•Use wires in the specified size. Otherwise, fire could occur.

•Do not use one multicore cable in order to connect several inverters with motors.

•Do not connect a surge killer to the inverter's output (secondary) circuit. Doing so could cause fire.

•Ground the inverter following Class C or Class D specifications or national/local electric code, depending on the input (primary) voltage of the

inverter. Otherwise, electric shock could occur.

•Qualified electricians should carry out wiring.

•Be sure to perform wiring after turning the power OFF.Otherwise,electric shock could occur.

•Be sure to perform wiring after installing the inverter body. Otherwise,electric shock or injuries could occur.

•Ensure that the number of input phases and the rated voltage of the product match the number of phases and the voltage of the AC power supply

to which the product is to be connected. Otherwise fire or an accident could occur.

•Do not connect the power source wires to output terminals (U, V, and W). Doing so could cause fire or an accident.

•Generally, control signal wires are not enforced-insulated. If they accidentally touch any of hot power lines, their insulation coat may break for any

reasons. In such a case, an extremely high voltage may be applied to the signal lines. Make a complete remedy to protect the signal line from

contacting any hot high voltage lines. Otherwise,an accident or electric shock could occur.

•Wire the three-phase motor to terminals U, V, and Wof the inverter, aligning phases each other. Otherwise injuries could occur.

•The inverter, motor and wiring generate electric noise. Take care of malfunction of the nearby sensors and devices. To prevent the motor from

malfunctioning, implement noise control measures. Otherwise an accident could occur.

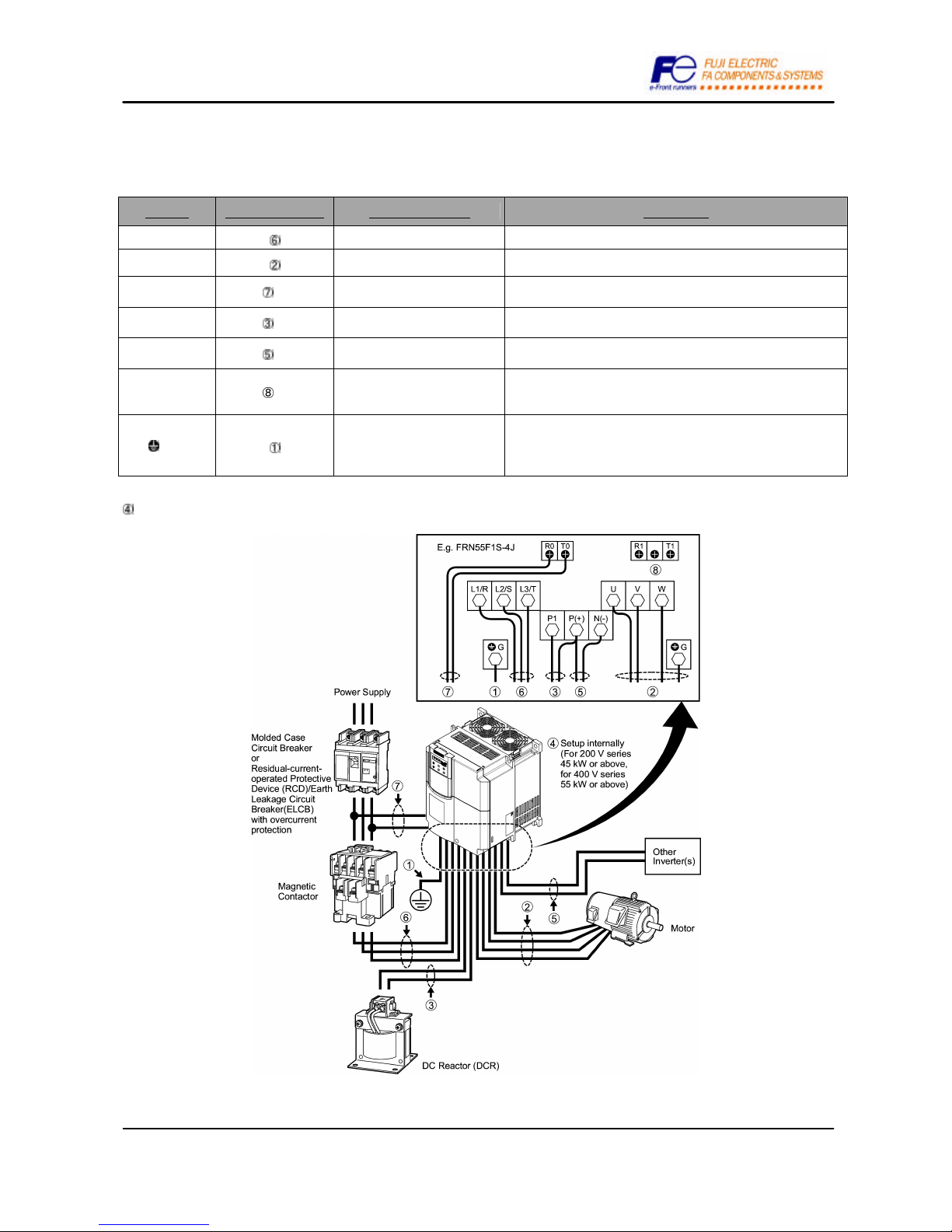

Setting control switches

•Before setting up any internal control switches, turn OFF the power, wait more than five minutes for models of 30 kW or below, or ten minutes for

models of 37 kW or above, and make sure, using a multimeter or a similar instrument, that the DC link bus voltage between the terminals P (+)

and N (-) has dropped below a safe voltage (+25 VDC).Otherwise electric shock could occur.

