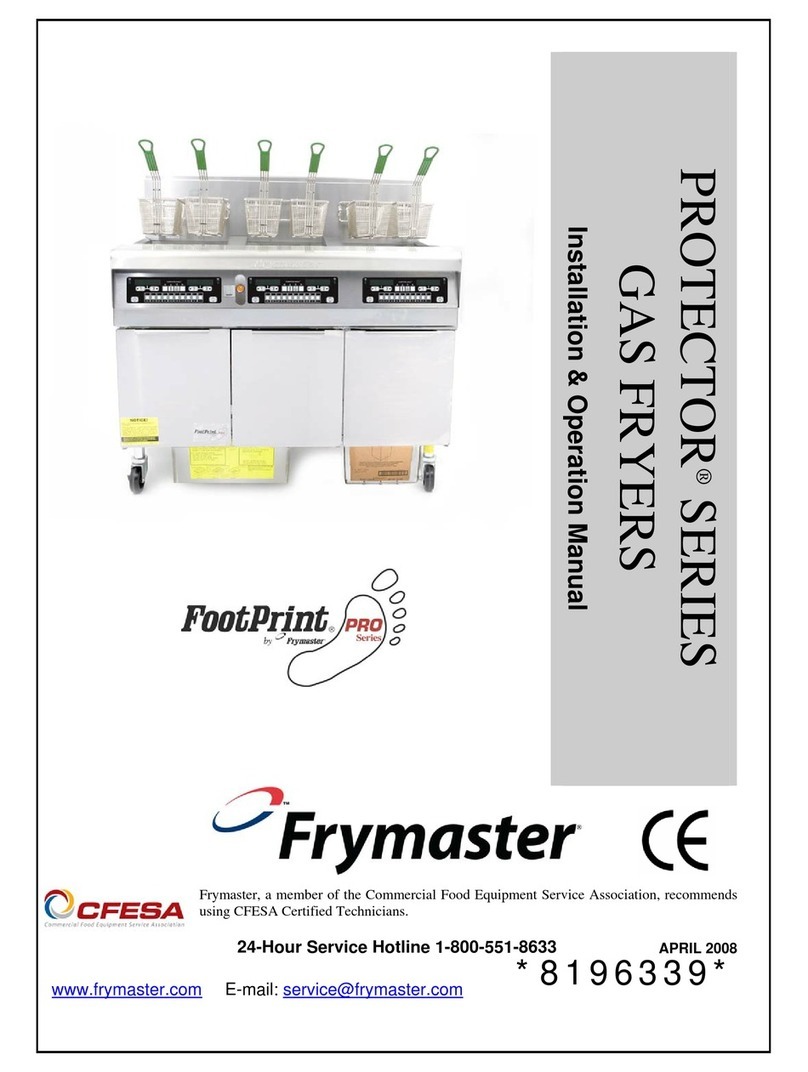

Frymaster Pro H55-Series Product manual

Other Frymaster Fryer manuals

Frymaster

Frymaster OCF30 Series Guide

Frymaster

Frymaster DECATHLON H55 User manual

Frymaster

Frymaster BIPH/MPH14 User manual

Frymaster

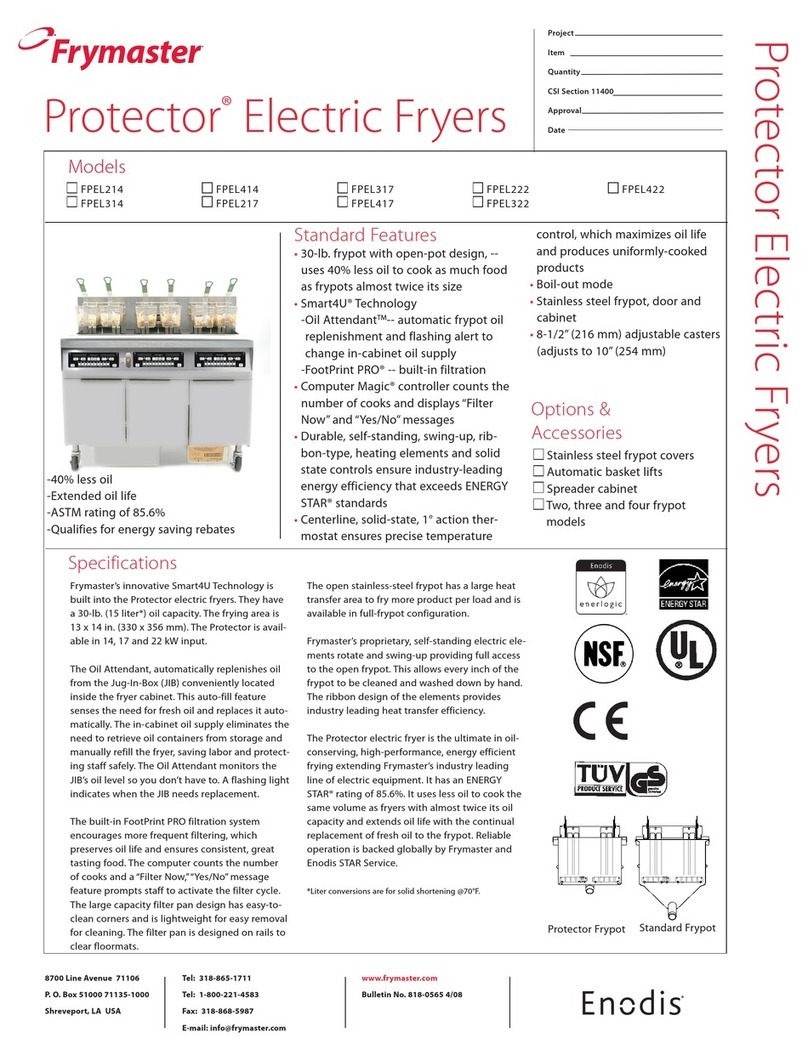

Frymaster Protector FPEL214 User manual

Frymaster

Frymaster H20.5 SERIES Guide

Frymaster

