Frymaster L.L.C., 8700 Line Avenue 71106, P.O. Box 51000, Shreveport, Louisiana 71135-1000

318-865-1711 FAX 318-862-2394

Printed in the United States Service Hotline Page 3

1-800-24-FRYER

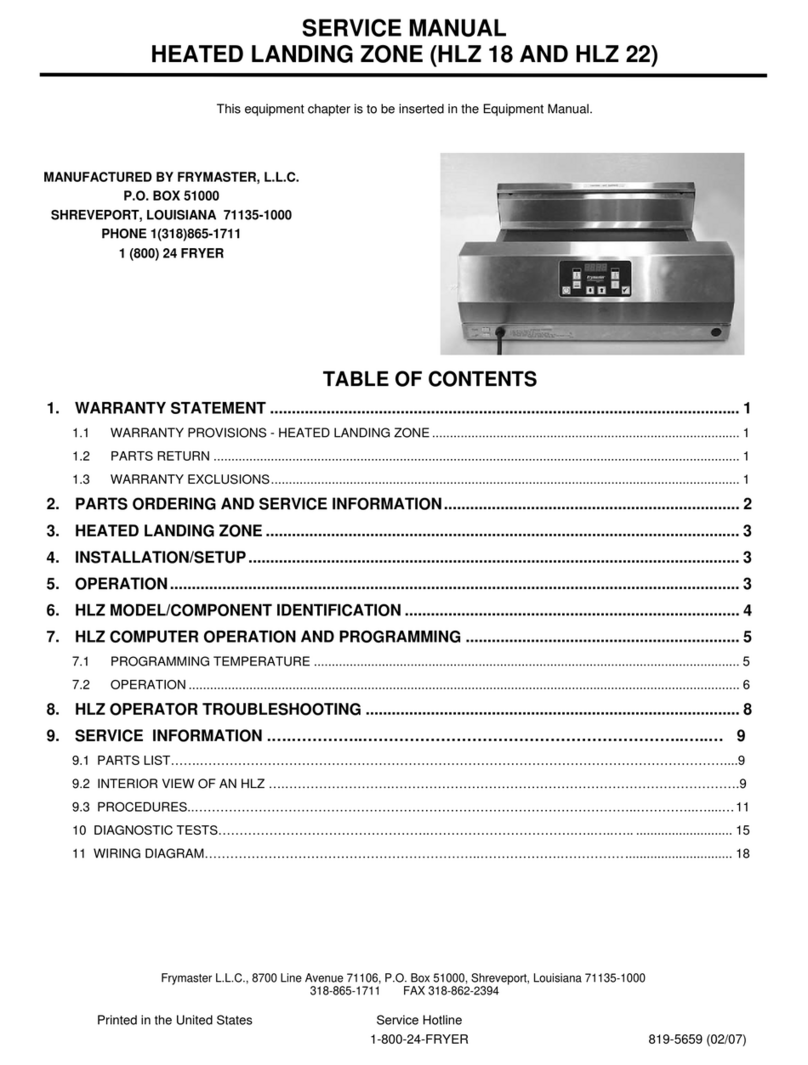

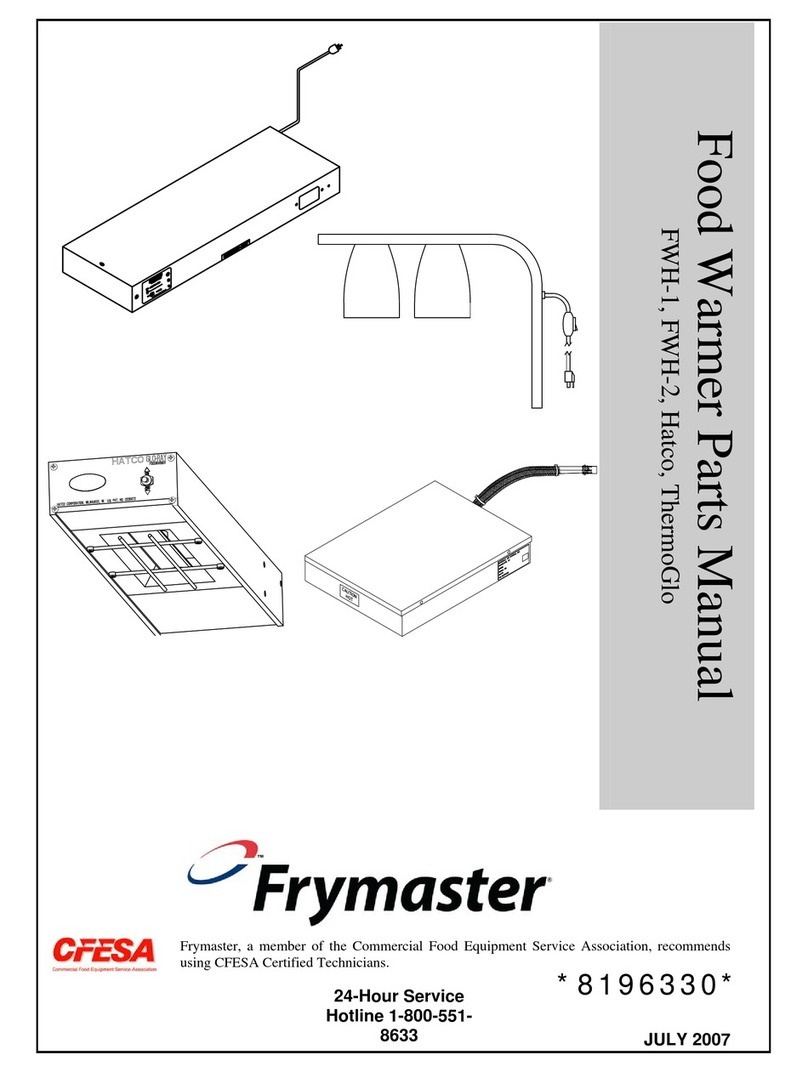

3. HEATED LANDING ZONE

The Heated Landing Zone or HLZ is designed to hold assembled sandwiches. By circulating heated

air evenly across the open staging area, the Heated Landing Zone keeps sandwiches hot without

