MT5F22233b

2. Mounting the module to printed circuit board

4

© Fuji Electric Co., Ltd. All rights reserved.

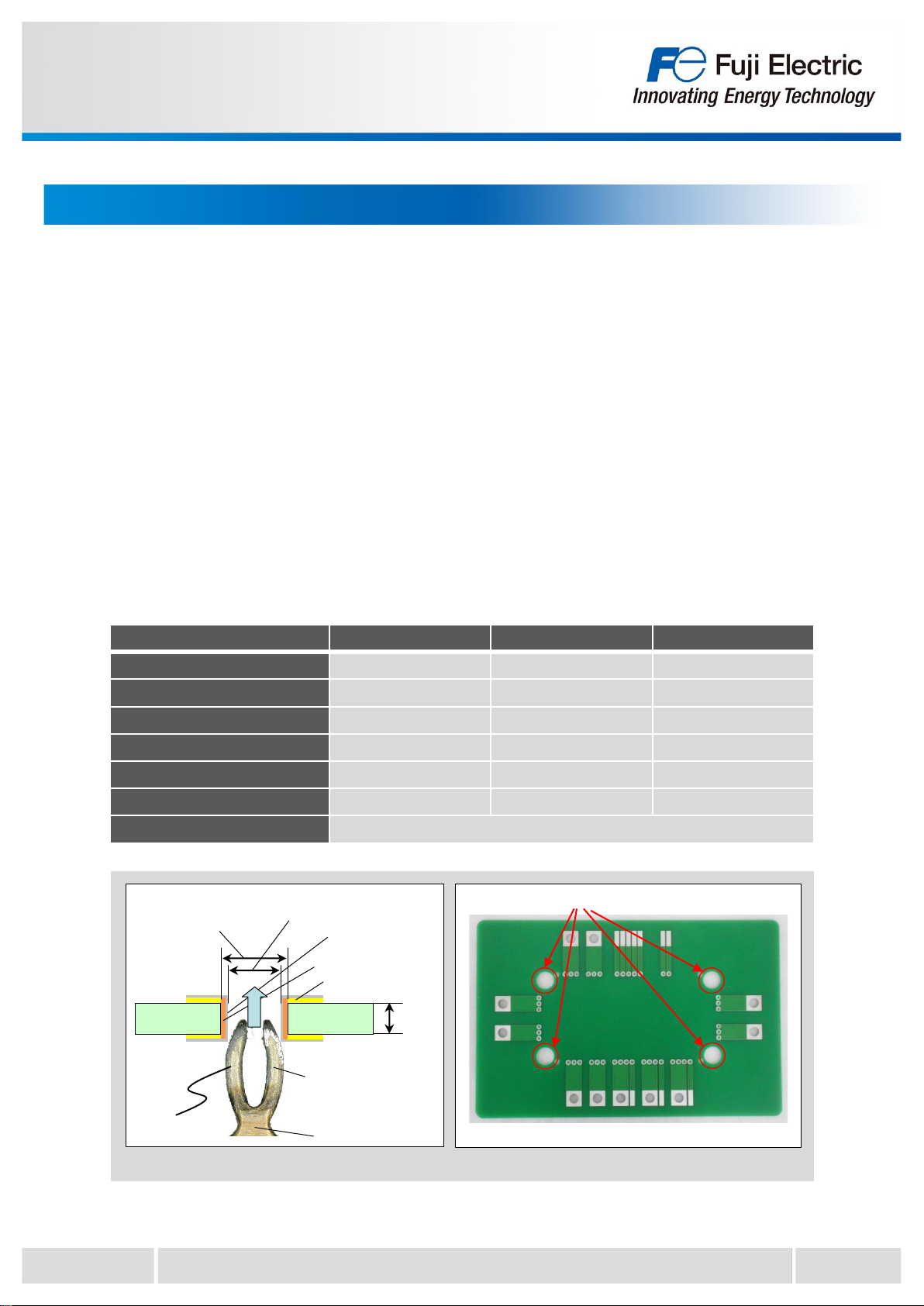

Table 2 Requirements for a printed circuit board

Min. Typ. Max.

Drill hole diameter - 2.35mm -

Through hole diameter 2.14mm 2.20mm 2.29mm

Cu thickness in hole 25μm - -

Electrolytic tin plating thickness - - 15μm

Cu thickness of conductors 35μm 70um, 105μm -

PCB thickness 1.6mm 2.0mm -

PCB material FR4

Fig.2 Recommended specification of a printed circuit board

(b) Holes for mounting the module(lower tool)(a) PCB cross section and each dimension

Example) for M722

2-1. Requirements for printed circuit board

Table 2 and Fig.2 show the recommended specifications of a printed circuit board (PCB).

The recommended specifications in Table 2 is evaluated based on IEC60352-5. When using a PCB

other than the recommended specifications, evaluation is required.

< Requirements for the PCB material >

Double-sided PCB in accordance with IEC 60249-2-4 or IEC 60249-2-5.

Multilayer PCB in accordance with IEC 60249-2-11 or IEC 60249-2-12.

For example, the through hole diameter should be in the range of 2.14mm to 2.29mm with properly

Sn/Cu plated sidewall. If the diameter is too small, problems such as damage to the terminals and

PCBs may occur during the press-in process. On the other hand, if the diameter is too large, a gap

will be created between the terminal and the PCB, causing problems such as vibration and shock,

resulting in reduced reliability.

In addition when mounting the module to the heatsink after mounting the PCB, holes for module

mounting are required on the PCB. (Fig. 2 (b)) These holes for mounting can be used as a guide pin

hole for the module fixing tool when inserting the module into the PCB.

Press fit terminal

Through hole diameter

PCBPCB

PCB thickness

Drill hole diameter Electrolytic tin plating

thickness

Cu thickness in hole

Cu thickness of

conductors

Electrolytic tin plating (tip)

Cu alloy + Ni plating

Holes for mounting the module to heat sink