9.2.14 ControlLogix Example: Reading and Writing MSG Instructions ........................................78

9.3 Allen Bradley CSP (PCCC).................................................................................... 79

9.3.1 Overview .........................................................................................................................79

9.3.2 Explicit Messaging Via Read/Write Services ....................................................................79

9.3.3 Inverter Function Code File Number Offset Format ..........................................................79

9.3.4 SLC-5/05 Example: Read Function Codes.......................................................................81

9.3.5 SLC-5/05 Example: Reading and Writing.........................................................................86

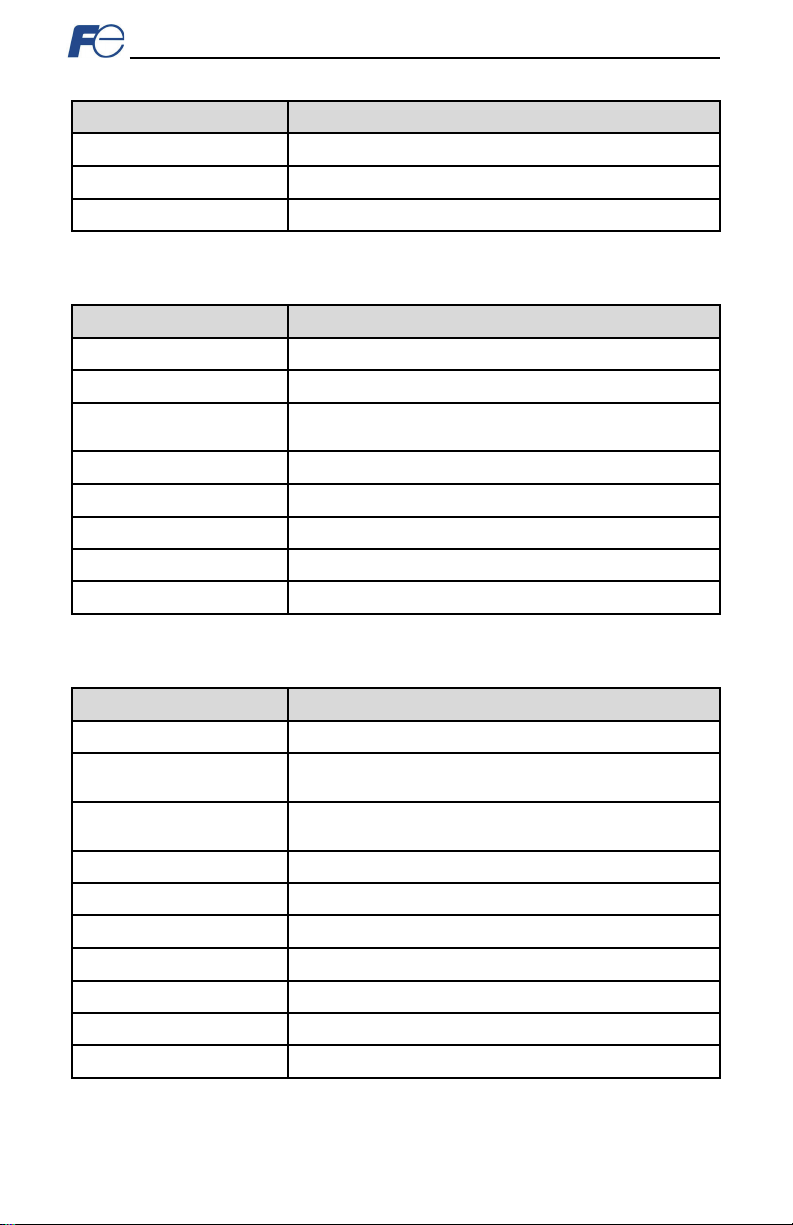

9.4 BACnet/IP ............................................................................................................... 87

9.4.1 Protocol Implementation Conformance Statement ...........................................................87

9.4.2 Default Supported Objects ...............................................................................................91

9.4.3 Default Supported Object Details .....................................................................................92

9.4.4 Server Settings ................................................................................................................93

9.4.5 Node Settings ..................................................................................................................93

9.4.6 Device Object Settings.....................................................................................................93

9.4.7 BACnet Object Settings ...................................................................................................93

9.4.8 Analog Input Object Settings............................................................................................93

9.4.9 Analog Output Object Settings .........................................................................................94

9.4.10 Analog Value Object Settings ..........................................................................................94

9.4.11 Binary Input Object Settings.............................................................................................94

9.4.12 Binary Output Object Settings ..........................................................................................95

9.4.13 Binary Value Object Settings ...........................................................................................96

9.4.14 Multi-state Input Object Settings ......................................................................................97

9.4.15 Multi-state Output Object Settings....................................................................................97

9.4.16 Multi-state Value Object Settings .....................................................................................97

9.5 PROFINET IO.......................................................................................................... 98

9.5.1 Overview .........................................................................................................................98

9.5.2 Device Settings................................................................................................................98

9.5.3 Connection Timeout Options............................................................................................98

9.5.4 Cyclic I/O Produced and Consumed Data Access Settings ..............................................98

9.5.5 PROFIdrive Profile.........................................................................................................100

9.5.5.1 PROFIdrive Standard Telegram 1...........................................................................100

9.5.5.2 PROFIdrive Control and Status Words ...................................................................100

9.5.5.3 PROFIdrive Reference Speed Setpoint and Actual Speed ......................................101

9.5.5.4 PROFIdrive State Diagram .....................................................................................102

9.5.5.5 PROFIdrive-Specific Parameters ............................................................................103

9.5.6 Acyclic Data Access ......................................................................................................103

9.5.7 TIA Portal (STEP 7) Hardware Configuration Example...................................................103

9.5.7.1 Register the GSDML File ........................................................................................103

9.5.7.2 Add the Device to the Configuration .......................................................................105

9.5.7.3 Select the IO Controller ..........................................................................................105

9.5.7.4 Assign IO Module ...................................................................................................105

9.5.7.5 Configure the Device Properties .............................................................................106

9.5.7.6 Online Device Discovery and Configuration ............................................................107

9.5.7.7 Save the Configuration ...........................................................................................108

9.5.8 GE Proficy Configuration Example .................................................................................108

9.5.8.1 Register the GSDML File ........................................................................................108

9.5.8.2 Add the Device to the Configuration .......................................................................110

9.5.8.3 Assign IO Module ...................................................................................................110

9.5.8.4 Configure the Device Properties .............................................................................111

9.5.8.5 Save the Configuration ...........................................................................................112

10 TROUBLESHOOTING ....................................................................... 113