i

Contents

1.1 GENERAL................................................................................................................................................................................1

1.1.1 KEY FEATURES: .........................................................................................................................................................1

1.2 PARTS......................................................................................................................................................................................2

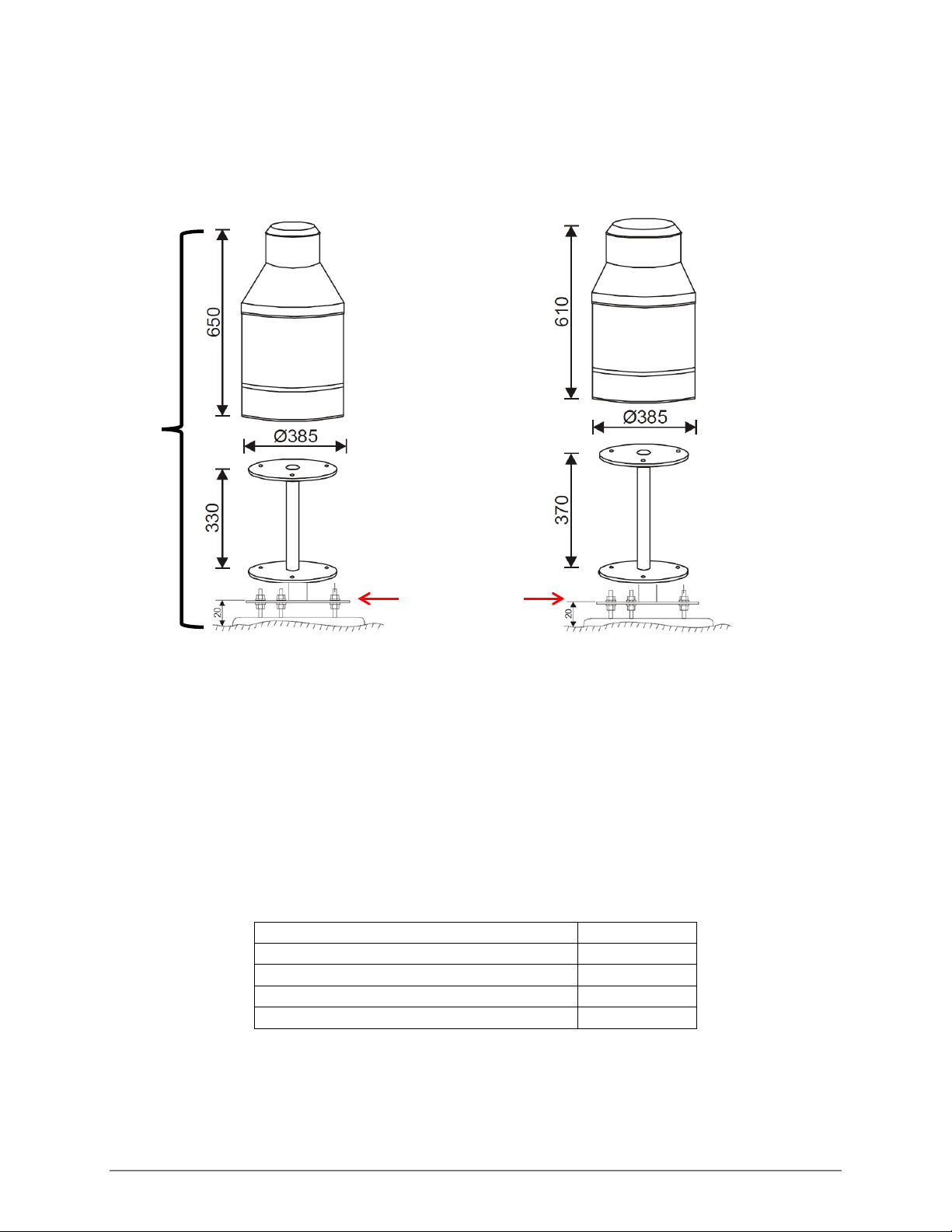

1.3 MOUNTING HEIGHTS ........................................................................................................................................................3

