......................................................................... 9

1.4.

OPERATING THE COOLING S STEM .................................................... 9

1.5.

RECEIPT OF REFRIGERATED CABINET ................................................. 9

1.6.

DAMAGE SUSTAINED IN TRANSIT ...................................................... 9

1.7.

TECHNICAL ASSISTANCE................................................................... 9

1.8.

STORAGE .......................................................................................10

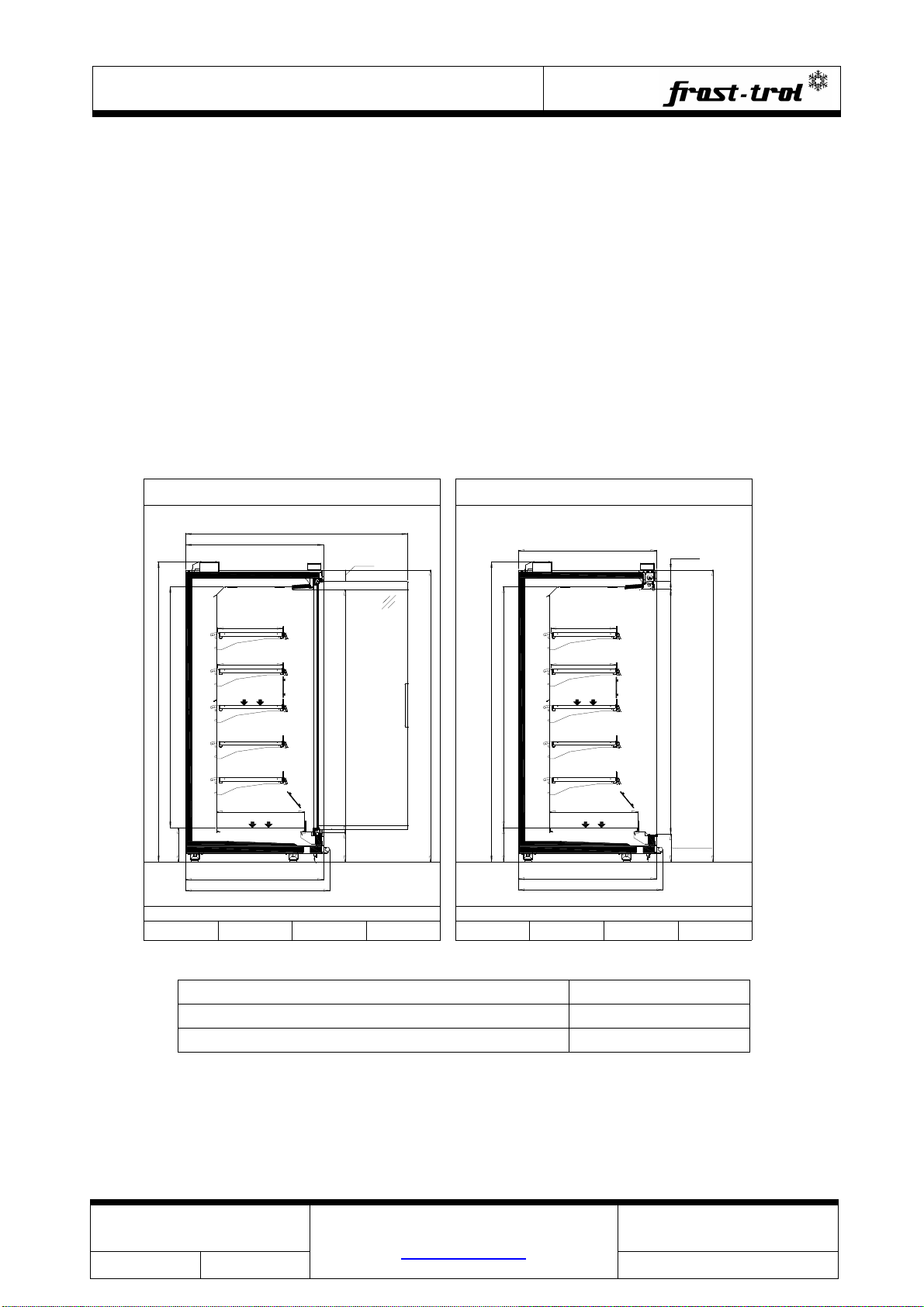

2.

INTALLATION OF REFRIGERATED DISPLA CABINET ............................10

2.1.

CABINET LOCATION .........................................................................10

2.2.

UPACKING ......................................................................................11

2.3.

LEVELLING .....................................................................................11

2.4.

INSTALLATING THE DRAINAGE SISTEM ..............................................11

2.5.

ASSEMBL ......................................................................................13

2.6.

REFRIGERATING S STEM CONNECTION .............................................18

2.7.

INSTALLATION’S DR ING .................................................................18

2.8.

THERMOSTATIC VALVE CONTROL ......................................................18

2.9.

ELECTRICAL CONNECTION ...............................................................19

2.10.

DOORS INTALLATION ......................................................................20

2.11.

CLEANING ......................................................................................20

3.

OPERATION ....................................................................................21

3.1.

INITIAL START-UP ...........................................................................21

3.2.

PRODUCT LOADING .........................................................................21

4.

MAINTENANCE AND CLEANING .........................................................22

4.1.

GENERIC CLEANING ROUTINE ...........................................................23

4.2.

INTERNAL CLEANING PROCEDURE .....................................................23

4.3.

DOORS MAINTENANCE .....................................................................24

4.4.

REPLACING LAMPS ..........................................................................24

5.

SPARE PARTS REQUEST ...................................................................25

6.

FAULTS AND REPAIRS ......................................................................26

6.1.

MALFUNCTIONS ..............................................................................26

6.1.1.

THE UNIT DOESN’T START UP OR IT STOPS: ......................................26

6.1.2.

THE UNIT DOES NOT GET COLD ENOUGH: .........................................26