Piktogramme/

Pictograms

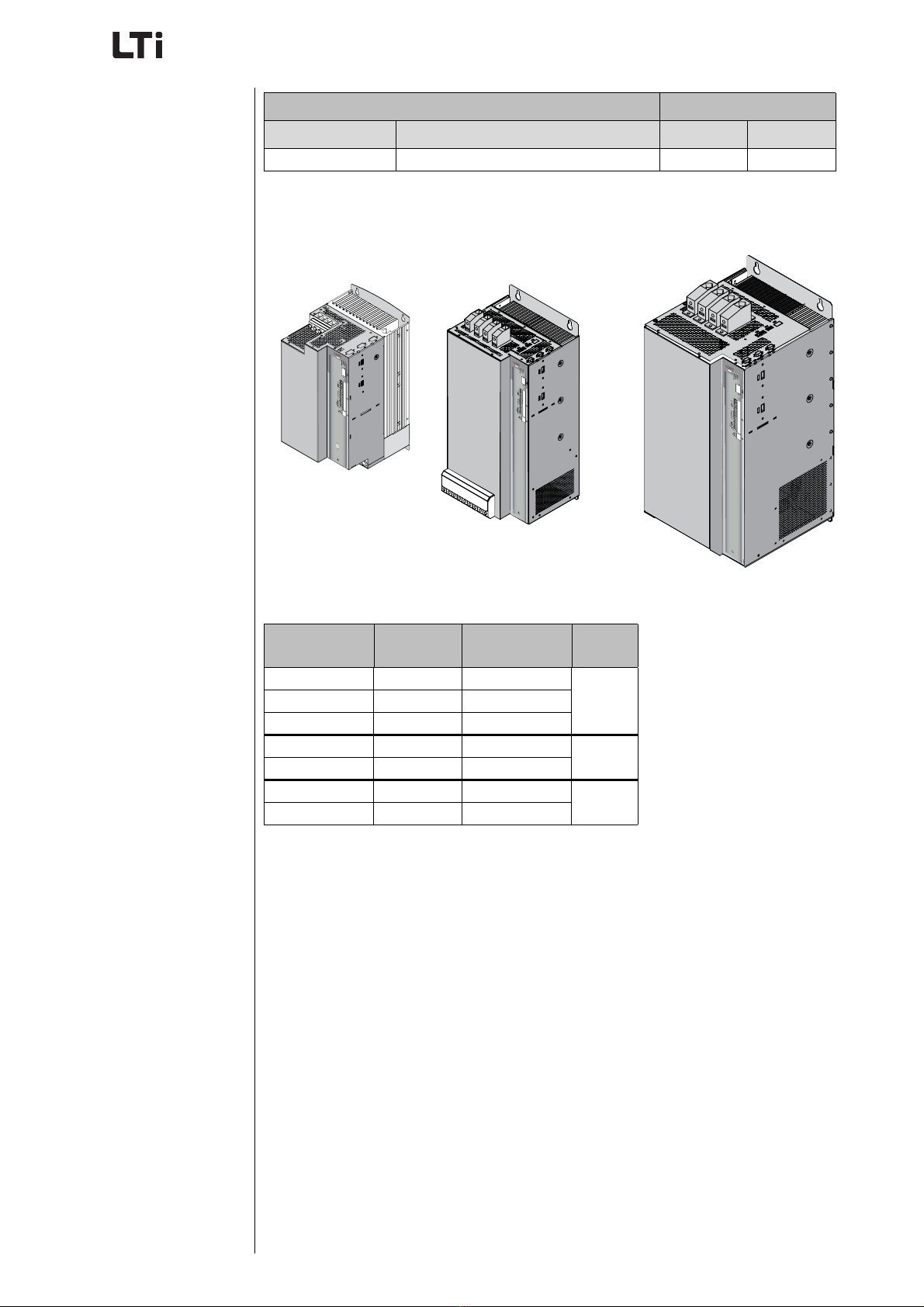

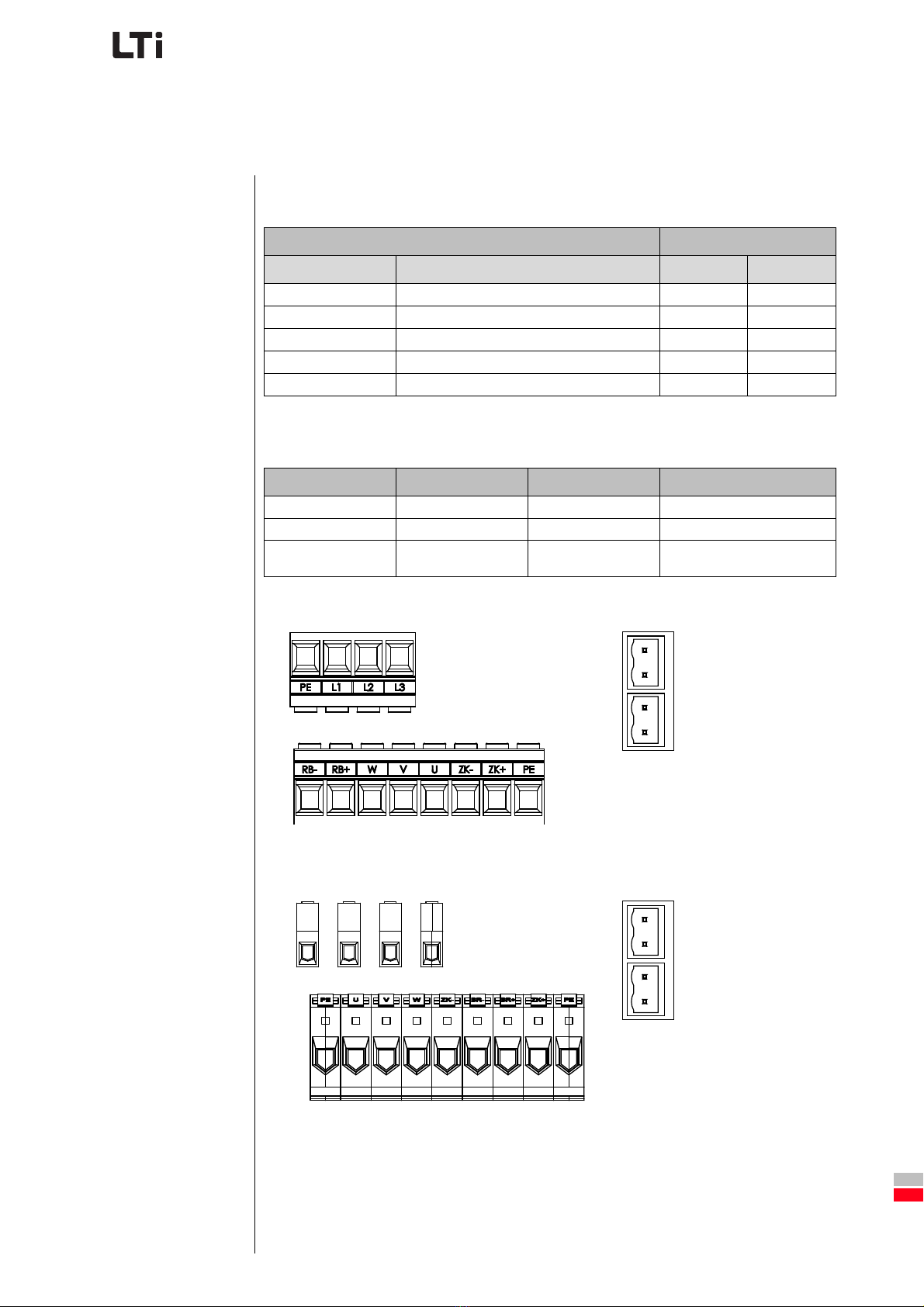

