INSTRUCTION MANUAL

This product is designed to be used with an abrasive product for grinding, cutting, or sanding, polishing

materials. The abrasive product to be used on each tool is shown below in this manual. No other use

permitted. For professional use only.

AIR LINE FILTER AND LUBRICATOR

It is necessary to get rid of moisture and dirt from the air line and give proper lubrication. If moisture, dirt

and/or other impurities are put in the tool, it may cause seize of the motor part, unnecessary wear of parts and

reduced performance. Air filter and air lubricator are recommended to be fitted as close as practicable to the

tool in use.

LUBRICANTS

Seek medical advice immediately if any lubricant should contaminate the eyes or be accidentally ingested. If

air line lubricator is not used, lubricate the motor part with ISOVG32 turbine oil or equivalent oil daily before

use. Do not burst into full speed operation after lubrication, or it may cause overspeed. Lithium system grease

is recommended for lubrication of bearings, cam and clutch part, gears and gear cases. Lubricate them when

giving maintenance or periodical inspection. Following are recommended lubricants.

MOTOR PART

Castrol Alphasyn T32

Mobil Mobil SHC 624

Texaco RD Lube 32

Kuwait Petroleum Q8 Schuman ISO VG32

Statoil Mereta 32

BEARING, GEAR, CLUTCH AND CAM

BP Energrese LS-EP2

Castrol Spheerol EP L2

Esso Beacon 2

Shell Alvania Grease EP2

Mobil Mobilplex 47

Texaco Multifak EP2

Kuwait Petroleum Q8 Rembrandt EP

When handling lubricants regularly, wear suitable clothes of impervious material. Clothing contaminated by

lubricants should be changed.

MAINTENANCE AND REPAIRS

The tool must be properly maintained and tested by competent and trained personnel. At any sign of

malfunction or unusual behavior, the tool should be taken out of service for examination and repair. If

necessary, you can get necessary information and instructions for repairs and maintenance from the

manufacturer or manufacturer's authorized agent in your country. It is recommended to dismantle the tool for

overhauling and cleaning periodically after 500 hours of operation or once every six months. When replacing

parts, be sure to use genuine Fuji Air Tools replacement parts. If not, it may result in decreased performance

and increased maintenance. When giving maintenance or repairs, be sure to disconnect the tool from the air

line or to shut off the air line.

Before clearing the tool for use, make sure that it has been correctly assembled with all fasteners tightened.

When giving maintenance or repairs to the speed governor, be sure to make it properly without any mistake. If

there should be any doubt about it, be sure to consult and get proper information from FUJI’s appointed

distributor and repairer. Any single mistake in fixing the speed governor may cause a serious accident. Be

sure to check after each repairing service and maintenance that the speed governor works properly and that

the free speed of the tool is less than the maximum speed displayed on the tool.

KEEPING TOOL AFTER USE

Always keep the tool clean so that it can be used properly and safely whenever necessary.

When storing the tool after use, keep the tool in a safe way.

DISPOSAL OF TOOL

The tool is made of steel, casting iron, brass, bronze casting, aluminum alloy, rubber and plastic components

or using some of those materials. When disposing of the tool, be sure not to cause pollution to human beings

and environment.

