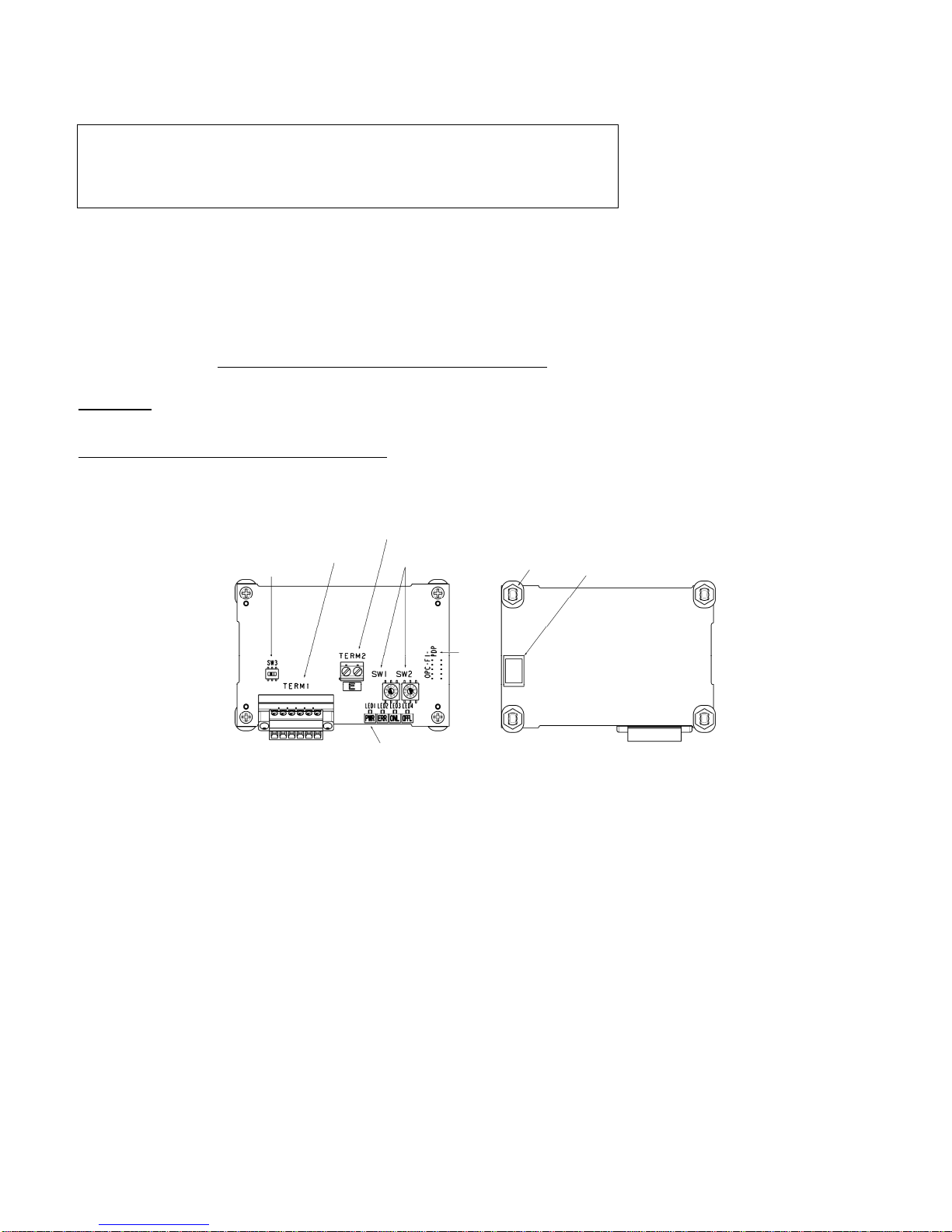

3.2 Node Address Switches

The node address switches (SW1 and SW2) on the interface card are rotary ones that are used to specify the PROFIBUS DP communications

network node address (station address) of the card. The setting range is from 0 to 99 in decimal. The SW1 specifies a 10s digit of the node address

and the SW2, a 1s digit.

The node address can also be specified with the inverter's function code o31. The setting range is from 0 to 125 in decimal. Note that validating the

node address specified with the function code o31 requires setting the node address switches to "00."

Example 1: Setting the node address 27 using the node address switches

SW1 SW2

1. When the inverter is powered OFF:

Set SW1 to "2."