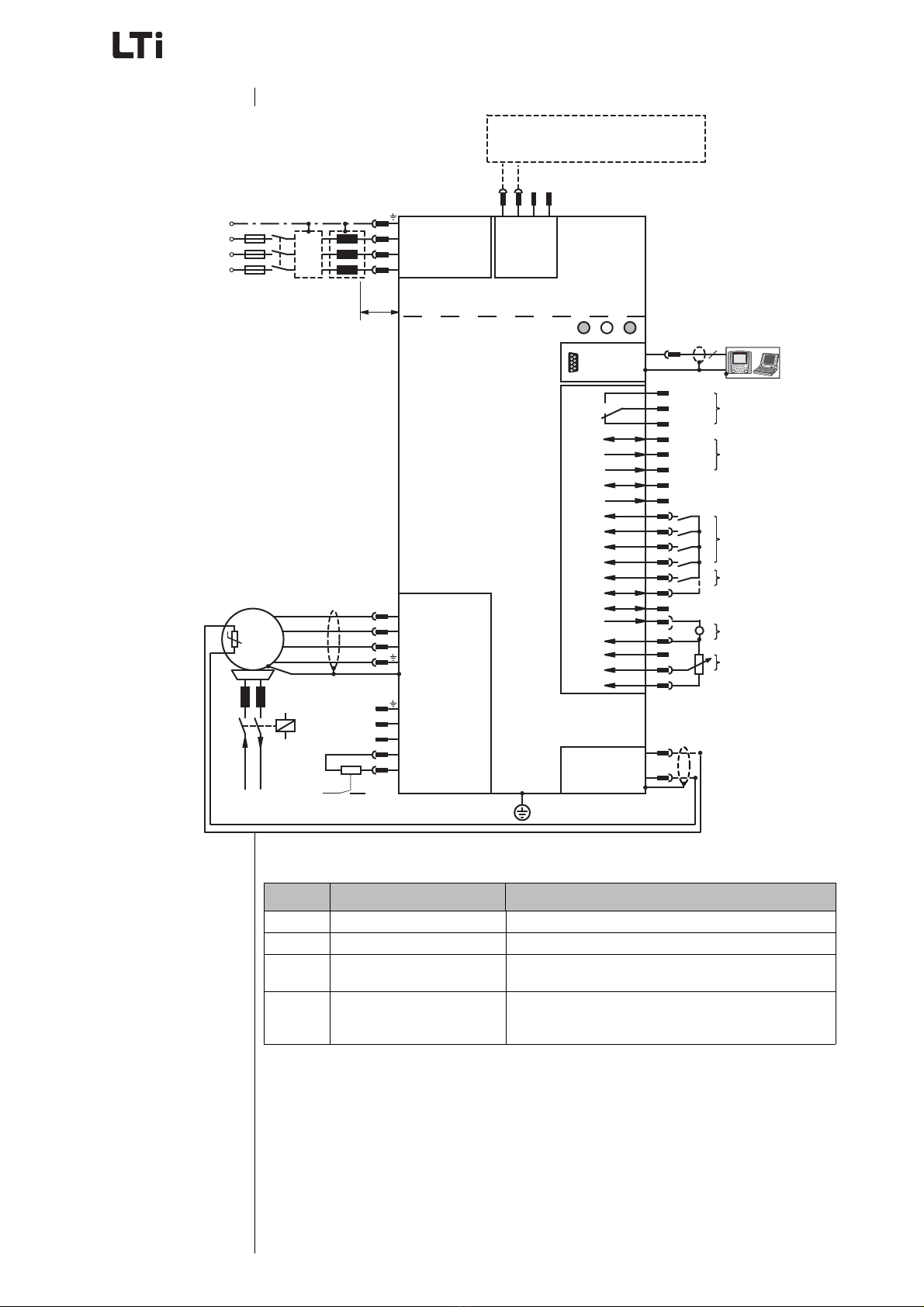

Ausführungsbeschreibung CDA/CDD54.xxx

CDA/CDD54.xxx Specification

ID no.: 1001.21B.2-00 • 04/2014

Technische Änderungen vorbehalten.

Subject to technical changes.