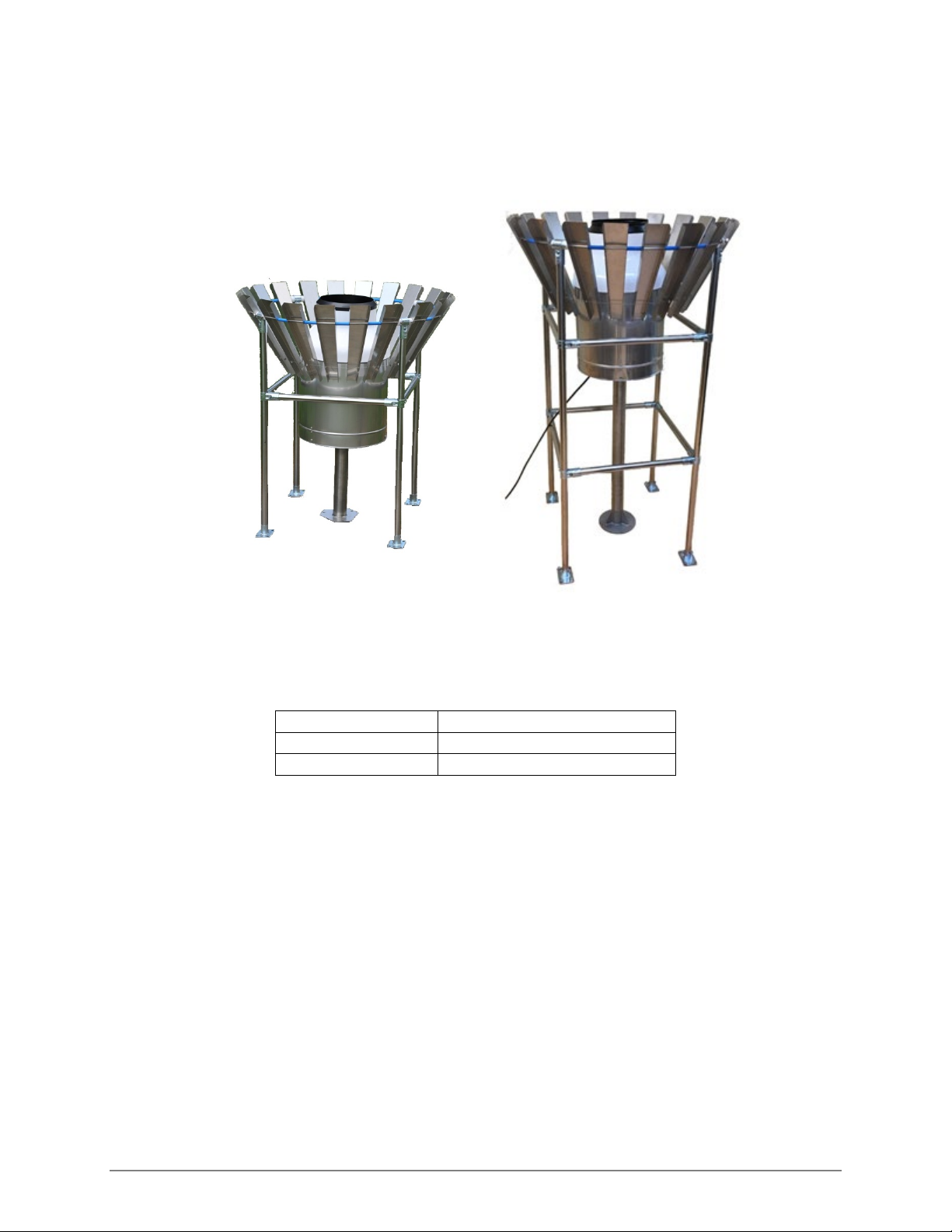

1.4 WIND SHIELD .......................................................................................................................................................................4

2.1 SITE SELECTION...................................................................................................................................................................5

2.2 CONCRETE BASE .................................................................................................................................................................5

2.3 REQUIRED TOOLS...............................................................................................................................................................6