Set SW2 to "7."

2. Turn the inverter power ON.

The setting procedure is completed.

Figure 4 Node Address Setting Example 1

Example 2: Setting the node address 125 using the function code o31

SW1 SW2

Figure 5 Node Address Setting Example 2

1. When the inverter is powered OFF:

Set both the SW1 and SW2 to "0."

2. Turn the inverter power ON and set the function code o31 data to "125."

3. Turn the inverter power OFF and ON.

The setting procedure is completed.

1. The node address switches should be accessed with all the inverter power (including the auxiliary power) being OFF. Setting

these switches with the inverter power being ON requires turning the power OFF and ON to validate the new setting.

2. To validate the node address setting using the function code o31, restart the inverter.

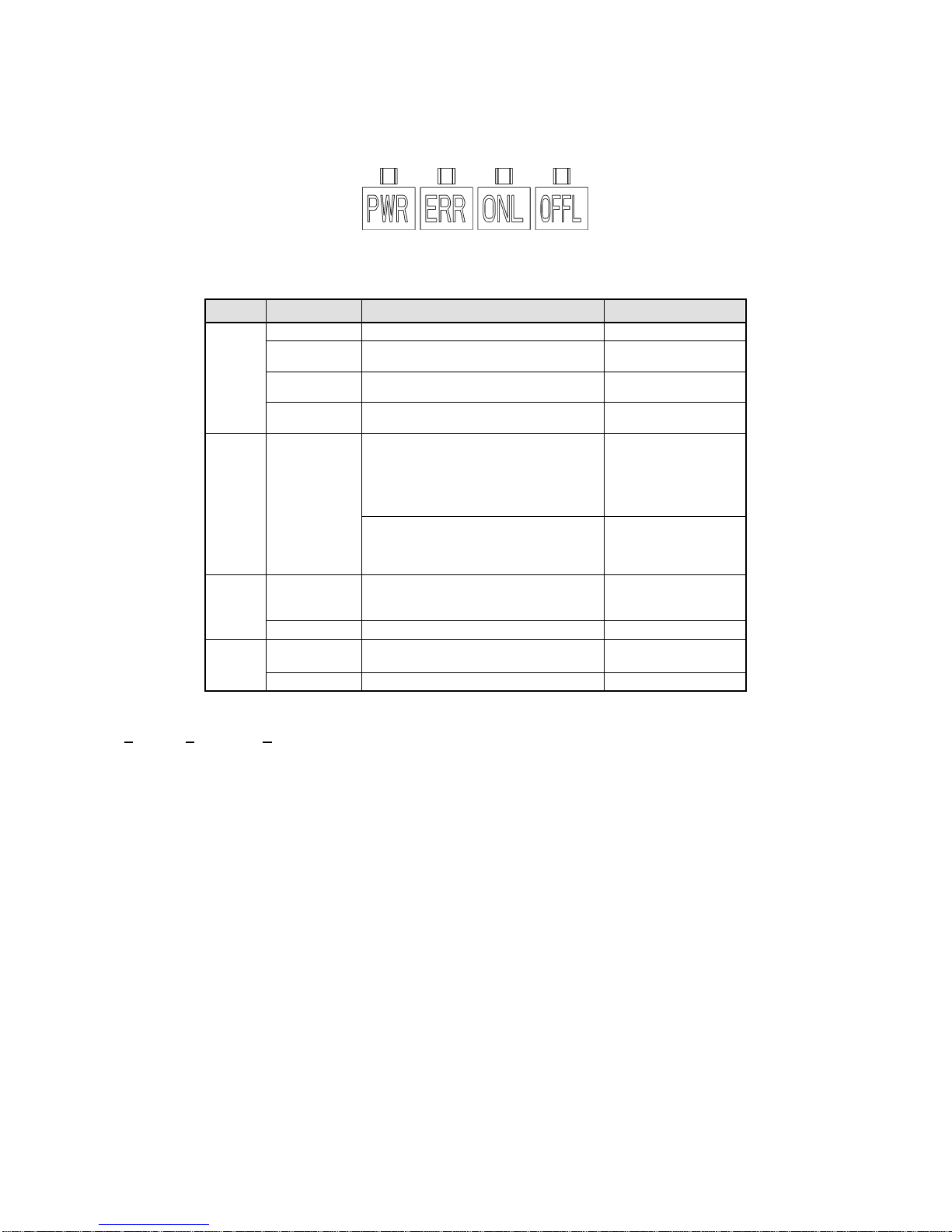

3. Setting the function code o31 data to "126" or greater will cause a data setting error. The ERR LED on the card blinks in red and

the inverter issues the alarm code er5.

