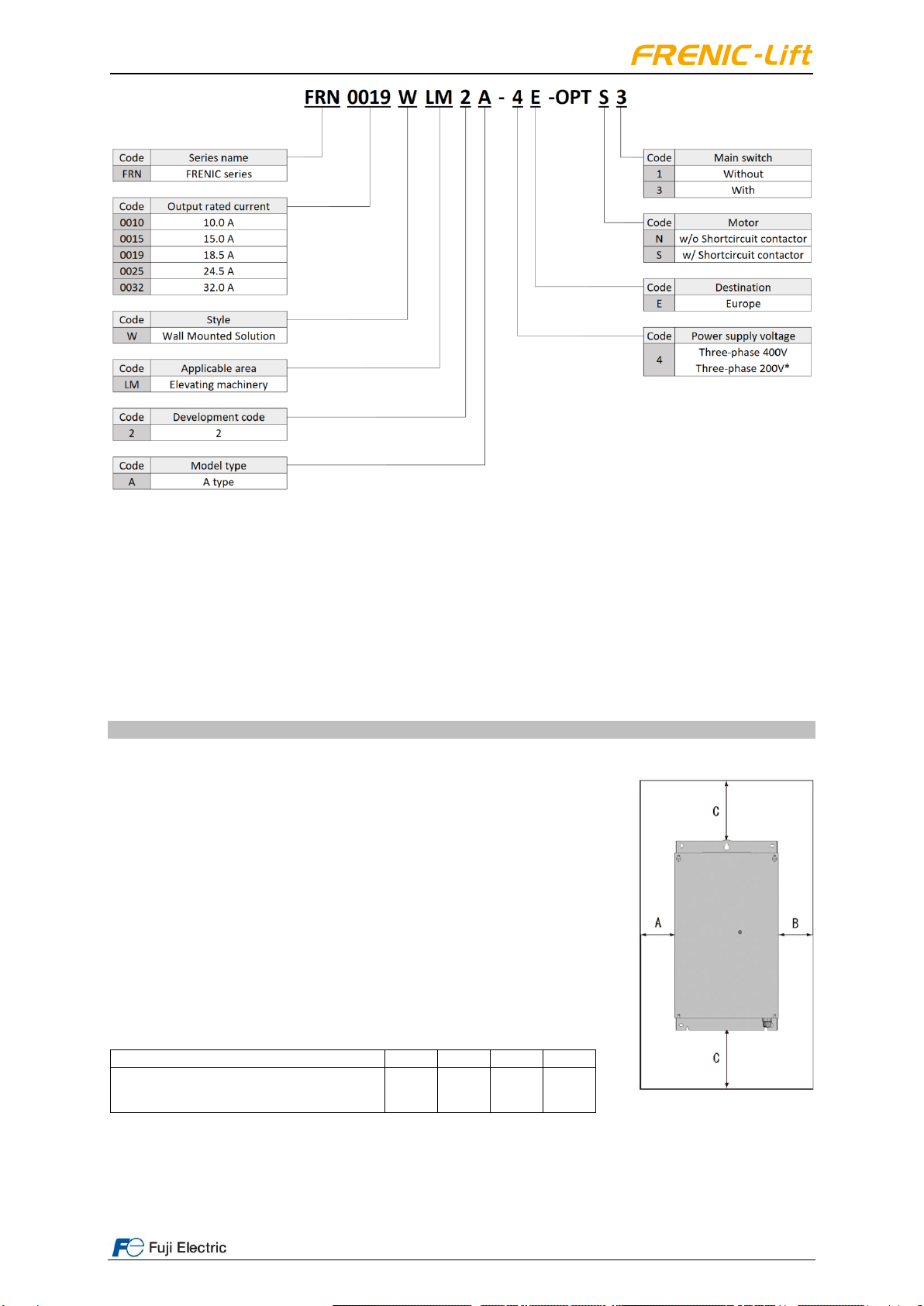

LM2A Wall Mounted Solution

Page 3of 20 Fuji Electric Europe GmbH

CONTENTS

0. Preface ...............................................................................................................................................................4

1. Before Use..........................................................................................................................................................8

1.1 Acceptance Inspection and Appearance of Product......................................................................................8

1.2 Usage and Storage environment...................................................................................................................9

2. Mounting and Wiring the Wall Mounted ..............................................................................................................9

2.1 Installing the cabinet......................................................................................................................................9

2.2 Circuit diagram............................................................................................................................................10

2.3 Wall Mounted diagrams...............................................................................................................................10

2.4 Wiring and terminals....................................................................................................................................13

2.4.1 Removing the front cover of the Wall Mounted......................................................................................13

2.4.2 Mounting the front cover........................................................................................................................13

2.4.3 Recommended wire sizes......................................................................................................................13

2.4.4 Terminal arrangement diagrams and screw specifications....................................................................14

2.4.5 Terminal functions .................................................................................................................................15

2.4.6 Inverter configuration.............................................................................................................................16

2.4.7 Mounting and connecting the keypad to the panel ................................................................................16

3. Operation Using the Keypad.............................................................................................................................16

4. Maintenance and Inspection.............................................................................................................................17

4.1 Daily Inspection...........................................................................................................................................17

4.2 Periodic Inspection......................................................................................................................................17

4.3 List of Replacement Parts...........................................................................................................................18

5. Dimensions.......................................................................................................................................................18

5.1 Frame 1.......................................................................................................................................................18

5.2 Frame 2.......................................................................................................................................................19

CONTACT INFORMATION....................................................................................................................................20