INSTRUCTION MANUAL

This product is designed for installing and removing threaded fasteners in wood, metal and plastic. No other

use permitted. For professional use only.

AIR LINE FILTER AND LUBRICATOR

It is necessary to get rid of moisture and dirt from the air line and give proper lubrication. If moisture, dirt

and/or other impurities are put in the tool, it may cause seize of the motor part, unnecessary wear of parts and

reduced performance. Air filter and air lubricator are recomended to be fitted as close as practicable to the tool

in use.

LUBRICANTS

Seek medical advice immediately if any lubricant should contaminate the eyes or be accidentally ingested.

If air line lubricator is not used, lubricate the motor part with ISOVG32 turbine oil or equivalent oil daily before

use. Do not burst into full speed operation after lubrication, or it may cause overspeed. Lithium system grease

is recommended for lubrication of bearings, cam and clutch part, gears and gear cases. Lubricate them when

giving maintenance or periodical inspection. Following are recommended lubricants.

MOTOR PART

Castrol Alphasyn T32

Mobil Mobil SHC 624

Texaco RD Lube 32

Kuwait Petroleum Q8 Schuman ISO VG32

Statoil Mereta 32

BEARING, GEAR, CLUTCH AND CAM

BP Energrese LS-EP2

Castrol Spheerol EP L2

Esso Beacon 2

Shell Alvania Grease EP2

Mobil Mobilplex 47

Texaco Multifak EP2

Kuwait Petroleum Q8 Rembrandt EP

When handling lubricants regularly, wear suitable clothes of impervious material. Clothing contaminated by

lubricants should be changed.

TEMPERATURE

The handles used for gripping the tool are designed to be free from high and low temperatures for the daily

continuous operation. The temperature on the handles can be lowered by cold weather and can accelerate the

risk caused by vibrations. In cold weather, wear suitable gloves to keep hands warm.

MAINTENANCE AND REPAIRS

The tool must be properly maintained and tested by competent and trained personnel. At any sign of

malfunction or unusual behavior, the tool should be taken out of service for examination and repair. If

necessary, you can get necessary information and instructions for repairs and maintenance from the

manufacturer or manufacturer's authorized agent in your country.

It is recommended to dismantle the tool for overhauling and cleaning periodically after 500 hours of operation

or once every six months.

When replacing parts, be sure to use genuine Fuji Air Tools replacement parts. If not, it may result in

decreased performance and increased maintenance.

When giving maintenance or repairs, be sure to disconnect the tool from the air line or to shut off the air line.

Before clearing the tool for use, make sure that it has been correctly assembled with all fasteners tightened.

Check the rpm. of the tool without the socket, the adaptor or the bit on the spindle after each maintenance or

repairing service.

During assembly, each unit needs to pass a series of ability tests. After assembly, the tool needs to pass a

series of ability tests. Those tests can only be done in FUJI Factory or authorized FUJI Service Center. Do not

try to disassemble and assemble the tool.

KEEPING TOOL AFTER USE

Always keep the tool clean so that it can be used properly and safely whenever necessary.

When storing the tool after use, keep the tool in a safe way.

DISPOSAL OF TOOL

The tool is made of steel, casting iron, brass, bronze casting, aluminum alloy, rubber and plastic components

or using some of those materials. When disposing of the tool, be sure not to cause pollution to human beings

and environment.

CHECK OF SOCKET, ADAPTOR AND BIT BEFORE USE

Handle and store the socket, the adaptor and the bit with care in accordance with their manufacturer's

instructions.

Use only a "power drive" socket.

Do not use the socket, the adaptor and the bit with chips, cracks or other damages.

Do not use an extremely worn socket, adaptor and bit.

The locking device of the socket must not be removed.