drying or cooking. The Heated Landing Zone meets all McDonald’s standards for safety, efficiency,

food safety, and cleanliness.

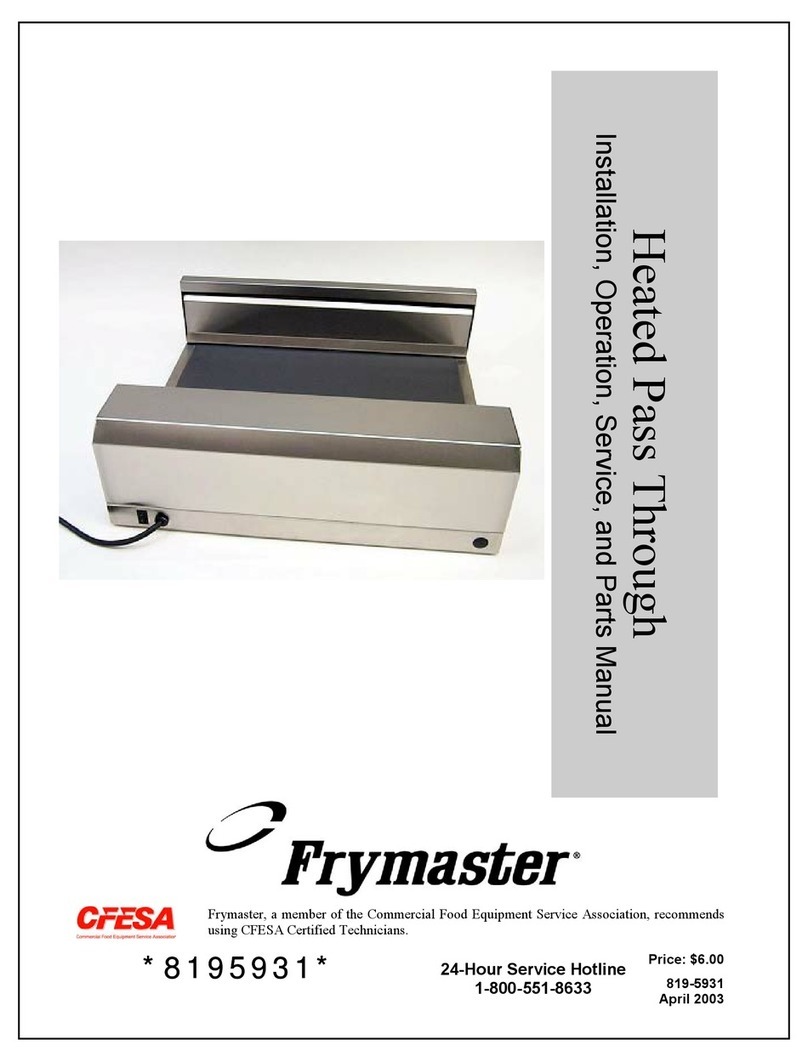

4. INSTALLATION/SETUP

Upon arrival, inspect the HLZ for concealed damage.

Immediately report any damage to the delivering freight

company. Claims must be filed within 15 days after

receipt of the unit.

Make sure that the unit is placed on an even surface and

that the area surrounding the HLZ is free of clutter that

would interfere with air flow.

