•

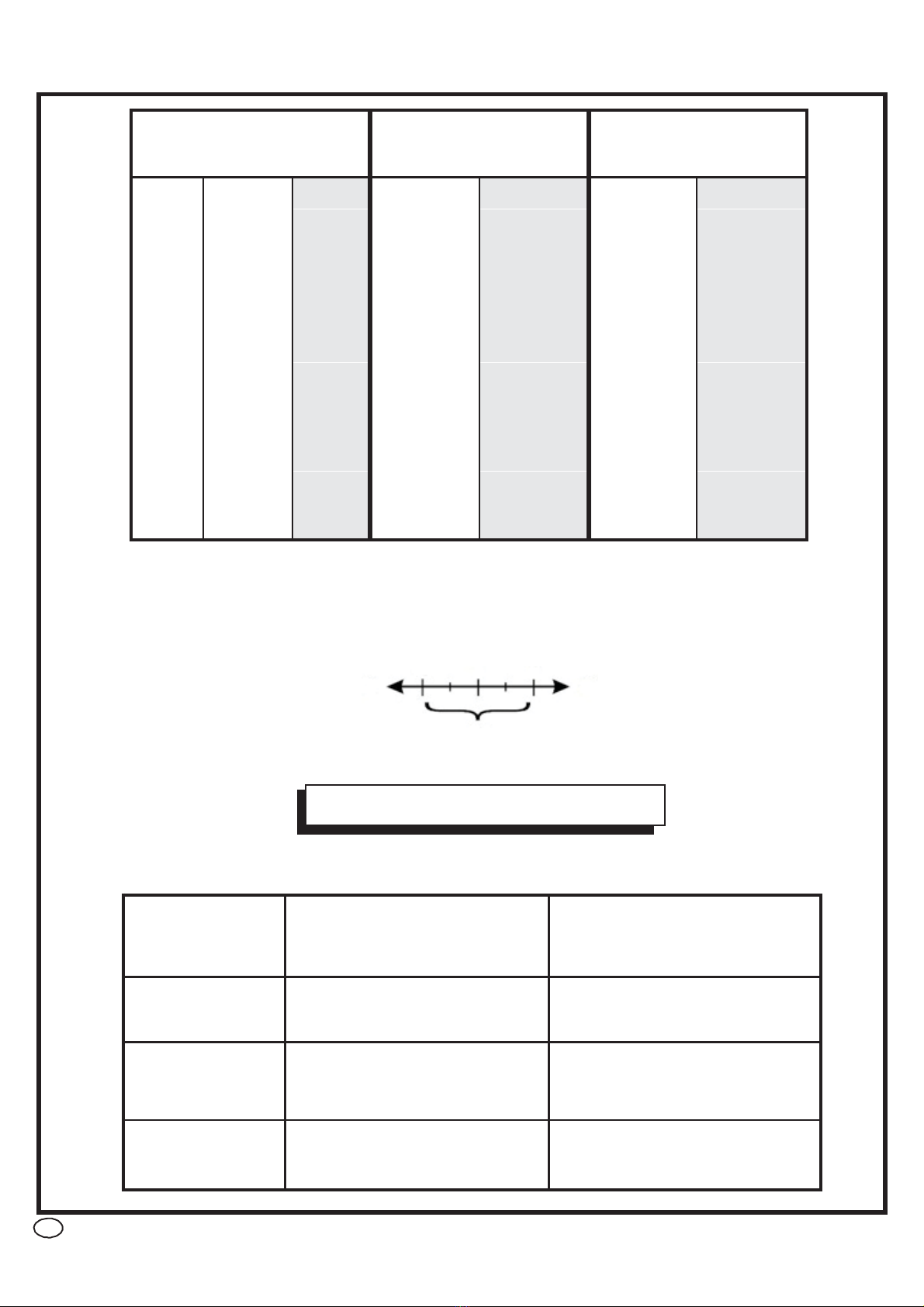

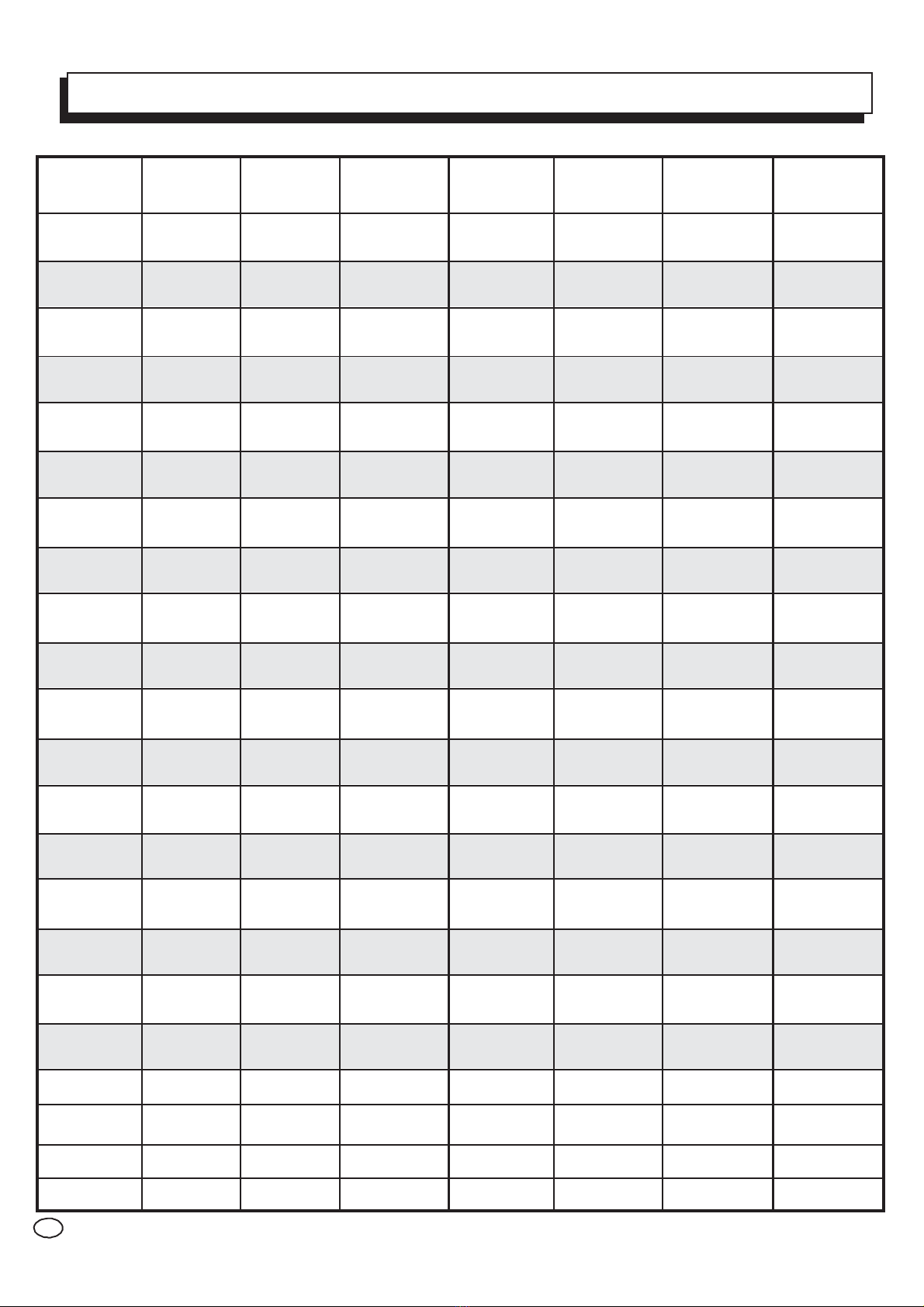

The ideal salt level is between 3200-4000 ppm. (parts per million) with 3600 ppm

being the optimal level. Calculate the number of gallons in the pool and add salt

according to the chart on page 8.

•

A LOW salt level will reduce the efficiency of the SPS and result in low chlorine

production.

•

Excessively HIGH salt levels will cause the SPS to shut down, making pool water

unsafe for bathers. LOW salt levels can cause the SPS to not operate efficiently,

causing the same.

TYPE OF SALT TO USE

•

It is important to use only sodium chloride (NaCl) that is 99% pure. This is common

food quality or water softener salt which is available in 40-80 lb/bag at your local pool

store. It is also acceptable to use water conditioning salt pellets; however it will take

longer for them to dissolve. DO NOT USE rock salt, salt with more than 1% yellow

prussiate of soda, salt with more than 1% of anti-caking additives, or iodized salt.

HOW TO ADD OR REMOVE SALT

•

ABOVE GROUND POOLS WITH MAIN DRAINS: Add directly in front of the return jet to

pool. Run the filter pump for 24 hours with the suction coming from the main drain

to allow the salt to evenly disperse throughout the pool.

•

ABOVE GROUND POOLS WITHOUT MAIN DRAINS: Add directly into the pool. Brush

the salt to speed up the dissolving process—to not allow the salt to sit in a pile on the

bottom of the pool (use the pool vacuum if there is no main drain) to allow the salt to

evenly disperse throughout the pool).

ON ANY POOL, DO NOT ADD SALT DIRECTLY TO THE SKIMMERS OR DIRECTLY

ONTO THE MAIN DRAIN. THIS WILL SHUT DOWN OR SHORTEN THE LIFE OF THE

CELL DUE TO HIGH SALT CONCENTRATION AND REDUCED FLOW TO THE PUMP.

If added incorrectly, immediately turn off SPS for 24 hours with the pump and filter

operating This will help to evenly distribute the salt. The salt display may take 24 hours

to respond to the change in salt concentration.

SALT DOES NOT EVAPORATE FROM POOL

•

The only way to lower the salt concentration is to partially drain the pool and refill

with fresh water.