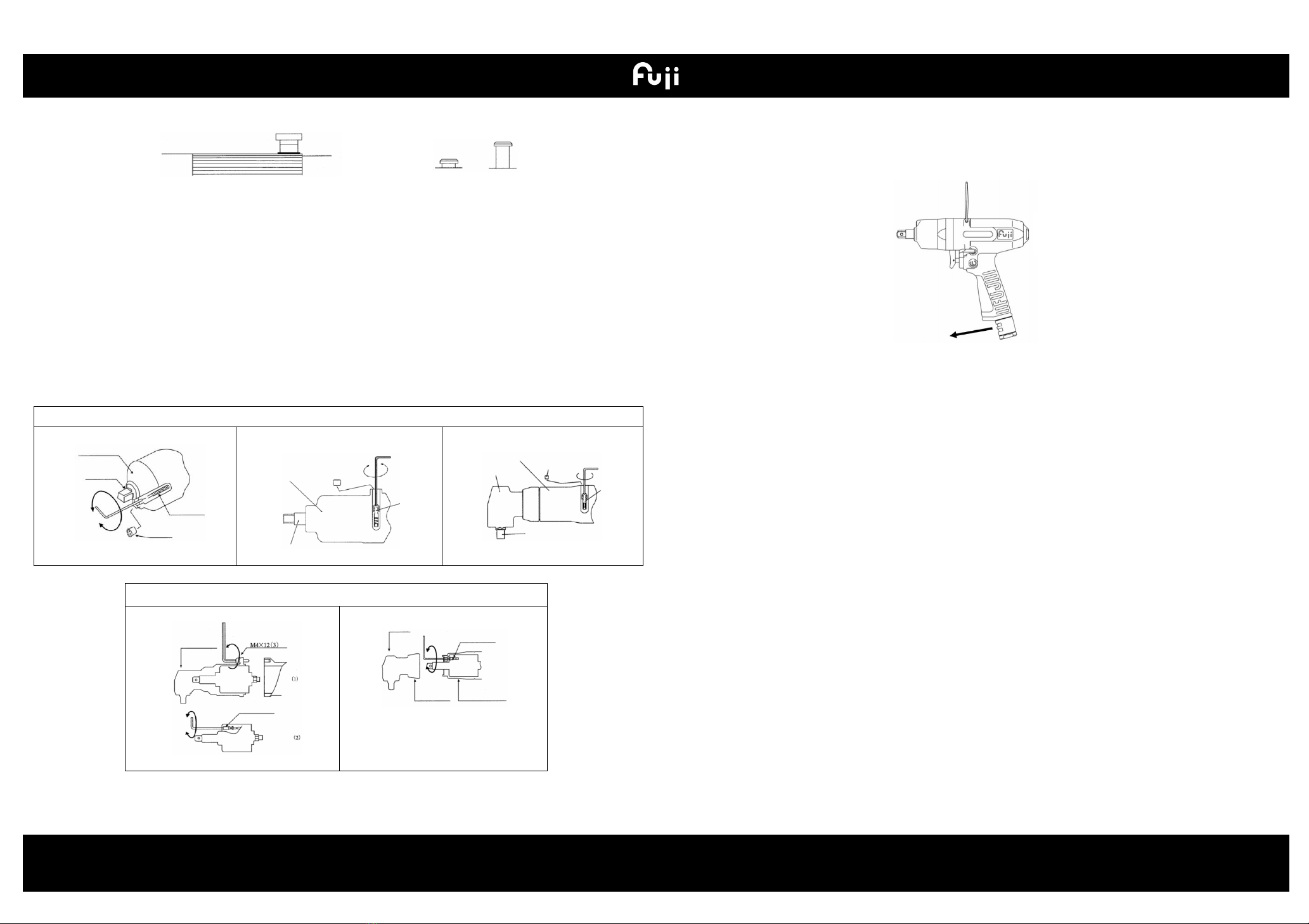

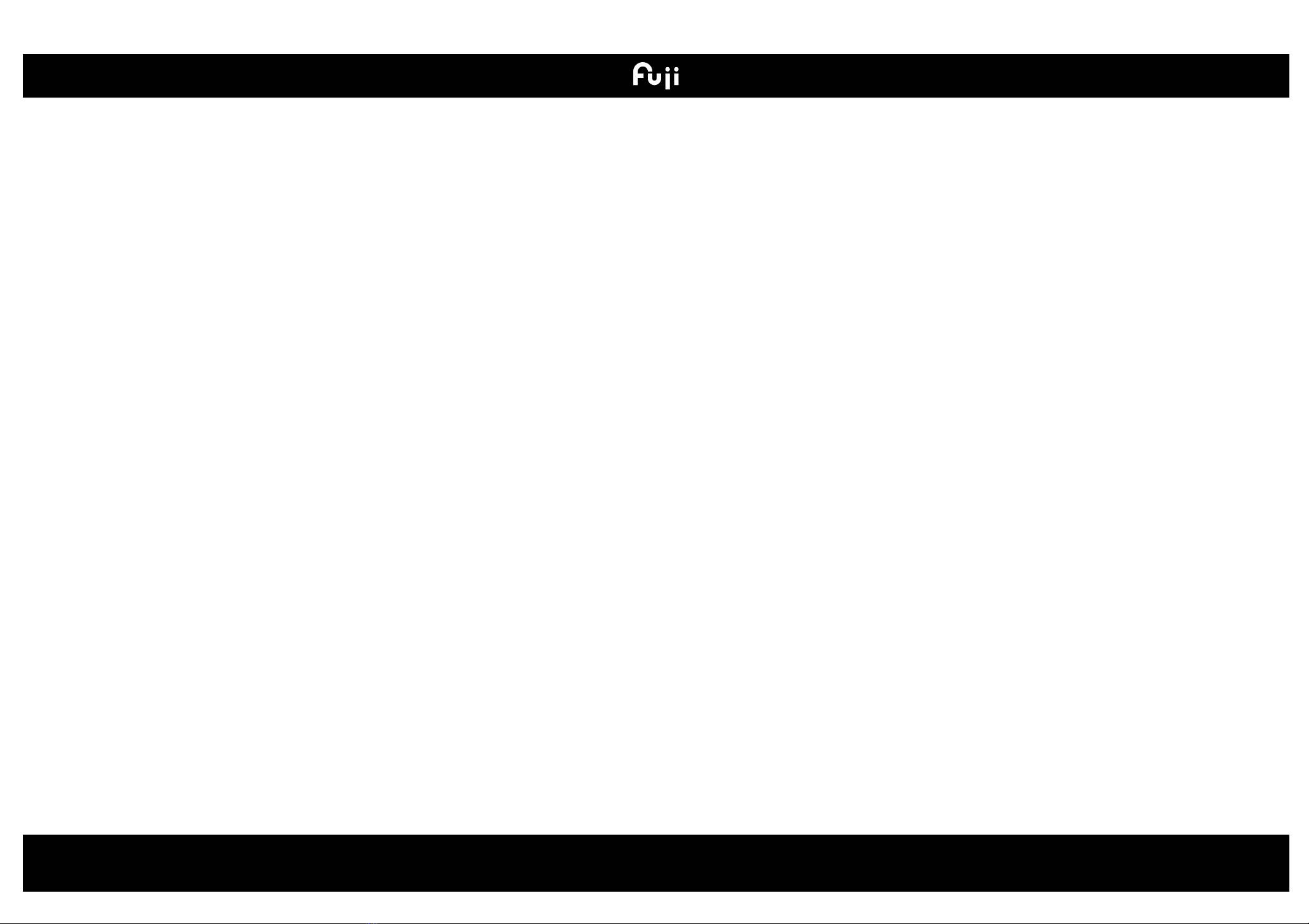

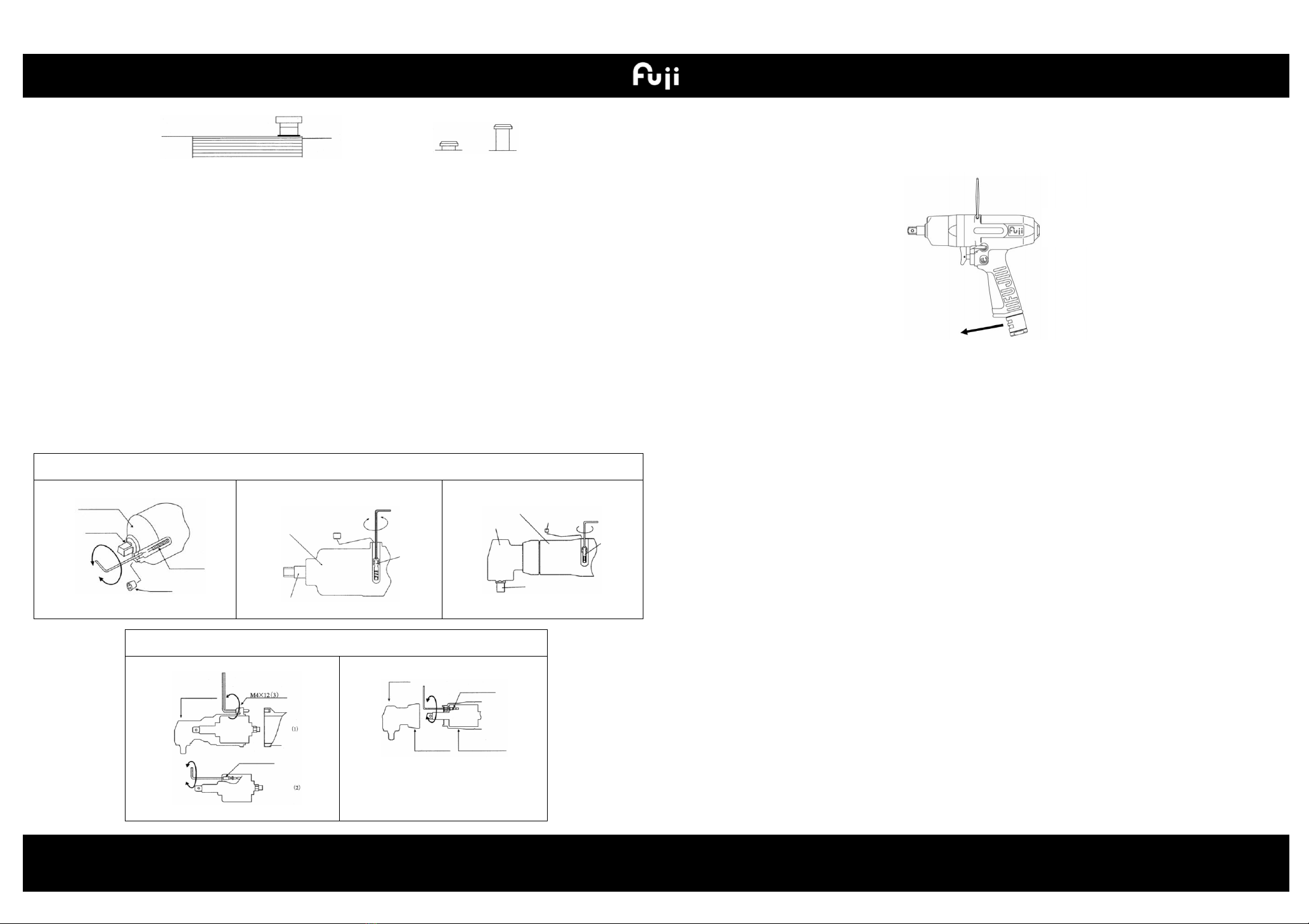

REVERSING OPERATION

All the tools, except the models with the arrow label showing a single direction of rotation, are reversible types

and reversing can be made by operating the reversing device. Make sure of the position of the reversing

device before use.

Do not change the direction of rotation when the tool is running.

"R" signifies the right-hand rotation (clockwise) and "L" the left-hand rotation (counter-clockwise).

As for the models having reversing device by button, the following positions signify the direction of the rotation.