3.3 Terminating Resistor Switch

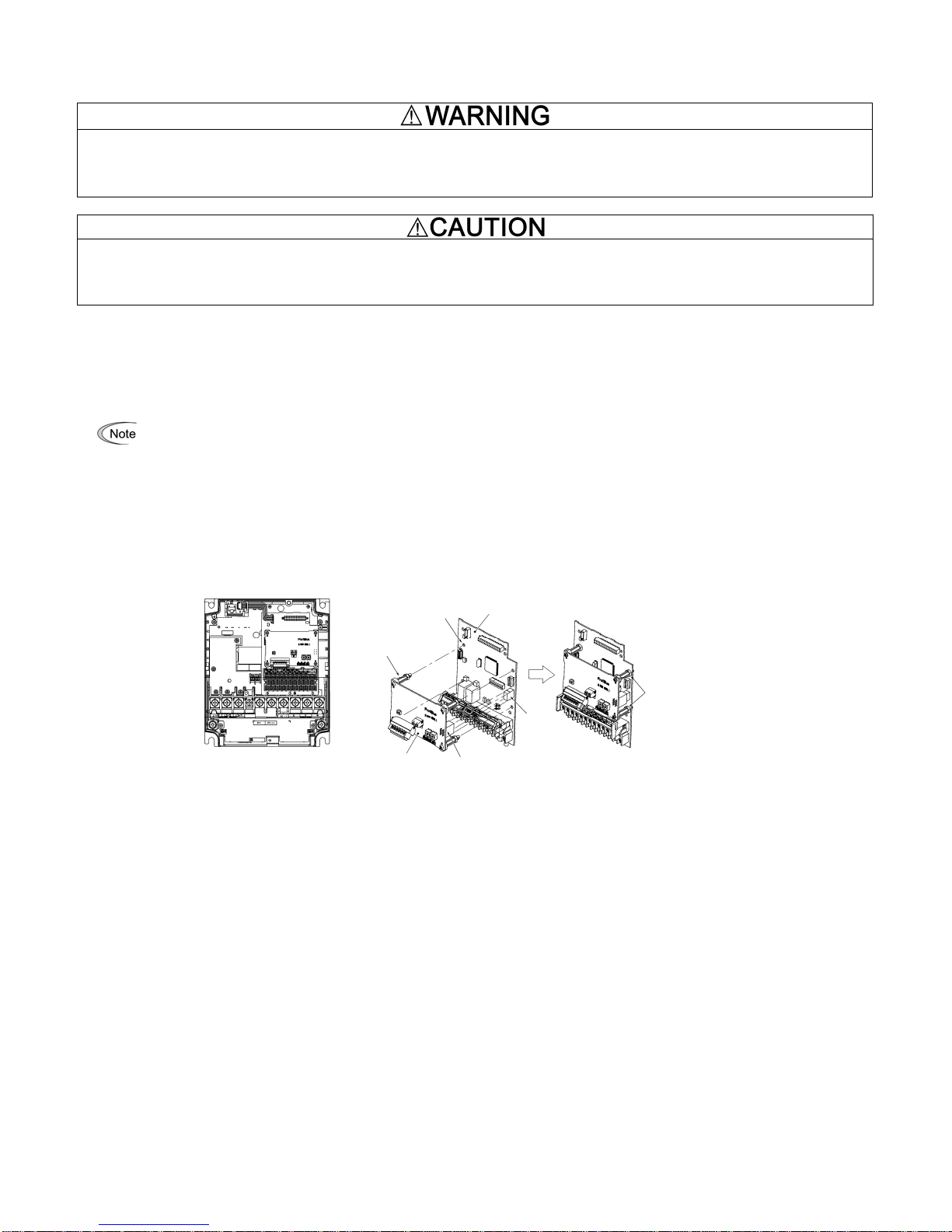

The PROFIBUS DP communications network requires insertion of line terminating resistors at its end. When the card is mounted in the inverter at

the end of the network, turn this switch ON to insert the terminating resistor. No external terminating resistor is required.