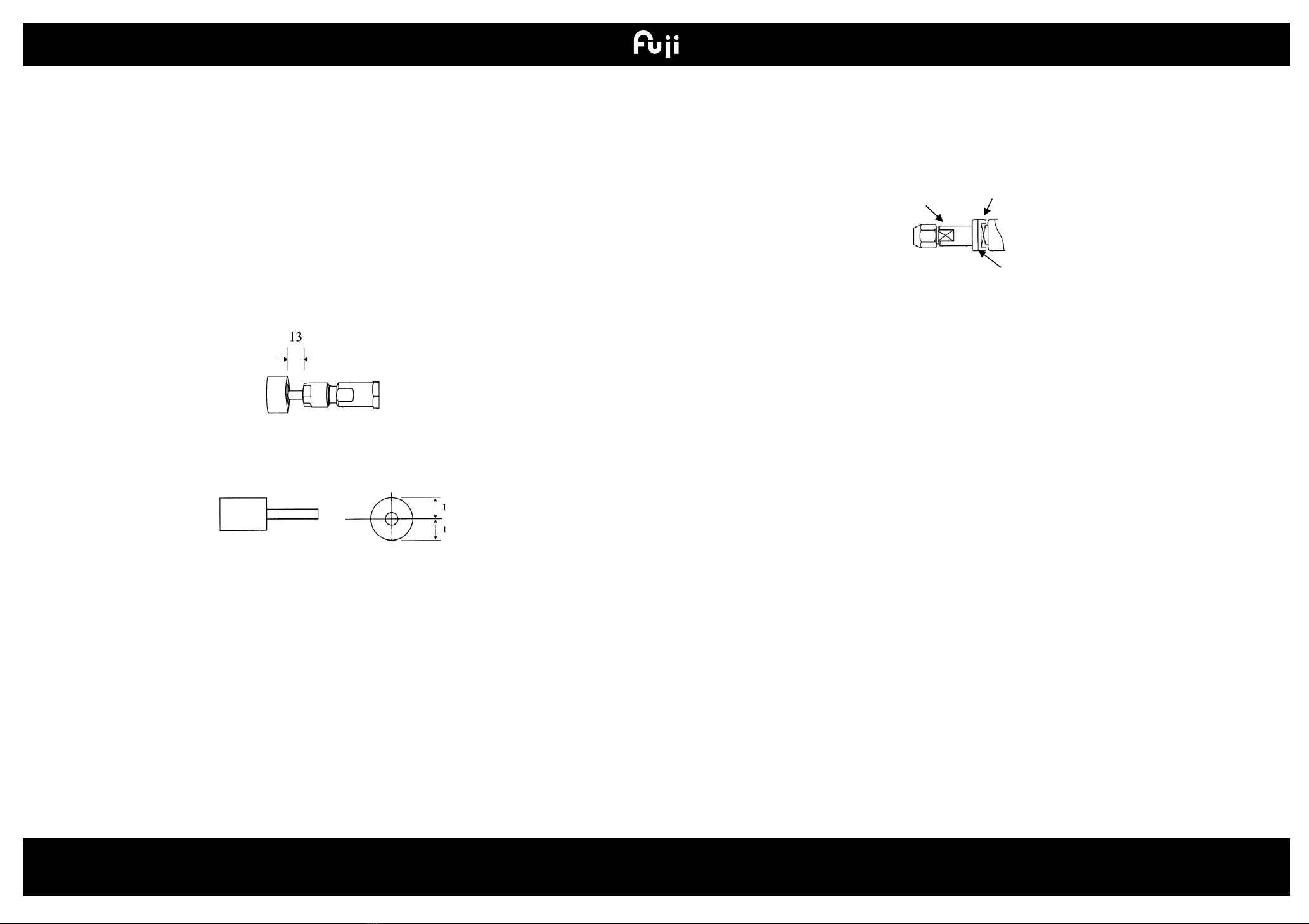

CORRECT WHEEL GUARD AND FLANGES FOR GRINDERS

Always use the recommended wheel guard and wheel flanges only and make sure that they are mounted in

the right places not too loose and not too tight when mounting the abrasive product to the grinder. Only trained

personnel who well know how to mount the abrasive product, the wheel guard and the flanges on the tool

must do this task.

Do not use a wheel guard and wheel flanges that are damaged, severely worn, nicked, bent, warped and

burred. Do not reform them.

CORRECT BACKING PAD AND FLANGES FOR SANDERS

Always use the recommended backing pad and flanges only and make sure that they are mounted in the right

places not too loose and not too tight when mounting the abrasive product to the sander. Only trained

personnel who well know how to mount the abrasive product on the tool must do this task.

Be sure to use a backing pad that fully supports the sanding disc over its diameter.

Do not use a backing pad and flanges that are damaged, severely worn, nicked, bent, warped and burred. Do

not reform them.