i

Table of Contents

Chapter 1 OPERATION .................................................................................................... 1

1.1 General description ......................................................................................................... 1

1.2 Unpacking ......................................................................................................................... 2

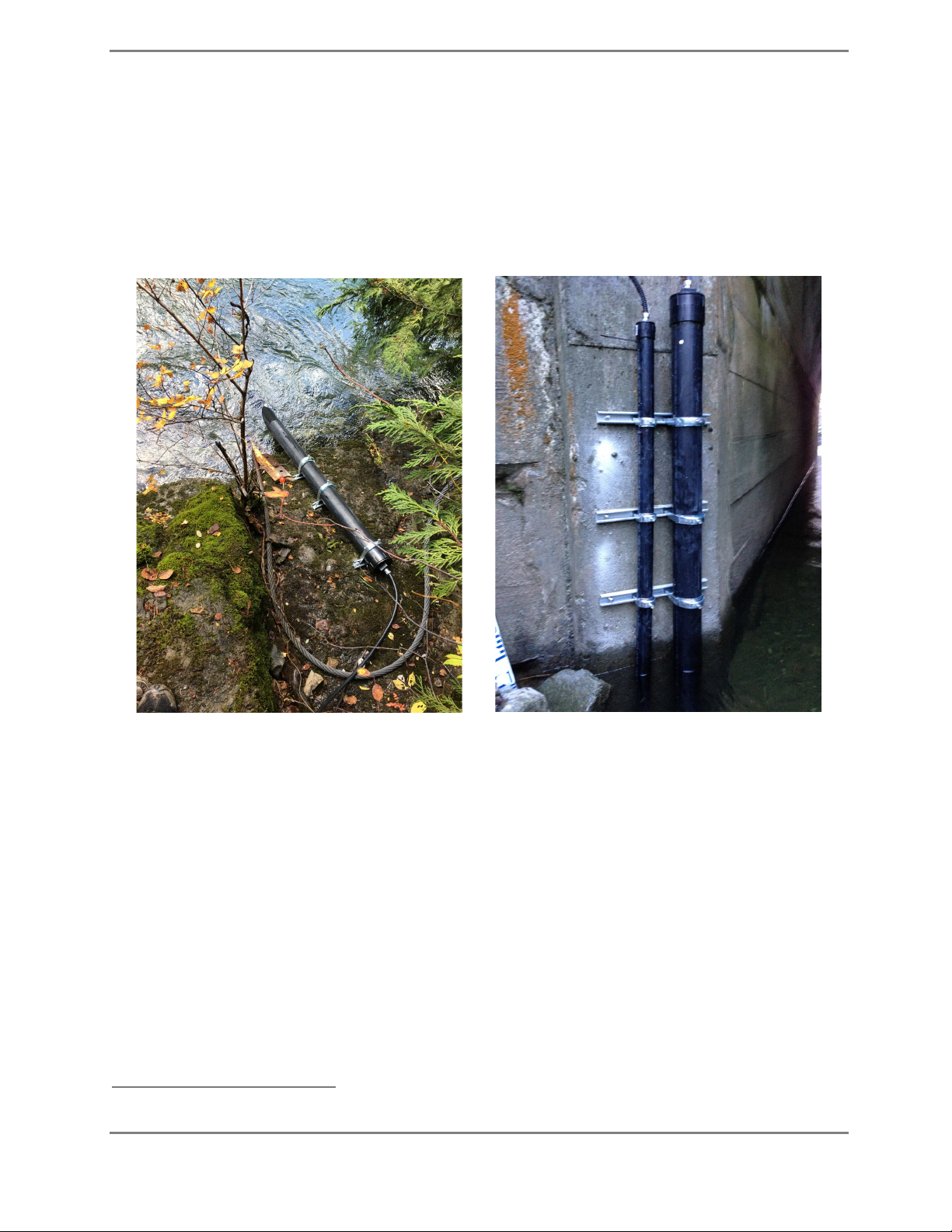

1.3 Site Selection..................................................................................................................... 2