Frymaster Application Series Manual

Frymaster

Frymaster SR42 Series, SR52 Series, SR62 Installation and operating instructions

Frymaster

Frymaster 1814E Series User manual

Frymaster

Frymaster FRYMASTER GF14 series User manual

Frymaster

Frymaster LOV M3000 Product manual

Frymaster

Frymaster 21814GF User manual

Frymaster

Frymaster 8196428 Guide

Frymaster

Frymaster BK1814 Series User manual

Frymaster

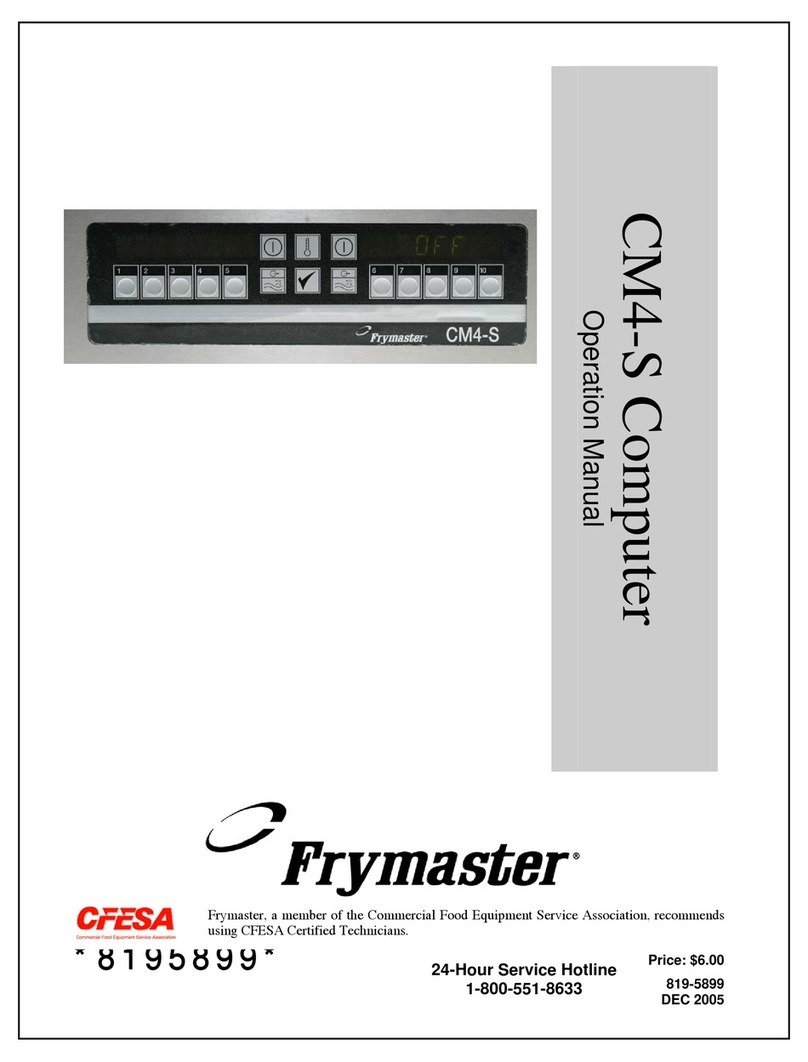

Frymaster cm45 s User manual

Frymaster

Frymaster 824E User manual

Frymaster

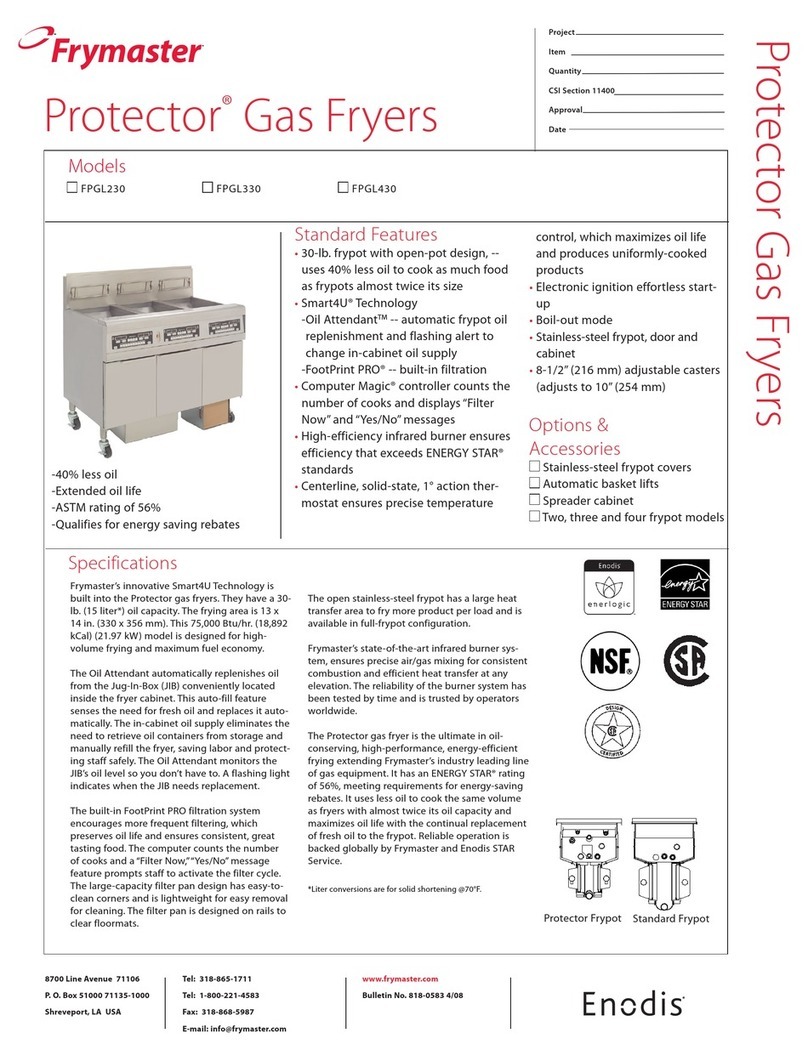

Frymaster Protector FPGL230 User manual

Frymaster

Frymaster SM80 User manual

Frymaster

Frymaster YSCFC24GSERIES YSCFC24GSERIES Guide

Frymaster

Frymaster LOV BIEL14 SERIES User manual

Frymaster

Frymaster BIRE14 Series User manual