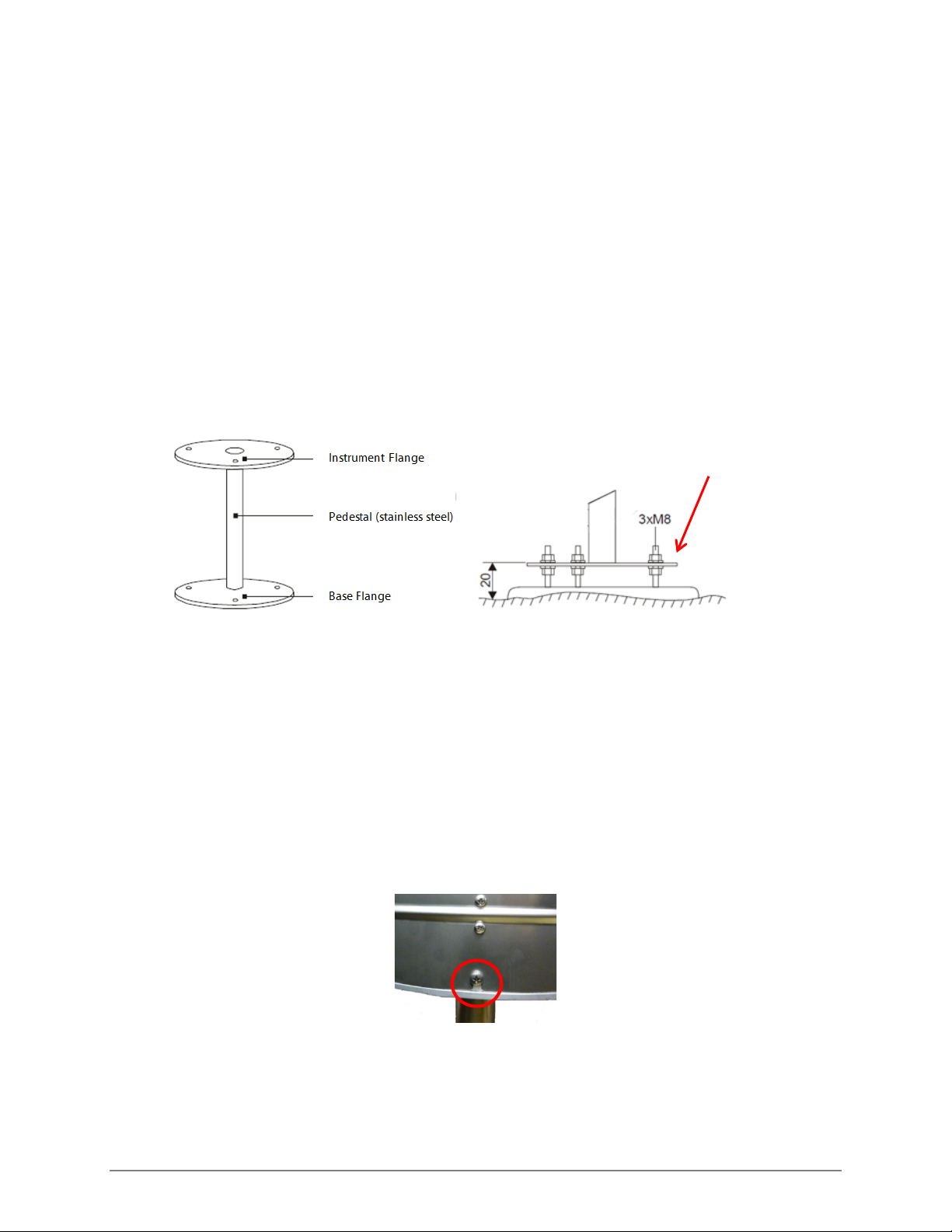

2.4 MOUNTING ...........................................................................................................................................................................6

2.5 CALIBRATION VERIFICATION..........................................................................................................................................9

2.6 MAINTENANCE..................................................................................................................................................................11

2.6.1 EMPTYING THE BUCKET......................................................................................................................................11

2.6.2 VISUAL INSPECTION .............................................................................................................................................11

2.6.3 ANTIFREEZE .............................................................................................................................................................12

2.7 TRANSPORTING THE AWP.............................................................................................................................................12

3.1 NOTATION FOR SDI COMMANDS ..............................................................................................................................13

3.1.1 BASIC COMMANDS...............................................................................................................................................13

3.1.2 MEASUREMENT AND SEND DATA COMMANDS .......................................................................................14

3.1.3 CONTINUOUS MEASUREMENT.........................................................................................................................15

3.2 X COMMANDS ...................................................................................................................................................................15

3.2.1 RAIN COUNTER RESET .........................................................................................................................................15

3.2.2 TIME SYNCHRONIZATION COMMAND..........................................................................................................16