OFF: No insertion of terminating resistor ON: Insertion of terminating resistor

Figure 6 Terminating Resistor Switch

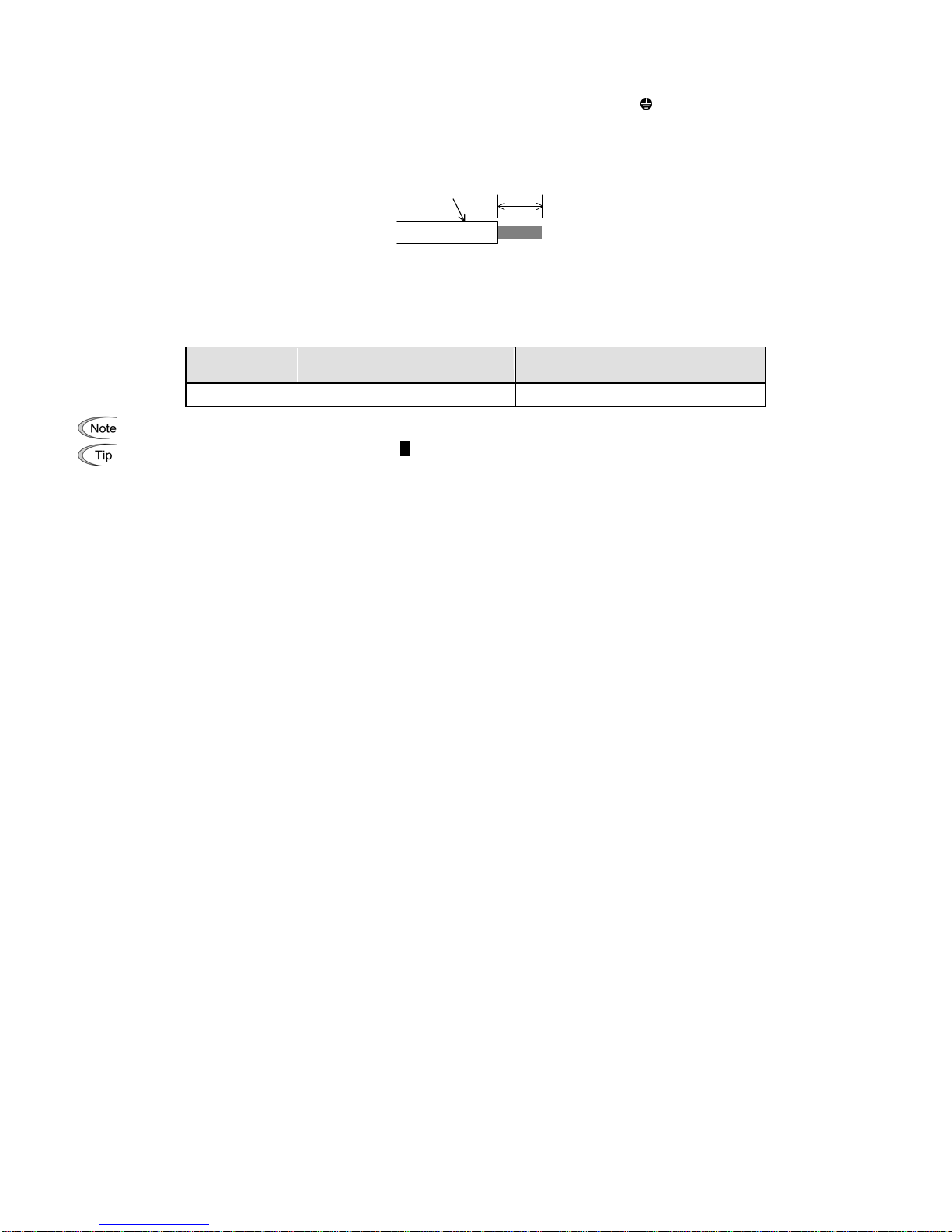

3.4 Terminal Board

This card provides two terminal blocks, one for the PROFIBUS communications and another for grounding (earthing).

For wiring of the terminal blocks, refer to Chapter 5 "WIRING."

3.5 Setting the Transmission Speed (Baud rate)

No transmission speed setting is required on the interface card (slave). Setting the transmission speed in the PROFIBUS DP network master node

automatically configures the transmission speed of this card.

5