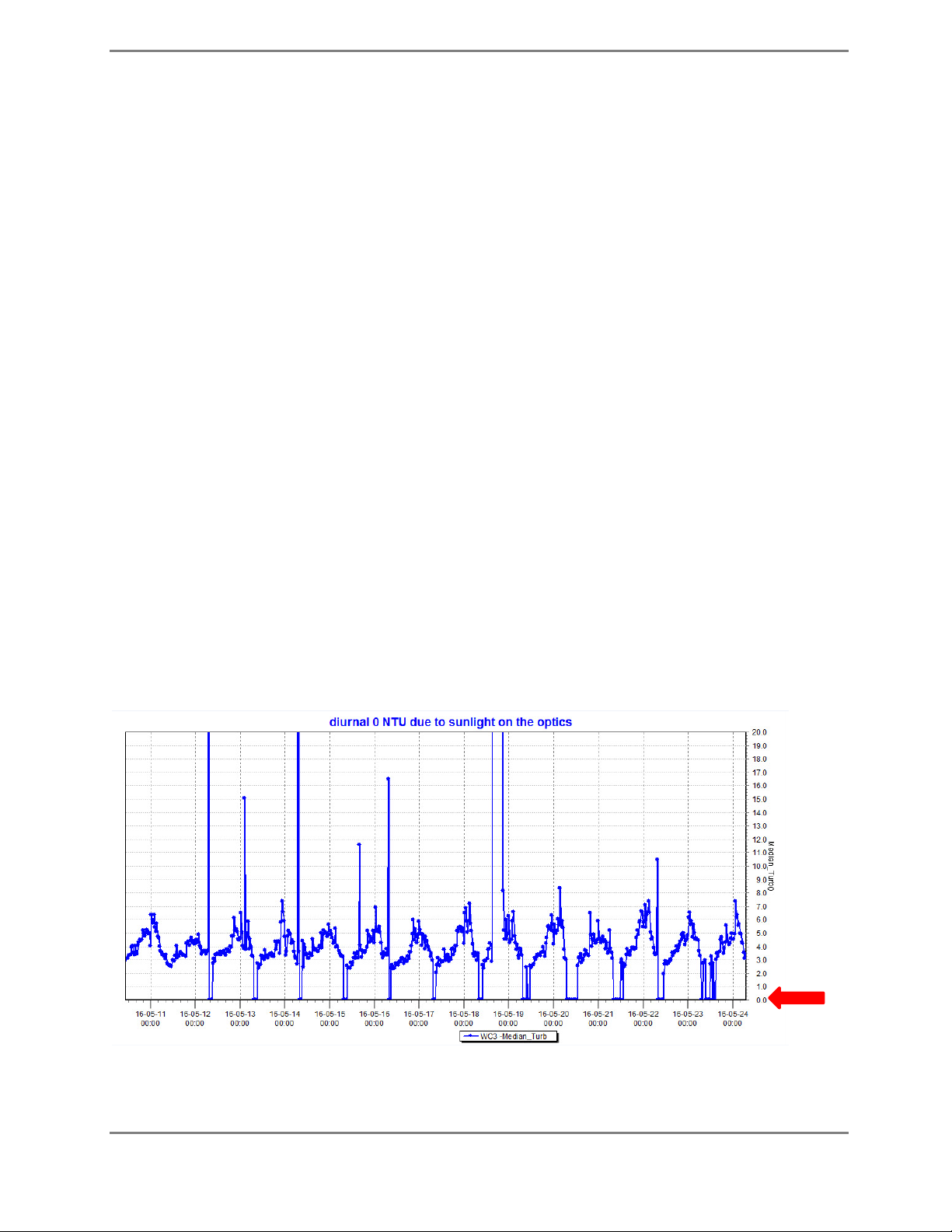

1.3.1 Avoiding Sun Spikes 2

1.4 Installation ........................................................................................................................ 3

1.5 SDI Connection................................................................................................................. 4

1.6 SDI-12 connectorized cable ............................................................................................ 5

1.6.1 Cable Connection and Disconnection (Original model) 5

1.6.2 Cable Connection and Disconnection (V2) 8

1.7 Operation .......................................................................................................................... 9

1.7.1 Turbidity Measurement 9

1.7.2 DTS-12 Calculations 9

1.8 Address Configuration ..................................................................................................10

1.9 Calibration.......................................................................................................................10

1.10 Maintenance ...................................................................................................................10

1.10.1 Routine Cleaning 10

1.10.2 Changing the Wiper Blade 10

1.10.3 Replacing the Wiper Blade Assembly 12

1.11 Replacement Parts.........................................................................................................12

Chapter 2 QUICK START GUIDE ................................................................................... 13

2.1 Detecting the DTS-12.....................................................................................................13

2.2 Mapping the Sensor.......................................................................................................14

2.3 Configuring the DTS-12 .................................................................................................15

2.4 Setting up Logging – In-line Logging Enabled.............................................................16

2.5 Setting Up Logging - Regular Logging..........................................................................17

Chapter 3 SDI-12 COMMANDS..................................................................................... 19

3.1 Notation for SDI-12 Commands...................................................................................19

3.1.1 General SDI-12 Commands 19

3.1.2 SDI-12 Measurement and Request Data Commands 20

3.2 SDI-12 Commands for DTS-12 ver 20 or later............................................................21

3.2.1 Measurement Command Table(ver 20 and later) 22

3.2.2 Request Data Commands 22