Operation

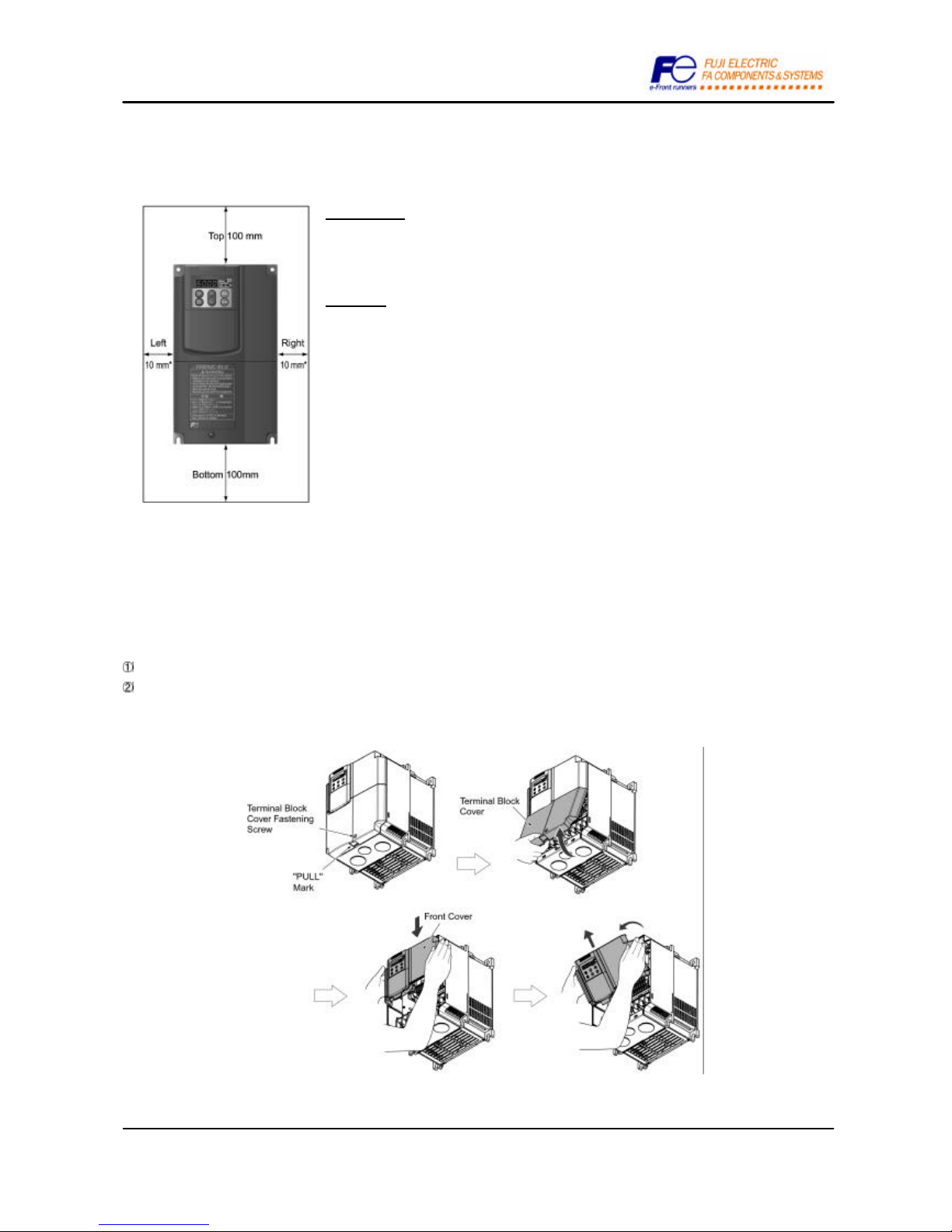

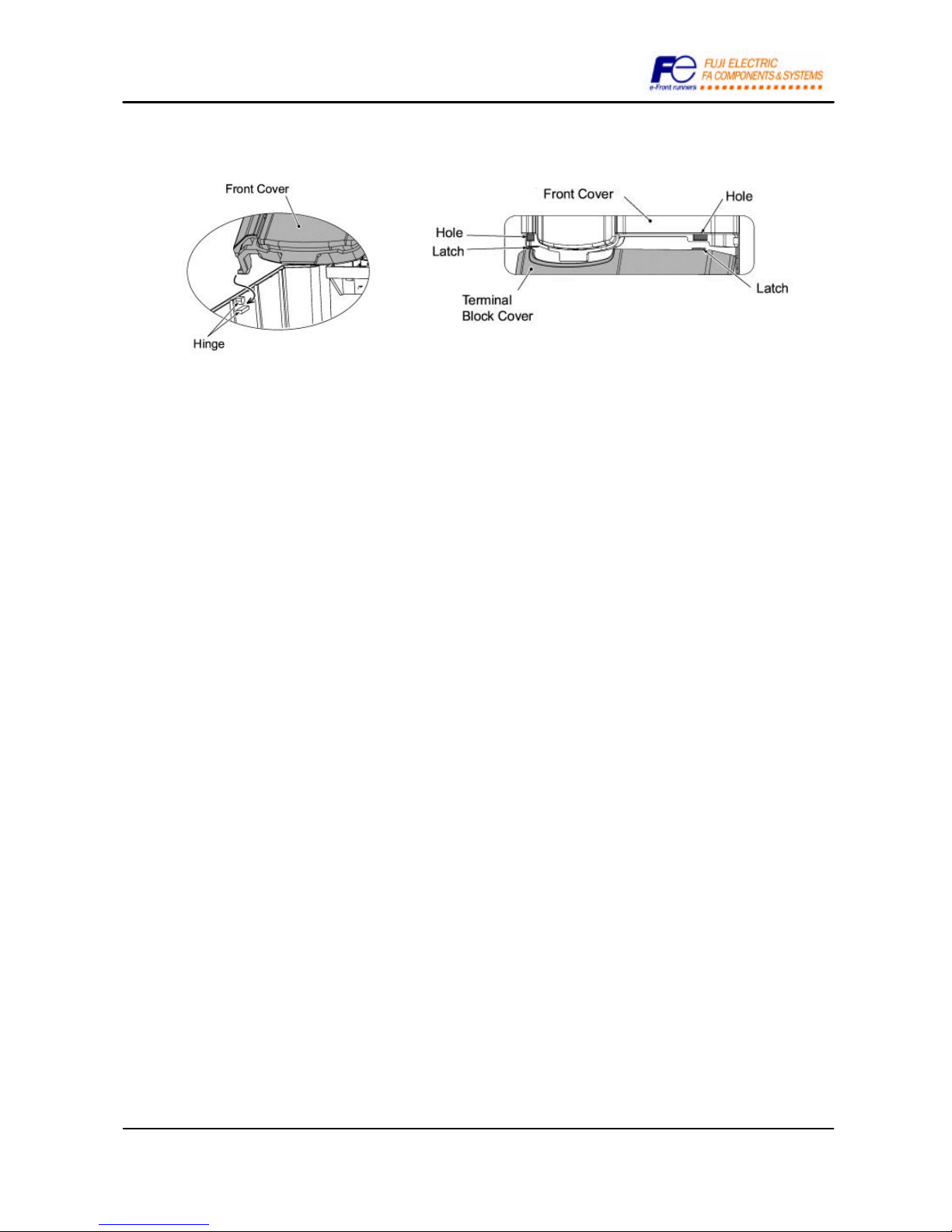

•Be sure to install the terminal block cover and the front cover before turning the power ON. Do not remove the coverswhile power is applied.

Otherwise electric shock could occur.

•Do not operate switches with wet hands. Doing so could cause electric shock.

•If the retry function has been selected, the inverter may automatically restart and drive the motor depending on the cause of tripping.

(Design the machinery or equipment so that human safety is ensured after restarting.)

•If the stall prevention function (current limiter), automatic deceleration, and overload prevention control have been selected, the inverter may

operate at an acceleration/deceleration time or frequency different from the commanded ones. Design the machine so that safety is ensured even

in such cases. Otherwise an accident could occur.

•The STOP key is only effective when function setting (Function code F02) has been established to enable the STOP key. Prepare an emergency

stop switch separately. If you disable the STOP key priority function and enable operation by external commands, you cannot emergency-stop the

inverter using the STOP key on the built-in keypad.

•If an alarm reset is made with the Run command signal turned ON, a sudden start will occur. Ensure that the Run command signal is turned OFF

in advance. Otherwise an accident could occur.

•If you enable the "restart mode after instantaneous power failure"(Function code F14 = 3, 4, or 5), then the inverter automatically restarts running

the motor when the power is recovered. (Design the machinery or equipment so that human safety is ensured after restarting.)

•If you set the function codes wrongly or without completely understanding this instruction manual and the FRENIC-Eco User's Manual (MEH456),

the motor may rotate with a torque or at a speed not permitted for the machine. An accident or injuries could occur.

•Do not touch the inverter terminals while the power is applied to the inverter even if the inverter stops. Doing so could cause electric shock.

•Do not turn the main circuit power (circuit breaker) ON or OFF in order to start or stop inverter operation. Doing so could cause failure.

•Do not touch the heat sink because they become very hot. Doing so could cause burns.

•Setting the inverter to high speeds is easy. Before changing the frequency (speed) setting, check the specifications of the motor and machinery.

•The brake function of the inverter does not provide mechanical holding means. Injuries could occur.

GENERAL PRECAUTIONS

Drawings in this manual may be illustrated without covers or safety shields for explanation of detail parts. Restore the covers and shields in the

original state and observe the description in the manual before starting operation.