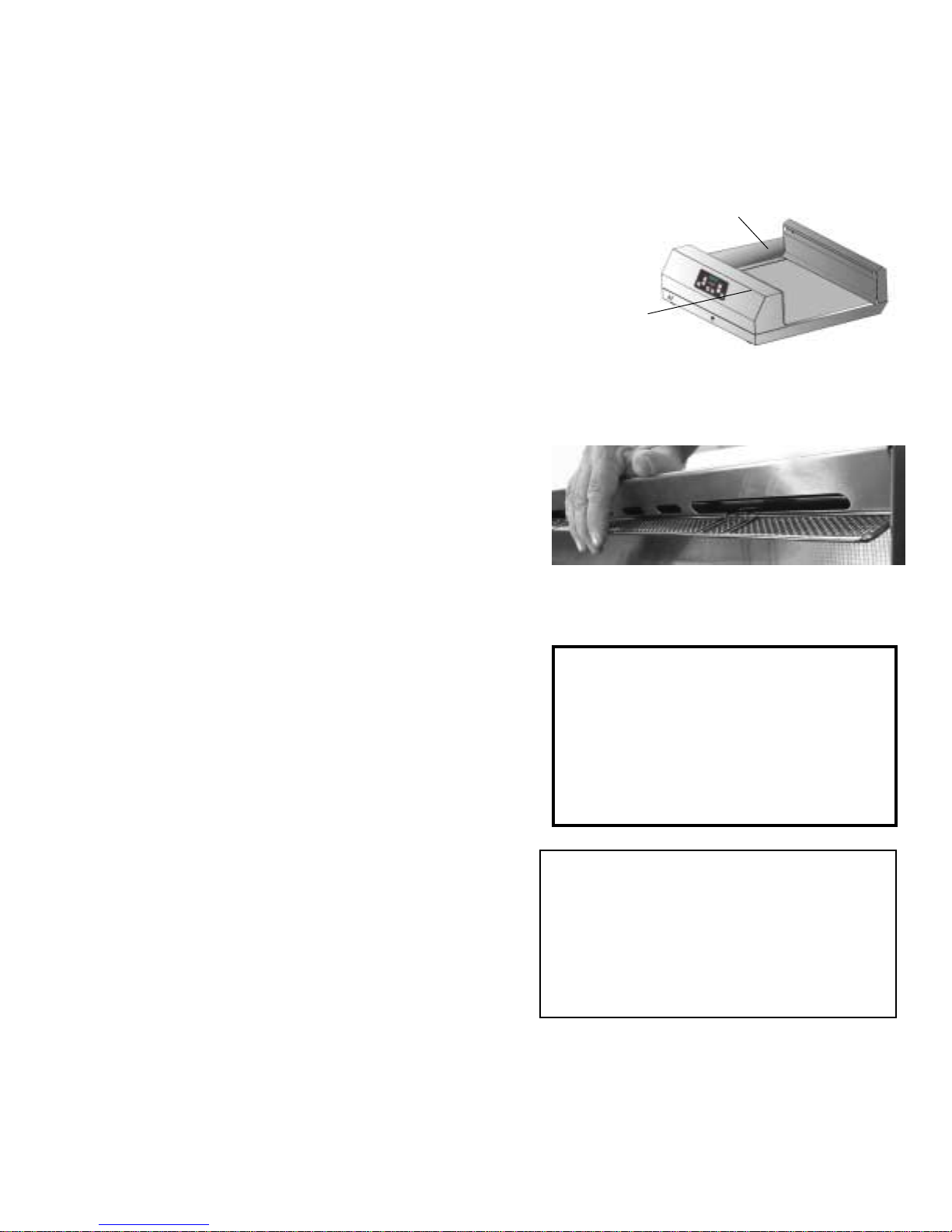

INSTALL OPTIONAL BURGER BUMPER (Units built before 10/98)

The burger bumper may be placed on either side of the

HLZ to prevent pass through of product. Burger bumpers

are provided by the KES. See figure 1.

INSTALL FILTER SCREEN (Units built after 10/98)

The filter screen is design to prevent debris from entering

the Computer Cowl Assembly and clogging the blower

assembly. Simply fit the part on to the vent opening of the

computer cowl assembly. The filter screen will snap into

position. If equipped with an optional holding screw,

tighten screw to pull the filter screen snug into position.

POWER REQUIREMENTS:

•Voltage – Two models are available: 208 VAC and 240 VAC*

•Frequency - 60 Hz

•Single Phase

•20 amp Service

5. OPERATION

1. Plug the unit into the power source.*

2. See “HLZ COMPUTER OPERATION AND

PROGRAMMING, Section 7” for proper setup and

operation of the computer.

3. Place product in the HLZ in accordance with the

restaurant’s established procedures.

4. CLOSING - When closing the store, remove all product from the HLZ and perform daily preventive

maintenance in accordance with the MRC. Turn the computer OFF.

THIS APPLIANCE IS EQUIPPED WITH

GROUNDING PLUG FOR YOUR

PROTECTION AGAINST SHOCK

HAZARD AND MUST BE PLUGGED INTO

A PROPERLY GROUNDED

RECEPTACLE. DO NOT CUT OR

REMOVE THE GROUNDING PRONG

FROM THIS PLUG.

Figure 1

Optional Burger Bumper

Installed (unit built before 10/98)

Compute

Cowl

* If the 240 VAC model is operated on

208 VAC, the unit will heat slowly an

may not reach maximum temperature. I

the 208 VAC model is operated on 24

VAC, component damage is probable.

To ensure proper operation, the powe

source should match the voltage on the

rating plate on the bottom of the HLZ.

The filter screen snaps into place on

rear of the air-intake tower.