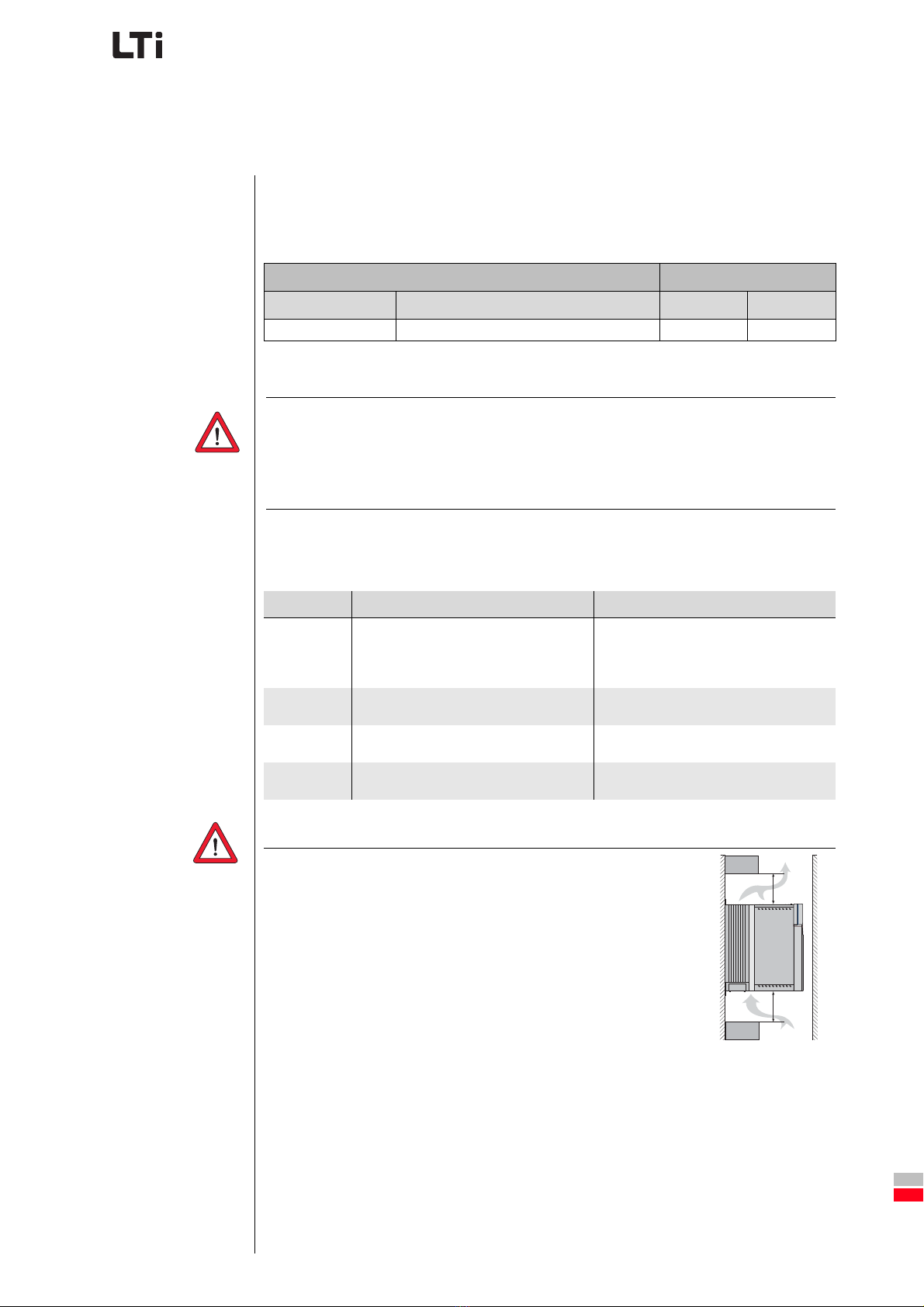

Achtung! Fehlbedienung kann zu

Beschädigung oder Fehlfunktion des

Antriebs führen.

Attention! Misoperation may result in

damage to the drive or malfunction.

Gefahr durch elektrische Spannung!

Falsches Verhalten kann Menschenle-

ben gefährden.

Danger from electrical tension! Impro-

per behaviour may endanger human life.

Gefahr durch rotierende Teile! Antrieb

kann automatisch loslaufen. Danger from rotating parts! The drive

may start running automatically.

Hinweis: Nützliche Information Note: Useful information

Verweis auf andere Dokumente Reference to other documents

Hinweis: Diese Ausführungsbeschreibung

ist keine Betriebsanleitung!

Sie ergänzt die Betriebsanleitun-

gen der jeweiligen Baureihen um

die Beschreibung der Bauvarian-

ten.

Note: This specification manual is not an

operation manual!

It is an add on to the referring ope-

ration manual of the units.

Grundsätzlich muss jede Person, die mit der

Montage, Inbetriebnahme, Bedienung und

Instandhaltung (Inspektion, Wartung, Instand-

setzung) des Umrichters befasst ist, eine ent-

sprechende autorisierte, eingewiesene und

qualifizierte Elektrofachkraft im Sinne VDE

0105 sein.

Any person involved with the installation, com-

missioning, operation and maintenance

(inspection, maintenance, and repair) of the

inverter must be an authorised, trained and

qualified electrician in accordance with VDE

0105.

Diese Elektrofachkraft muss diese Ausfüh-

rungsbeschreibung und die Betriebsanleitung,

im besonderen die Sicherheitshinweise, gele-

sen und verstanden haben.

The qualified electrician must have read and

understood this specification, the operation

manual and in particular the safety information.

Geräte mit folgender Bezeichnung werden in dieser

Ausführungsbeschreibung beschrieben: Devices with the following nominations are described in

this specification:

➢ CDA54.xxx

➢ CDD54.xxx

➢ CDA54.xxx

➢ CDD54.xxx

D