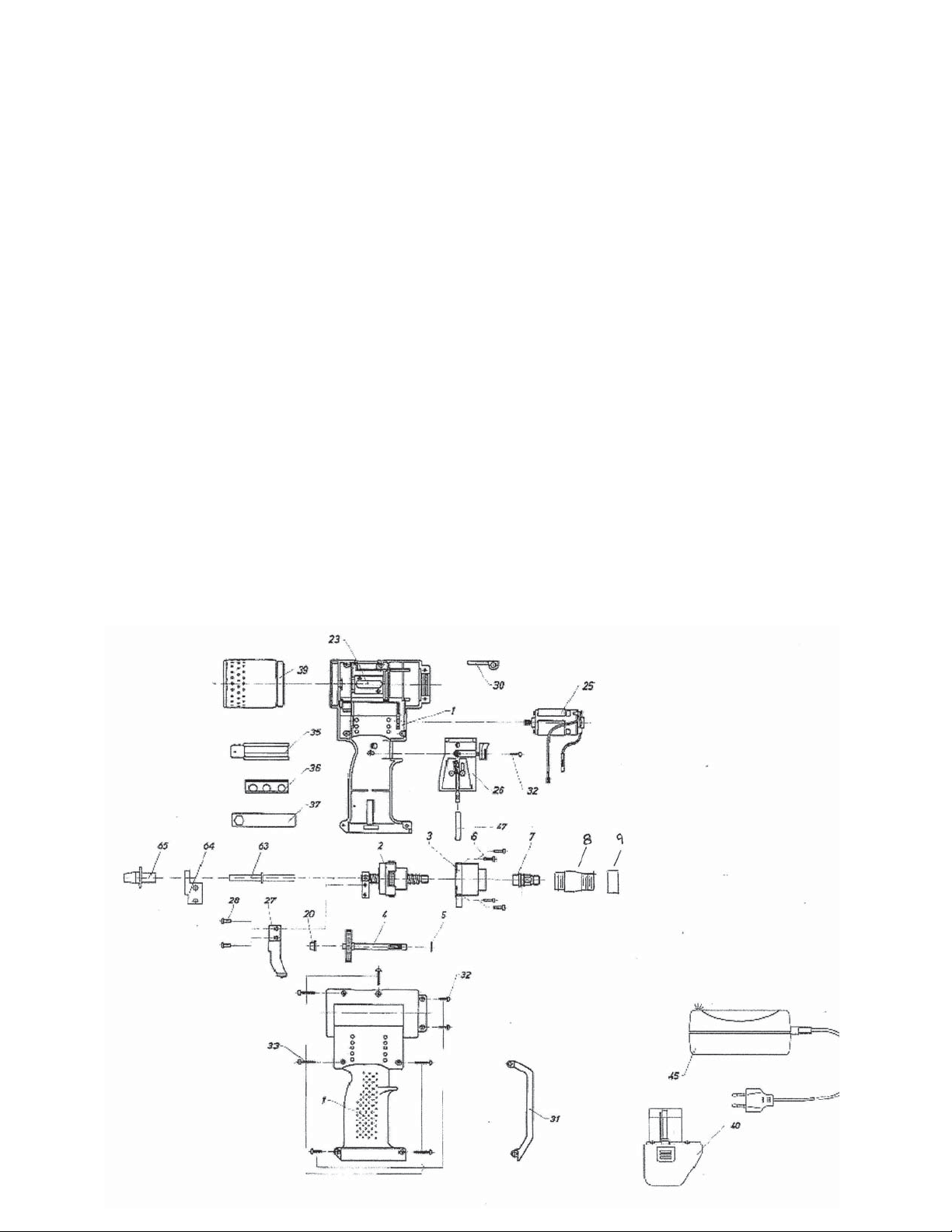

Assembly & Stroke Adjustment

Assembly of Drive System (#42) Slip drive bearing (#3) over ball screw drive (#2) and put

pinion shaft (#4) together with snap ring (#5) in bearing place.

Attention: Before screwing ball screw drive (#2) and drive bearing (#3) together, make sure

the locating marking “B” of the bearing disk inside the ball screw drive (#2) is placed opposite

the pinion shaft (#4). See Parts Drawing.

Assemble this entire unit together with the 4 screws (#6) using hexagonal wrench SW 2.5mm.

Screw jaw housing coupler (#7) with scraper ring (#8) onto ball screw using open end wrench

SW 14mm.

Put jaw pusher spring (#9) and jaw pusher (#10) onto jaw housing coupler (#7). Place the jaws

(#11) in jaw housing (#12) and screw this onto jaw housing coupler (#7) using open end wrench

SW 17mm.

Screw head (#13) on using open end wrench SW 27mm.

Assembly of the PT-4000H-1

The sub-assemblies and other parts should be put into tool housing half (#1) containing the

nosepiece bracket as follows:

To install drive system (#42), slip the bushing (#20) onto the shorter end of the pinion shaft (#4)

while ensuring that the snap ring (#5) in pressed to the gear.

To insert the tube (#22), the longer end of the tube must be inserted into the ball screw, while

the collar of the tube must be inserted into the provided recess of the tool housing.

To place the motor connecting wire, the red wire should be bent downwards at the soldering tag

towards the blue wire, then bent again to be parallel with the blue wire.

To install motor (#25), the two connecting wires are to be places side by aide around the first

guiding stud of the tool housing and behind the middle guiding studs. The wires should then be

brought up in front of the third guiding stud.

The electronic control unit (#26) should be installed by putting it on the stud inside the tool

housing and then fastened with the housing screw (#32). Click magnet holder (#27) in the

guiding slot of the electronic control (#26).

Fasten other end of magnet holder (#27) to ball screw drive (#2) with magnet holder screws

(#28) together with two spring lock washers (#29) using the hexagonal screw drive SW 2.5.

For later stroke adjustment, do not tighten the screws. Plug the two blue connecting wires of

motor (#25) and electronic control until (#26) together.

DO NOT CONNECT RED WIRE YET!!

6.